steering JEEP WRANGLER 2015 JK / 3.G Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 2015, Model line: WRANGLER, Model: JEEP WRANGLER 2015 JK / 3.GPages: 695, PDF Size: 20.64 MB

Page 514 of 695

CAUTION!(Continued)

•Observe the traction device manufacturer ’s instruc-

tions on the method of installation, operating

speed, and conditions for use. Always use the

suggested operating speed of the device manufac-

turer ’s if it is less than 30 mph (48 km/h).

•Do not use traction devices on a compact spare tire.

TIRE ROTATION RECOMMENDATIONS

The tires on the front and rear of your vehicle operate at

different loads and perform different steering, handling,

and braking functions. For these reasons, they wear at

unequal rates.

These effects can be reduced by timely rotation of tires.

The benefits of rotation are especially worthwhile with

aggressive tread designs such as those on On/Off Road

type tires. Rotation will increase tread life, help to main-

tain mud, snow, and wet traction levels, and contribute to

a smooth, quiet ride.

Refer to the “Maintenance Schedule” for the proper

maintenance intervals. The reasons for any rapid or

unusual wear should be corrected prior to rotation being

performed.

The suggested rotation method is the “forward-cross”

shown in the following diagram.

512 STARTING AND OPERATING

Page 538 of 695

Trailer Sway Control – If Equipped

The trailer sway control is a telescoping link that can be

installed between the hitch receiver and the trailer

tongue. It typically provides adjustable friction associ-

ated with the telescoping motion to dampen any un-

wanted trailer swaying motions while traveling.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch ball or

some other connecting point of the vehicle. These kinds

of hitches are the most popular on the market today and

they are commonly used to tow small and medium sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying lever-

age through spring (load) bars. They are typically used

for heavier loads to distribute trailer tongue weight to the

tow vehicle’s front axle and the trailer axle(s). When used

in accordance with the manufacturer’s directions, it pro-

vides for a more level ride, offering more consistent

steering and brake control thereby enhancing towing

safety. The addition of a friction/hydraulic sway control

also dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer stability.

Trailer sway control and a weight distributing (load

equalizing) hitch are recommended for heavier Tongue

Weights (TW) and may be required depending on vehicle

and trailer configuration/loading to comply with Gross

Axle Weight Rating (GAWR) requirements.

WARNING!

•An improperly adjusted Weight Distributing Hitch

system may reduce handling, stability, braking

performance, and could result in a collision.

(Continued)

536 STARTING AND OPERATING

Page 576 of 695

CAUTION!(Continued)

the vehicle’s battery will discharge sufficiently to

degrade battery life and/or prevent the engine from

starting.

FREEING A STUCK VEHICLE

If your vehicle becomes stuck in mud, sand or snow, it

can often be moved using a rocking motion. Turn the

steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between DRIVE

and REVERSE (with automatic transmission) or 2nd gear

and REVERSE (with manual transmission), while gently

pressing the accelerator. Use the least amount of accel-

erator pedal pressure that will maintain the rocking

motion, without spinning the wheels, or racing the

engine.

CAUTION!

Racing the engine or spinning the wheels may lead to

transmission overheating and failure. Allow the en-

gine to idle with the transmission in NEUTRAL for at

least one minute after every five rocking-motion

cycles. This will minimize overheating and reduce

the risk of clutch or transmission failure during

prolonged efforts to free a stuck vehicle.

NOTE:Press the#ESC Off#switch, to place the Electronic

Stability Control (ESC) system in#Partial Off#mode,

before rocking the vehicle. Refer to “Electronic Brake

Control” in “Starting And Operating” for further infor-

mation. Once the vehicle has been freed, press the#ESC

Off#switch again to restore#ESC On#mode.

574 WHAT TO DO IN EMERGENCIES

Page 585 of 695

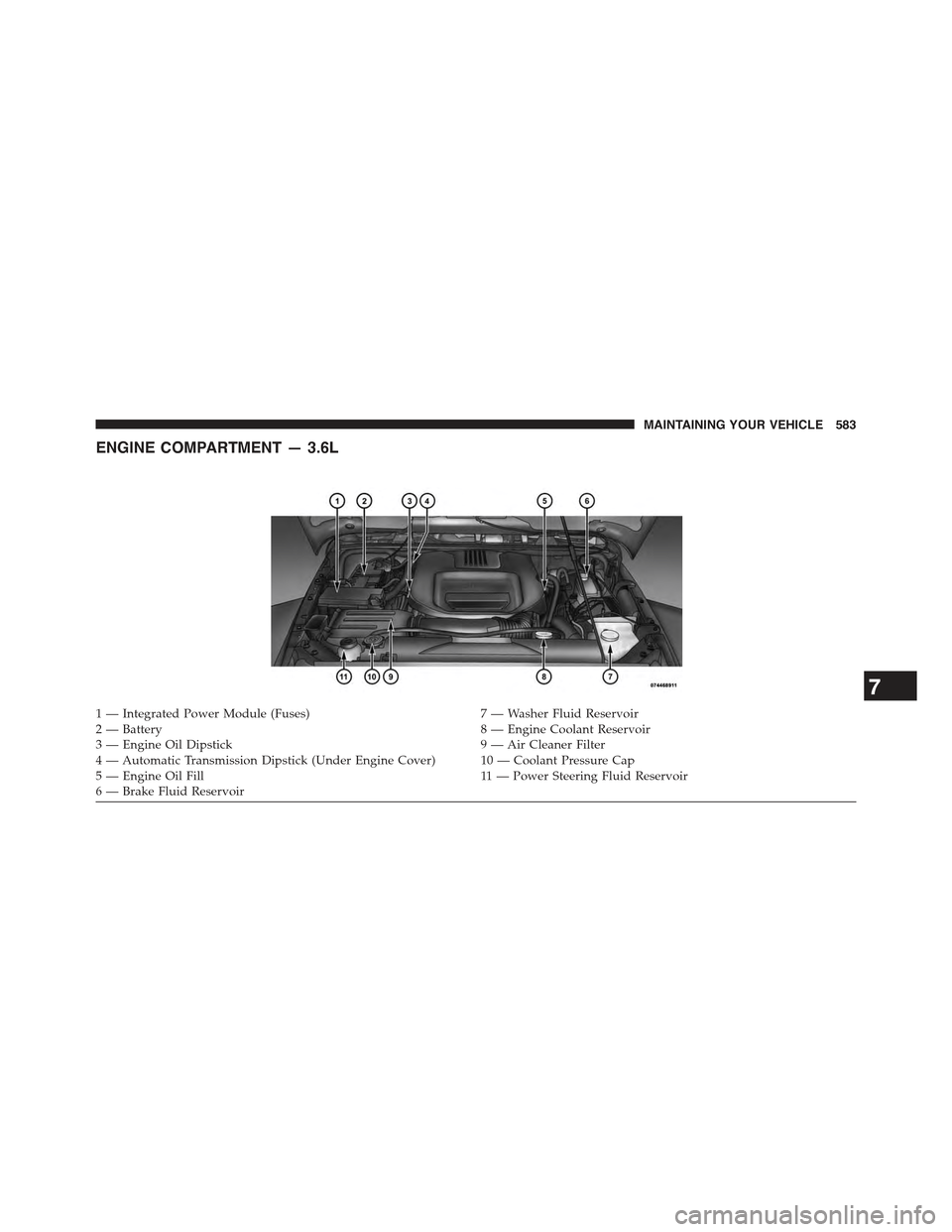

ENGINE COMPARTMENT — 3.6L

1 — Integrated Power Module (Fuses)7 — Washer Fluid Reservoir2—Battery8—EngineCoolantReservoir3 — Engine Oil Dipstick9 — Air Cleaner Filter4 — Automatic Transmission Dipstick (Under Engine Cover) 10 — Coolant Pressure Cap5 — Engine Oil Fill11 — Power Steering Fluid Reservoir6 — Brake Fluid Reservoir

7

MAINTAINING YOUR VEHICLE 583

Page 590 of 695

CAUTION!(Continued)

•Your vehicle has been built with improved fluids

that protect the performance and durability of your

vehicle and also allow extended maintenance inter-

vals. Do not use chemical flushes in these compo-

nents as the chemicals can damage your engine,

transmission, power steering or air conditioning.

Such damage is not covered by the New Vehicle

Limited Warranty. If a flush is needed because of

component malfunction, use only the specified

fluid for the flushing procedure.

Engine Oil

Checking Oil Level

To assure proper lubrication of your vehicle’s engine, the

engine oil must be maintained at the correct level. The

engine oil level should be checked five minutes after a

warmed up engine has been shut off.

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Always

maintain the oil level within the SAFE zone on the

dipstick. Adding 1 U.S. Quart (0.95L) of oil when the

reading is at the bottom of the SAFE zone will result in a

reading at the top of the safe zone on these engines.

CAUTION!

Overfilling or underfilling the crankcase will cause

aeration or loss of oil pressure. This could damage

your engine.

588 MAINTAINING YOUR VEHICLE

Page 635 of 695

the MOPAR® Soft Top Zipper Cleaner and Lubricant or

equivalent into the zipper slide. Several applications

may be required before the zipper comes free.

6. Never paste stickers, gummed labels or any tape to the

windows. Adhesives are hard to remove and may

damage the windows.

FUSES

WARNING!

•When replacing a blown fuse, always use an appro-

priate replacement fuse with the same amp rating as

the original fuse. Never replace a fuse with another

fuse of higher amp rating. Never replace a blown

fuse with metal wires or any other material. Failure

to use proper fuses may result in serious personal

injury, fire and/or property damage.

(Continued)

WARNING!(Continued)

•Before replacing a fuse, make sure that the ignition

is off and that all the other services are switched off

and/or disengaged.

•If the replaced fuse blows again, contact an autho-

rized dealer.

•If a general protection fuse for safety systems (air

bag system, braking system), power unit systems

(engine system, gearbox system) or steering system

blows, contact an authorized dealer.

7

MAINTAINING YOUR VEHICLE 633

Page 652 of 695

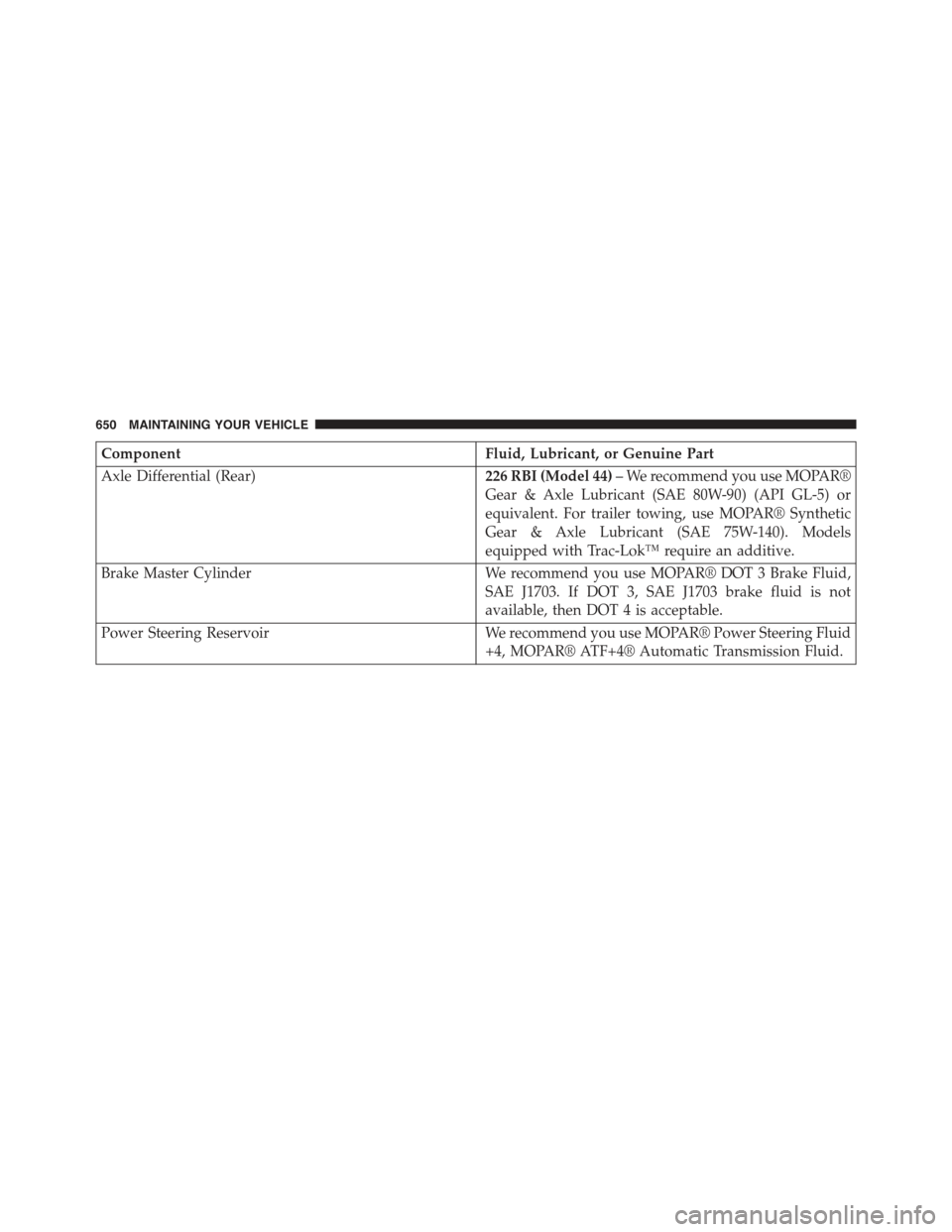

ComponentFluid, Lubricant, or Genuine Part

Axle Differential (Rear)226 RBI (Model 44)– We recommend you use MOPAR®

Gear & Axle Lubricant (SAE 80W-90) (API GL-5) or

equivalent. For trailer towing, use MOPAR® Synthetic

Gear & Axle Lubricant (SAE 75W-140). Models

equipped with Trac-Lok™ require an additive.

Brake Master CylinderWe recommend you use MOPAR® DOT 3 Brake Fluid,

SAE J1703. If DOT 3, SAE J1703 brake fluid is not

available, then DOT 4 is acceptable.

Power Steering ReservoirWe recommend you use MOPAR® Power Steering Fluid

+4, MOPAR® ATF+4® Automatic Transmission Fluid.

650 MAINTAINING YOUR VEHICLE

Page 655 of 695

Once A Month Or Before A Long Trip:

•Check engine oil level

•Check windshield washer fluid level

•Check the tire inflation pressures and look for unusual

wear or damage

•Check the fluid levels of the coolant reservoir, brake

master cylinder, power steering and automatic trans-

mission, and fill as needed

•Check function of all interior and exterior lights

Required Maintenance Intervals.

Refer to the maintenance schedules on the following

page for the required maintenance intervals.

At Every Oil Change Interval As Indicated By Oil

Change Indicator System:

•Change oil and filter

At Every Oil Change Interval As Indicated By Oil

Change Indicator System:

•Rotate the tires.Rotate at the first sign of irregu-

lar wear, even if it occurs before the oil indicator

system turns on.

•Inspect battery and clean and tighten terminals as

required

•Inspect automatic transmission fluid if equipped

with dipstick

•Inspect brake pads, shoes, rotors, drums, hoses

and park brake

•Inspect engine cooling system protection and hoses

•Inspect exhaust system

•Inspect engine air cleaner if using in dusty or

off-road conditions

•Inspect all door latches for presence of grease,

reapply if necessary.

8

MAINTENANCE

SCHEDULES

MAINTENANCE SCHEDULES 653

Page 676 of 695

Capacities, Fluid..........................646

Caps, Filler

Fuel.................................530

Power Steering.........................465

Radiator (Coolant Pressure)................615

Carbon Monoxide Warning..................100

Cargo Light.............................173

Car Washes.............................626

Cellular Phone...........................115

Center High Mounted Stop Light..............645

Certification Label.........................532

Chains, Tire.............................510

Changing A Flat Tire.......................563

Chart, Tire Sizing.........................488

Check Engine Light (Malfunction Indicator Light) . .310

Checking Your Vehicle For Safety...............99

Checks, Safety............................99

Child Restraint............................76

Child Restraints

Booster Seats...........................81

Child Restraints.........................76

Child Seat Installation.....................95

How To Stow An Unused ALR Seat Belt........91

Infants And Child Restraints................79

Install A LATCH-compatible Child Restraint.....90

Installing Child Restraints Using The Vehicle Seat

Belt..................................92

Locating The LATCH Anchorages............87

Lower Anchors And Tethers For Children.......83

Older Children And Child Restraints..........79

Seating Positions........................82

Child Safety Locks.........................42

Clean Air Gasoline........................526

Cleaning

Wheels...............................627

Climate Control..........................400

Clock..................................344

Cold Weather Operation....................421

674 INDEX

Page 678 of 695

Dimmer Switch, Headlight...................170

Dipsticks

Oil (Engine)...........................588

Power Steering.........................465

Disabled Vehicle Towing....................577

Disarming, Security System...................21

Disposal

Antifreeze (Engine Coolant)................616

Door Locks..............................38

Child-Protection Door Lock — Rear Doors......42

Door Locks............................38

Key Fob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Remote...............................38

Remote Keyless Entry (RKE)................38

Door Locks, Automatic......................41

Doors..................................32

Driver’s Seat Back Tilt......................154

Driving................................449

Dual Top...............................192

Electrical Outlet, Auxiliary (Power Outlet)........183

Electrical Power Outlets.....................183

Electric Remote Mirrors.....................113

Electronic Brake Control System...............469

Brake Assist System.....................471

Electronic Roll Mitigation.................476

Traction Control System...................471

Electronic Roll Mitigation (ERM)..............476

Electronic Speed Control (Cruise Control)........179

Electronic Stability Control (ESC)..............477

Electronic Throttle Control Warning Light........321

Electronic Vehicle Information Center (EVIC)......321

Emergency Brake.........................466

Emergency, In Case of

Jacking...............................563

Jump Starting..........................570

Tow Hooks............................575

676 INDEX