lock JEEP WRANGLER 2021 Owner handbook (in English)

[x] Cancel search | Manufacturer: JEEP, Model Year: 2021, Model line: WRANGLER, Model: JEEP WRANGLER 2021Pages: 276, PDF Size: 4.47 MB

Page 135 of 276

To activate the system, push the bottom of

the AXLE LOCK switch once to lock the rear

axle only (the “Rear Axle Lock Indicator

Light” will illuminate), push the bottom of

the switch again to lock the front axle (the

“Front Axle Lock Indicator Light” will illumi-

nate). When the rear axle is locked, pushing

the bottom of switch again will lock or unlock

the front axle.

NOTE:

The indicator lights will flash until the axles

are fully locked or unlocked.

To unlock the axles, push the top of the AXLE

LOCK switch.

Axle lock will disengage if the vehicle is taken

out of 4L (Low) range, or the ignition switch is

turned to the OFF position.

Electronic Sway Bar Disconnect — If

Equipped

Your vehicle may be equipped with an elec-

tronic disconnecting stabilizer/sway bar. This

system allows greater front suspension travel

in off-road situations.This system is controlled by the SWAY BAR

switch located on the instrument panel (to

the left of the steering column).

Push the SWAY BAR switch to activate the

system. Push the switch again to deactivate

the system. The “Sway Bar Indicator Light”

(located in the instrument cluster) will illumi-

nate when the bar is disconnected. The

“Sway Bar Indicator Light” will flash during

activation transition, or when activation con-ditions are not met. The stabilizer/sway bar

should remain in on-road mode during nor-

mal driving conditions.

WARNING!

Do not disconnect the stabilizer bar and

drive on hardsurfaced roads or at speeds

above 18 mph (29 km/h); you may lose

control of the vehicle, which could result

in serious injury. The front stabilizer bar

enhances vehicle stability and is neces-

sary for maintaining control of the vehicle.

The system monitors vehicle speed and

will attempt to reconnect the stabilizer bar

at speeds over 18 mph (29 km/h). This is

indicated by a flashing or solid “Sway Bar

Indicator Light.” Once vehicle speed is

reduced below 14 mph (22 km/h), the

system will once again attempt to return to

off-road mode.

To disconnect the stabilizer/sway bar, shift to

either 4H or 4L and push the SWAY BAR

switch to obtain the off-road position. Refer

to “Four-Wheel Drive Operation” in this sec-

Sway Bar Switch

133

Page 136 of 276

tion for further information. The “Sway Bar

Indicator Light” will flash until the stabilizer/

sway bar has been fully disconnected.

NOTE:

The stabilizer/sway bar may be torque locked

due to left and right suspension height differ-

ences. This condition is due to driving sur-

face differences or vehicle loading. In order

for the stabilizer/sway bar to disconnect/

reconnect, the right and left halves of the bar

must be aligned. This alignment may require

that the vehicle be driven onto level ground or

rocked from side to side.

To return to on-road mode, push the SWAY

BAR switch again.

WARNING!

If the stabilizer/sway bar will not return to

on-road mode, the “Sway Bar Indicator

Light” will flash in the instrument cluster

and vehicle stability is greatly reduced. Do

not attempt to drive the vehicle over

18 mph (29 km/h). Driving faster than

18 mph (29 km/ h) may cause loss of

control of the vehicle, which could result

WARNING!

in serious injury. Contact your local autho-

rized dealer for assistance.

STOP/START SYSTEM —

DIESEL MODELS WITH

MANUAL TRANSMISSION

ONLY

The Stop/Start function is developed to save

fuel and reduce emissions. The system will

stop the engine automatically during a ve-

hicle stop if the required conditions are met.

Pressing the clutch pedal will automatically

restart the vehicle.

Automatic Mode

The Stop/Start feature is en-

abled after every normal cus-

tomer engine start. It will remain

in STOP/START NOT READY un-

til you drive forward with a ve-

hicle speed greater than 3 mph (5 km/h). Atthat time, the system will go into STOP/

START READY and if all other conditions are

met, can go into an STOP/START AUTO STOP

ACTIVE mode.

To Activate The STOP/START AUTO STOP ACTIVE

Mode, The Following Must Occur:

• The system must be in STOP/START

READY state. A STOP/START READY mes-

sage will be displayed in the instrument

cluster. Refer to “Instrument Cluster Dis-

play” in “Getting To Know Your Instrument

Panel” for further information.

• Vehicle speed must be less 3 mph (5 km/h).

• The gear selector must be in the NEUTRAL

position and the clutch pedal must be fully

released

The engine will shut down,the tachometer will

fall to the Stop/Start position,the STOP/START

AUTO STOP ACTIVE message will appear,

and the heater/air conditioning (HVAC) air

flow will be reduced.

STARTING AND OPERATING

134

Page 145 of 276

CAUTION!

• Automatic transmissions must be

placed in PARK for recreational towing.

• Manual transmissions must be placed in

gear (not in Neutral) for recreational

towing.

• Before recreational towing, perform the

procedure outlined under “Shifting Into

NEUTRAL (N)” to be certain that the

transfer case is fully in NEUTRAL (N).

Otherwise, internal damage will result.

• Towing this vehicle in violation of the

above requirements can cause severe

transmission and/or transfer case dam-

age. Damage from improper towing is

not covered under the New Vehicle Lim-

ited Warranty.

• Do not use a bumper-mounted clamp-on

tow bar on your vehicle. The bumper

face bar will be damaged.

Shifting Into NEUTRAL (N)

Use the following procedure to prepare your

vehicle for recreational towing.

WARNING!

You or others could be injured or killed if

you leave the vehicle unattended with the

transfer case in the NEUTRAL (N) position

without first fully engaging the parking

brake. The transfer case NEUTRAL (N)

position disengages both the front and rear

driveshafts from the powertrain, and will

allow the vehicle to roll, even if the auto-

matic transmission is in PARK (or manual

transmission is in gear). The parking brake

should always be applied when the driver

is not in the vehicle.

CAUTION!

It is necessary to follow these steps to be

certain that the transfer case is fully in

NEUTRAL (N) before recreational towing

to prevent damage to internal parts.

1. Bring the vehicle to a complete stop on

level ground.

2. Press and hold the brake pedal.3. Shift the automatic transmission into

NEUTRAL or depress the clutch pedal on

a manual transmission.

4. Turn the engine OFF.

5. Shift the transfer case lever into NEU-

TRAL (N).

6. Start the engine.

7. Shift the transmission into REVERSE.

8. Release the brake pedal (and clutch pedal

on manual transmissions) for five seconds

and ensure that there is no vehicle

movement.

9. Repeat steps seven and eight with auto-

matic transmission in DRIVE or manual

transmission in first gear.

10. Turn the engine OFF and leave the igni-

tion in the unlocked ACC position.

11. Firmly apply the parking brake.

12. Shift the transmission into PARK or

place manual transmission in gear (NOT

in NEUTRAL).

143

Page 146 of 276

CAUTION!

Damage to the transmission may occur if

the transmission is shifted into PARK with

the transfer case in NEUTRAL (N) and the

engine running. With the transfer case in

NEUTRAL (N) ensure that the engine is

OFF before shifting the transmission into

PARK.

13. Attach the vehicle to the tow vehicle

using a suitable tow bar.

14. Release the parking brake.

15. Disconnect the negative battery cable,

and secure it away from the negative

battery post.

Shifting Out of NEUTRAL (N)

Use the following procedure to prepare your

vehicle for normal usage.

1. Bring the vehicle to a complete stop,

leaving it connected to the tow vehicle.

2. Firmly apply the parking brake.

3. Reconnect the negative battery cable.

4. Turn the ignition to the LOCK position.

5. Turn the ignition to the ON/RUN position,

but do not start the engine.

6. Press and hold the brake pedal.

7. Shift the transmission into NEUTRAL.8. Shift the transfer case lever to the desired

position.

NOTE:

When shifting the transfer case out of

NEUTRAL (N), the engine should remain

OFF to avoid gear clash.

9. Shift the automatic transmission into

PARK, or place manual transmission in

NEUTRAL.

10. Release the brake pedal.

11. Disconnect vehicle from the tow vehicle.

12. Start the engine.

13. Press and hold the brake pedal.

14. Release the parking brake.

15. Shift the transmission into gear, release

the brake pedal (and clutch pedal on

manual transmissions), and check that

the vehicle operates normally.

STARTING AND OPERATING

144

Page 149 of 276

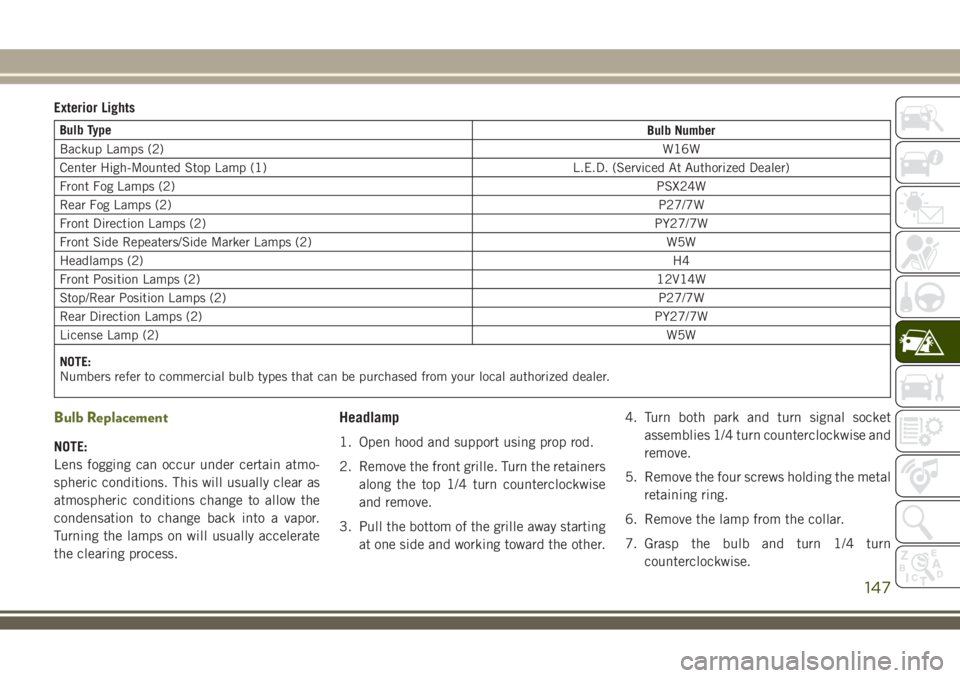

Exterior Lights

Bulb Type

Bulb Number

Backup Lamps (2)W16W

Center High-Mounted Stop Lamp (1) L.E.D. (Serviced At Authorized Dealer)

Front Fog Lamps (2)PSX24W

Rear Fog Lamps (2)P27/7W

Front Direction Lamps (2)PY27/7W

Front Side Repeaters/Side Marker Lamps (2) W5W

Headlamps (2)H4

Front Position Lamps (2)12V14W

Stop/Rear Position Lamps (2)P27/7W

Rear Direction Lamps (2)PY27/7W

License Lamp (2)W5W

NOTE:

Numbers refer to commercial bulb types that can be purchased from your local authorized dealer.

Bulb Replacement

NOTE:

Lens fogging can occur under certain atmo-

spheric conditions. This will usually clear as

atmospheric conditions change to allow the

condensation to change back into a vapor.

Turning the lamps on will usually accelerate

the clearing process.

Headlamp

1. Open hood and support using prop rod.

2. Remove the front grille. Turn the retainers

along the top 1/4 turn counterclockwise

and remove.

3. Pull the bottom of the grille away starting

at one side and working toward the other.4. Turn both park and turn signal socket

assemblies 1/4 turn counterclockwise and

remove.

5. Remove the four screws holding the metal

retaining ring.

6. Remove the lamp from the collar.

7. Grasp the bulb and turn 1/4 turn

counterclockwise.

147

Page 150 of 276

8. Pull the bulb from the housing.

9. Push connector locking tab to the unlock

position.

10. Remove connector from bulb.

11. Push connector onto new bulb base, and

push the connector locking tab to the

lock position.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

12. Reinstall bulb housing. Rotate the bulb

1/4 turn clockwise.

Front Park/Turn Signal

1. Remove the front grille. Turn the retainers

along the top 1/4 turn counterclockwise

and remove.

2. Pull the bottom of the grille away starting

at one side and working toward the other.3. Turn the socket assembly 1/4 turn coun-

terclockwise and remove from housing.

Pull the bulb straight from the socket to

replace.

Front Side Marker

1. Reach under the front fender flare and

locate the front side marker socket.

2. Turn the socket assembly counterclock-

wise 1/3 turn and remove it from the

housing. Pull the bulb straight from the

socket to replace.

Front Fog Lamp

1. Reach under the vehicle to access the

back of the front fog lamp.

2. Disconnect the wire harness connector

from the front fog lamp connector

receptacle.

3. Firmly grasp the bulb by the two latch

features and squeeze them together to

unlock the bulb from the back of the front

fog lamp housing.4. Pull the bulb straight out from the keyed

opening in the housing and then connect

the replacement bulb.

CAUTION!

Do not touch the new bulb with your fin-

gers. Oil contamination will severely

shorten bulb life. If the bulb comes in

contact with any oily surface, clean the

bulb with rubbing alcohol.

Rear Fog Lamp

1. Reach under the vehicle to access the

back of the rear fog lamp.

2. Turn the socket assembly counterclock-

wise 1/4 turn and remove it from the

housing. Pull the bulb straight from the

socket to replace.IN CASE OF EMERGENCY

148

Page 151 of 276

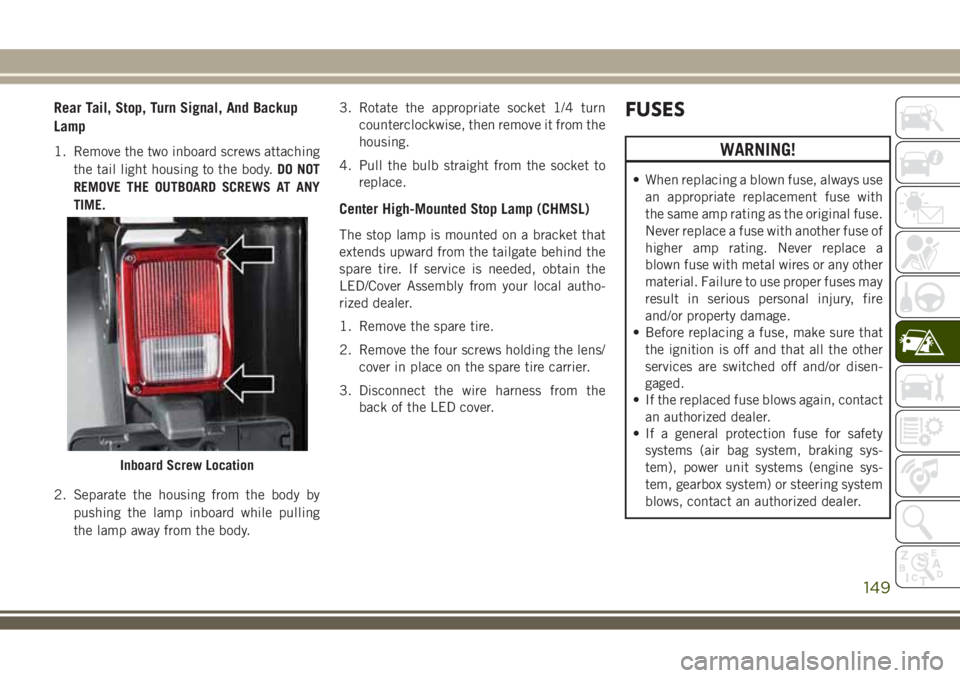

Rear Tail, Stop, Turn Signal, And Backup

Lamp

1. Remove the two inboard screws attaching

the tail light housing to the body.DO NOT

REMOVE THE OUTBOARD SCREWS AT ANY

TIME.

2. Separate the housing from the body by

pushing the lamp inboard while pulling

the lamp away from the body.3. Rotate the appropriate socket 1/4 turn

counterclockwise, then remove it from the

housing.

4. Pull the bulb straight from the socket to

replace.

Center High-Mounted Stop Lamp (CHMSL)

The stop lamp is mounted on a bracket that

extends upward from the tailgate behind the

spare tire. If service is needed, obtain the

LED/Cover Assembly from your local autho-

rized dealer.

1. Remove the spare tire.

2. Remove the four screws holding the lens/

cover in place on the spare tire carrier.

3. Disconnect the wire harness from the

back of the LED cover.

FUSES

WARNING!

• When replacing a blown fuse, always use

an appropriate replacement fuse with

the same amp rating as the original fuse.

Never replace a fuse with another fuse of

higher amp rating. Never replace a

blown fuse with metal wires or any other

material. Failure to use proper fuses may

result in serious personal injury, fire

and/or property damage.

• Before replacing a fuse, make sure that

the ignition is off and that all the other

services are switched off and/or disen-

gaged.

• If the replaced fuse blows again, contact

an authorized dealer.

• If a general protection fuse for safety

systems (air bag system, braking sys-

tem), power unit systems (engine sys-

tem, gearbox system) or steering system

blows, contact an authorized dealer.

Inboard Screw Location

149

Page 152 of 276

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check

the fuse element inside the blade fuse for a

break/melt.

Also, please be aware that when using power

outlets for extended periods of time with the

engine off may result in vehicle battery dis-

charge.

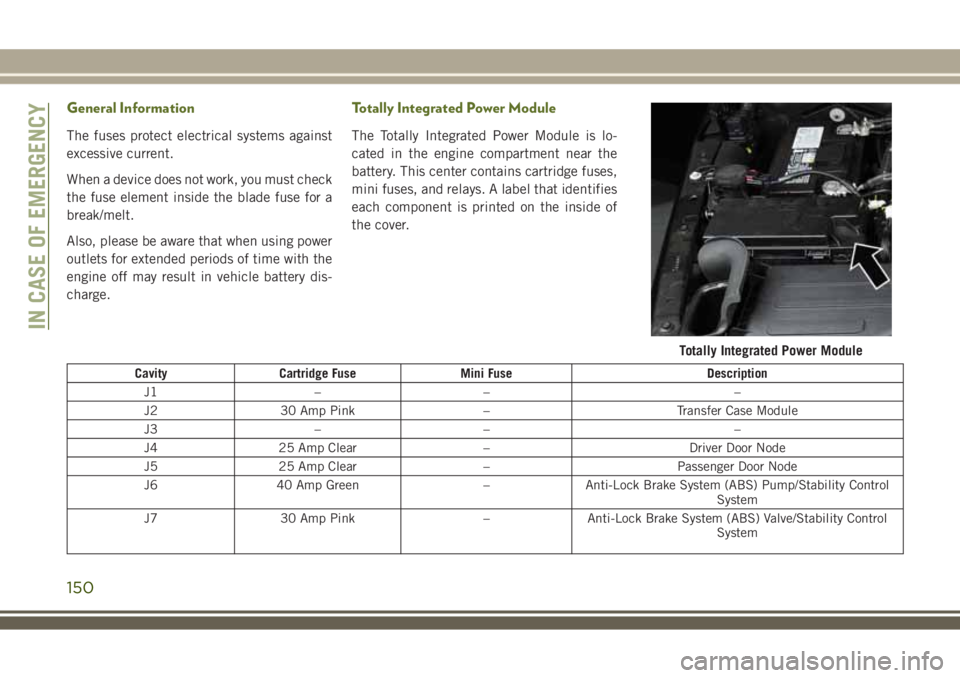

Totally Integrated Power Module

The Totally Integrated Power Module is lo-

cated in the engine compartment near the

battery. This center contains cartridge fuses,

mini fuses, and relays. A label that identifies

each component is printed on the inside of

the cover.

Cavity Cartridge Fuse Mini Fuse Description

J1 – – –

J2 30 Amp Pink – Transfer Case Module

J3 – – –

J4 25 Amp Clear – Driver Door Node

J5 25 Amp Clear – Passenger Door Node

J6 40 Amp Green – Anti-Lock Brake System (ABS) Pump/Stability Control

System

J7 30 Amp Pink – Anti-Lock Brake System (ABS) Valve/Stability Control

System

Totally Integrated Power Module

IN CASE OF EMERGENCY

150

Page 153 of 276

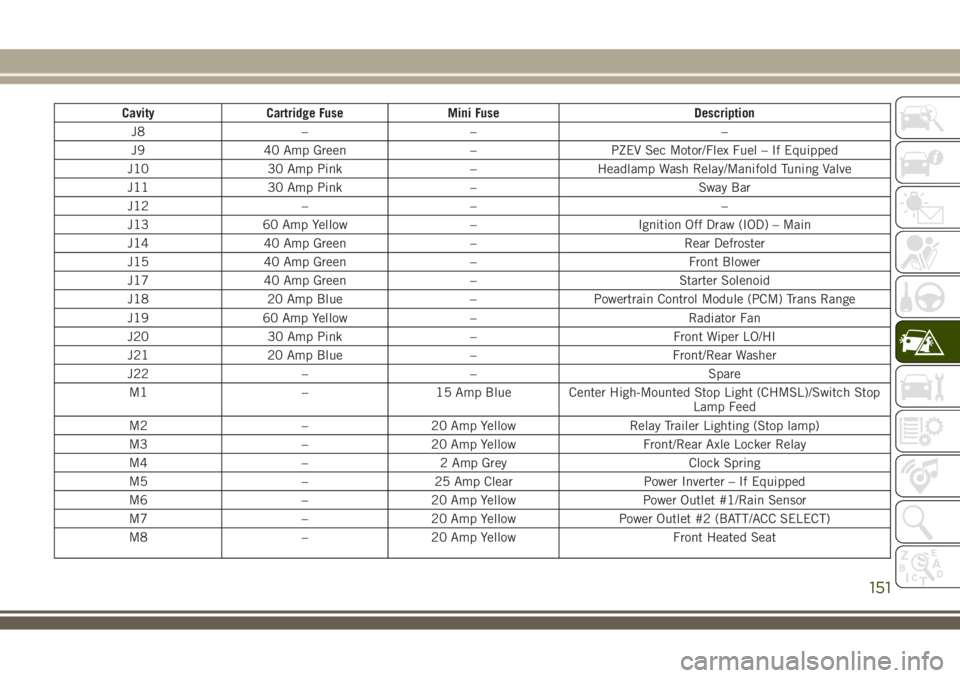

Cavity Cartridge Fuse Mini Fuse Description

J8 – – –

J9 40 Amp Green – PZEV Sec Motor/Flex Fuel – If Equipped

J10 30 Amp Pink – Headlamp Wash Relay/Manifold Tuning Valve

J11 30 Amp Pink – Sway Bar

J12 – – –

J13 60 Amp Yellow – Ignition Off Draw (IOD) – Main

J14 40 Amp Green – Rear Defroster

J15 40 Amp Green – Front Blower

J17 40 Amp Green – Starter Solenoid

J18 20 Amp Blue – Powertrain Control Module (PCM) Trans Range

J19 60 Amp Yellow – Radiator Fan

J20 30 Amp Pink – Front Wiper LO/HI

J21 20 Amp Blue – Front/Rear Washer

J22 – – Spare

M1 – 15 Amp Blue Center High-Mounted Stop Light (CHMSL)/Switch Stop

Lamp Feed

M2 – 20 Amp Yellow Relay Trailer Lighting (Stop lamp)

M3 – 20 Amp Yellow Front/Rear Axle Locker Relay

M4 – 2 Amp Grey Clock Spring

M5 – 25 Amp Clear Power Inverter – If Equipped

M6 – 20 Amp Yellow Power Outlet #1/Rain Sensor

M7 – 20 Amp Yellow Power Outlet #2 (BATT/ACC SELECT)

M8 – 20 Amp Yellow Front Heated Seat

151

Page 155 of 276

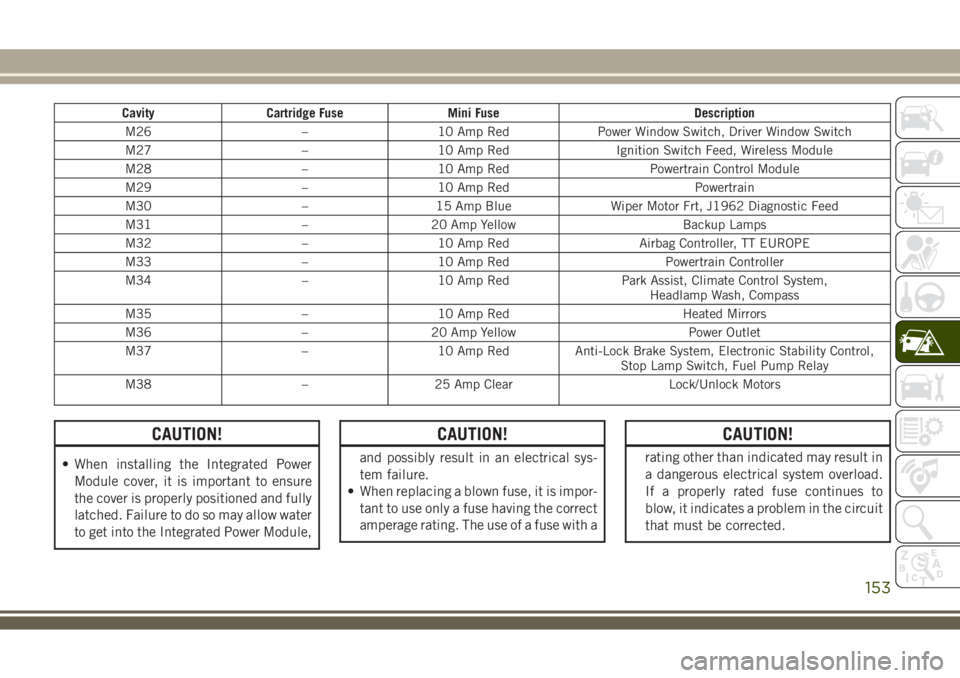

Cavity Cartridge Fuse Mini Fuse Description

M26 – 10 Amp Red Power Window Switch, Driver Window Switch

M27 – 10 Amp Red Ignition Switch Feed, Wireless Module

M28 – 10 Amp Red Powertrain Control Module

M29 – 10 Amp Red Powertrain

M30 – 15 Amp Blue Wiper Motor Frt, J1962 Diagnostic Feed

M31 – 20 Amp Yellow Backup Lamps

M32 – 10 Amp Red Airbag Controller, TT EUROPE

M33 – 10 Amp Red Powertrain Controller

M34 – 10 Amp Red Park Assist, Climate Control System,

Headlamp Wash, Compass

M35 – 10 Amp Red Heated Mirrors

M36 – 20 Amp Yellow Power Outlet

M37 – 10 Amp Red Anti-Lock Brake System, Electronic Stability Control,

Stop Lamp Switch, Fuel Pump Relay

M38 – 25 Amp Clear Lock/Unlock Motors

CAUTION!

• When installing the Integrated Power

Module cover, it is important to ensure

the cover is properly positioned and fully

latched. Failure to do so may allow water

to get into the Integrated Power Module,

CAUTION!

and possibly result in an electrical sys-

tem failure.

• When replacing a blown fuse, it is impor-

tant to use only a fuse having the correct

amperage rating. The use of a fuse with a

CAUTION!

rating other than indicated may result in

a dangerous electrical system overload.

If a properly rated fuse continues to

blow, it indicates a problem in the circuit

that must be corrected.

153