JEEP WRANGLER 2023 Owners Manual

Manufacturer: JEEP, Model Year: 2023, Model line: WRANGLER, Model: JEEP WRANGLER 2023Pages: 396, PDF Size: 25.15 MB

Page 321 of 396

SERVICING AND MAINTENANCE319

Materials Added To Engine Oil

The manufacturer strongly recommends against the

addition of any additives (other than leak detection dyes)

to the engine oil. Engine oil is an engineered product and

its performance may be impaired by supplemental

additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine oil and

oil filters from your vehicle. Used oil and oil filters,

indiscriminately discarded, can present a problem to the

environment. Contact an authorized dealer, service

station or governmental agency for advice on how and

where used oil and oil filters can be safely discarded in

your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new filter at

every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used for

replacement. The quality of replacement filters varies

considerably. We recommend using a Mopar® Engine Oil

Filter. If a Mopar® Engine Oil Filter is unavailable only use

filters that meet or exceed SAE/USCAR-36 Filter

Performance Requirements.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 307 for

gasoline engines or Úpage 311 for diesel engines.

NOTE:Be sure to follow the “Severe Duty Conditions” mainte -

nance interval if applicable.

Engine Air Cleaner Filter Selection

The quality of replacement engine air cleaner filters varies

considerably. Only high quality Mopar® filters should be

used.

Engine Air Cleaner Filter Inspection and

Replacement— Gasoline Engine

Follow the recommended maintenance intervals as shown

in the Maintenance Schedule in this section.

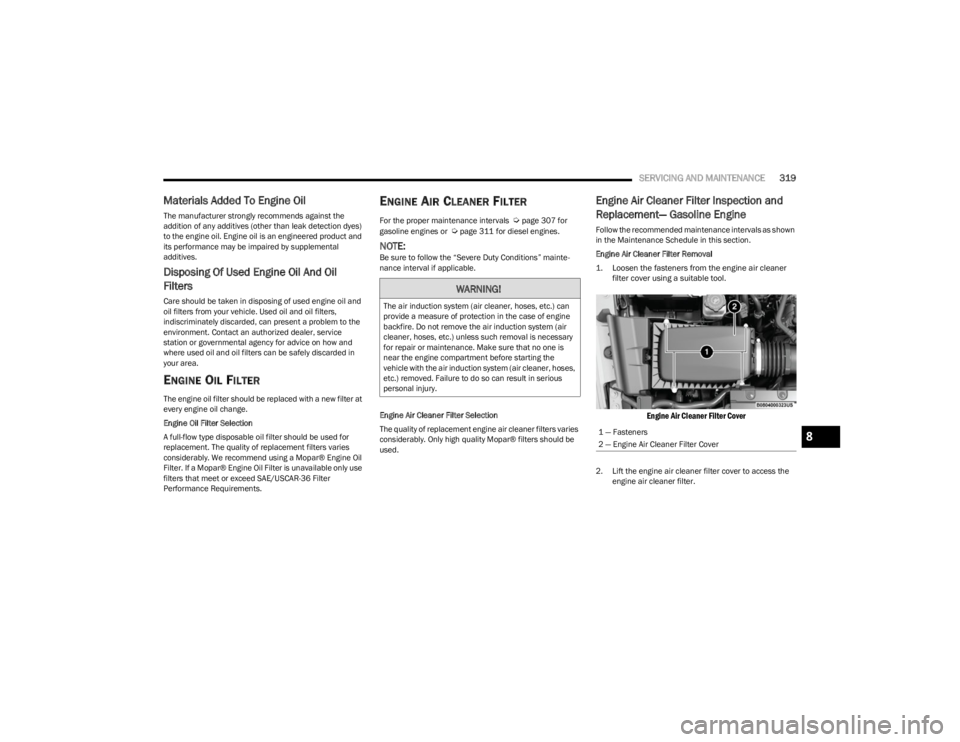

Engine Air Cleaner Filter Removal

1. Loosen the fasteners from the engine air cleaner filter cover using a suitable tool.

Engine Air Cleaner Filter Cover

2. Lift the engine air cleaner filter cover to access the engine air cleaner filter.

WARNING!

The air induction system (air cleaner, hoses, etc.) can

provide a measure of protection in the case of engine

backfire. Do not remove the air induction system (air

cleaner, hoses, etc.) unless such removal is necessary

for repair or maintenance. Make sure that no one is

near the engine compartment before starting the

vehicle with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in serious

personal injury.

1 — Fasteners

2 — Engine Air Cleaner Filter Cover8

23_JL_OM_EN_USC_t.book Page 319

Page 322 of 396

320SERVICING AND MAINTENANCE

3. Remove the engine air cleaner filter from the housing

assembly.

Engine Air Cleaner Filter Cover

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing if significant dirt or debris is

present before replacing the engine air cleaner filter.

1. Install the engine air cleaner filter into the housing assembly with the engine air cleaner filter

inspection surface facing downward.

2. Tighten engine air cleaner filter cover fasteners using a suitable tool.

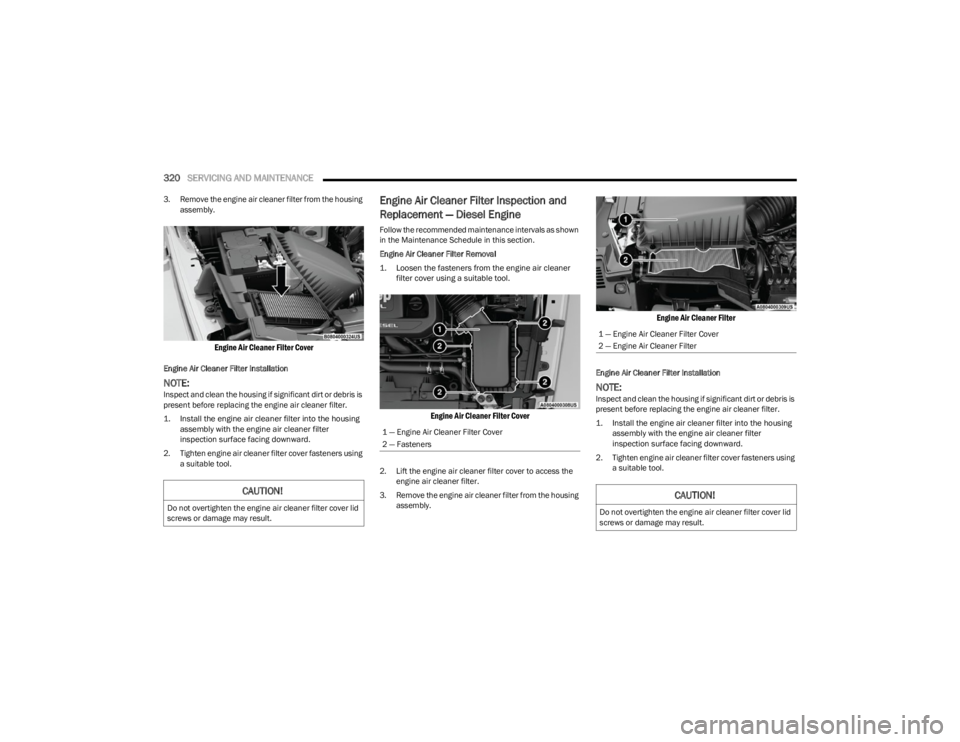

Engine Air Cleaner Filter Inspection and

Replacement — Diesel Engine

Follow the recommended maintenance intervals as shown

in the Maintenance Schedule in this section.

Engine Air Cleaner Filter Removal

1. Loosen the fasteners from the engine air cleaner filter cover using a suitable tool.

Engine Air Cleaner Filter Cover

2. Lift the engine air cleaner filter cover to access the engine air cleaner filter.

3. Remove the engine air cleaner filter from the housing assembly.

Engine Air Cleaner Filter

Engine Air Cleaner Filter Installation

NOTE:Inspect and clean the housing if significant dirt or debris is

present before replacing the engine air cleaner filter.

1. Install the engine air cleaner filter into the housing assembly with the engine air cleaner filter

inspection surface facing downward.

2. Tighten engine air cleaner filter cover fasteners using a suitable tool.

CAUTION!

Do not overtighten the engine air cleaner filter cover lid

screws or damage may result.

1 — Engine Air Cleaner Filter Cover

2 — Fasteners

1 — Engine Air Cleaner Filter Cover

2 — Engine Air Cleaner Filter

CAUTION!

Do not overtighten the engine air cleaner filter cover lid

screws or damage may result.

23_JL_OM_EN_USC_t.book Page 320

Page 323 of 396

SERVICING AND MAINTENANCE321

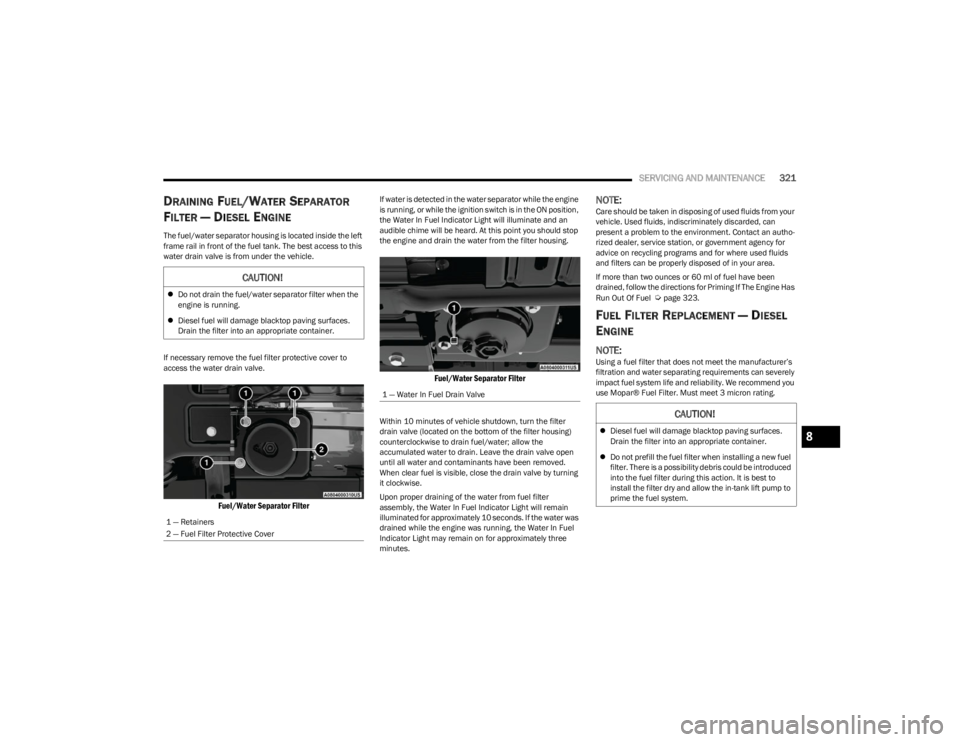

DRAINING FUEL/WATER SEPARATOR

F

ILTER — DIESEL ENGINE

The fuel/water separator housing is located inside the left

frame rail in front of the fuel tank. The best access to this

water drain valve is from under the vehicle.

If necessary remove the fuel filter protective cover to

access the water drain valve.

Fuel/Water Separator Filter

If water is detected in the water separator while the engine

is running, or while the ignition switch is in the ON position,

the Water In Fuel Indicator Light will illuminate and an

audible chime will be heard. At this point you should stop

the engine and drain the water from the filter housing.

Fuel/Water Separator Filter

Within 10 minutes of vehicle shutdown, turn the filter

drain valve (located on the bottom of the filter housing)

counterclockwise to drain fuel/water; allow the

accumulated water to drain. Leave the drain valve open

until all water and contaminants have been removed.

When clear fuel is visible, close the drain valve by turning

it clockwise.

Upon proper draining of the water from fuel filter

assembly, the Water In Fuel Indicator Light will remain

illuminated for approximately 10 seconds. If the water was

drained while the engine was running, the Water In Fuel

Indicator Light may remain on for approximately three

minutes.

NOTE:Care should be taken in disposing of used fluids from your

vehicle. Used fluids, indiscriminately discarded, can

present a problem to the environment. Contact an autho-

rized dealer, service station, or government agency for

advice on recycling programs and for where used fluids

and filters can be properly disposed of in your area.

If more than two ounces or 60 ml of fuel have been

drained, follow the directions for Priming If The Engine Has

Run Out Of Fuel

Úpage 323.

FUEL FILTER REPLACEMENT — DIESEL

E

NGINE

NOTE:Using a fuel filter that does not meet the manufacturer’s

filtration and water separating requirements can severely

impact fuel system life and reliability. We recommend you

use Mopar® Fuel Filter. Must meet 3 micron rating.

CAUTION!

Do not drain the fuel/water separator filter when the

engine is running.

Diesel fuel will damage blacktop paving surfaces.

Drain the filter into an appropriate container.

1 — Retainers

2 — Fuel Filter Protective Cover

1 — Water In Fuel Drain Valve

CAUTION!

Diesel fuel will damage blacktop paving surfaces.

Drain the filter into an appropriate container.

Do not prefill the fuel filter when installing a new fuel

filter. There is a possibility debris could be introduced

into the fuel filter during this action. It is best to

install the filter dry and allow the in-tank lift pump to

prime the fuel system.8

23_JL_OM_EN_USC_t.book Page 321

Page 324 of 396

322SERVICING AND MAINTENANCE

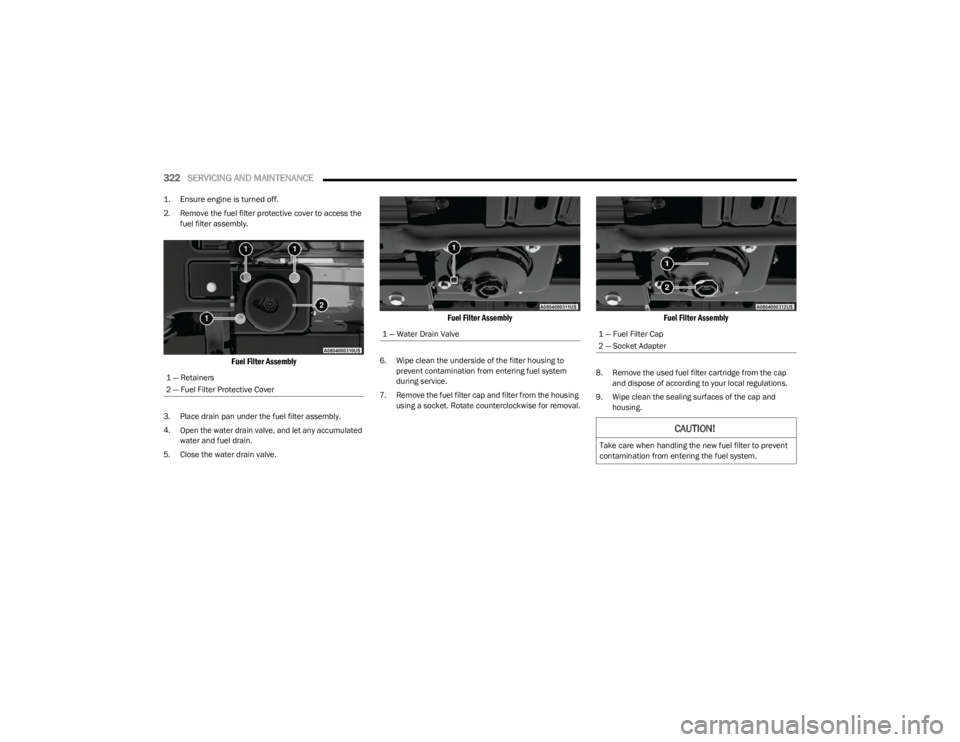

1. Ensure engine is turned off.

2. Remove the fuel filter protective cover to access the

fuel filter assembly.

Fuel Filter Assembly

3. Place drain pan under the fuel filter assembly.

4. Open the water drain valve, and let any accumulated water and fuel drain.

5. Close the water drain valve.

Fuel Filter Assembly

6. Wipe clean the underside of the filter housing to prevent contamination from entering fuel system

during service.

7. Remove the fuel filter cap and filter from the housing using a socket. Rotate counterclockwise for removal.

Fuel Filter Assembly

8. Remove the used fuel filter cartridge from the cap and dispose of according to your local regulations.

9. Wipe clean the sealing surfaces of the cap and housing.

1 — Retainers

2 — Fuel Filter Protective Cover

1 — Water Drain Valve1 — Fuel Filter Cap

2 — Socket Adapter

CAUTION!

Take care when handling the new fuel filter to prevent

contamination from entering the fuel system.

23_JL_OM_EN_USC_t.book Page 322

Page 325 of 396

SERVICING AND MAINTENANCE323

10. Lubricate o-ring on the cap with clean engine oil.

11. Install the new fuel filter cartridge onto the cap.

12. Insert the cap and filter into the housing with

clockwise rotation, use a socket to tighten.

13. Push the ignition switch twice without your foot on the brake to place vehicle in RUN position. This will

activate the in tank fuel pump for approximately 30

seconds. Repeat this process twice to prime the fuel

system. Start the engine using the Normal Starting

procedure. After engine start, verify the fuel filter cap

does not leak.

PRIMING IF THE ENGINE HAS RUN OUT

O

F FUEL — DIESEL ENGINE

1. Add a substantial amount of fuel to the tank, approx -

imately 2 to 5 gal (8L to 19L).

2. Push ignition switch twice without your foot on brake to put vehicle in RUN position. This will activate the in

tank fuel pump for approximately 30 seconds.

Repeat this process twice to prime the fuel system.

3. Start the engine using the Normal Starting procedure

Úpage 130.

NOTE:The engine may run rough until the air is forced from all

the fuel lines.

NOTE:

Use of biodiesel mixture in excess of 20% can nega -

tively impact the fuel filter's ability to separate water

from the fuel, resulting in high pressure fuel system

corrosion or damage.

In addition, commercially available fuel additives are

not necessary for the proper operation of your diesel

engine.

For extreme cold conditions, "Mopar® Premium Diesel

Fuel Treatment" is recommended to assist with cold

starting.

INTERVENTION REGENERATION

S

TRATEGY — MESSAGE PROCESS FLOW

This engine meets all required diesel engine emissions

standards. To achieve these emissions standards, your

vehicle is equipped with a state-of-the-art engine and

exhaust system. These systems are seamlessly integrated

into your vehicle and managed by the Powertrain Control

Module (PCM). The PCM manages engine combustion to

allow the exhaust system’s catalyst to trap and burn

Particulate Matter (PM) pollutants, with no input or

interaction on your part.

Additionally, your vehicle has the ability to alert you to

additional maintenance required on your vehicle or

engine.

Refer to Instrument Cluster Display for further information

Úpage 108.

DIESEL EXHAUST FLUID

Diesel Exhaust Fluid (DEF) sometimes known simply by

the name of its active component, UREA—is a key

component of Selective Catalytic Reduction (SCR)

systems, which help diesel vehicles meet stringent

emission regulations. DEF is a liquid reducing agent that

WARNING!

Do not open the high pressure fuel system with the

engine running. Engine operation causes high fuel

pressure. High pressure fuel spray can cause serious

injury or death.

CAUTION!

The starter motor will engage for approximately

30 seconds at a time. Allow two minutes between

cranking intervals.

WARNING!

Do not use alcohol or gasoline as a fuel blending agent.

They can be unstable under certain conditions and be

hazardous or explosive when mixed with diesel fuel.

CAUTION!

Due to lack of lubricants in alcohol or gasoline, the use

of these fuels can cause damage to the fuel system.WARNING!

A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be grass

or leaves coming into contact with your exhaust system.

Do not park or operate your vehicle in areas where your

exhaust system can contact anything that can burn.

8

23_JL_OM_EN_USC_t.book Page 323

Page 326 of 396

324SERVICING AND MAINTENANCE

reacts with engine exhaust in the presence of a catalyst to

convert smog-forming Nitrogen Oxides (NOx) into

harmless nitrogen and water vapor.

For further information

Úpage 374.

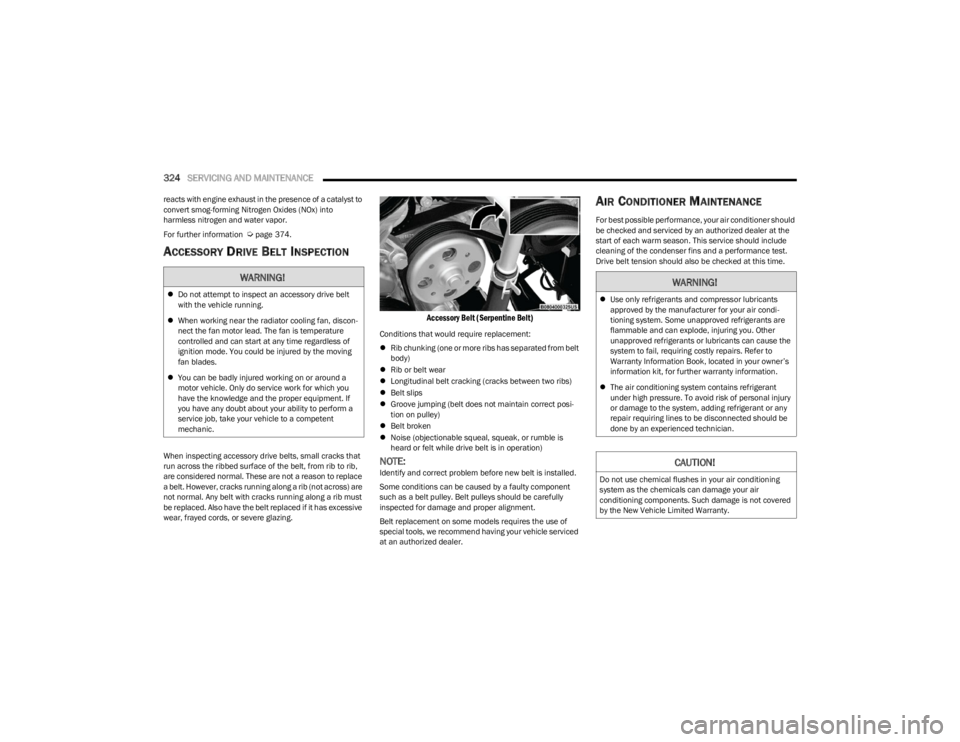

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small cracks that

run across the ribbed surface of the belt, from rib to rib,

are considered normal. These are not a reason to replace

a belt. However, cracks running along a rib (not across) are

not normal. Any belt with cracks running along a rib must

be replaced. Also have the belt replaced if it has excessive

wear, frayed cords, or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated from belt

body)

Rib or belt wear

Longitudinal belt cracking (cracks between two ribs)

Belt slips

Groove jumping (belt does not maintain correct posi -

tion on pulley)

Belt broken

Noise (objectionable squeal, squeak, or rumble is

heard or felt while drive belt is in operation)

NOTE:Identify and correct problem before new belt is installed.

Some conditions can be caused by a faulty component

such as a belt pulley. Belt pulleys should be carefully

inspected for damage and proper alignment.

Belt replacement on some models requires the use of

special tools, we recommend having your vehicle serviced

at an authorized dealer.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner should

be checked and serviced by an authorized dealer at the

start of each warm season. This service should include

cleaning of the condenser fins and a performance test.

Drive belt tension should also be checked at this time.

WARNING!

Do not attempt to inspect an accessory drive belt

with the vehicle running.

When working near the radiator cooling fan, discon -

nect the fan motor lead. The fan is temperature

controlled and can start at any time regardless of

ignition mode. You could be injured by the moving

fan blades.

You can be badly injured working on or around a

motor vehicle. Only do service work for which you

have the knowledge and the proper equipment. If

you have any doubt about your ability to perform a

service job, take your vehicle to a competent

mechanic.WARNING!

Use only refrigerants and compressor lubricants

approved by the manufacturer for your air condi -

tioning system. Some unapproved refrigerants are

flammable and can explode, injuring you. Other

unapproved refrigerants or lubricants can cause the

system to fail, requiring costly repairs. Refer to

Warranty Information Book, located in your owner’s

information kit, for further warranty information.

The air conditioning system contains refrigerant

under high pressure. To avoid risk of personal injury

or damage to the system, adding refrigerant or any

repair requiring lines to be disconnected should be

done by an experienced technician.

CAUTION!

Do not use chemical flushes in your air conditioning

system as the chemicals can damage your air

conditioning components. Such damage is not covered

by the New Vehicle Limited Warranty.

23_JL_OM_EN_USC_t.book Page 324

Page 327 of 396

SERVICING AND MAINTENANCE325

Refrigerant Recovery And Recycling —

R–1234yf

R–1234yf Air Conditioning Refrigerant is a Hydrofluo -

roolefin (HFO) that is endorsed by the Environmental

Protection Agency and is an ozone-friendly substance with

a low global-warming potential. The manufacturer

recommends that air conditioning service be performed by

an authorized dealer using recovery and recycling

equipment.

NOTE:Use only the manufacturer approved A/C system PAG

compressor oil, and refrigerants.

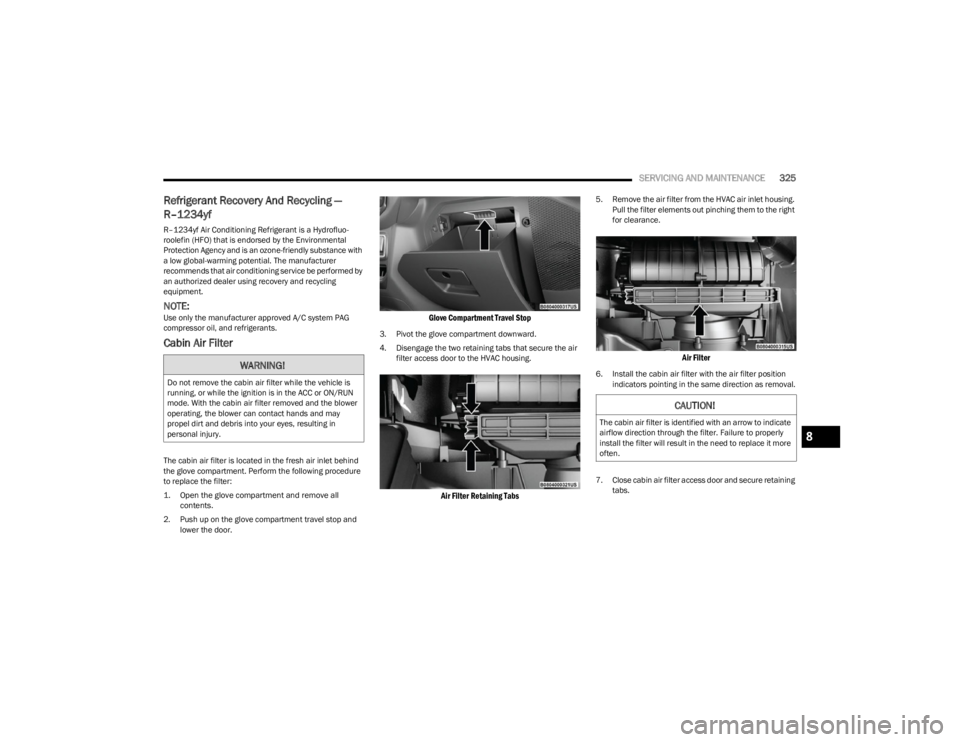

Cabin Air Filter

The cabin air filter is located in the fresh air inlet behind

the glove compartment. Perform the following procedure

to replace the filter:

1. Open the glove compartment and remove all contents.

2. Push up on the glove compartment travel stop and lower the door.

Glove Compartment Travel Stop

3. Pivot the glove compartment downward.

4. Disengage the two retaining tabs that secure the air filter access door to the HVAC housing.

Air Filter Retaining Tabs

5. Remove the air filter from the HVAC air inlet housing. Pull the filter elements out pinching them to the right

for clearance.

Air Filter

6. Install the cabin air filter with the air filter position indicators pointing in the same direction as removal.

7. Close cabin air filter access door and secure retaining tabs.WARNING!

Do not remove the cabin air filter while the vehicle is

running, or while the ignition is in the ACC or ON/RUN

mode. With the cabin air filter removed and the blower

operating, the blower can contact hands and may

propel dirt and debris into your eyes, resulting in

personal injury.

CAUTION!

The cabin air filter is identified with an arrow to indicate

airflow direction through the filter. Failure to properly

install the filter will result in the need to replace it more

often.

8

23_JL_OM_EN_USC_t.book Page 325

Page 328 of 396

326SERVICING AND MAINTENANCE

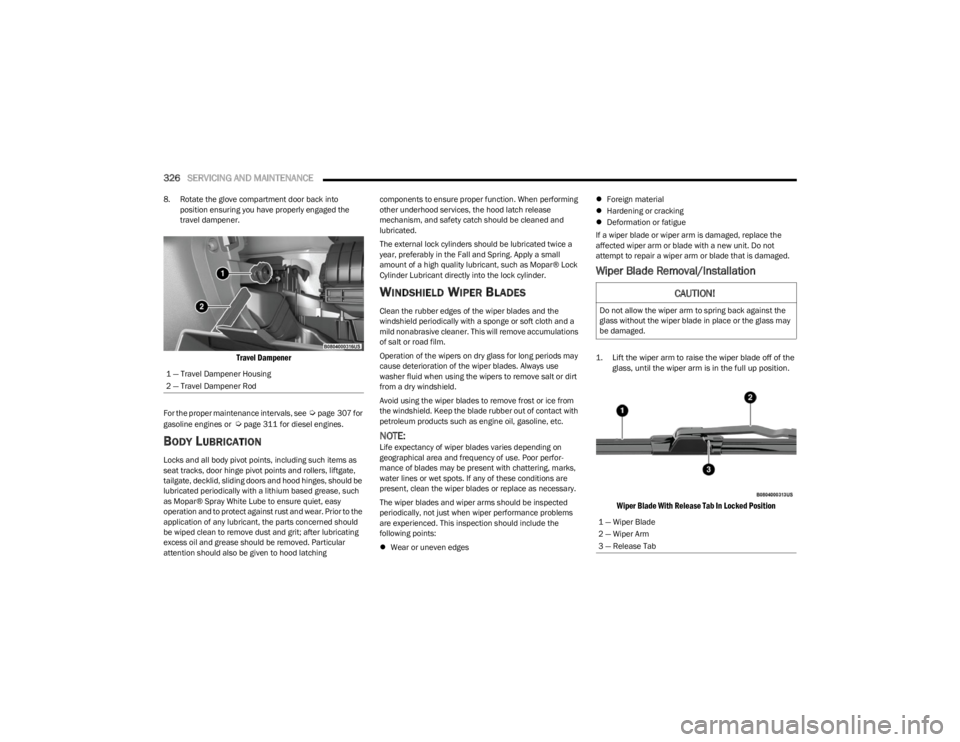

8. Rotate the glove compartment door back into

position ensuring you have properly engaged the

travel dampener.

Travel Dampener

For the proper maintenance intervals, see Úpage 307 for

gasoline engines or Úpage 311 for diesel engines.

BODY LUBRICATION

Locks and all body pivot points, including such items as

seat tracks, door hinge pivot points and rollers, liftgate,

tailgate, decklid, sliding doors and hood hinges, should be

lubricated periodically with a lithium based grease, such

as Mopar® Spray White Lube to ensure quiet, easy

operation and to protect against rust and wear. Prior to the

application of any lubricant, the parts concerned should

be wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particular

attention should also be given to hood latching components to ensure proper function. When performing

other underhood services, the hood latch release

mechanism, and safety catch should be cleaned and

lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the Fall and Spring. Apply a small

amount of a high quality lubricant, such as Mopar® Lock

Cylinder Lubricant directly into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth and a

mild nonabrasive cleaner. This will remove accumulations

of salt or road film.

Operation of the wipers on dry glass for long periods may

cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending on

geographical area and frequency of use. Poor perfor

-

mance of blades may be present with chattering, marks,

water lines or wet spots. If any of these conditions are

present, clean the wiper blades or replace as necessary.

The wiper blades and wiper arms should be inspected

periodically, not just when wiper performance problems

are experienced. This inspection should include the

following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged, replace the

affected wiper arm or blade with a new unit. Do not

attempt to repair a wiper arm or blade that is damaged.

Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off of the glass, until the wiper arm is in the full up position.

Wiper Blade With Release Tab In Locked Position

1 — Travel Dampener Housing

2 — Travel Dampener Rod

CAUTION!

Do not allow the wiper arm to spring back against the

glass without the wiper blade in place or the glass may

be damaged.

1 — Wiper Blade

2 — Wiper Arm

3 — Release Tab

23_JL_OM_EN_USC_t.book Page 326

Page 329 of 396

SERVICING AND MAINTENANCE327

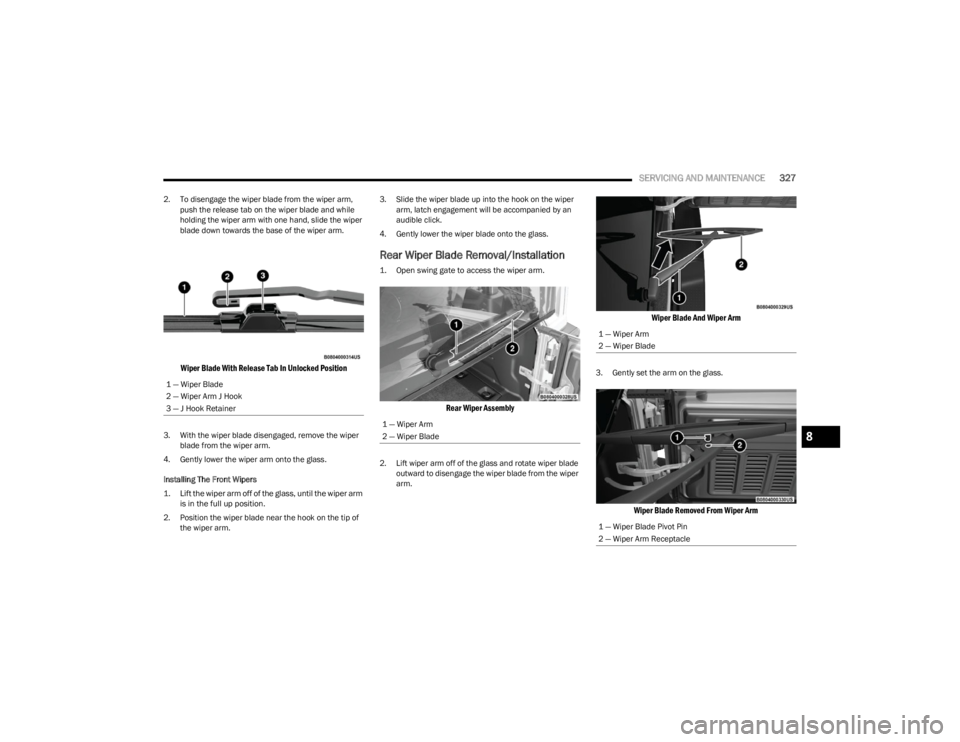

2. To disengage the wiper blade from the wiper arm,

push the release tab on the wiper blade and while

holding the wiper arm with one hand, slide the wiper

blade down towards the base of the wiper arm.

Wiper Blade With Release Tab In Unlocked Position

3. With the wiper blade disengaged, remove the wiper blade from the wiper arm.

4. Gently lower the wiper arm onto the glass.

Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the wiper arm is in the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm. 3. Slide the wiper blade up into the hook on the wiper

arm, latch engagement will be accompanied by an

audible click.

4. Gently lower the wiper blade onto the glass.

Rear Wiper Blade Removal/Installation

1. Open swing gate to access the wiper arm.

Rear Wiper Assembly

2. Lift wiper arm off of the glass and rotate wiper blade outward to disengage the wiper blade from the wiper

arm.

Wiper Blade And Wiper Arm

3. Gently set the arm on the glass.

Wiper Blade Removed From Wiper Arm

1 — Wiper Blade

2 — Wiper Arm J Hook

3 — J Hook Retainer

1 — Wiper Arm

2 — Wiper Blade

1 — Wiper Arm

2 — Wiper Blade

1 — Wiper Blade Pivot Pin

2 — Wiper Arm Receptacle

8

23_JL_OM_EN_USC_t.book Page 327

Page 330 of 396

328SERVICING AND MAINTENANCE

(Continued)

(Continued)

Installing The Rear Wiper

1. Lift the wiper arm off of the glass.

2. Insert the wiper blade pivot pin into the opening on

the end of the wiper arm and rotate the wiper in to

place.

3. Place with wiper on the glass and close the tail gate.

EXHAUST SYSTEM

The best protection against carbon monoxide entry into

the vehicle body is a properly maintained engine exhaust

system.

If you notice a change in the sound of the exhaust system;

or if the exhaust fumes can be detected inside the vehicle;

or when the underside or rear of the vehicle is damaged;

have an authorized technician inspect the complete

exhaust system and adjacent body areas for broken,

damaged, deteriorated, or mispositioned parts. Open

seams or loose connections could permit exhaust fumes

to seep into the passenger compartment. In addition, have

the exhaust system inspected each time the vehicle is

raised for lubrication or oil change. Replace as required.

Under normal operating conditions, the catalytic converter

will not require maintenance. However, it is important to

keep the engine properly tuned to ensure proper catalyst

operation and prevent possible catalyst damage.

NOTE:Intentional tampering with emissions control systems can

result in civil penalties being assessed against you.

In unusual situations involving grossly malfunctioning

engine operation, a scorching odor may suggest severe

and abnormal catalyst overheating. If this occurs, stop the

vehicle, turn off the engine and allow it to cool. Service,

including a tune-up to manufacturer's specifications,

should be obtained immediately.

To minimize the possibility of catalytic converter damage:

Do not interrupt the ignition when the transmission is

in gear and the vehicle is in motion.

Do not try to start the vehicle by pushing or towing the

vehicle.

Do not idle the engine with any ignition components

disconnected or removed, such as when diagnostic

testing, or for prolonged periods during very rough idle

or malfunctioning operating conditions.

COOLING SYSTEM

WARNING!

Exhaust gases can injure or kill. They contain Carbon

Monoxide (CO), which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you

Úpage 288.

A hot exhaust system can start a fire if you park over

materials that can burn. Such materials might be

grass or leaves coming into contact with your

exhaust system. Do not park or operate your vehicle

in areas where your exhaust system can contact

anything that can burn.

CAUTION!

The catalytic converter requires the use of unleaded

fuel only. Leaded gasoline will destroy the effective -

ness of the catalyst as an emissions control device

and may seriously reduce engine performance and

cause serious damage to the engine.

Damage to the catalytic converter can result if your

vehicle is not kept in proper operating condition. In

the event of engine malfunction, particularly

involving engine misfire or other apparent loss of

performance, have your vehicle serviced promptly.

Continued operation of your vehicle with a severe

malfunction could cause the converter to overheat,

resulting in possible damage to the converter and

vehicle.

WARNING!

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator. If

you see or hear steam coming from under the hood,

do not open the hood until the radiator has had time

to cool. Never open a cooling system pressure cap

when the radiator or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry away from

the radiator cooling fan when the hood is raised. The

fan starts automatically and may start at any time,

whether the engine is running or not.

23_JL_OM_EN_USC_t.book Page 328