JEEP WRANGLER 2023 Owners Manual

Manufacturer: JEEP, Model Year: 2023, Model line: WRANGLER, Model: JEEP WRANGLER 2023Pages: 396, PDF Size: 25.15 MB

Page 361 of 396

SERVICING AND MAINTENANCE359

on a specified government test course.

For example, a tire graded 150 would

wear one and one-half times as well on

the government course as a tire graded

100. The relative performance of tires

depends upon the actual conditions of

their use, however, and may depart

significantly from the norm due to

variations in driving habits, service

practices, and differences in road

characteristics and climate.

TRACTION GRADES

The Traction grades, from highest to

lowest, are AA, A, B, and C. These grades

represent the tire's ability to stop on wet

pavement, as measured under

controlled conditions on specified

government test surfaces of asphalt and

concrete. A tire marked C may have poor

traction performance.

TEMPERATURE GRADES

The Temperature grades are A (the

highest), B, and C, representing the tire's

resistance to the generation of heat and

its ability to dissipate heat, when tested

under controlled conditions on a

specified indoor laboratory test wheel.

Sustained high temperature can cause

the material of the tire to degenerate

and reduce tire life, and excessive

temperature can lead to sudden tire

failure. The grade C corresponds to a

level of performance, which all

passenger vehicle tires must meet

under the Federal Motor Vehicle Safety

Standard No. 109. Grades B and A

represent higher levels of performance on the laboratory test wheel, than the

minimum required by law.

STORING THE VEHICLE

WARNING!

The traction grade assigned to this tire is based on

straight-ahead braking traction tests, and does not

include acceleration, cornering, hydroplaning, or peak

traction characteristics.

WARNING!

The temperature grade for this tire is established for a

tire that is properly inflated and not overloaded.

Excessive speed, underinflation, or excessive loading,

either separately or in combination, can cause heat

buildup and possible tire failure.

WARNING!

Take care to avoid the radiator cooling fan whenever

the hood is raised. It can start anytime the ignition

switch is ON. You can be injured by moving fan

blades.

Remove any metal jewelry such as rings, watch

bands and bracelets that could make an inadvertent

electrical contact. You could be seriously injured.

Vehicles with the Stop/Start system will be equipped

with two batteries. Both the main and the supple -

mental batteries must be disconnected to

completely de-energize the 12 Volt electrical system.

Serious injury or death could result if you do not

disconnect both batteries. To learn how to properly

disconnect, see an authorized dealer.

8

23_JL_OM_EN_USC_t.book Page 359

Page 362 of 396

360SERVICING AND MAINTENANCE

If you are storing your vehicle for more than three weeks,

we recommend that you take the following steps to

minimize the drain on your vehicle's battery:

Disconnect the negative cable from battery.

If your vehicle is equipped with Stop/Start system then

disconnect both the main and supplemental negative

battery cables.

Any time you store your vehicle or keep it out of service

(i.e., vacation) for two weeks or more, run the air condi -

tioning system at idle for about five minutes in the

fresh air and high blower setting. This will ensure

adequate system lubrication to minimize the possibility

of compressor damage when the system is started

again.

If assistance is needed to disconnect the battery

system, see an authorized dealer.

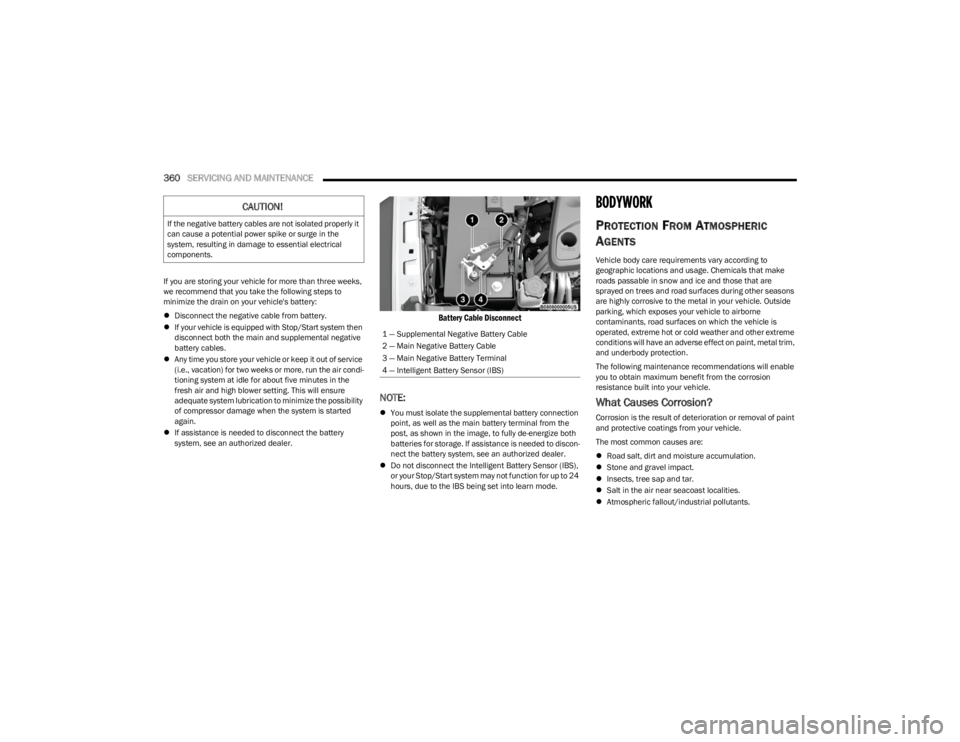

Battery Cable Disconnect

NOTE:

You must isolate the supplemental battery connection

point, as well as the main battery terminal from the

post, as shown in the image, to fully de-energize both

batteries for storage. If assistance is needed to discon -

nect the battery system, see an authorized dealer.

Do not disconnect the Intelligent Battery Sensor (IBS),

or your Stop/Start system may not function for up to 24

hours, due to the IBS being set into learn mode.

BODYWORK

PROTECTION FROM ATMOSPHERIC

A

GENTS

Vehicle body care requirements vary according to

geographic locations and usage. Chemicals that make

roads passable in snow and ice and those that are

sprayed on trees and road surfaces during other seasons

are highly corrosive to the metal in your vehicle. Outside

parking, which exposes your vehicle to airborne

contaminants, road surfaces on which the vehicle is

operated, extreme hot or cold weather and other extreme

conditions will have an adverse effect on paint, metal trim,

and underbody protection.

The following maintenance recommendations will enable

you to obtain maximum benefit from the corrosion

resistance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or removal of paint

and protective coatings from your vehicle.

The most common causes are:

Road salt, dirt and moisture accumulation.

Stone and gravel impact.

Insects, tree sap and tar.

Salt in the air near seacoast localities.

Atmospheric fallout/industrial pollutants.

CAUTION!

If the negative battery cables are not isolated properly it

can cause a potential power spike or surge in the

system, resulting in damage to essential electrical

components.

1 — Supplemental Negative Battery Cable

2 — Main Negative Battery Cable

3 — Main Negative Battery Terminal

4 — Intelligent Battery Sensor (IBS)

23_JL_OM_EN_USC_t.book Page 360

Page 363 of 396

SERVICING AND MAINTENANCE361

8

BODY AND UNDERBODY MAINTENANCE

Cleaning Headlights

Your vehicle is equipped with plastic headlights and fog

lights that are lighter and less susceptible to stone

breakage than glass headlights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution followed

by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

PRESERVING THE BODYWORK

Washing

Wash your vehicle regularly. Always wash your vehicle

in the shade using Mopar® Car Wash, or a mild car

wash soap and rinse the panels completely with water.

If insects, tar, or other similar deposits have accumu -

lated on your vehicle, use Mopar® Super Kleen Bug

and Tar Remover to remove.

Use a high quality cleaner wax, such as Mopar®

Cleaner Wax to remove road film, stains and to protect

your paint finish. Use precautions to not scratch the

paint.

Avoid using abrasive compounds and power buffing

that may diminish the gloss or thin out the paint finish.

Special Care

If you drive on salted or dusty roads or if you drive near

the ocean, hose off the undercarriage at least once a

month.

It is important that the drain holes in the lower edges of

the doors, rocker panels, and trunk be kept clear and

open.

If you detect any stone chips or scratches in the paint,

touch them up immediately. The cost of such repairs is

considered the responsibility of the owner.

If your vehicle is damaged due to a collision or similar

cause that destroys the paint and protective coating,

have your vehicle repaired as soon as possible. The

cost of such repairs is considered the responsibility of

the owner.

If you carry special cargo such as chemicals, fertilizers,

de-icer salt, etc., be sure that such materials are well

packaged and sealed.

If a lot of driving is done on gravel roads, consider mud

or stone shields behind each wheel.

Use Mopar® Touch Up Paint on scratches as soon as

possible. An authorized dealer has touch up paint to

match the color of your vehicle.

Appearance Care For Fabric Top Models

To maintain the appearance of your vehicle's interior trim

and top, follow these precautions:

Do not run a fabric top through an automatic car wash.

Window scratches and wax build-up may result.

Avoid leaving your vehicle unattended with the top

down, as exposure to sun or rain may damage interior

trim.

Do not use harsh cleaners or bleaching agents on top

material, as damage may result.

Do not allow any vinyl cleaner to run down and dry on

the paint, leaving a streak.

After cleaning your vehicle's fabric top, always make

sure it is completely dry before lowering.

Be especially careful when washing the windows by

following the directions for “Care of Fabric Top

Windows.”

Washing – Use Mopar® Car Wash or equivalent, or mild

soap suds, lukewarm water, and a brush with soft bristles.

If extra cleaning is required, use Mopar® Convertible Cloth

Top Cleaner or equivalent, or a mild foaming cleaner on

the entire top, but support the top from underneath.

Rinsing – Be sure to remove all traces of cleaner by rinsing

the top thoroughly with clean water. Remember to allow

the top to dry before lowering it.CAUTION!

Do not use abrasive or strong cleaning materials

such as steel wool or scouring powder that will

scratch metal and painted surfaces.

Use of power washers exceeding 1,200 psi

(8,274 kPa) can result in damage or removal of paint

and decals.

23_JL_OM_EN_USC_t.book Page 361

Page 364 of 396

362SERVICING AND MAINTENANCE

(Continued)

Care Of Fabric Top Windows

Your vehicle's fabric top has pliable plastic windows which

can be scratched unless special care is taken by following

these directions:

Never use a dry cloth to remove dust. Instead, use a

microfiber towel or soft cotton cloth moistened with

cold or warm, clean water, and wipe across the

window, not up and down. Mopar® Jeep® Soft Glass

Window Cleaner or equivalent will safely clean all

plastic windows without scratching. It removes fine

scratches to improve visibility and provides UV protec -

tion to help prevent yellowing.

When washing, never use hot water or anything

stronger than a mild soap. Never use solvents such as

alcohol or harsh cleaning agents.

Always rinse thoroughly with cold water, then wipe with

a soft and slightly moist, clean cloth.

When removing frost, snow or ice, never use a scraper

or de-icing chemicals. Use warm water only if you must

clean the window quickly.

Debris (sand, mud/dirt, dust, or salt) from off-road

driving will have an impact on plastic retainer opera -

tion. Even normal on-road driving and vehicle washing

will eventually impact window plastic retainer opera -

tion. To maintain ease of use of the window plastic

retainers, each window plastic retainer should be

cleaned and lubricated regularly. Clean them with a

mild soap solution and a small brush. Cleaning prod -

ucts are available through an authorized dealer.

Never paste stickers, gummed labels or any tape to the

windows. Adhesives are hard to remove and may

damage the windows.

INTERIORS

CARPET SAFETY INFORMATION

Always use carpet designed to fit your vehicle. Only use

carpet that does not interfere with the operation of the

pedal assemblies. Only operate the vehicle when the

carpet is securely attached by the grommets so it cannot

slip out of position and interfere with the pedal assemblies

or impair safe operation of your vehicle in other ways.

CAUTION!

Failure to follow these cautions may cause interior

water damage, stains, or mildew of the top material:

Do not run a fabric top through an automatic car

wash. Window scratches and wax build-up may

result.

It is recommended that the top be free of water prior

to opening it. Operating the top, opening a door or

lowering a window while the top is wet may allow

water to drip into the vehicle’s interior.

Use care when washing the vehicle, water pressure

directed at the weather strip seals may cause water

to leak into the vehicle’s interior.

Careless handling and storage of the removable roof

panels may damage the seals, causing water to leak

into the vehicle’s interior.

The front panel(s) must be positioned properly to

ensure sealing. Improper installation can cause

water to leak into the vehicle’s interior.

CAUTION!

Avoid washing with rollers and/or brushes in washing

stations. Wash the vehicle only by hand using neutral

pH detergents; dry it with a wet chamois leather.

Abrasive products and/or polishes should not be

used for cleaning the car.

Bird droppings must be washed off immediately and

thoroughly as the acid they contain is particularly

aggressive.

Avoid (if at all possible) parking the vehicle under

trees; remove vegetable resins immediately as, when

dried, it may only be possible to remove them with

abrasive products and/or polishes, which is highly

inadvisable as they could alter the typical opaque -

ness of the paint.

Do not use pure windshield washer fluid for cleaning

the front windshield and rear window; dilute it to a

minimum of 50% water. Only use pure windshield

washer fluid when strictly necessary due to outside

temperature conditions.

CAUTION!

23_JL_OM_EN_USC_t.book Page 362

Page 365 of 396

SERVICING AND MAINTENANCE363

CARPET REMOVAL

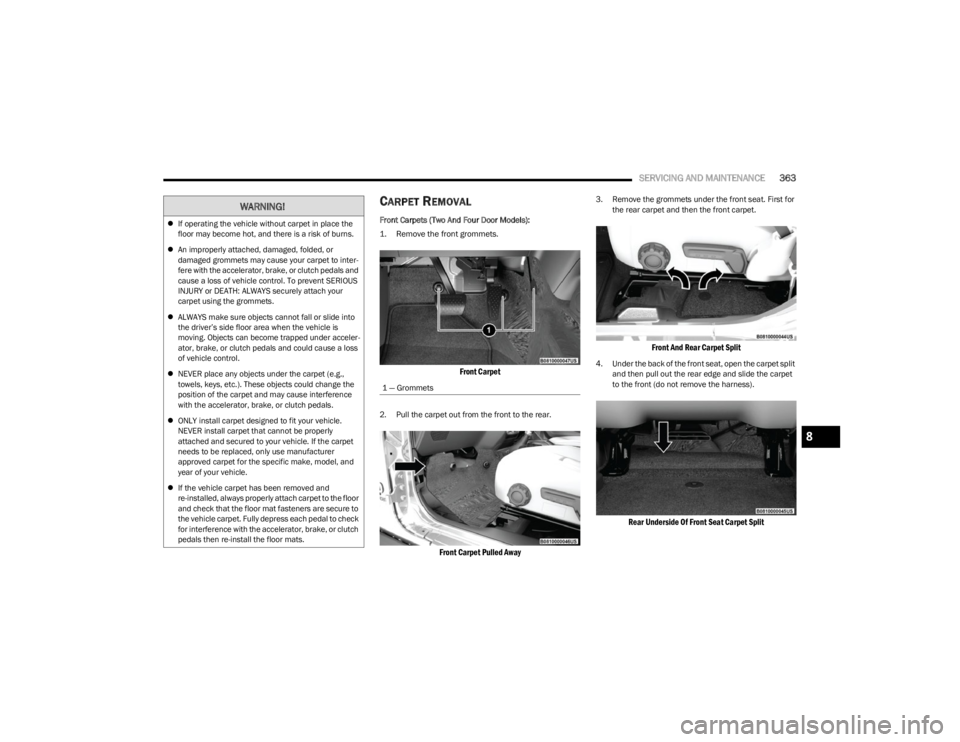

Front Carpets (Two And Four Door Models):

1. Remove the front grommets.

Front Carpet

2. Pull the carpet out from the front to the rear.

Front Carpet Pulled Away

3. Remove the grommets under the front seat. First for

the rear carpet and then the front carpet.

Front And Rear Carpet Split

4. Under the back of the front seat, open the carpet split and then pull out the rear edge and slide the carpet

to the front (do not remove the harness).

Rear Underside Of Front Seat Carpet Split

WARNING!

If operating the vehicle without carpet in place the

floor may become hot, and there is a risk of burns.

An improperly attached, damaged, folded, or

damaged grommets may cause your carpet to inter -

fere with the accelerator, brake, or clutch pedals and

cause a loss of vehicle control. To prevent SERIOUS

INJURY or DEATH: ALWAYS securely attach your

carpet using the grommets.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

NEVER place any objects under the carpet (e.g.,

towels, keys, etc.). These objects could change the

position of the carpet and may cause interference

with the accelerator, brake, or clutch pedals.

ONLY install carpet designed to fit your vehicle.

NEVER install carpet that cannot be properly

attached and secured to your vehicle. If the carpet

needs to be replaced, only use manufacturer

approved carpet for the specific make, model, and

year of your vehicle.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check that the floor mat fasteners are secure to

the vehicle carpet. Fully depress each pedal to check

for interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

1 — Grommets

8

23_JL_OM_EN_USC_t.book Page 363

Page 366 of 396

364SERVICING AND MAINTENANCE

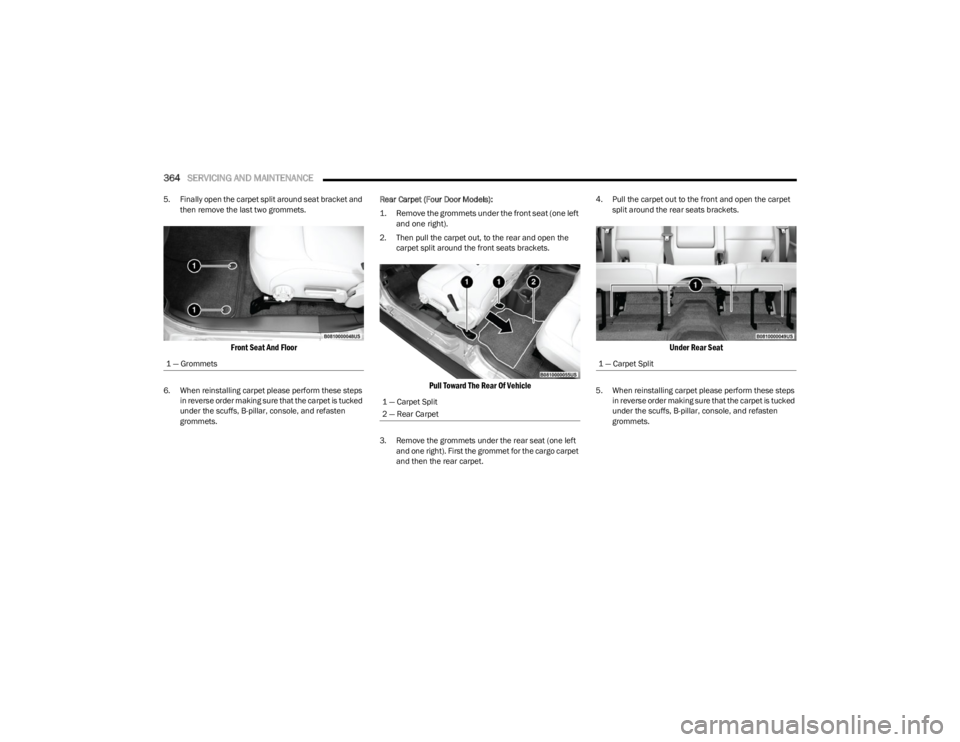

5. Finally open the carpet split around seat bracket and

then remove the last two grommets.

Front Seat And Floor

6. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets. Rear Carpet (Four Door Models):

1. Remove the grommets under the front seat (one left

and one right).

2. Then pull the carpet out, to the rear and open the carpet split around the front seats brackets.

Pull Toward The Rear Of Vehicle

3. Remove the grommets under the rear seat (one left and one right). First the grommet for the cargo carpet

and then the rear carpet. 4. Pull the carpet out to the front and open the carpet

split around the rear seats brackets.

Under Rear Seat

5. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets.

1 — Grommets1 — Carpet Split

2 — Rear Carpet

1 — Carpet Split

23_JL_OM_EN_USC_t.book Page 364

Page 367 of 396

SERVICING AND MAINTENANCE365

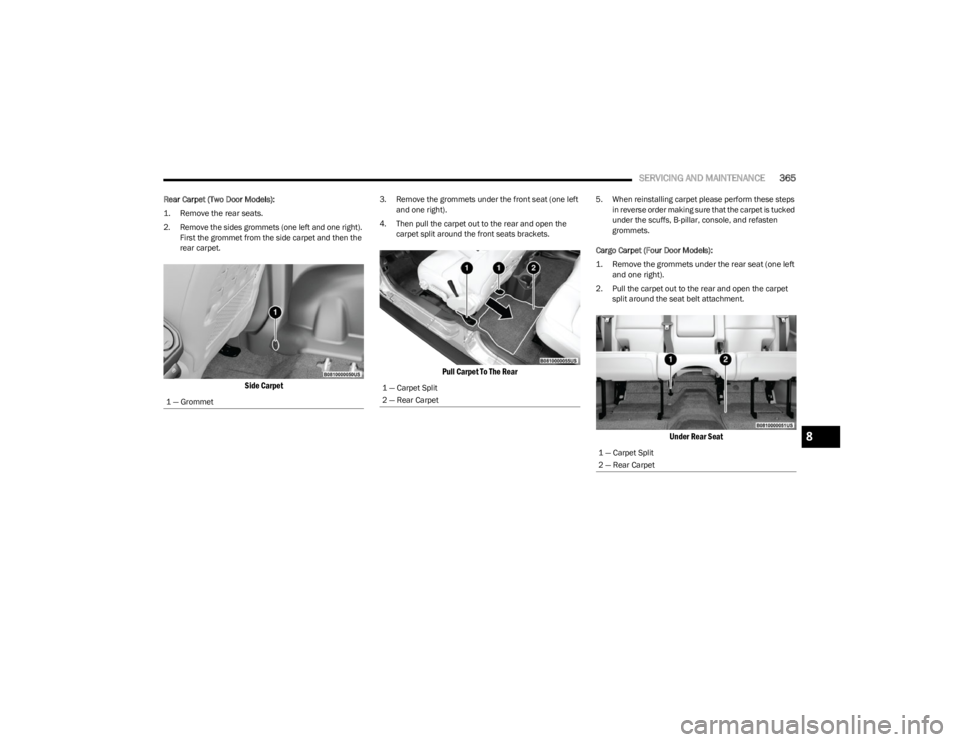

Rear Carpet (Two Door Models):

1. Remove the rear seats.

2. Remove the sides grommets (one left and one right).

First the grommet from the side carpet and then the

rear carpet.

Side Carpet

3. Remove the grommets under the front seat (one left and one right).

4. Then pull the carpet out to the rear and open the carpet split around the front seats brackets.

Pull Carpet To The Rear

5. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets.

Cargo Carpet (Four Door Models):

1. Remove the grommets under the rear seat (one left and one right).

2. Pull the carpet out to the rear and open the carpet split around the seat belt attachment.

Under Rear Seat

1 — Grommet

1 — Carpet Split

2 — Rear Carpet

1 — Carpet Split

2 — Rear Carpet

8

23_JL_OM_EN_USC_t.book Page 365

Page 368 of 396

366SERVICING AND MAINTENANCE

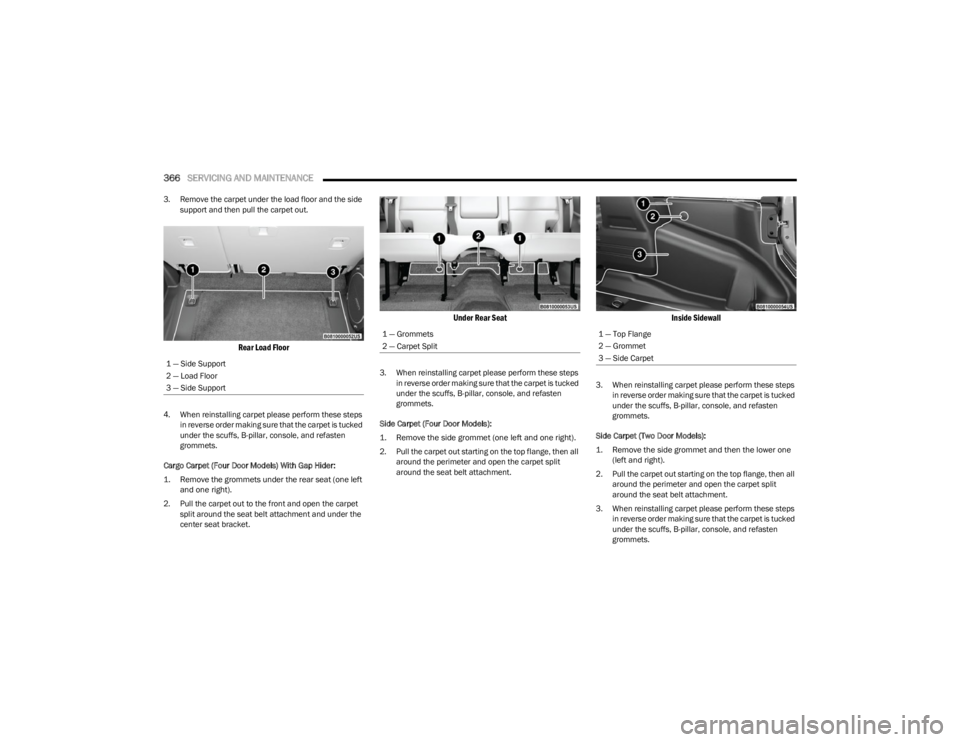

3. Remove the carpet under the load floor and the side

support and then pull the carpet out.

Rear Load Floor

4. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets.

Cargo Carpet (Four Door Models) With Gap Hider:

1. Remove the grommets under the rear seat (one left and one right).

2. Pull the carpet out to the front and open the carpet split around the seat belt attachment and under the

center seat bracket.

Under Rear Seat

3. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets.

Side Carpet (Four Door Models):

1. Remove the side grommet (one left and one right).

2. Pull the carpet out starting on the top flange, then all around the perimeter and open the carpet split

around the seat belt attachment.

Inside Sidewall

3. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets.

Side Carpet (Two Door Models):

1. Remove the side grommet and then the lower one (left and right).

2. Pull the carpet out starting on the top flange, then all around the perimeter and open the carpet split

around the seat belt attachment.

3. When reinstalling carpet please perform these steps in reverse order making sure that the carpet is tucked

under the scuffs, B-pillar, console, and refasten

grommets.

1 — Side Support

2 — Load Floor

3 — Side Support

1 — Grommets

2 — Carpet Split1 — Top Flange

2 — Grommet

3 — Side Carpet

23_JL_OM_EN_USC_t.book Page 366

Page 369 of 396

SERVICING AND MAINTENANCE367

SEATS AND FABRIC PARTS

Use Mopar® Total Clean to clean fabric upholstery and

carpeting.

Seat Belt Maintenance

Do not bleach, dye or clean the belts with chemical

solvents or abrasive cleaners. This will weaken the fabric.

Sun damage can also weaken the fabric.

If the belts need cleaning, use a mild soap solution or

lukewarm water. Do not remove the belts from the vehicle

to wash them. Dry with a soft cloth.

Replace the belts if they appear frayed or worn or if the

buckles do not work properly.

PLASTIC AND COATED PARTS

Use Mopar® Total Clean to clean vinyl upholstery.

Cleaning Plastic Instrument Cluster

Lenses

The lenses in front of the instruments in this vehicle are

molded in clear plastic. When cleaning the lenses, care

must be taken to avoid scratching the plastic.

Clean with a wet soft cloth. A mild soap solution may be

used, but do not use high alcohol content or abrasive

cleaners. If soap is used, wipe clean with a clean damp

cloth. Dry with a soft cloth.

LEATHER SURFACES

Mopar® Total Clean is specifically recommended for

leather upholstery.

Your leather upholstery can be best preserved by regular

cleaning with a damp soft cloth. Small particles of dirt can

act as an abrasive and damage the leather upholstery and

should be removed promptly with a damp cloth. Stubborn

soils can be removed easily with a soft cloth and Mopar®

Total Clean. Care should be taken to avoid soaking your leather upholstery with any liquid. Please do not use

polishes, oils, cleaning fluids, solvents, detergents, or

ammonia-based cleaners to clean your leather upholstery.

NOTE:If equipped with light colored leather, it tends to show any

foreign material, dirt, and fabric dye transfer more so than

darker colors. The leather is designed for easy cleaning,

and FCA recommends Mopar® total care leather cleaner

applied on a cloth to clean the leather seats as needed.

GLASS SURFACES

All glass surfaces should be cleaned on a regular basis

with Mopar® Glass Cleaner, or any commercial

household-type glass cleaner. Never use an abrasive type

cleaner. Use caution when cleaning the inside rear

window equipped with electric defrosters or windows

equipped with radio antennas. Do not use scrapers or

other sharp instruments that may scratch the elements.

When cleaning the rearview mirror, spray cleaner on the

towel or cloth that you are using. Do not spray cleaner

directly on the mirror.

WARNING!

Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in closed

areas they may cause respiratory harm.

WARNING!

A frayed or torn seat belt could rip apart in a collision

and leave you with no protection. Inspect the seat belt

system periodically, checking for cuts, frays, or loose

parts. Damaged parts must be replaced immediately.

Do not disassemble or modify the seat belt system. If

your vehicle is involved in a collision, or if you have

questions regarding seat belt or retractor conditions,

take your vehicle to an authorized FCA dealer or

authorized FCA Certified Collision Care Program facility

for inspection.

CAUTION!

Direct contact of air fresheners, insect repellents,

suntan lotions, or hand sanitizers to the plastic,

painted, or decorated surfaces of the interior may

cause permanent damage. Wipe away immediately.

Damage caused by these type of products may not

be covered by your New Vehicle Limited Warranty.

CAUTION!

Do not use alcohol and alcohol-based and/or ketone

based cleaning products to clean leather upholstery, as

damage to the upholstery may result.

8

23_JL_OM_EN_USC_t.book Page 367

Page 370 of 396

368

TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is found on the left front corner of the A-pillar,

visible from outside of the vehicle through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN plate.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose normal

capability, the remaining system will still function.

However, there will be some loss of overall braking

effectiveness. You may notice increased pedal travel during application, greater pedal force required to slow or

stop, and potential activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repeated brake applications with the engine off) the

brakes will still function. However, the effort required to

brake the vehicle will be much greater than that required

with the power system operating.

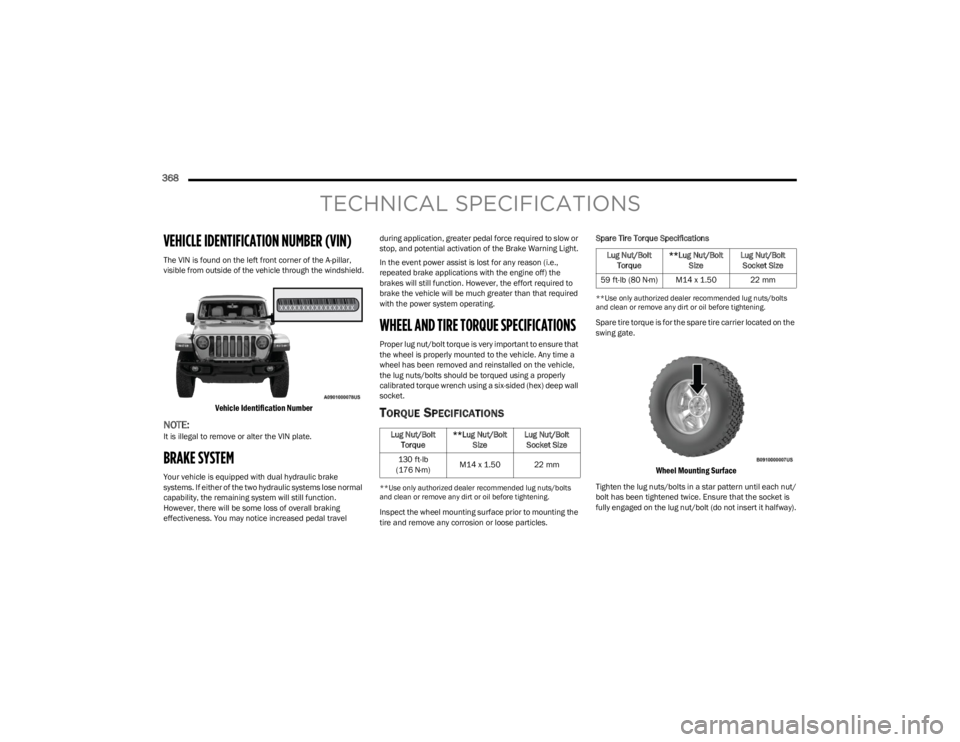

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to ensure that

the wheel is properly mounted to the vehicle. Any time a

wheel has been removed and reinstalled on the vehicle,

the lug nuts/bolts should be torqued using a properly

calibrated torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug nuts/bolts

and clean or remove any dirt or oil before tightening.

Inspect the wheel mounting surface prior to mounting the

tire and remove any corrosion or loose particles.Spare Tire Torque Specifications

**Use only authorized dealer recommended lug nuts/bolts

and clean or remove any dirt or oil before tightening.

Spare tire torque is for the spare tire carrier located on the

swing gate.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until each nut/

bolt has been tightened twice. Ensure that the socket is

fully engaged on the lug nut/bolt (do not insert it halfway).

Lug Nut/Bolt

Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

130 ft-lb

(176 N·m) M14 x 1.50 22 mm

Lug Nut/Bolt

Torque **Lug Nut/Bolt

Size Lug Nut/Bolt

Socket Size

59 ft-lb (80 N·m) M14 x 1.50 22 mm

23_JL_OM_EN_USC_t.book Page 368