JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995,

Model line: XJ,

Model: JEEP XJ 1995

Pages: 2158, PDF Size: 81.9 MB

JEEP XJ 1995 Service And Repair Manual

XJ 1995

JEEP

JEEP

https://www.carmanualsonline.info/img/16/57043/w960_57043-0.png

JEEP XJ 1995 Service And Repair Manual

Trending: stop start, engine oil capacity, gas tank size, oil, fuse box, heater, wheelbase

Page 1271 of 2158

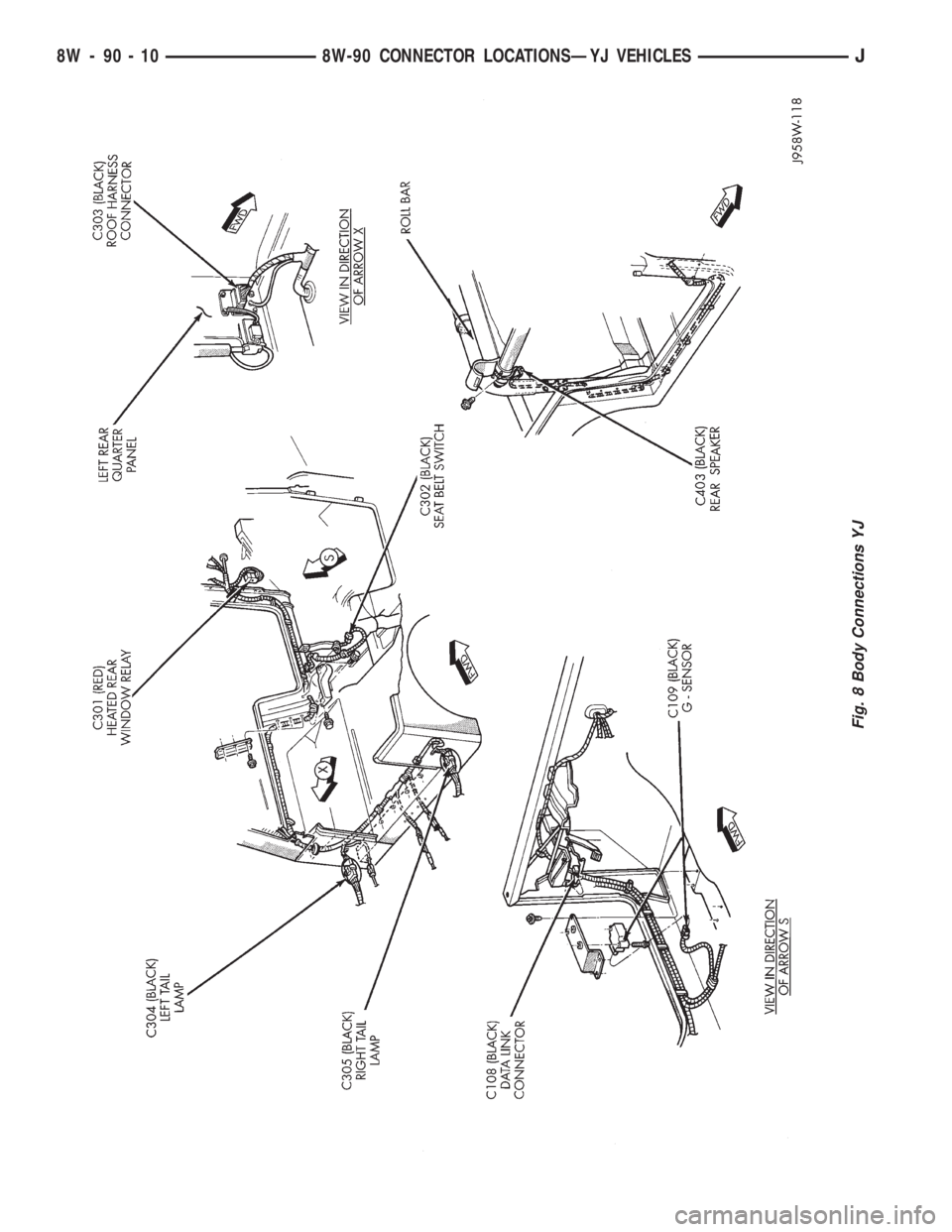

Fig. 8 Body Connections YJ

8W - 90 - 10 8W-90 CONNECTOR LOCATIONSÐYJ VEHICLESJ

Page 1272 of 2158

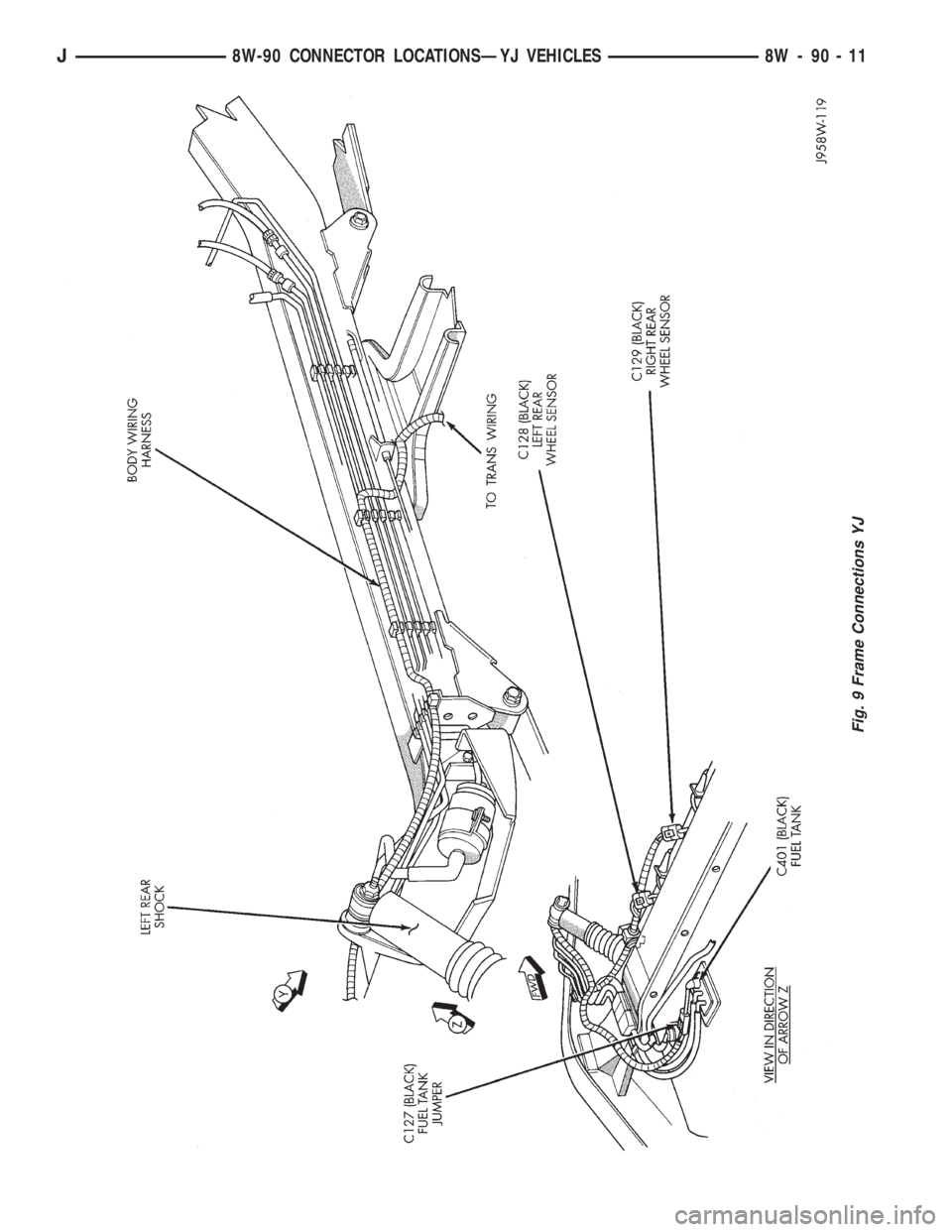

Fig. 9 Frame Connections YJ

J8W-90 CONNECTOR LOCATIONSÐYJ VEHICLES 8W - 90 - 11

Page 1273 of 2158

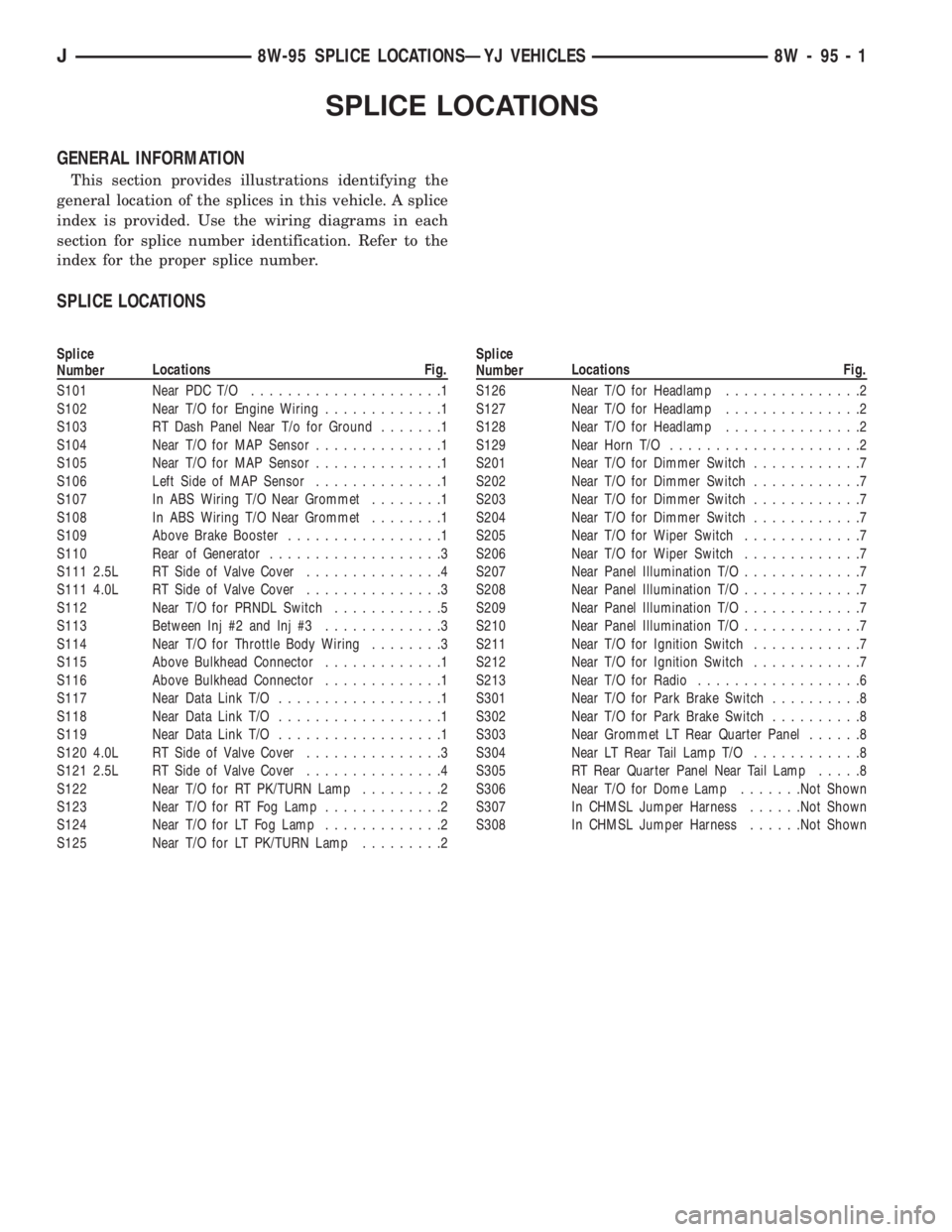

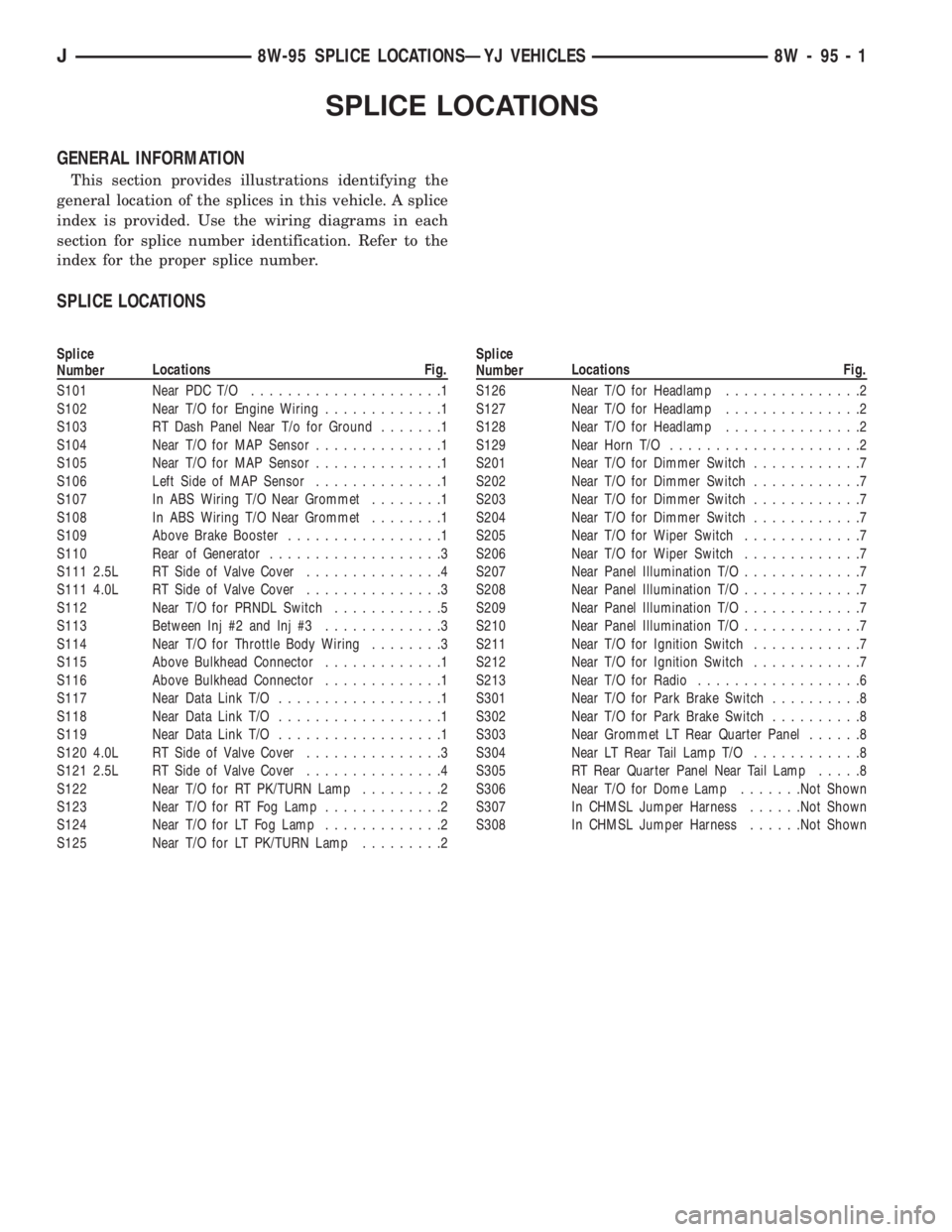

SPLICE LOCATIONS

GENERAL INFORMATION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for the proper splice number.

SPLICE LOCATIONS

Splice

NumberLocations Fig.

S101 Near PDC T/O.....................1

S102 Near T/O for Engine Wiring.............1

S103 RT Dash Panel Near T/o for Ground.......1

S104 Near T/O for MAP Sensor..............1

S105 Near T/O for MAP Sensor..............1

S106 Left Side of MAP Sensor..............1

S107 In ABS Wiring T/O Near Grommet........1

S108 In ABS Wiring T/O Near Grommet........1

S109 Above Brake Booster.................1

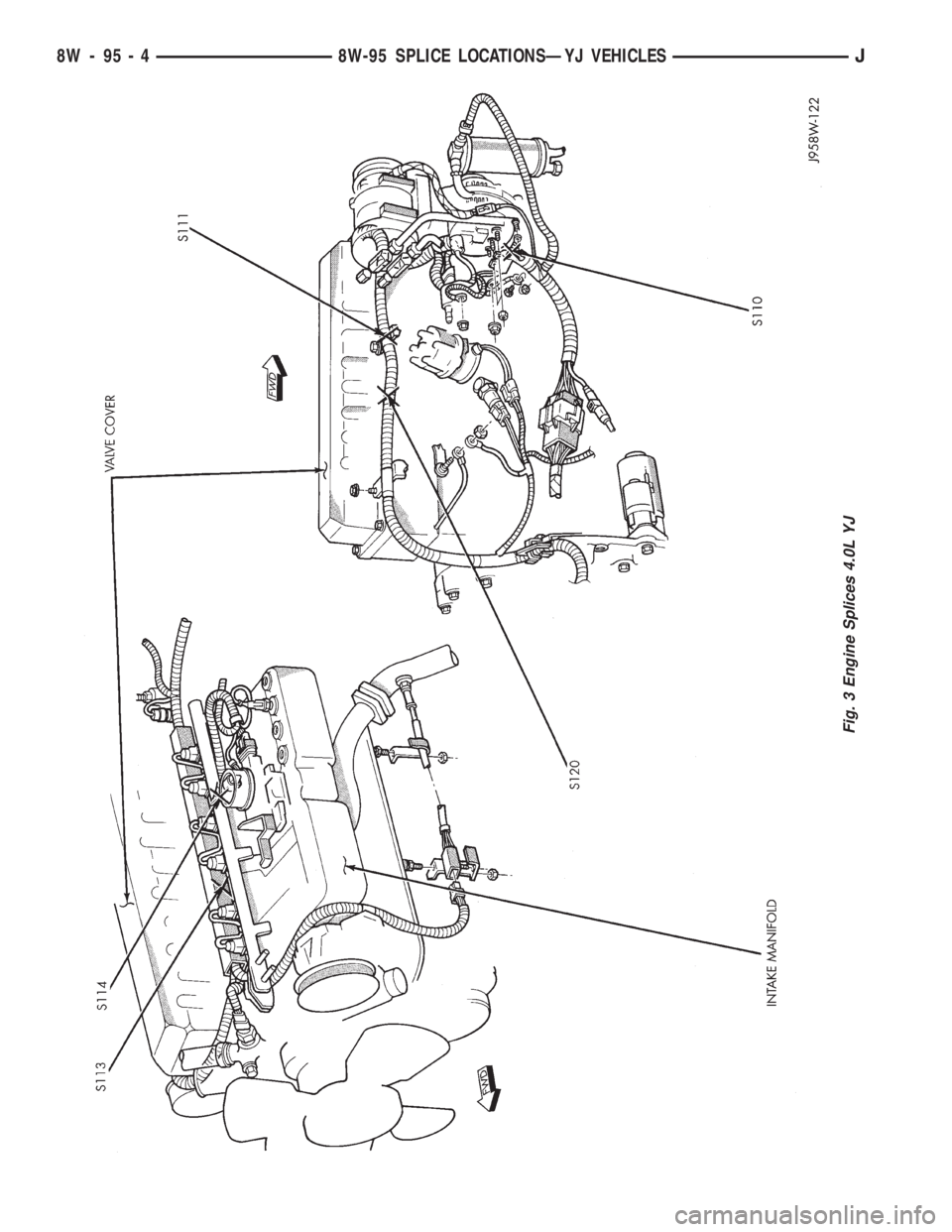

S110 Rear of Generator...................3

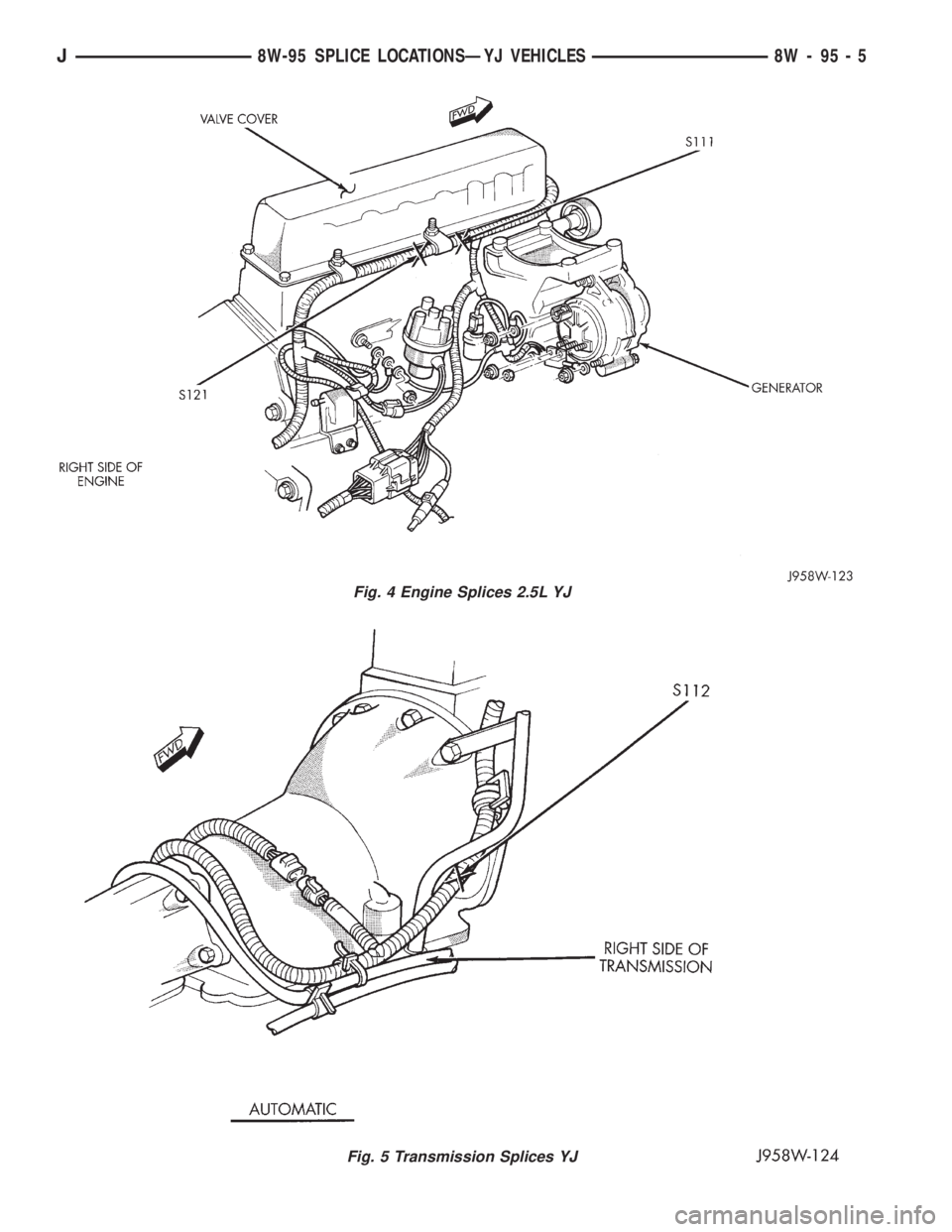

S111 2.5L RT Side of Valve Cover...............4

S111 4.0L RT Side of Valve Cover...............3

S112 Near T/O for PRNDL Switch............5

S113 Between Inj #2 and Inj #3.............3

S114 Near T/O for Throttle Body Wiring........3

S115 Above Bulkhead Connector.............1

S116 Above Bulkhead Connector.............1

S117 Near Data Link T/O..................1

S118 Near Data Link T/O..................1

S119 Near Data Link T/O..................1

S120 4.0L RT Side of Valve Cover...............3

S121 2.5L RT Side of Valve Cover...............4

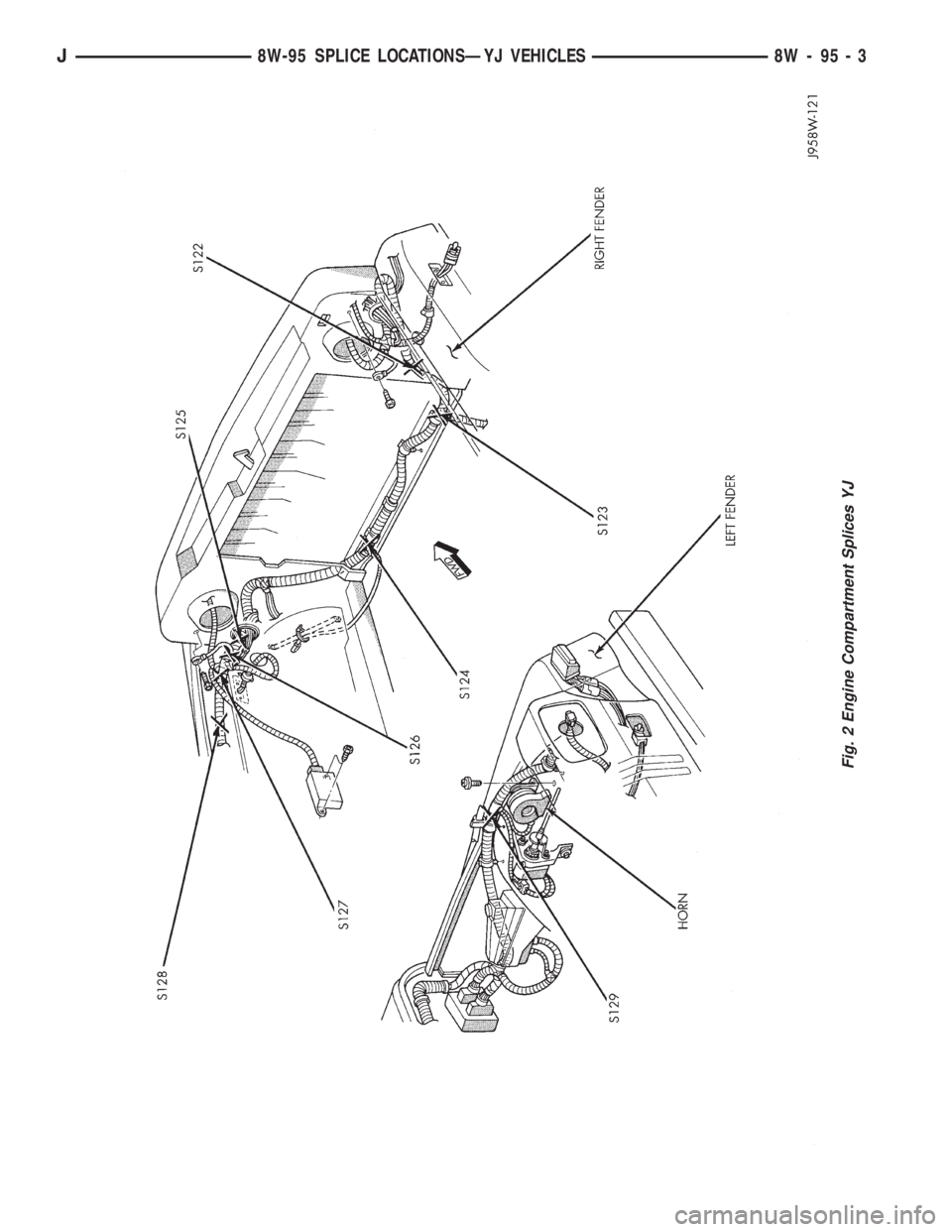

S122 Near T/O for RT PK/TURN Lamp.........2

S123 Near T/O for RT Fog Lamp.............2

S124 Near T/O for LT Fog Lamp.............2

S125 Near T/O for LT PK/TURN Lamp.........2Splice

NumberLocations Fig.

S126 Near T/O for Headlamp...............2

S127 Near T/O for Headlamp...............2

S128 Near T/O for Headlamp...............2

S129 Near Horn T/O.....................2

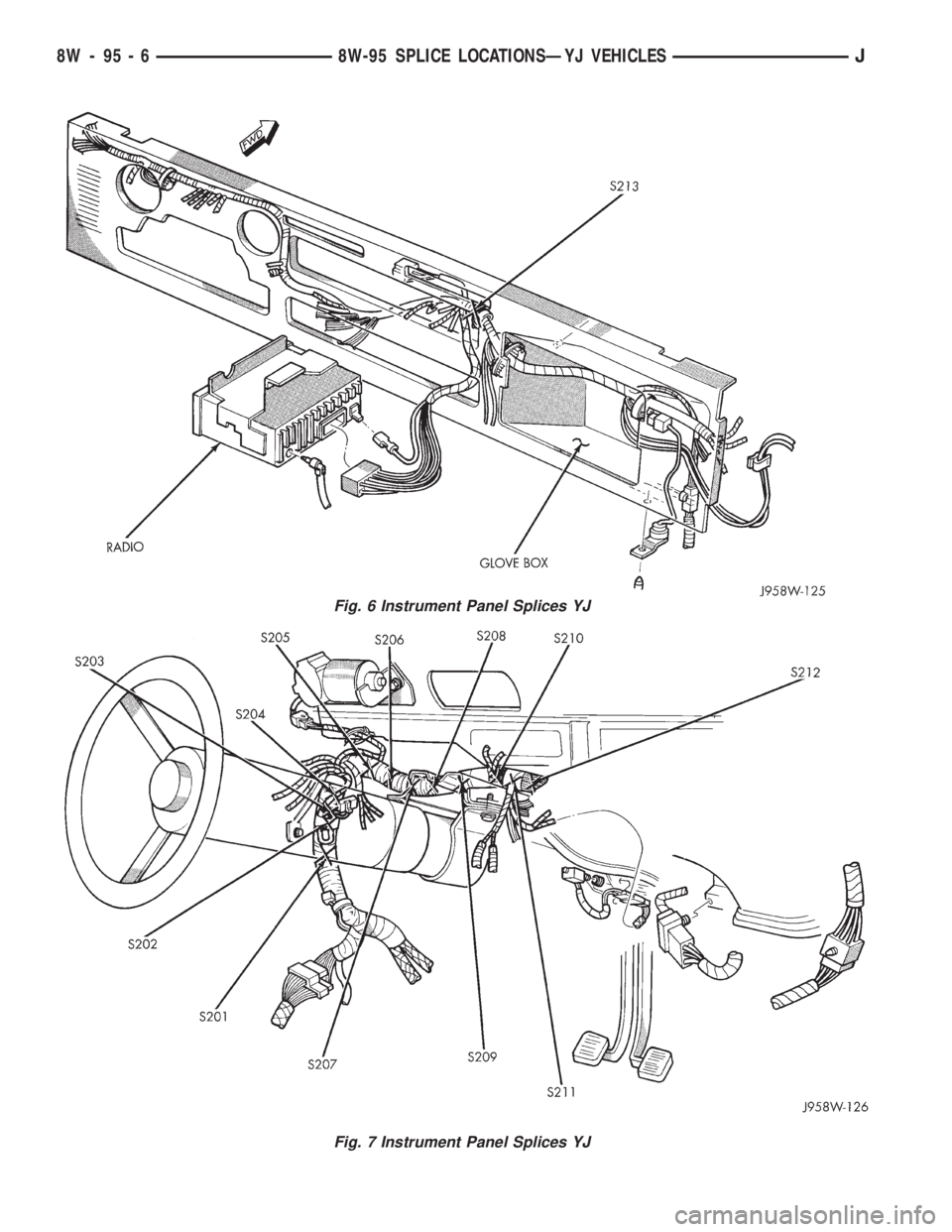

S201 Near T/O for Dimmer Switch............7

S202 Near T/O for Dimmer Switch............7

S203 Near T/O for Dimmer Switch............7

S204 Near T/O for Dimmer Switch............7

S205 Near T/O for Wiper Switch.............7

S206 Near T/O for Wiper Switch.............7

S207 Near Panel Illumination T/O.............7

S208 Near Panel Illumination T/O.............7

S209 Near Panel Illumination T/O.............7

S210 Near Panel Illumination T/O.............7

S211 Near T/O for Ignition Switch............7

S212 Near T/O for Ignition Switch............7

S213 Near T/O for Radio..................6

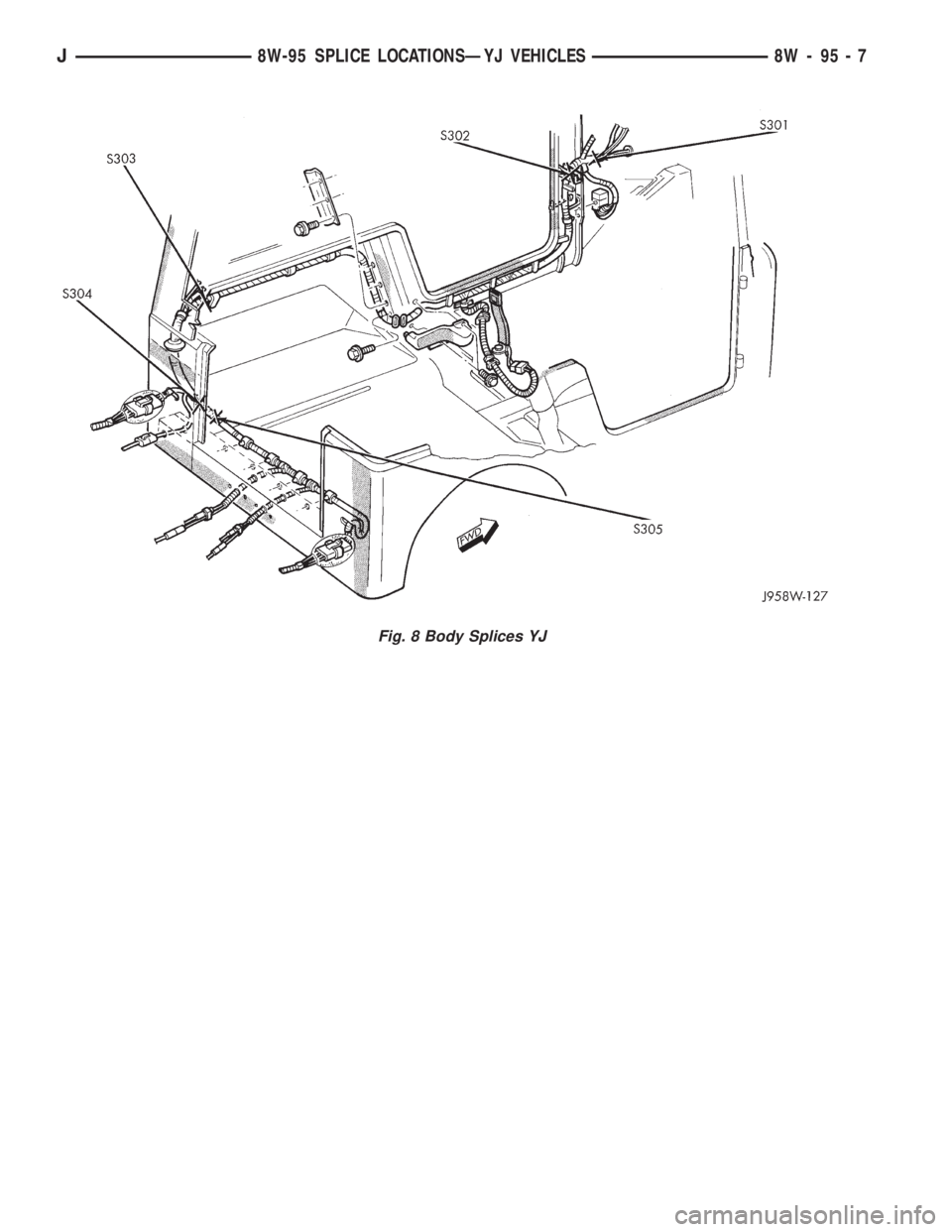

S301 Near T/O for Park Brake Switch..........8

S302 Near T/O for Park Brake Switch..........8

S303 Near Grommet LT Rear Quarter Panel......8

S304 Near LT Rear Tail Lamp T/O............8

S305 RT Rear Quarter Panel Near Tail Lamp.....8

S306 Near T/O for Dome Lamp.......Not Shown

S307 In CHMSL Jumper Harness......Not Shown

S308 In CHMSL Jumper Harness......Not Shown

J8W-95 SPLICE LOCATIONSÐYJ VEHICLES 8W - 95 - 1

Page 1274 of 2158

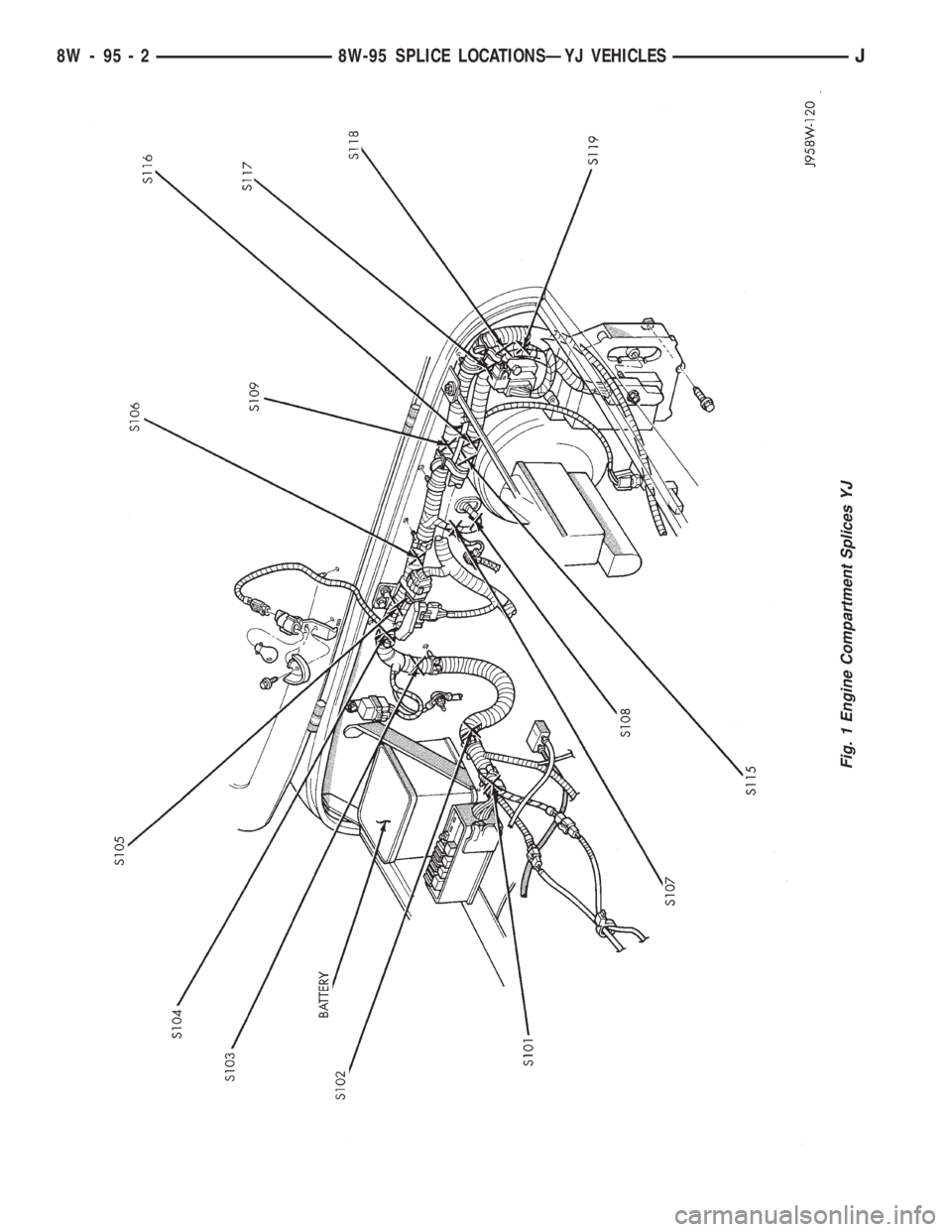

Fig. 1 Engine Compartment Splices YJ

8W - 95 - 2 8W-95 SPLICE LOCATIONSÐYJ VEHICLESJ

Page 1275 of 2158

Fig. 2 Engine Compartment Splices YJ

J8W-95 SPLICE LOCATIONSÐYJ VEHICLES 8W - 95 - 3

Page 1276 of 2158

Fig. 3 Engine Splices 4.0L YJ

8W - 95 - 4 8W-95 SPLICE LOCATIONSÐYJ VEHICLESJ

Page 1277 of 2158

Fig. 4 Engine Splices 2.5L YJ

Fig. 5 Transmission Splices YJ

J8W-95 SPLICE LOCATIONSÐYJ VEHICLES 8W - 95 - 5

Page 1278 of 2158

Fig. 6 Instrument Panel Splices YJ

Fig. 7 Instrument Panel Splices YJ

8W - 95 - 6 8W-95 SPLICE LOCATIONSÐYJ VEHICLESJ

Page 1279 of 2158

Fig. 8 Body Splices YJ

J8W-95 SPLICE LOCATIONSÐYJ VEHICLES 8W - 95 - 7

Page 1280 of 2158

ENGINES

CONTENTS

page page

LUBRICATION SYSTEM................... 37

LUBRICATION SYSTEM................... 79

2.5L ENGINE SERVICE PROCEDURES....... 134.0L ENGINE SERVICE PROCEDURES....... 55

ENGINE DIAGNOSIS...................... 5

STANDARD SERVICE PROCEDURES......... 1

STANDARD SERVICE PROCEDURES

INDEX

page page

Engine Performance........................ 2

Form-In-Place Gaskets...................... 1

Honing Cylinder Bores...................... 2

Hydrostatic Lock........................... 4Measuring with Plastigage.................... 3

Repair Damaged or Worn Threads............. 4

Service Engine Assembly (Short Block).......... 4

FORM-IN-PLACE GASKETS

There are several places where form-in-place gas-

kets are used on the engine.DO NOT use form-in-

place gasket material unless specified.Care

must be taken when applying form-in-place gaskets.

Bead size, continuity and location are of great impor-

tance. Too thin a bead can result in leakage while too

much can result in spill-over. A continuous bead of

the proper width is essential to obtain a leak-free

joint.

Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber Ad-

hesive Sealant and Mopar Gasket Maker). Each have

different properties and cannot be used interchange-

ably.

MOPAR SILICONE RUBBER ADHESIVE

SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture

in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of a year and will not properly cure

if over aged. Always inspect the package for the ex-

piration date before use.

MOPAR GASKET MAKER

Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezedbetween smooth machined metallic surfaces. It will

not cure if left in the uncovered tube. DO NOT use

on flexible metal flanges.

SURFACE PREPARATION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some in-

stances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket re-

quires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket con-

tact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

JENGINES 9 - 1

Trending: service interval, snow chains, tire size, coolant level, tire pressure, ESP inoperative, engine overheat