JEEP XJ 1995 Service And Repair Manual

Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1871 of 2158

SHIFT LINKAGE ADJUSTMENT

(1) Shift transfer case into 4L position.

(2) Raise vehicle.

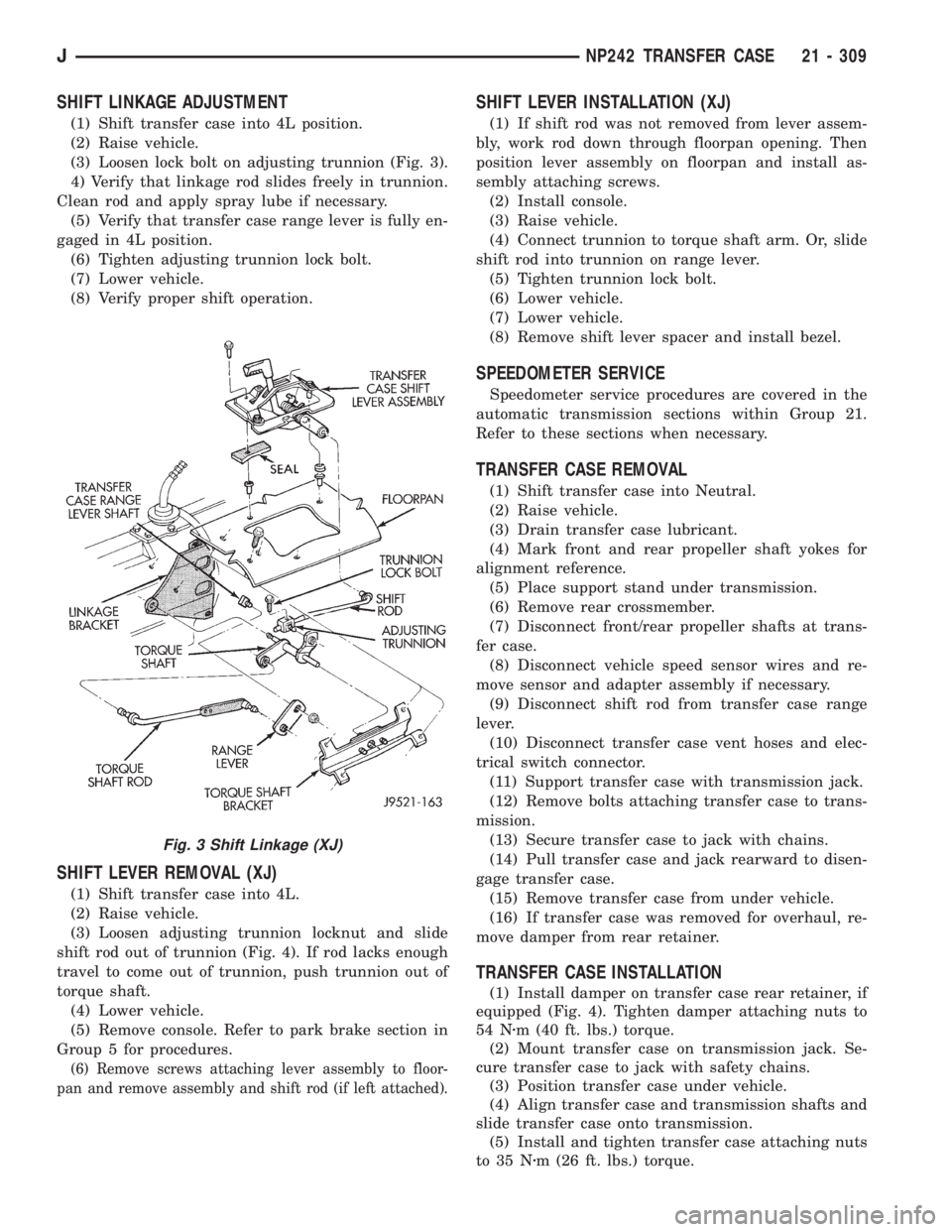

(3) Loosen lock bolt on adjusting trunnion (Fig. 3).

4) Verify that linkage rod slides freely in trunnion.

Clean rod and apply spray lube if necessary.

(5) Verify that transfer case range lever is fully en-

gaged in 4L position.

(6) Tighten adjusting trunnion lock bolt.

(7) Lower vehicle.

(8) Verify proper shift operation.

SHIFT LEVER REMOVAL (XJ)

(1) Shift transfer case into 4L.

(2) Raise vehicle.

(3) Loosen adjusting trunnion locknut and slide

shift rod out of trunnion (Fig. 4). If rod lacks enough

travel to come out of trunnion, push trunnion out of

torque shaft.

(4) Lower vehicle.

(5) Remove console. Refer to park brake section in

Group 5 for procedures.

(6) Remove screws attaching lever assembly to floor-

pan and remove assembly and shift rod (if left attached).

SHIFT LEVER INSTALLATION (XJ)

(1) If shift rod was not removed from lever assem-

bly, work rod down through floorpan opening. Then

position lever assembly on floorpan and install as-

sembly attaching screws.

(2) Install console.

(3) Raise vehicle.

(4) Connect trunnion to torque shaft arm. Or, slide

shift rod into trunnion on range lever.

(5) Tighten trunnion lock bolt.

(6) Lower vehicle.

(7) Lower vehicle.

(8) Remove shift lever spacer and install bezel.

SPEEDOMETER SERVICE

Speedometer service procedures are covered in the

automatic transmission sections within Group 21.

Refer to these sections when necessary.

TRANSFER CASE REMOVAL

(1) Shift transfer case into Neutral.

(2) Raise vehicle.

(3) Drain transfer case lubricant.

(4) Mark front and rear propeller shaft yokes for

alignment reference.

(5) Place support stand under transmission.

(6) Remove rear crossmember.

(7) Disconnect front/rear propeller shafts at trans-

fer case.

(8) Disconnect vehicle speed sensor wires and re-

move sensor and adapter assembly if necessary.

(9) Disconnect shift rod from transfer case range

lever.

(10) Disconnect transfer case vent hoses and elec-

trical switch connector.

(11) Support transfer case with transmission jack.

(12) Remove bolts attaching transfer case to trans-

mission.

(13) Secure transfer case to jack with chains.

(14) Pull transfer case and jack rearward to disen-

gage transfer case.

(15) Remove transfer case from under vehicle.

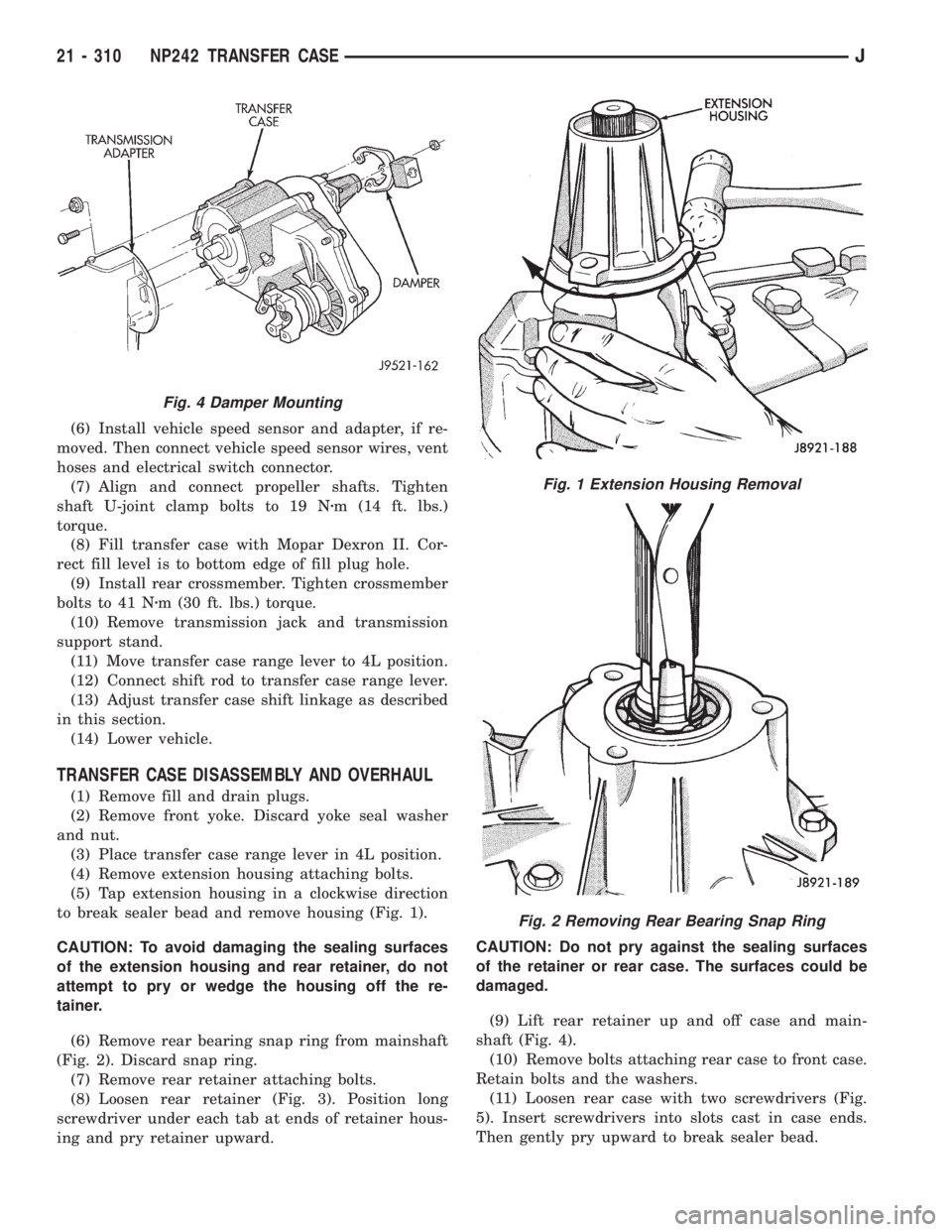

(16) If transfer case was removed for overhaul, re-

move damper from rear retainer.

TRANSFER CASE INSTALLATION

(1) Install damper on transfer case rear retainer, if

equipped (Fig. 4). Tighten damper attaching nuts to

54 Nzm (40 ft. lbs.) torque.

(2) Mount transfer case on transmission jack. Se-

cure transfer case to jack with safety chains.

(3) Position transfer case under vehicle.

(4) Align transfer case and transmission shafts and

slide transfer case onto transmission.

(5) Install and tighten transfer case attaching nuts

to 35 Nzm (26 ft. lbs.) torque.

Fig. 3 Shift Linkage (XJ)

JNP242 TRANSFER CASE 21 - 309

Page 1872 of 2158

(6) Install vehicle speed sensor and adapter, if re-

moved. Then connect vehicle speed sensor wires, vent

hoses and electrical switch connector.

(7) Align and connect propeller shafts. Tighten

shaft U-joint clamp bolts to 19 Nzm (14 ft. lbs.)

torque.

(8) Fill transfer case with Mopar Dexron II. Cor-

rect fill level is to bottom edge of fill plug hole.

(9) Install rear crossmember. Tighten crossmember

bolts to 41 Nzm (30 ft. lbs.) torque.

(10) Remove transmission jack and transmission

support stand.

(11) Move transfer case range lever to 4L position.

(12) Connect shift rod to transfer case range lever.

(13) Adjust transfer case shift linkage as described

in this section.

(14) Lower vehicle.

TRANSFER CASE DISASSEMBLY AND OVERHAUL

(1) Remove fill and drain plugs.

(2) Remove front yoke. Discard yoke seal washer

and nut.

(3) Place transfer case range lever in 4L position.

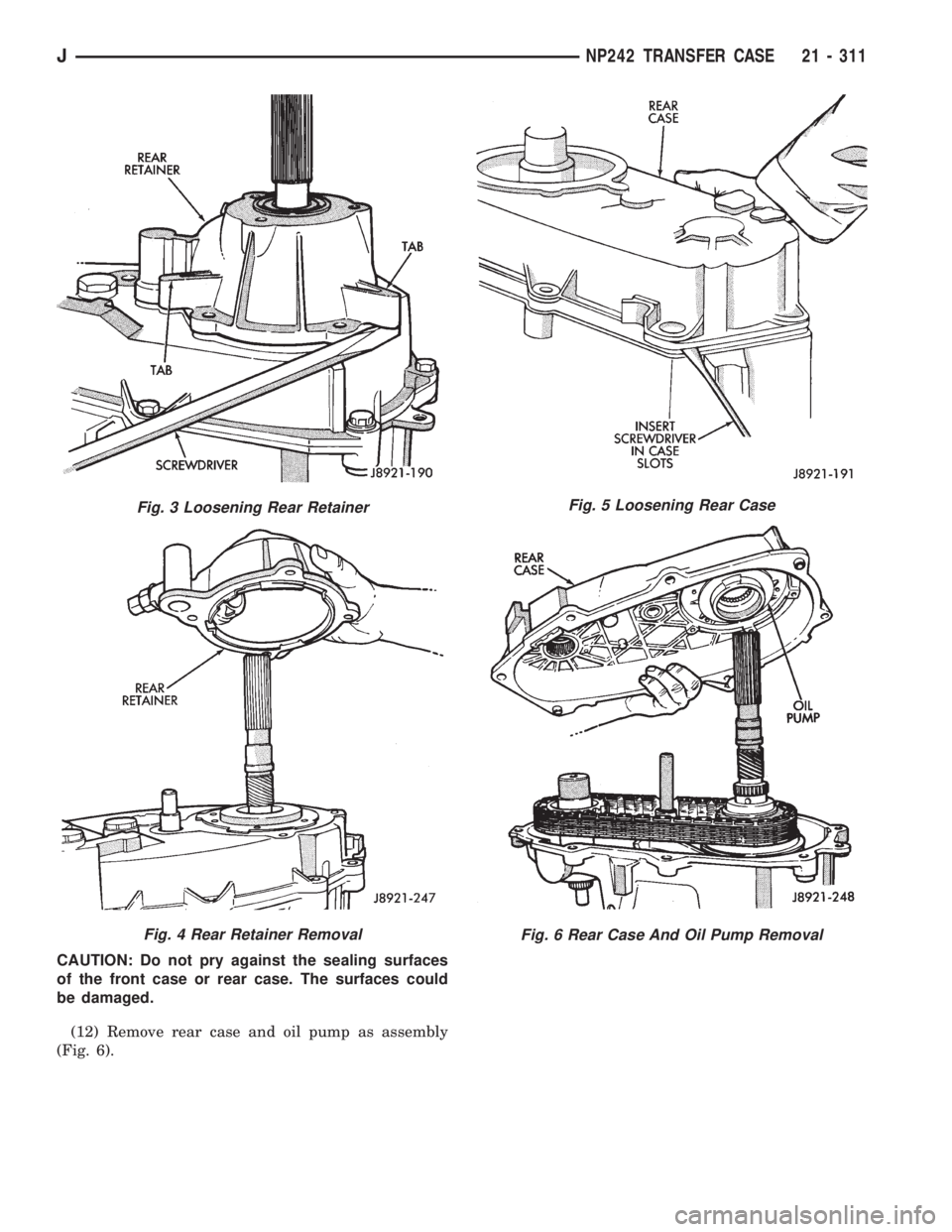

(4) Remove extension housing attaching bolts.

(5) Tap extension housing in a clockwise direction

to break sealer bead and remove housing (Fig. 1).

CAUTION: To avoid damaging the sealing surfaces

of the extension housing and rear retainer, do not

attempt to pry or wedge the housing off the re-

tainer.

(6) Remove rear bearing snap ring from mainshaft

(Fig. 2). Discard snap ring.

(7) Remove rear retainer attaching bolts.

(8) Loosen rear retainer (Fig. 3). Position long

screwdriver under each tab at ends of retainer hous-

ing and pry retainer upward.CAUTION: Do not pry against the sealing surfaces

of the retainer or rear case. The surfaces could be

damaged.

(9) Lift rear retainer up and off case and main-

shaft (Fig. 4).

(10) Remove bolts attaching rear case to front case.

Retain bolts and the washers.

(11) Loosen rear case with two screwdrivers (Fig.

5). Insert screwdrivers into slots cast in case ends.

Then gently pry upward to break sealer bead.

Fig. 4 Damper Mounting

Fig. 1 Extension Housing Removal

Fig. 2 Removing Rear Bearing Snap Ring

21 - 310 NP242 TRANSFER CASEJ

Page 1873 of 2158

CAUTION: Do not pry against the sealing surfaces

of the front case or rear case. The surfaces could

be damaged.

(12) Remove rear case and oil pump as assembly

(Fig. 6).

Fig. 3 Loosening Rear Retainer

Fig. 4 Rear Retainer Removal

Fig. 5 Loosening Rear Case

Fig. 6 Rear Case And Oil Pump Removal

JNP242 TRANSFER CASE 21 - 311

Page 1874 of 2158

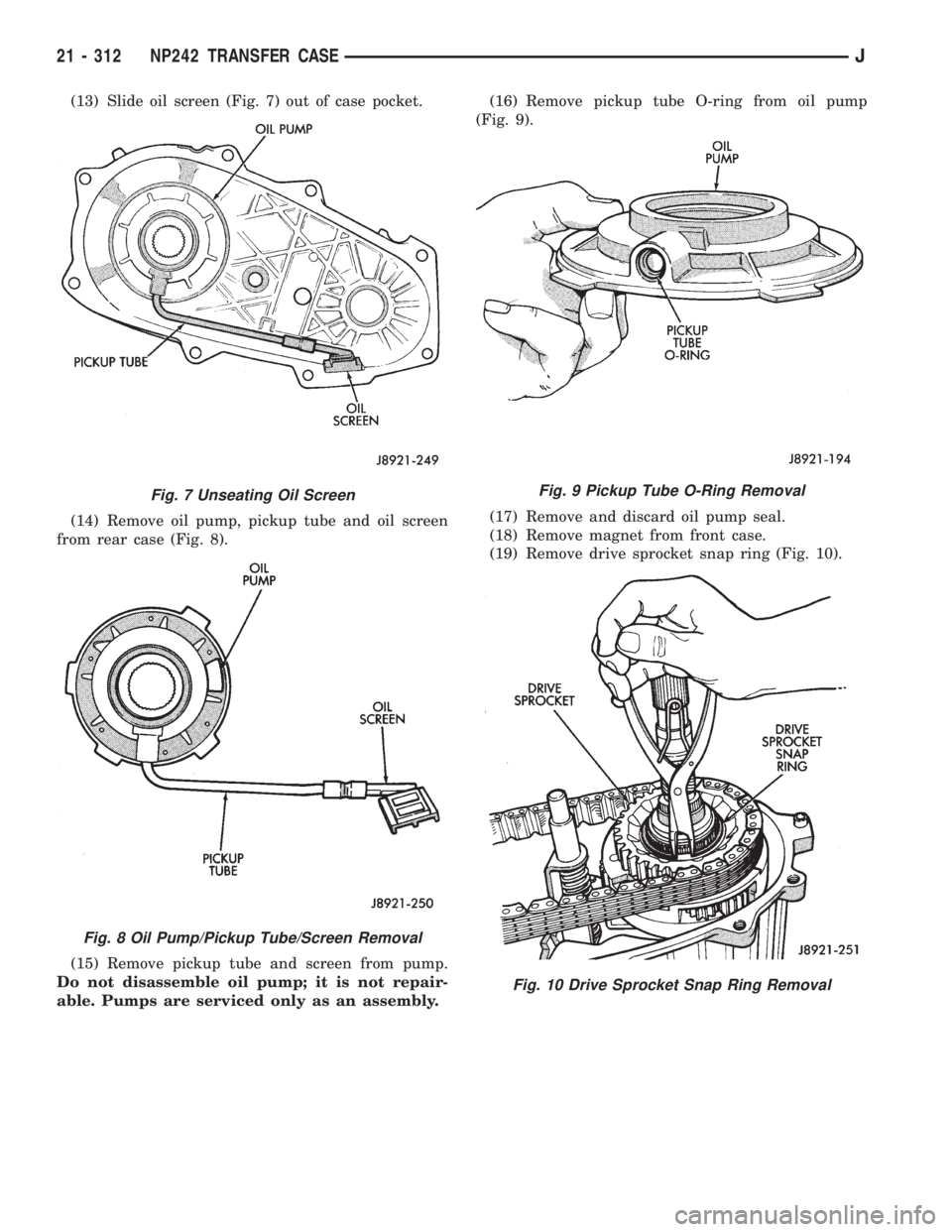

(13) Slide oil screen (Fig. 7) out of case pocket.

(14) Remove oil pump, pickup tube and oil screen

from rear case (Fig. 8).

(15) Remove pickup tube and screen from pump.

Do not disassemble oil pump; it is not repair-

able. Pumps are serviced only as an assembly.(16) Remove pickup tube O-ring from oil pump

(Fig. 9).

(17) Remove and discard oil pump seal.

(18) Remove magnet from front case.

(19) Remove drive sprocket snap ring (Fig. 10).

Fig. 7 Unseating Oil Screen

Fig. 8 Oil Pump/Pickup Tube/Screen Removal

Fig. 9 Pickup Tube O-Ring Removal

Fig. 10 Drive Sprocket Snap Ring Removal

21 - 312 NP242 TRANSFER CASEJ

Page 1875 of 2158

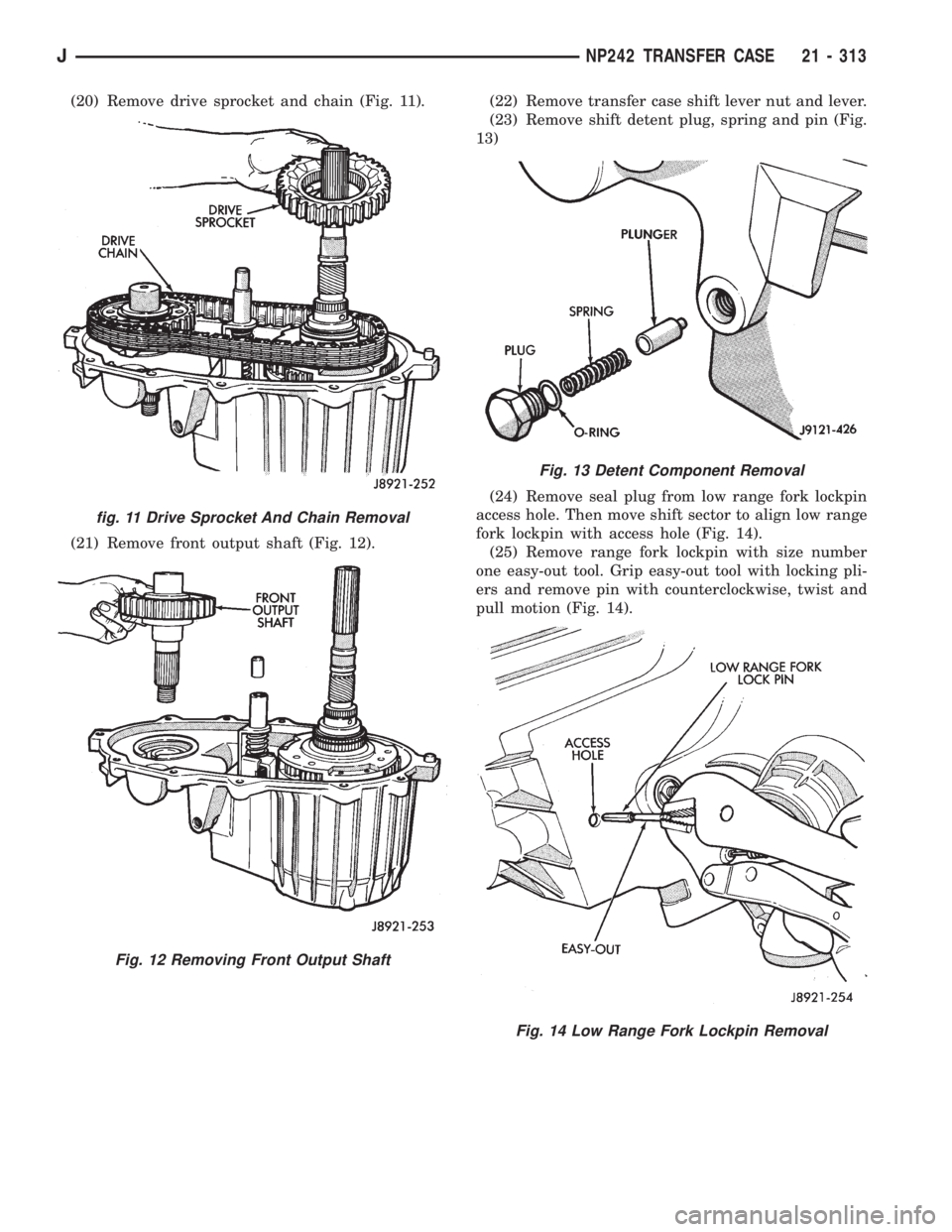

(20) Remove drive sprocket and chain (Fig. 11).

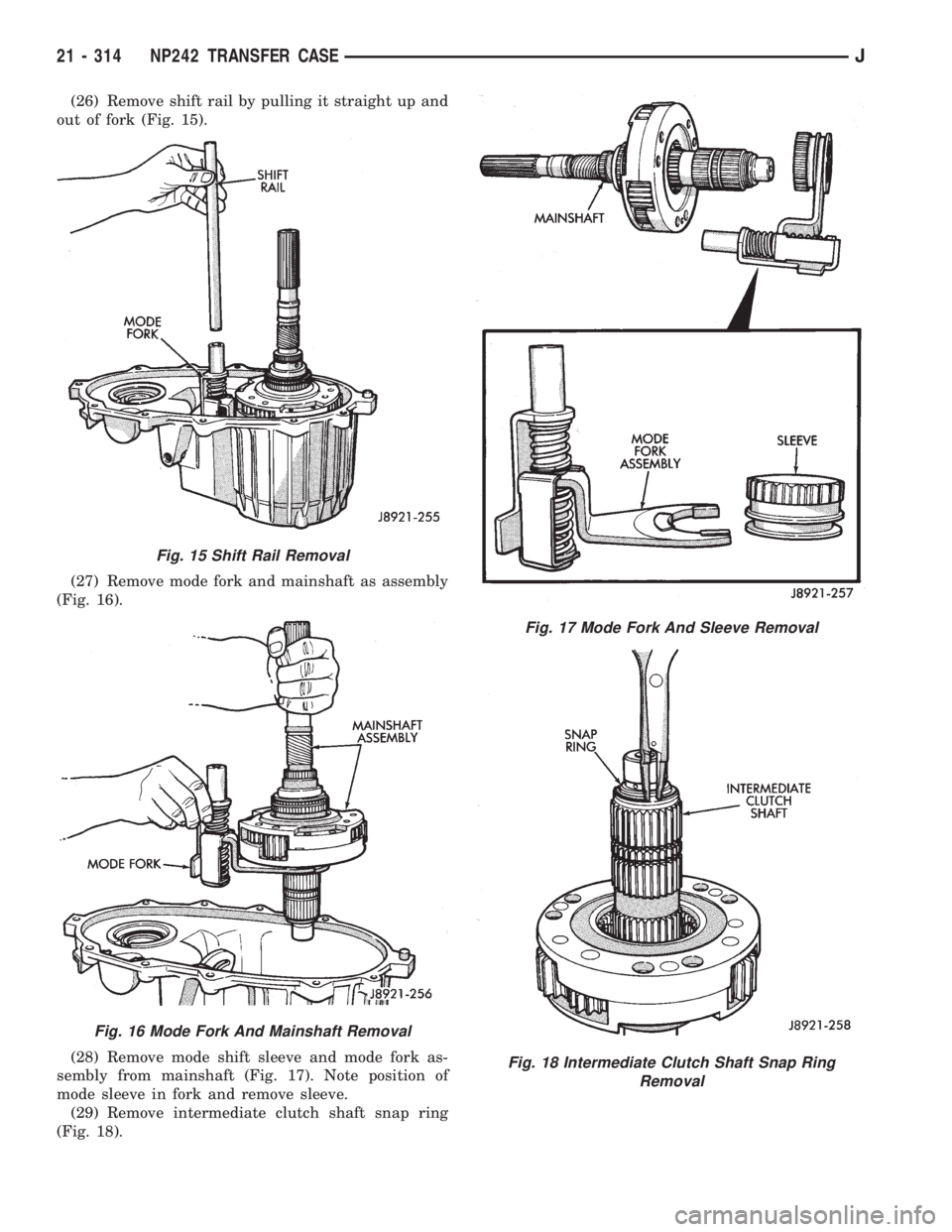

(21) Remove front output shaft (Fig. 12).(22) Remove transfer case shift lever nut and lever.

(23) Remove shift detent plug, spring and pin (Fig.

13)

(24) Remove seal plug from low range fork lockpin

access hole. Then move shift sector to align low range

fork lockpin with access hole (Fig. 14).

(25) Remove range fork lockpin with size number

one easy-out tool. Grip easy-out tool with locking pli-

ers and remove pin with counterclockwise, twist and

pull motion (Fig. 14).

fig. 11 Drive Sprocket And Chain Removal

Fig. 12 Removing Front Output Shaft

Fig. 13 Detent Component Removal

Fig. 14 Low Range Fork Lockpin Removal

JNP242 TRANSFER CASE 21 - 313

Page 1876 of 2158

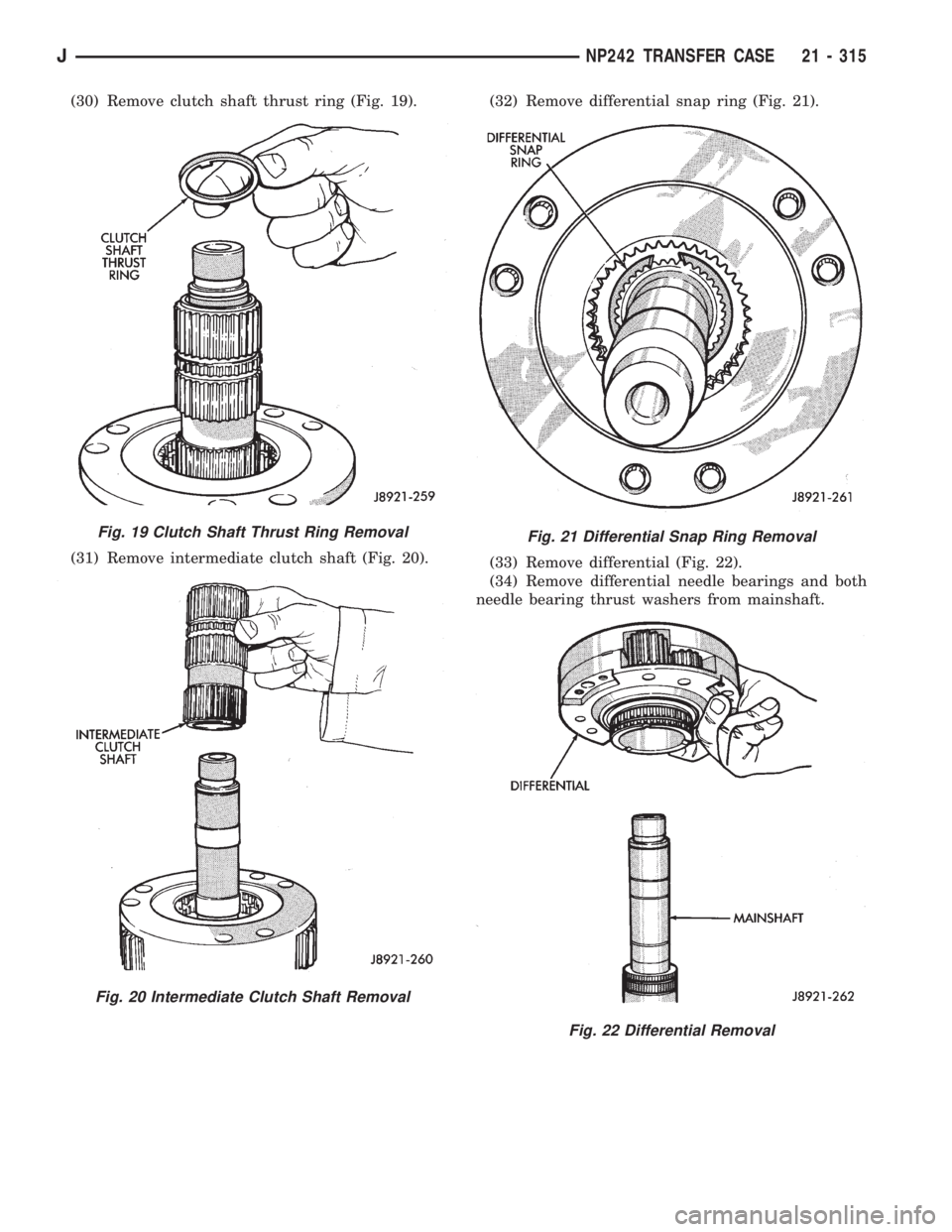

(26) Remove shift rail by pulling it straight up and

out of fork (Fig. 15).

(27) Remove mode fork and mainshaft as assembly

(Fig. 16).

(28) Remove mode shift sleeve and mode fork as-

sembly from mainshaft (Fig. 17). Note position of

mode sleeve in fork and remove sleeve.

(29) Remove intermediate clutch shaft snap ring

(Fig. 18).

Fig. 15 Shift Rail Removal

Fig. 16 Mode Fork And Mainshaft Removal

Fig. 17 Mode Fork And Sleeve Removal

Fig. 18 Intermediate Clutch Shaft Snap Ring

Removal

21 - 314 NP242 TRANSFER CASEJ

Page 1877 of 2158

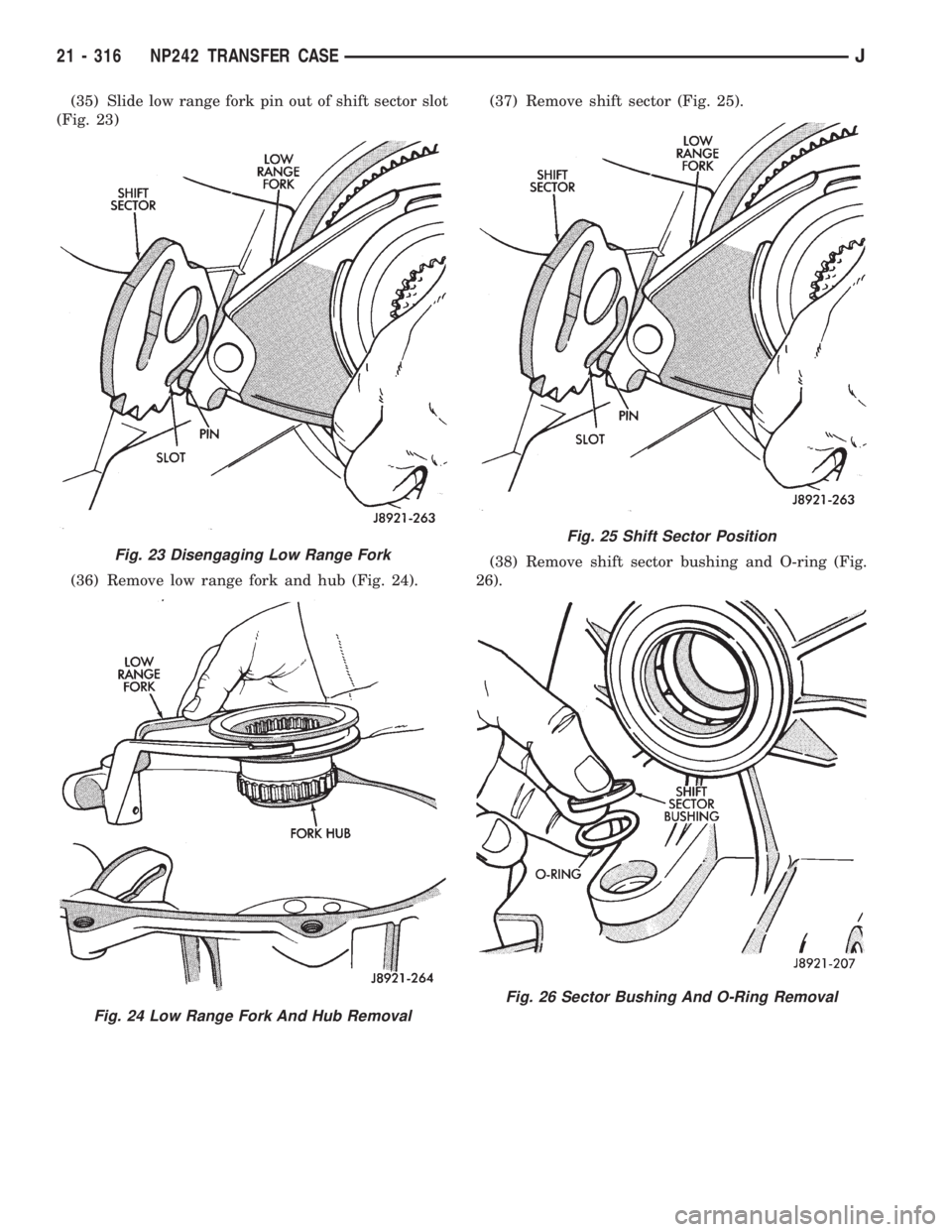

(30) Remove clutch shaft thrust ring (Fig. 19).

(31) Remove intermediate clutch shaft (Fig. 20).(32) Remove differential snap ring (Fig. 21).

(33) Remove differential (Fig. 22).

(34) Remove differential needle bearings and both

needle bearing thrust washers from mainshaft.

Fig. 19 Clutch Shaft Thrust Ring Removal

Fig. 20 Intermediate Clutch Shaft Removal

Fig. 21 Differential Snap Ring Removal

Fig. 22 Differential Removal

JNP242 TRANSFER CASE 21 - 315

Page 1878 of 2158

(35) Slide low range fork pin out of shift sector slot

(Fig. 23)

(36) Remove low range fork and hub (Fig. 24).(37) Remove shift sector (Fig. 25).

(38) Remove shift sector bushing and O-ring (Fig.

26).

Fig. 23 Disengaging Low Range Fork

Fig. 24 Low Range Fork And Hub Removal

Fig. 25 Shift Sector Position

Fig. 26 Sector Bushing And O-Ring Removal

21 - 316 NP242 TRANSFER CASEJ

Page 1879 of 2158

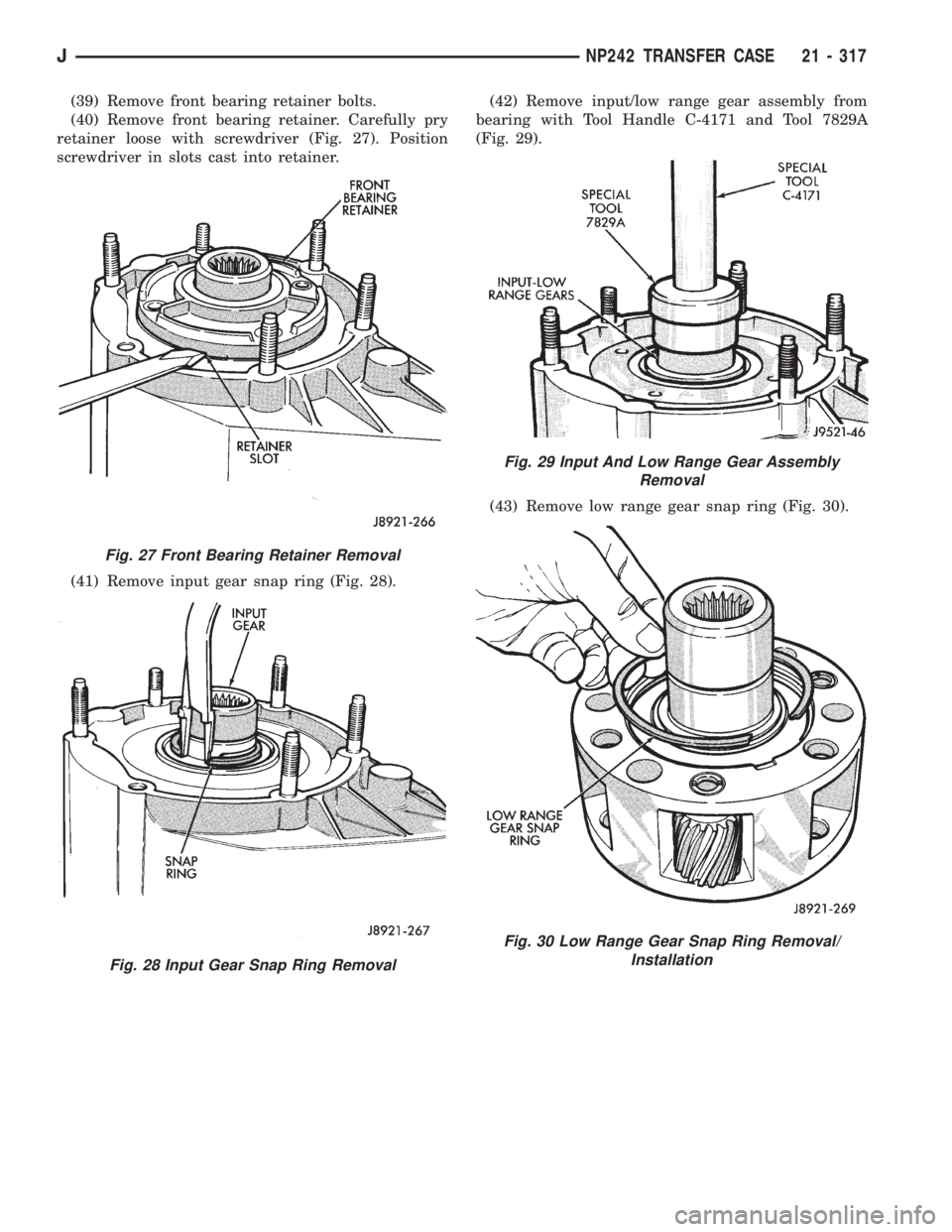

(39) Remove front bearing retainer bolts.

(40) Remove front bearing retainer. Carefully pry

retainer loose with screwdriver (Fig. 27). Position

screwdriver in slots cast into retainer.

(41) Remove input gear snap ring (Fig. 28).(42) Remove input/low range gear assembly from

bearing with Tool Handle C-4171 and Tool 7829A

(Fig. 29).

(43) Remove low range gear snap ring (Fig. 30).

Fig. 27 Front Bearing Retainer Removal

Fig. 28 Input Gear Snap Ring Removal

Fig. 29 Input And Low Range Gear Assembly

Removal

Fig. 30 Low Range Gear Snap Ring Removal/

Installation

JNP242 TRANSFER CASE 21 - 317

Page 1880 of 2158

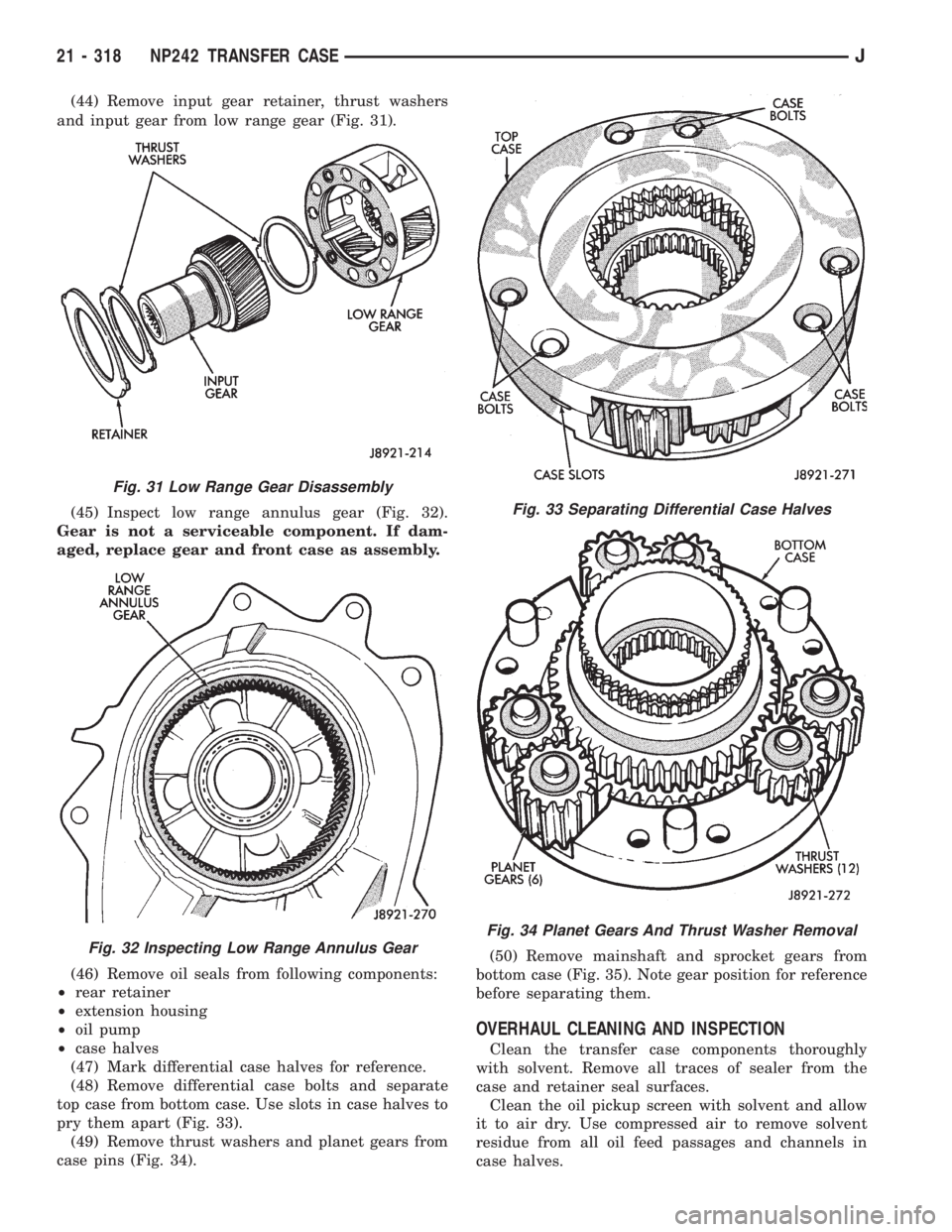

(44) Remove input gear retainer, thrust washers

and input gear from low range gear (Fig. 31).

(45) Inspect low range annulus gear (Fig. 32).

Gear is not a serviceable component. If dam-

aged, replace gear and front case as assembly.

(46) Remove oil seals from following components:

²rear retainer

²extension housing

²oil pump

²case halves

(47) Mark differential case halves for reference.

(48) Remove differential case bolts and separate

top case from bottom case. Use slots in case halves to

pry them apart (Fig. 33).

(49) Remove thrust washers and planet gears from

case pins (Fig. 34).(50) Remove mainshaft and sprocket gears from

bottom case (Fig. 35). Note gear position for reference

before separating them.

OVERHAUL CLEANING AND INSPECTION

Clean the transfer case components thoroughly

with solvent. Remove all traces of sealer from the

case and retainer seal surfaces.

Clean the oil pickup screen with solvent and allow

it to air dry. Use compressed air to remove solvent

residue from all oil feed passages and channels in

case halves.

Fig. 31 Low Range Gear Disassembly

Fig. 32 Inspecting Low Range Annulus Gear

Fig. 33 Separating Differential Case Halves

Fig. 34 Planet Gears And Thrust Washer Removal

21 - 318 NP242 TRANSFER CASEJ