tow JEEP XJ 1995 Service And Owner's Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: XJ, Model: JEEP XJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 110 of 2158

AXLE NOISE/VIBRATION DIAGNOSIS

INDEX

page page

Driveline Snap........................... 10

Gear and Bearing Noise..................... 9

General Information........................ 9

Limited Slip Differential..................... 10Low Speed Knock......................... 10

Rear Axle Alignment....................... 10

Vibration................................ 10

GENERAL INFORMATION

Axle bearing problem conditions are usually caused

by:

²Insufficient or incorrect lubricant

²Foreign matter/water contamination

²Incorrect bearing preload torque adjustment

²Incorrect backlash (to tight)

When serviced, the bearings must be cleaned thor-

oughly. They should be dried with lint-free shop tow-

els.Never dry bearings with compressed air.

This will overheat them and brinell the bearing

surfaces. This will result in noisy operation af-

ter repair.

Axle gear problem conditions are usually the result of:

²Insufficient lubrication

²Incorrect or contaminated lubricant

²Overloading (excessive engine torque) or exceeding

vehicle weight capacity

²Incorrect clearance or backlash adjustment

Insufficient lubrication is usually the result of a

housing cover leak. It can also be from worn axle

shaft or pinion gear seals. Check for cracks or porous

areas in the housing or tubes.

Using the wrong lubricant will cause overheating

and gear failure. Gear tooth cracking and bearing

spalling are indicators of this.

Axle component breakage is most often the result of:

²Severe overloading

²Insufficient lubricant

²Incorrect lubricant

²Improperly tightened components

Overloading occurs when towing heavier than rec-

ommended loads. Component breakage can occur

when the wheels are spun excessively. Incorrect lu-

bricant quantity contributes to breakage. Loose dif-

ferential components can also cause breakage.

Incorrect bearing preload or gear backlash will not

result in component breakage. Mis-adjustment will

produce enough noise to cause service repair before a

failure occurs. If a mis-adjustment condition is not

corrected, component failure can result.

Excessive bearing preload may not be noisy. This

condition will cause high temperature which can re-

sult in bearing failure.

GEAR AND BEARING NOISE

GEAR NOISE

Axle gear noise can be caused by insufficient lubri-

cant. Incorrect backlash, tooth contact, or worn/dam-

aged gears can cause noise.

Gear noise usually happens at a specific speed

range. The range is 30 to 40 mph, or above 50 mph.

The noise can also occur during a specific type of

driving condition. These conditions are acceleration,

deceleration, coast, or constant load.

When road testing, accelerate the vehicle to the

speed range where the noise is the greatest. Shift

out-of-gear and coast through the peak-noise range.

If the noise stops or changes greatly, check for insuf-

ficient lubricant. Incorrect ring gear backlash, or

gear damage can cause noise changes.

Differential side and pinion gears can be checked

by turning the vehicle. They usually do not cause

noise in straight-ahead driving. These gears are

loaded during vehicle turns. If noise does occur dur-

ing vehicle turns, the side or pinion gears could be

worn or damaged. A worn pinion gear mate shaft can

also cause a snapping or a knocking noise.

BEARING NOISE

The axle shaft, differential and pinion gear bear-

ings can all produce noise when worn or damaged.

Bearing noise can be either a whining, or a growling

sound.

Pinion gear bearings have a constant-pitch noise.

This noise changes only with vehicle speed. Pinion

bearing noise will be higher because it rotates at a

faster rate. Drive the vehicle and load the differen-

tial. If bearing noise occurs the pinion rear bearing is

the source of the noise. If the bearing noise is heard

during a coast, front bearing is the source.

Worn, damaged differential bearings usually pro-

duce a low pitch noise. Differential bearing noise is

similar to pinion bearing. The pitch of differential

bearing noise is also constant and varies only with

vehicle speed.

Axle shaft bearings produce noise and vibration

when worn or damaged. The noise generally changes

when the bearings are loaded. Road test the vehicle.

Turn the vehicle sharply to the left and to the right.

JREAR SUSPENSION AND AXLES 3 - 9

Page 114 of 2158

MODEL 35 AXLE

INDEX

page page

Axle Shaft............................... 16

Axle Shaft Seal and Bearing................. 17

Backlash and Contact Pattern Analysis......... 27

Cleaning/Inspection........................ 20

Differential Assembly....................... 21

Differential Disassembly.................... 18

Differential Measurement and Installation........ 25

Differential Removal....................... 18

Drive Axle Assembly ReplacementÐXJ Vehicles . . 14Drive Axle Assembly ReplacementÐYJ Vehicles . . 14

Final Assembly........................... 29

General Information....................... 13

Lubricant Change......................... 13

Lubricant Specifications..................... 13

Pinion Gear Depth Information............... 21

Pinion Measurement and Assembly............ 22

Pinion Removal/Disassembly................. 19

Pinion Shaft Seal Replacement............... 15

GENERAL INFORMATION

The Model 35 housing has an iron center casting

(differential housing) with axle shaft tubes extending

from either side. The tubes are pressed into and

welded to the differential housing to form a one-piece

axle housing.

The integral type housing, hypoid gear design has

the centerline of the pinion set below the centerline

of the ring gear.

The axle has a vent hose to relieve internal pres-

sure caused by lubricant vaporization and internal

expansion.

The axles are equipped with semi-floating axle

shafts, meaning that loads are supported by the axle

shaft and bearings. The axle shafts are retained by

C-clips in the differential side gears.

The cover provides a means for servicing the differ-

ential without removing the axle.

Axles may be equipped with drum or disc brakes.

The axles that are equipped with ABS brake have a

tone ring pressed on the axle shaft. Use care when

removing axle shafts as NOT to damage the tone

wheel or the sensor.

The Model 35 axle has the assembly part number

and gear ratio listed on a tag. The tag is attached to

the housing cover. Build date identification codes are

stamped on the axle shaft tube cover side.

The differential case is a one-piece design. The dif-

ferential pinion mate shaft is retained with a

threaded roll pin. Differential bearing preload and

ring gear backlash is adjusted by the use of spacer

shims. Pinion bearing preload is set and maintained

by the use of a collapsible spacer.

For complete drive axle assembly removal

and installation refer to Drive Axle Assembly

Replacement in this Group.

LUBRICANT SPECIFICATIONS

Multi-purpose, hypoid gear lubricant should be

used for Model 35 axle. The lubricant should haveMIL-L-2105C and API GL 5 quality specifications.

MOPAR Hypoid Gear Lubricant conforms to both of

these specifications.

²Lubricant for Model 35 axle is a thermally stable

SAE 80W-90 gear lubricant.

²Lubricant for Model 35 axle with Trailer Tow is

SAE 75W-140 SYNTHETIC gear lubricant.

²Trac-Lok differentials add 4 oz. of friction modifier.

²Lubricant quantity is 1.66 L (3.50 pts.).

Refer to Group 0, Lubrication and Maintenance for

additional information.

CAUTION: If axle is submerged in water, lubricant

must be replaced immediately to avoid possible

premature axle failure.

LUBRICANT CHANGE

The gear lubricant will drain quicker if the vehicle

has been recently driven.

(1) Raise and support the vehicle.

(2) Remove the lubricant fill hole plug from the dif-

ferential housing cover.

(3) Remove the differential housing cover and

drain the lubricant from the housing.

(4) Clean the housing cavity with a flushing oil,

light engine oil or lint free cloth.Do not use water,

steam, kerosene or gasoline for cleaning.

(5) Remove the sealant from the housing and cover

surfaces.

(6) Apply a bead of MOPARtSilicone Rubber Seal-

ant to the housing cover (Fig. 1).Allow the sealant

to cure for a few minutes.

Install the housing cover within 5 minutes af-

ter applying the sealant. If not installed the

sealant must be removed and another bead ap-

plied.

(7) Install the cover and any identification tag.

Tighten the cover bolts to 41 Nzm (30 ft. lbs.) torque.

(8) Refill differential with Mopar Hypoid Gear Lu-

bricant to bottom of the fill plug hole.

JREAR SUSPENSION AND AXLES 3 - 13

Page 117 of 2158

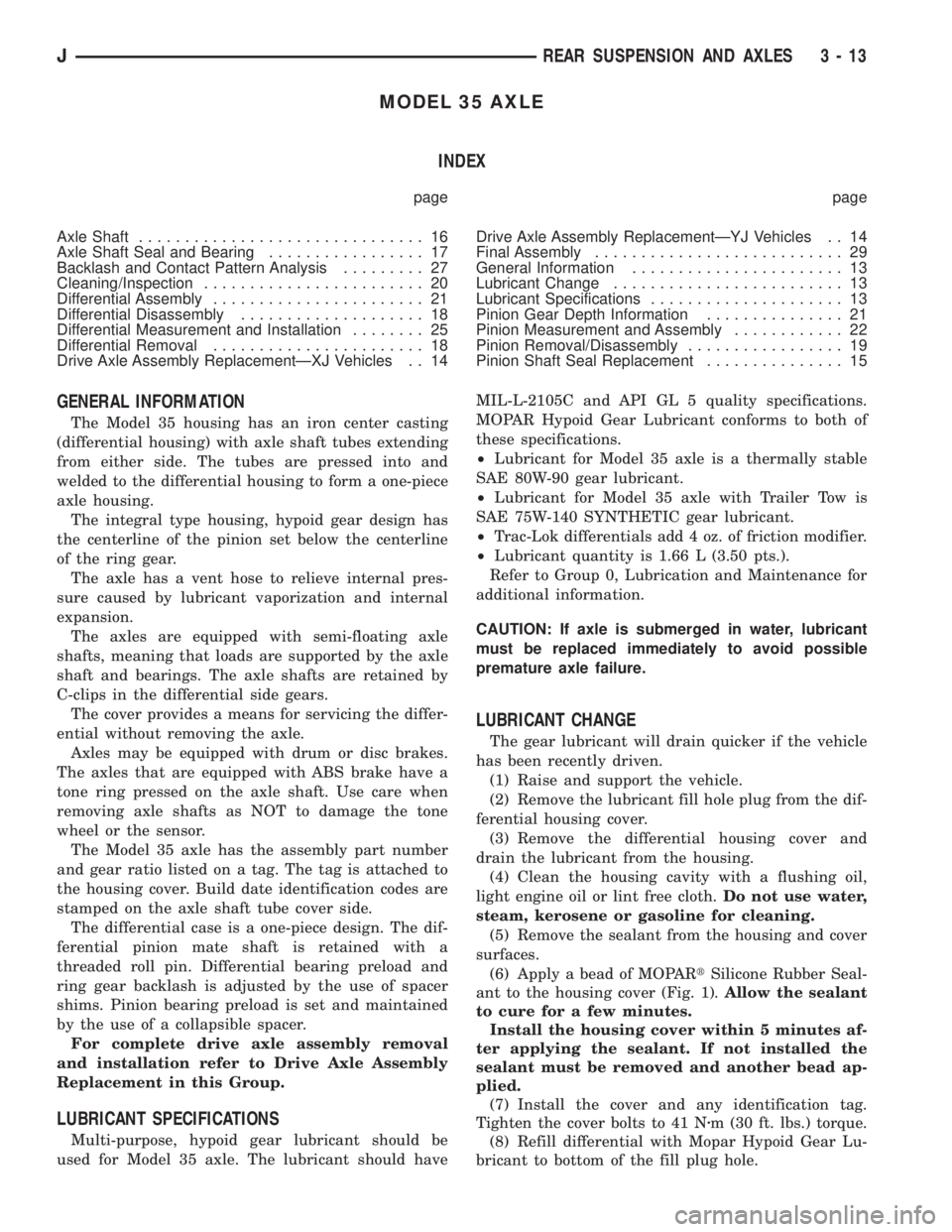

CAUTION: Exercise care during the bearing preload

torque adjustment. Do not over-tighten, or loosen

and then re-tighten the nut. Do not exceed the bear-

ing preload torque. The collapsible preload spacer

on the shaft will have to be replaced. The bearing

preload torque will be re-adjusted afterward.

(4) Install a socket and inch-pound torque wrench

on the pinion nut.

(5) Rotate the shaft with the torque wrench and

note the torque.

The required preload torque is equal to the

amount recorded during removal plus an addi-

tional 0.56 Nzm (5 in. lbs.).

(6) Use Flange Wrench C-3281 to retain the yoke

and shaft (Fig. 5). Tighten the shaft nut in very

small increments.(7) Continue tightening the shaft nut in small in-

crements until the correct bearing preload torque is

attained.

(8) Align the installation reference marks and at-

tach the drive shaft to the yoke.

(9) Add API grade GL 5 hypoid gear lubricant to

the differential housing, if necessary.

(10) Install wheel and tire assemblies.

(10) Lower the vehicle.

AXLE SHAFT

REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire.

(3) Remove the brake drum.

(4) Clean all the foreign material from housing

cover area.

(5) Loosen the housing cover bolts. Drain the lubri-

cant from the housing and the axle shaft tubes. Re-

move the housing cover.

(6) Rotate the differential case so that the pinion

mate gear shaft lock screw is accessible. Remove the

lock screw and the pinion mate gear shaft from the

case (Fig. 6).

(7) Force the axle shaft in toward the center of the

vehicle. Remove the axle shaft C-clip lock from the

axle shaft (Fig. 7).

(8) Remove the axle shaft. Use care to prevent

damage to the axle shaft bearing and seal, which will

remain in the axle shaft tube.

(9) Inspect axle shaft seal for leakage or damage.

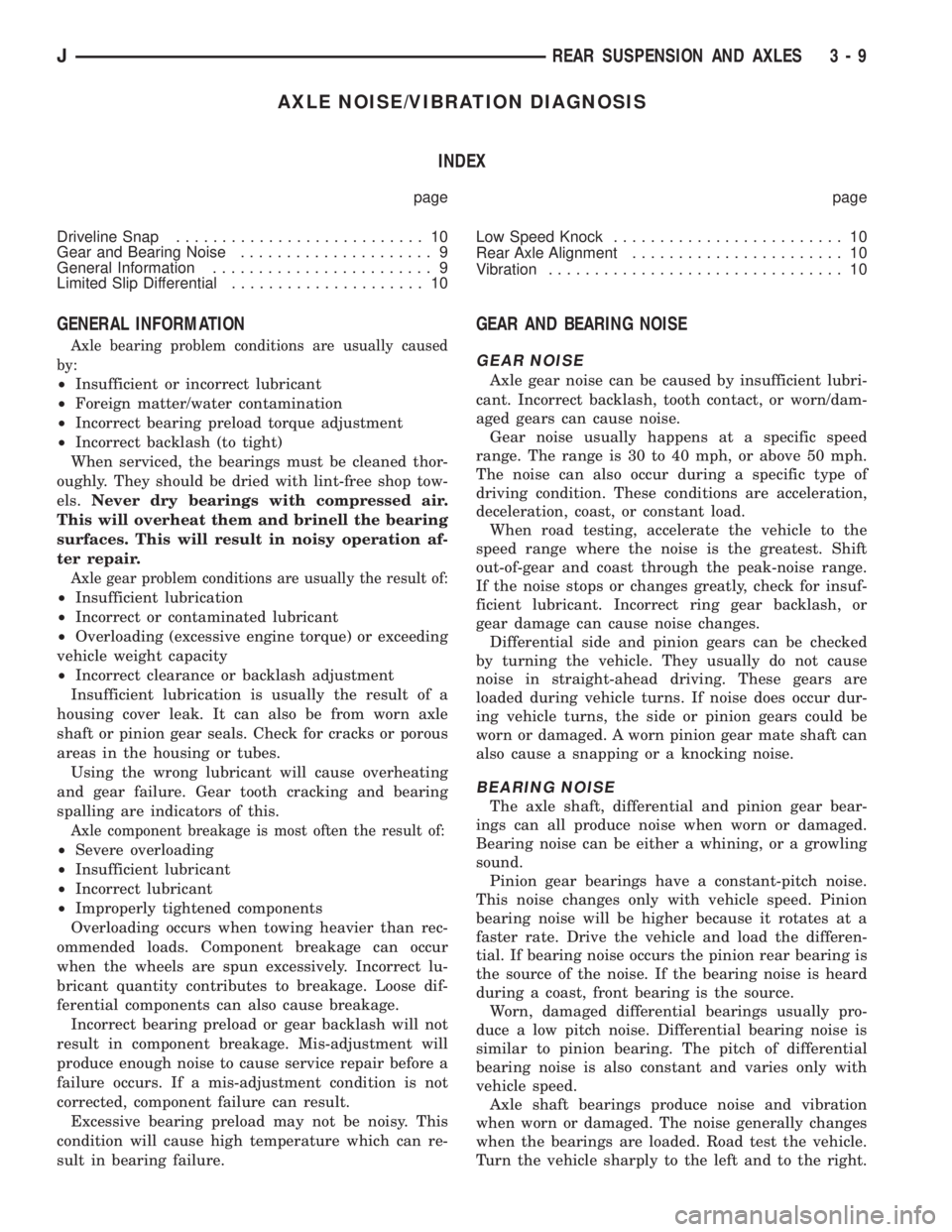

Fig. 3 Seal Removal

Fig. 4 Pinion Seal Installation

Fig. 5 Tightening Pinion Shaft Nut

3 - 16 REAR SUSPENSION AND AXLESJ

Page 121 of 2158

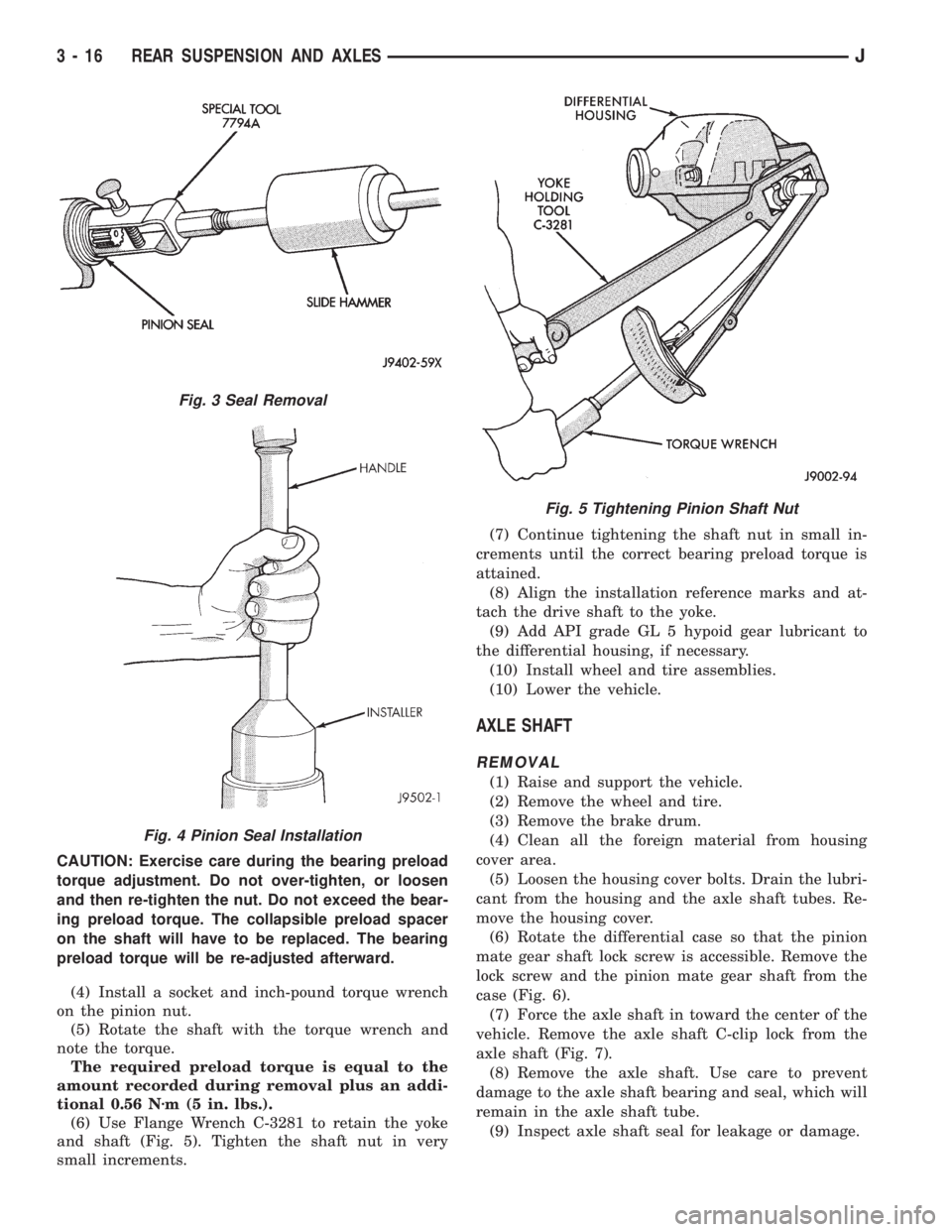

(7) Remove the collapsible preload spacer (Fig. 20).

(8) Remove the inner bearing from the pinion with

Puller C-293-PA and Adapter C-293-39 (Fig. 21).

Place adapter rings so they do not damage

the bearing cage.

(9) Remove the depth shims from the pinion gear

shaft. Record the thickness of the depth shims.CLEANING/INSPECTION

Wash differential components with cleaning solvent

and dry with compressed air.Do not steam clean

the differential components.

Wash bearings with solvent and towel dry, or dry

with compressed air. DO NOT spin bearings with

compressed airCup and bearing must be re-

placed as a matched sets only.

Clean axle shaft tubes and oil channels in housing.

Inspect for;

Fig. 17 Remove Pinion Gear

Fig. 18 Front Bearing Cup Removal

Fig. 19 Rear Bearing Cup Removal

Fig. 20 Collapsible Spacer

3 - 20 REAR SUSPENSION AND AXLESJ

Page 133 of 2158

AXLE SHAFT, SEAL AND BEARING SERVICE

CAUTION: When rear axle service is necessary,

both rear wheels must be raised off the surface so

that they are free to rotate. Be cautious when the

tires are being rotated by the engine or by other

means.

AXLE SHAFT REMOVAL

(1) Raise and support the vehicle.

(2) Remove the wheel and tire.

(3) Remove the brake drum.

(4) Clean all the foreign material from housing

cover area.

(5) Loosen the housing cover bolts and drain the

lubricant from the housing. Remove the housing

cover.

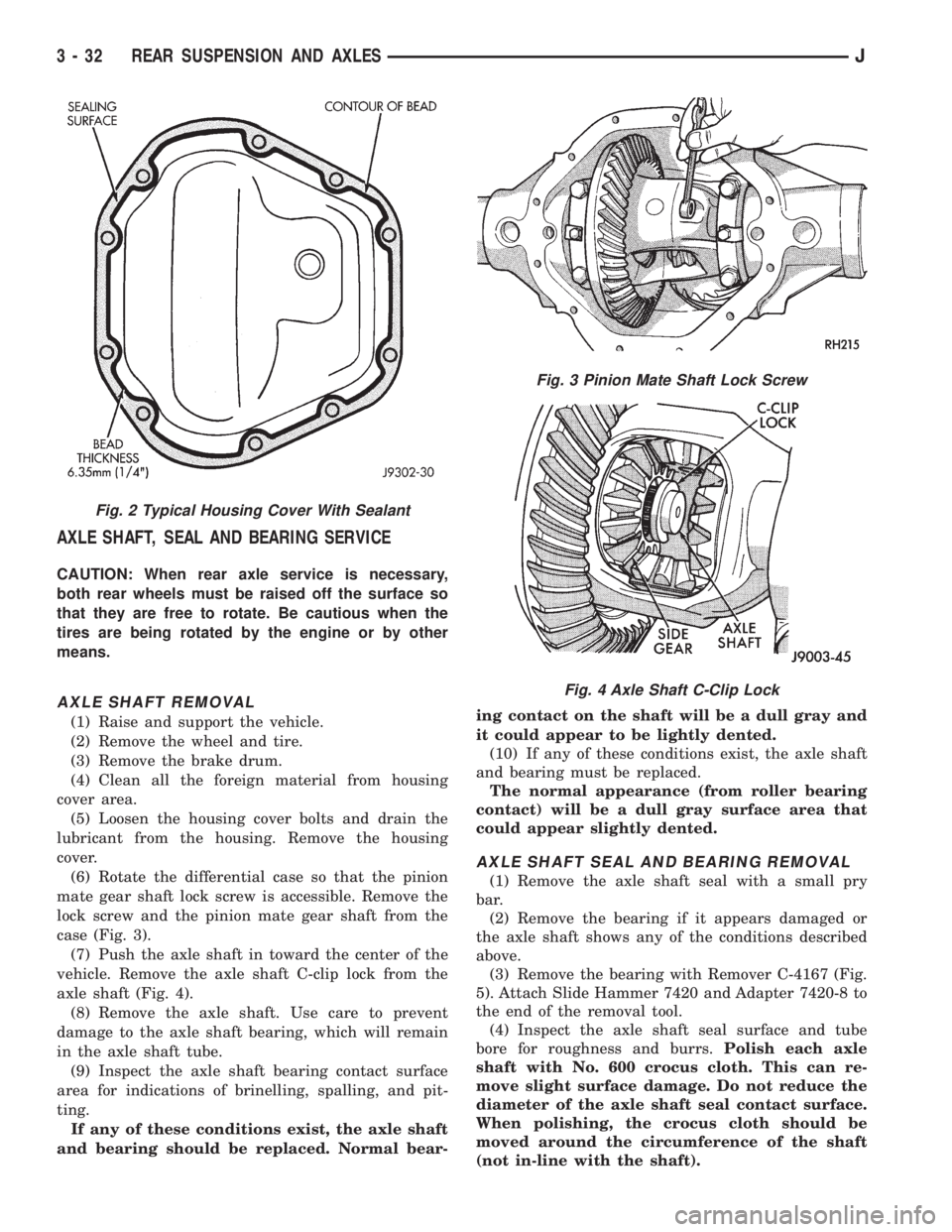

(6) Rotate the differential case so that the pinion

mate gear shaft lock screw is accessible. Remove the

lock screw and the pinion mate gear shaft from the

case (Fig. 3).

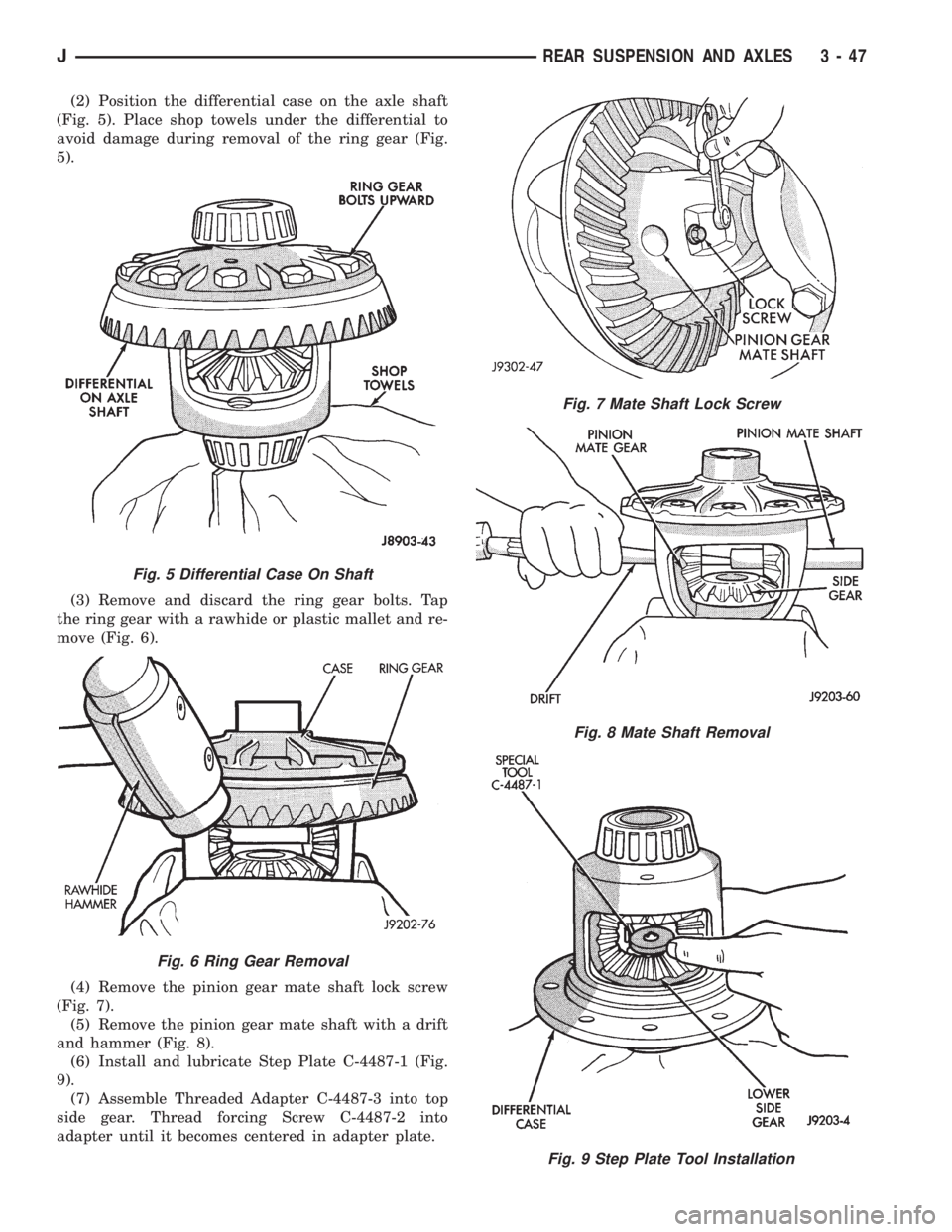

(7) Push the axle shaft in toward the center of the

vehicle. Remove the axle shaft C-clip lock from the

axle shaft (Fig. 4).

(8) Remove the axle shaft. Use care to prevent

damage to the axle shaft bearing, which will remain

in the axle shaft tube.

(9) Inspect the axle shaft bearing contact surface

area for indications of brinelling, spalling, and pit-

ting.

If any of these conditions exist, the axle shaft

and bearing should be replaced. Normal bear-ing contact on the shaft will be a dull gray and

it could appear to be lightly dented.

(10) If any of these conditions exist, the axle shaft

and bearing must be replaced.

The normal appearance (from roller bearing

contact) will be a dull gray surface area that

could appear slightly dented.

AXLE SHAFT SEAL AND BEARING REMOVAL

(1) Remove the axle shaft seal with a small pry

bar.

(2) Remove the bearing if it appears damaged or

the axle shaft shows any of the conditions described

above.

(3) Remove the bearing with Remover C-4167 (Fig.

5). Attach Slide Hammer 7420 and Adapter 7420-8 to

the end of the removal tool.

(4) Inspect the axle shaft seal surface and tube

bore for roughness and burrs.Polish each axle

shaft with No. 600 crocus cloth. This can re-

move slight surface damage. Do not reduce the

diameter of the axle shaft seal contact surface.

When polishing, the crocus cloth should be

moved around the circumference of the shaft

(not in-line with the shaft).

Fig. 2 Typical Housing Cover With Sealant

Fig. 3 Pinion Mate Shaft Lock Screw

Fig. 4 Axle Shaft C-Clip Lock

3 - 32 REAR SUSPENSION AND AXLESJ

Page 148 of 2158

(2) Position the differential case on the axle shaft

(Fig. 5). Place shop towels under the differential to

avoid damage during removal of the ring gear (Fig.

5).

(3) Remove and discard the ring gear bolts. Tap

the ring gear with a rawhide or plastic mallet and re-

move (Fig. 6).

(4) Remove the pinion gear mate shaft lock screw

(Fig. 7).

(5) Remove the pinion gear mate shaft with a drift

and hammer (Fig. 8).

(6) Install and lubricate Step Plate C-4487-1 (Fig.

9).

(7) Assemble Threaded Adapter C-4487-3 into top

side gear. Thread forcing Screw C-4487-2 into

adapter until it becomes centered in adapter plate.

Fig. 7 Mate Shaft Lock Screw

Fig. 8 Mate Shaft Removal

Fig. 9 Step Plate Tool Installation

Fig. 5 Differential Case On Shaft

Fig. 6 Ring Gear Removal

JREAR SUSPENSION AND AXLES 3 - 47

Page 152 of 2158

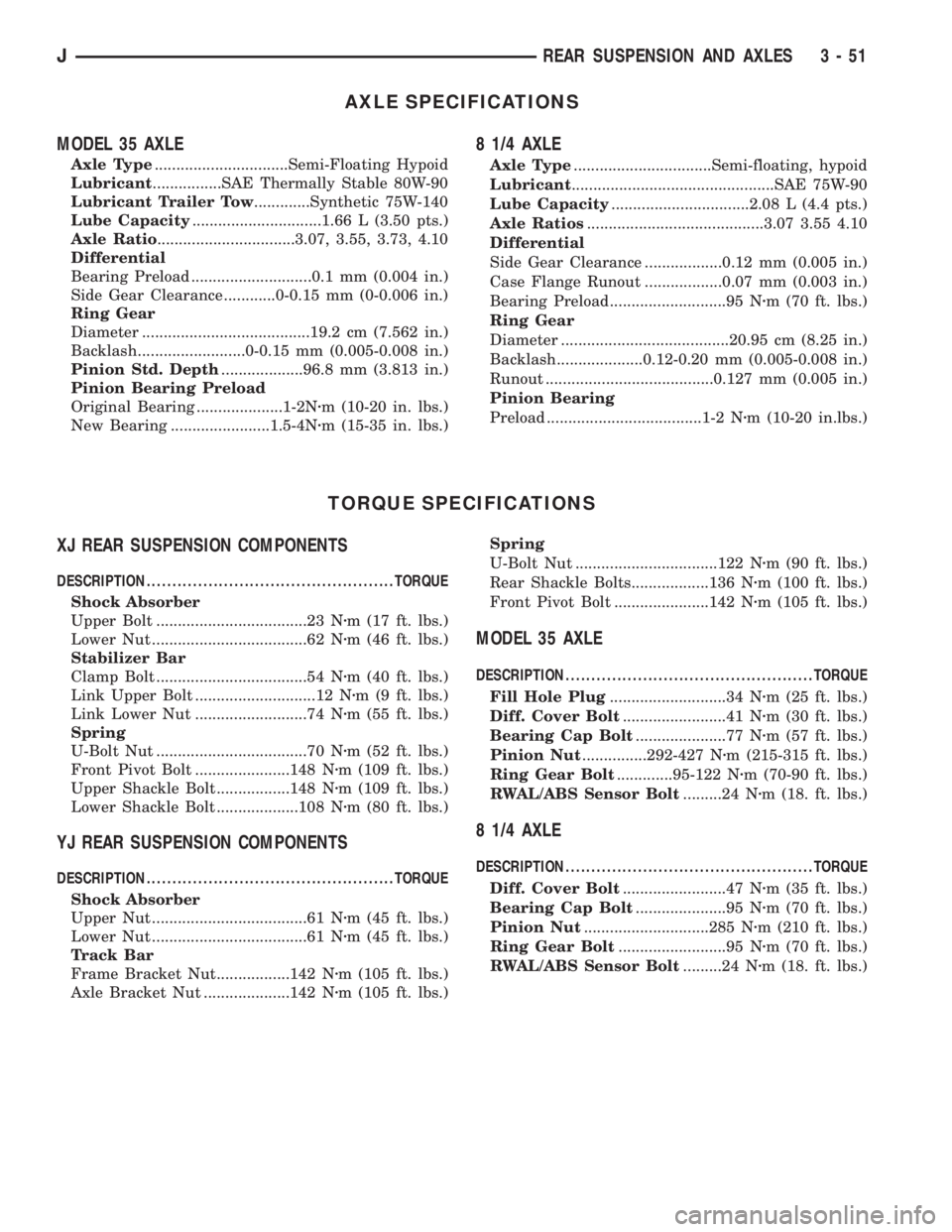

AXLE SPECIFICATIONS

MODEL 35 AXLE

Axle Type...............................Semi-Floating Hypoid

Lubricant................SAE Thermally Stable 80W-90

Lubricant Trailer Tow.............Synthetic 75W-140

Lube Capacity..............................1.66 L (3.50 pts.)

Axle Ratio................................3.07, 3.55, 3.73, 4.10

Differential

Bearing Preload ............................0.1 mm (0.004 in.)

Side Gear Clearance ............0-0.15 mm (0-0.006 in.)

Ring Gear

Diameter .......................................19.2 cm (7.562 in.)

Backlash.........................0-0.15 mm (0.005-0.008 in.)

Pinion Std. Depth...................96.8 mm (3.813 in.)

Pinion Bearing Preload

Original Bearing ....................1-2Nzm (10-20 in. lbs.)

New Bearing .......................1.5-4Nzm (15-35 in. lbs.)

8 1/4 AXLE

Axle Type................................Semi-floating, hypoid

Lubricant...............................................SAE 75W-90

Lube Capacity................................2.08 L (4.4 pts.)

Axle Ratios.........................................3.07 3.55 4.10

Differential

Side Gear Clearance ..................0.12 mm (0.005 in.)

Case Flange Runout ..................0.07 mm (0.003 in.)

Bearing Preload ...........................95 Nzm (70 ft. lbs.)

Ring Gear

Diameter .......................................20.95 cm (8.25 in.)

Backlash....................0.12-0.20 mm (0.005-0.008 in.)

Runout .......................................0.127 mm (0.005 in.)

Pinion Bearing

Preload ....................................1-2 Nzm (10-20 in.lbs.)

TORQUE SPECIFICATIONS

XJ REAR SUSPENSION COMPONENTS

DESCRIPTION ................................................TORQUE

Shock Absorber

Upper Bolt ...................................23 Nzm (17 ft. lbs.)

Lower Nut ....................................62 Nzm (46 ft. lbs.)

Stabilizer Bar

Clamp Bolt ...................................54 Nzm (40 ft. lbs.)

Link Upper Bolt ............................12 Nzm (9 ft. lbs.)

Link Lower Nut ..........................74 Nzm (55 ft. lbs.)

Spring

U-Bolt Nut ...................................70 Nzm (52 ft. lbs.)

Front Pivot Bolt ......................148 Nzm (109 ft. lbs.)

Upper Shackle Bolt .................148 Nzm (109 ft. lbs.)

Lower Shackle Bolt ...................108 Nzm (80 ft. lbs.)

YJ REAR SUSPENSION COMPONENTS

DESCRIPTION ................................................TORQUE

Shock Absorber

Upper Nut ....................................61 Nzm (45 ft. lbs.)

Lower Nut ....................................61 Nzm (45 ft. lbs.)

Track Bar

Frame Bracket Nut.................142 Nzm (105 ft. lbs.)

Axle Bracket Nut ....................142 Nzm (105 ft. lbs.)Spring

U-Bolt Nut .................................122 Nzm (90 ft. lbs.)

Rear Shackle Bolts..................136 Nzm (100 ft. lbs.)

Front Pivot Bolt ......................142 Nzm (105 ft. lbs.)

MODEL 35 AXLE

DESCRIPTION ................................................TORQUE

Fill Hole Plug...........................34 Nzm (25 ft. lbs.)

Diff. Cover Bolt........................41 Nzm (30 ft. lbs.)

Bearing Cap Bolt.....................77 Nzm (57 ft. lbs.)

Pinion Nut...............292-427 Nzm (215-315 ft. lbs.)

Ring Gear Bolt.............95-122 Nzm (70-90 ft. lbs.)

RWAL/ABS Sensor Bolt.........24 Nzm (18. ft. lbs.)

8 1/4 AXLE

DESCRIPTION ................................................TORQUE

Diff. Cover Bolt........................47 Nzm (35 ft. lbs.)

Bearing Cap Bolt.....................95 Nzm (70 ft. lbs.)

Pinion Nut.............................285 Nzm (210 ft. lbs.)

Ring Gear Bolt.........................95 Nzm (70 ft. lbs.)

RWAL/ABS Sensor Bolt.........24 Nzm (18. ft. lbs.)

JREAR SUSPENSION AND AXLES 3 - 51

Page 163 of 2158

bubbles that are distributed throughout the hydrau-

lic system. This will make extra bleeding operations

necessary.

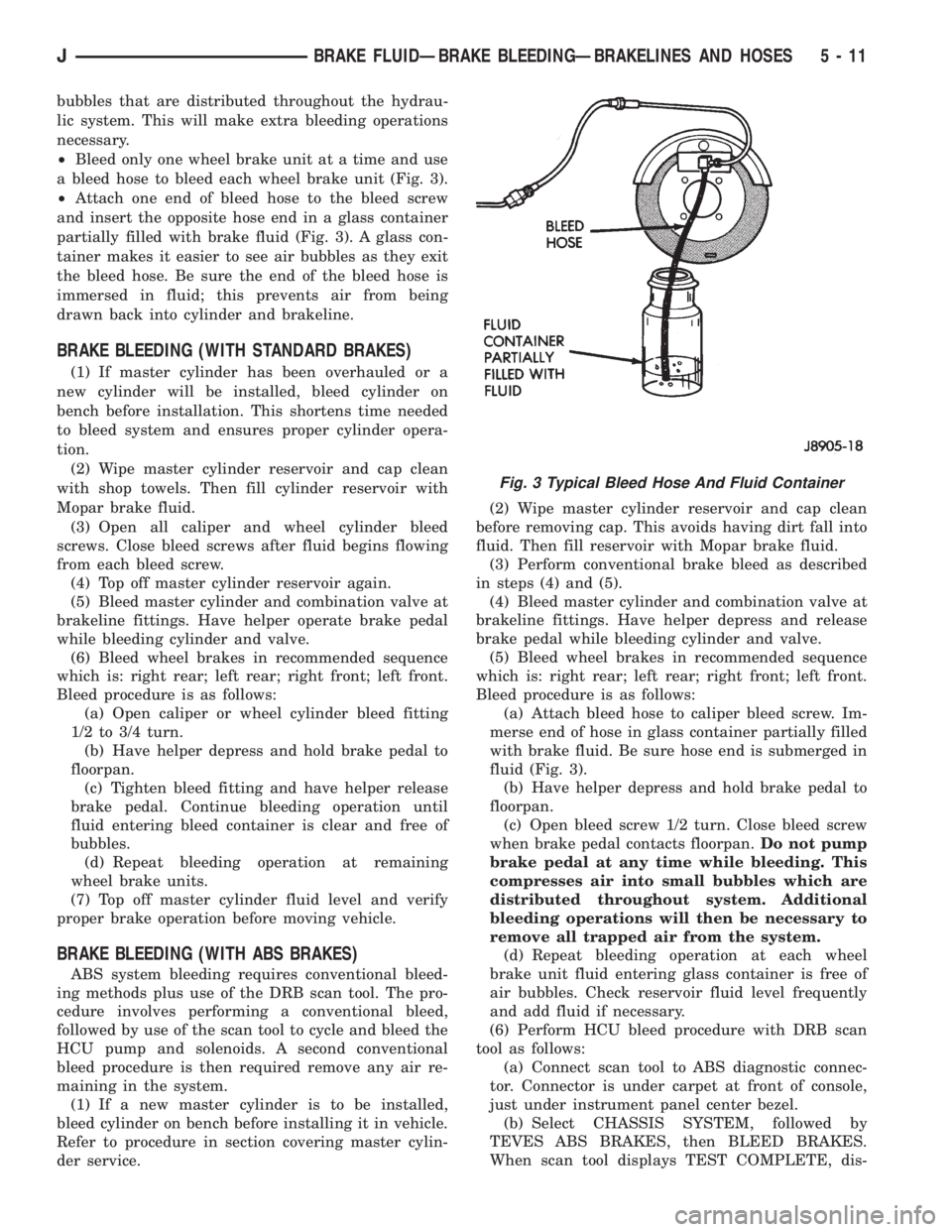

²Bleed only one wheel brake unit at a time and use

a bleed hose to bleed each wheel brake unit (Fig. 3).

²Attach one end of bleed hose to the bleed screw

and insert the opposite hose end in a glass container

partially filled with brake fluid (Fig. 3). A glass con-

tainer makes it easier to see air bubbles as they exit

the bleed hose. Be sure the end of the bleed hose is

immersed in fluid; this prevents air from being

drawn back into cylinder and brakeline.

BRAKE BLEEDING (WITH STANDARD BRAKES)

(1) If master cylinder has been overhauled or a

new cylinder will be installed, bleed cylinder on

bench before installation. This shortens time needed

to bleed system and ensures proper cylinder opera-

tion.

(2) Wipe master cylinder reservoir and cap clean

with shop towels. Then fill cylinder reservoir with

Mopar brake fluid.

(3) Open all caliper and wheel cylinder bleed

screws. Close bleed screws after fluid begins flowing

from each bleed screw.

(4) Top off master cylinder reservoir again.

(5) Bleed master cylinder and combination valve at

brakeline fittings. Have helper operate brake pedal

while bleeding cylinder and valve.

(6) Bleed wheel brakes in recommended sequence

which is: right rear; left rear; right front; left front.

Bleed procedure is as follows:

(a) Open caliper or wheel cylinder bleed fitting

1/2 to 3/4 turn.

(b) Have helper depress and hold brake pedal to

floorpan.

(c) Tighten bleed fitting and have helper release

brake pedal. Continue bleeding operation until

fluid entering bleed container is clear and free of

bubbles.

(d) Repeat bleeding operation at remaining

wheel brake units.

(7) Top off master cylinder fluid level and verify

proper brake operation before moving vehicle.

BRAKE BLEEDING (WITH ABS BRAKES)

ABS system bleeding requires conventional bleed-

ing methods plus use of the DRB scan tool. The pro-

cedure involves performing a conventional bleed,

followed by use of the scan tool to cycle and bleed the

HCU pump and solenoids. A second conventional

bleed procedure is then required remove any air re-

maining in the system.

(1) If a new master cylinder is to be installed,

bleed cylinder on bench before installing it in vehicle.

Refer to procedure in section covering master cylin-

der service.(2) Wipe master cylinder reservoir and cap clean

before removing cap. This avoids having dirt fall into

fluid. Then fill reservoir with Mopar brake fluid.

(3) Perform conventional brake bleed as described

in steps (4) and (5).

(4) Bleed master cylinder and combination valve at

brakeline fittings. Have helper depress and release

brake pedal while bleeding cylinder and valve.

(5) Bleed wheel brakes in recommended sequence

which is: right rear; left rear; right front; left front.

Bleed procedure is as follows:

(a) Attach bleed hose to caliper bleed screw. Im-

merse end of hose in glass container partially filled

with brake fluid. Be sure hose end is submerged in

fluid (Fig. 3).

(b) Have helper depress and hold brake pedal to

floorpan.

(c) Open bleed screw 1/2 turn. Close bleed screw

when brake pedal contacts floorpan.Do not pump

brake pedal at any time while bleeding. This

compresses air into small bubbles which are

distributed throughout system. Additional

bleeding operations will then be necessary to

remove all trapped air from the system.

(d) Repeat bleeding operation at each wheel

brake unit fluid entering glass container is free of

air bubbles. Check reservoir fluid level frequently

and add fluid if necessary.

(6) Perform HCU bleed procedure with DRB scan

tool as follows:

(a) Connect scan tool to ABS diagnostic connec-

tor. Connector is under carpet at front of console,

just under instrument panel center bezel.

(b) Select CHASSIS SYSTEM, followed by

TEVES ABS BRAKES, then BLEED BRAKES.

When scan tool displays TEST COMPLETE, dis-

Fig. 3 Typical Bleed Hose And Fluid Container

JBRAKE FLUIDÐBRAKE BLEEDINGÐBRAKELINES AND HOSES 5 - 11

Page 168 of 2158

(2) Disconnect brake lines at master cylinder and

combination valve.

(3) Remove nuts attaching master cylinder to

booster studs.

(4) Remove master cylinder.

(5) Remove cylinder cover and drain fluid.

(6) If two-piece master cylinder reservoir requires

service, refer to reservoir replacement procedure in

this section.

MASTER CYLINDER INSTALLATION (NON-ABS)

(1) Bleed master cylinder on bench before installa-

tion. Refer to procedure in this section.

(2) If new two-piece master cylinder is being in-

stalled, remove plastic protective sleeve from primary

piston shank. Also check condition of seal at rear of

cylinder body. Reposition seal if dislodged. Replace

seal if cut, or torn.

(3) Clean cylinder mounting surface of brake booster.

Use shop towel wetted with brake cleaner for this pur-

pose. Dirt, grease, or similar materials will prevent

proper cylinder seating and could result in vacuum leak.

(4) Slide master cylinder onto brake booster studs.

(5) Install nuts attaching master cylinder to booster

studs. Tighten nuts to 25 Nzm (220 in. lbs.) torque.

(6) Connect brakelines to master cylinder and com-

bination valve (Figs. 1 and 2).

(7) Fill and bleed brake system.

COMBINATION VALVE REPLACEMENT (NON-ABS)

The combination valve is not a repairable compo-

nent. The valve is serviced as an assembly whenever

diagnosis indicates replacement is necessary.

(1) Remove air cleaner cover and hose for access to

valve, if necessary.

(2) Disconnect differential pressure switch wire at

combination valve. Do not pull switch wire to discon-

nect. Unsnap connecter lock tabs to remove.

(3) Disconnect brakelines at combination valve and

remove valve.

(4) Connect brakelines to replacement valve. Start

line fittings by hand to avoid cross threading.

Tighten fittings snug but not to required torque at

this time.

(5) Connect wire to pressure differential switch.

(6) Bleed brakes.

(7) Tighten brakeline fittings to 18-24 Nzm

(160-210 in. lbs.) torque after bleeding.

MASTER CYLINDER OVERHAUL (4-CYLINDER

MODELS)

CYLINDER DISASSEMBLY

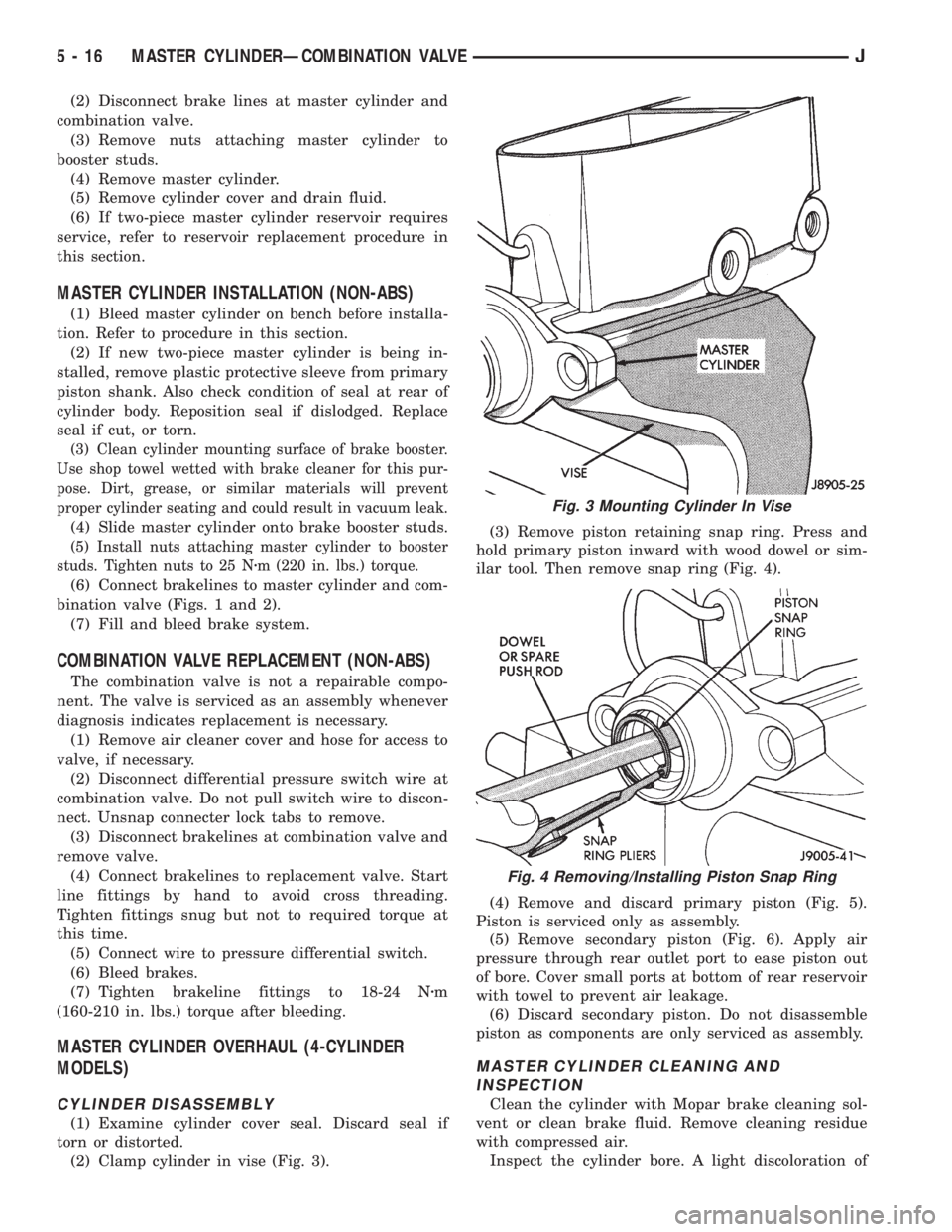

(1) Examine cylinder cover seal. Discard seal if

torn or distorted.

(2) Clamp cylinder in vise (Fig. 3).(3) Remove piston retaining snap ring. Press and

hold primary piston inward with wood dowel or sim-

ilar tool. Then remove snap ring (Fig. 4).

(4) Remove and discard primary piston (Fig. 5).

Piston is serviced only as assembly.

(5) Remove secondary piston (Fig. 6). Apply air

pressure through rear outlet port to ease piston out

of bore. Cover small ports at bottom of rear reservoir

with towel to prevent air leakage.

(6) Discard secondary piston. Do not disassemble

piston as components are only serviced as assembly.

MASTER CYLINDER CLEANING AND

INSPECTION

Clean the cylinder with Mopar brake cleaning sol-

vent or clean brake fluid. Remove cleaning residue

with compressed air.

Inspect the cylinder bore. A light discoloration of

Fig. 3 Mounting Cylinder In Vise

Fig. 4 Removing/Installing Piston Snap Ring

5 - 16 MASTER CYLINDERÐCOMBINATION VALVEJ

Page 172 of 2158

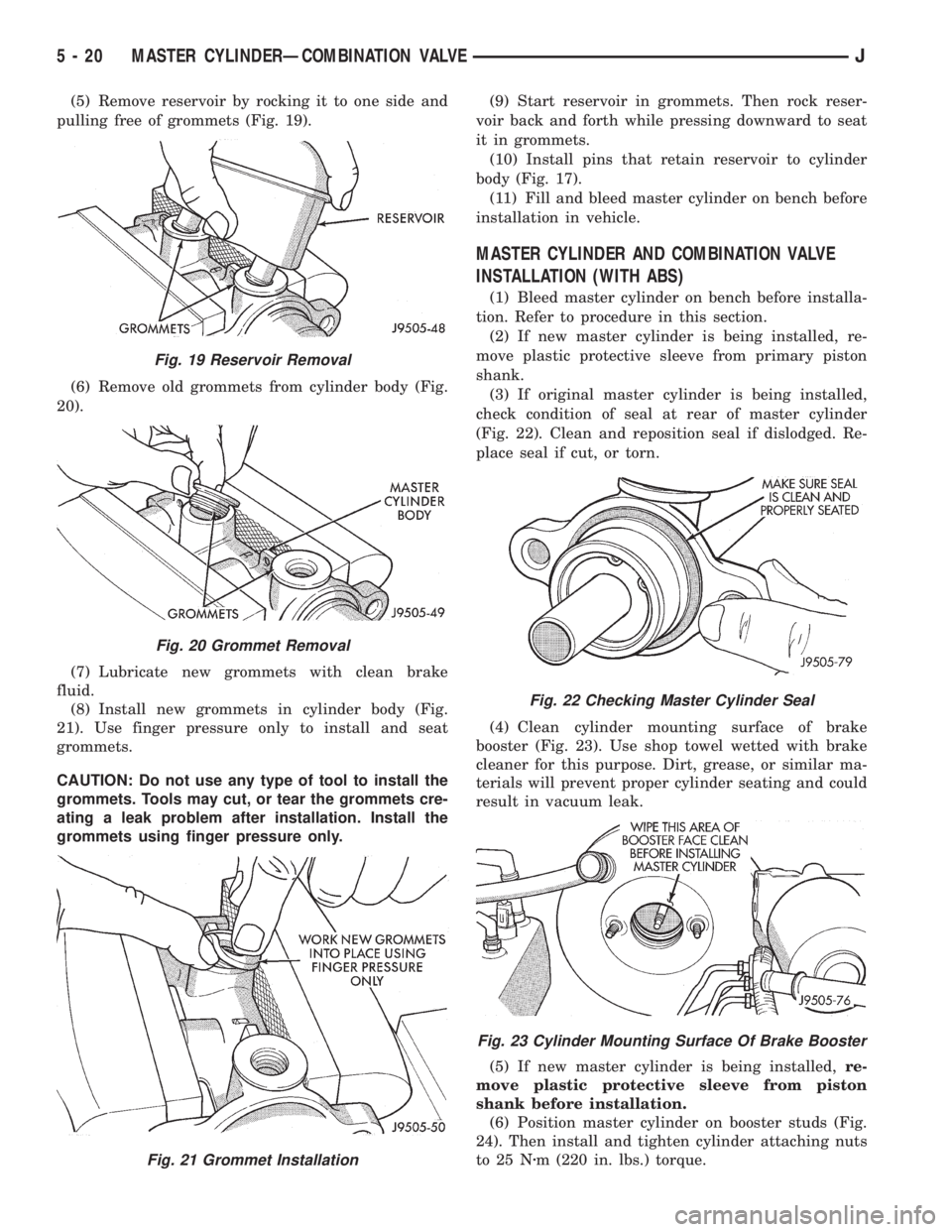

(5) Remove reservoir by rocking it to one side and

pulling free of grommets (Fig. 19).

(6) Remove old grommets from cylinder body (Fig.

20).

(7) Lubricate new grommets with clean brake

fluid.

(8) Install new grommets in cylinder body (Fig.

21). Use finger pressure only to install and seat

grommets.

CAUTION: Do not use any type of tool to install the

grommets. Tools may cut, or tear the grommets cre-

ating a leak problem after installation. Install the

grommets using finger pressure only.(9) Start reservoir in grommets. Then rock reser-

voir back and forth while pressing downward to seat

it in grommets.

(10) Install pins that retain reservoir to cylinder

body (Fig. 17).

(11) Fill and bleed master cylinder on bench before

installation in vehicle.

MASTER CYLINDER AND COMBINATION VALVE

INSTALLATION (WITH ABS)

(1) Bleed master cylinder on bench before installa-

tion. Refer to procedure in this section.

(2) If new master cylinder is being installed, re-

move plastic protective sleeve from primary piston

shank.

(3) If original master cylinder is being installed,

check condition of seal at rear of master cylinder

(Fig. 22). Clean and reposition seal if dislodged. Re-

place seal if cut, or torn.

(4) Clean cylinder mounting surface of brake

booster (Fig. 23). Use shop towel wetted with brake

cleaner for this purpose. Dirt, grease, or similar ma-

terials will prevent proper cylinder seating and could

result in vacuum leak.

(5) If new master cylinder is being installed,re-

move plastic protective sleeve from piston

shank before installation.

(6) Position master cylinder on booster studs (Fig.

24). Then install and tighten cylinder attaching nuts

to 25 Nzm (220 in. lbs.) torque.

Fig. 19 Reservoir Removal

Fig. 20 Grommet Removal

Fig. 21 Grommet Installation

Fig. 22 Checking Master Cylinder Seal

Fig. 23 Cylinder Mounting Surface Of Brake Booster

5 - 20 MASTER CYLINDERÐCOMBINATION VALVEJ