belt JEEP YJ 1995 Service And Repair Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 2001 of 2158

INSTALLATION

(1) Position the replacement cover on the cushion.

(2) Compress the cover and attach the retaining

clips to the front and rear wire retainers.

(3) Install the serrated retainers at the ends of the

cover.

(4) Install the seat cushion in the vehicle. If neces-

sary, refer to the installation procedure.

REAR SEATBACKÐXJ

REMOVAL

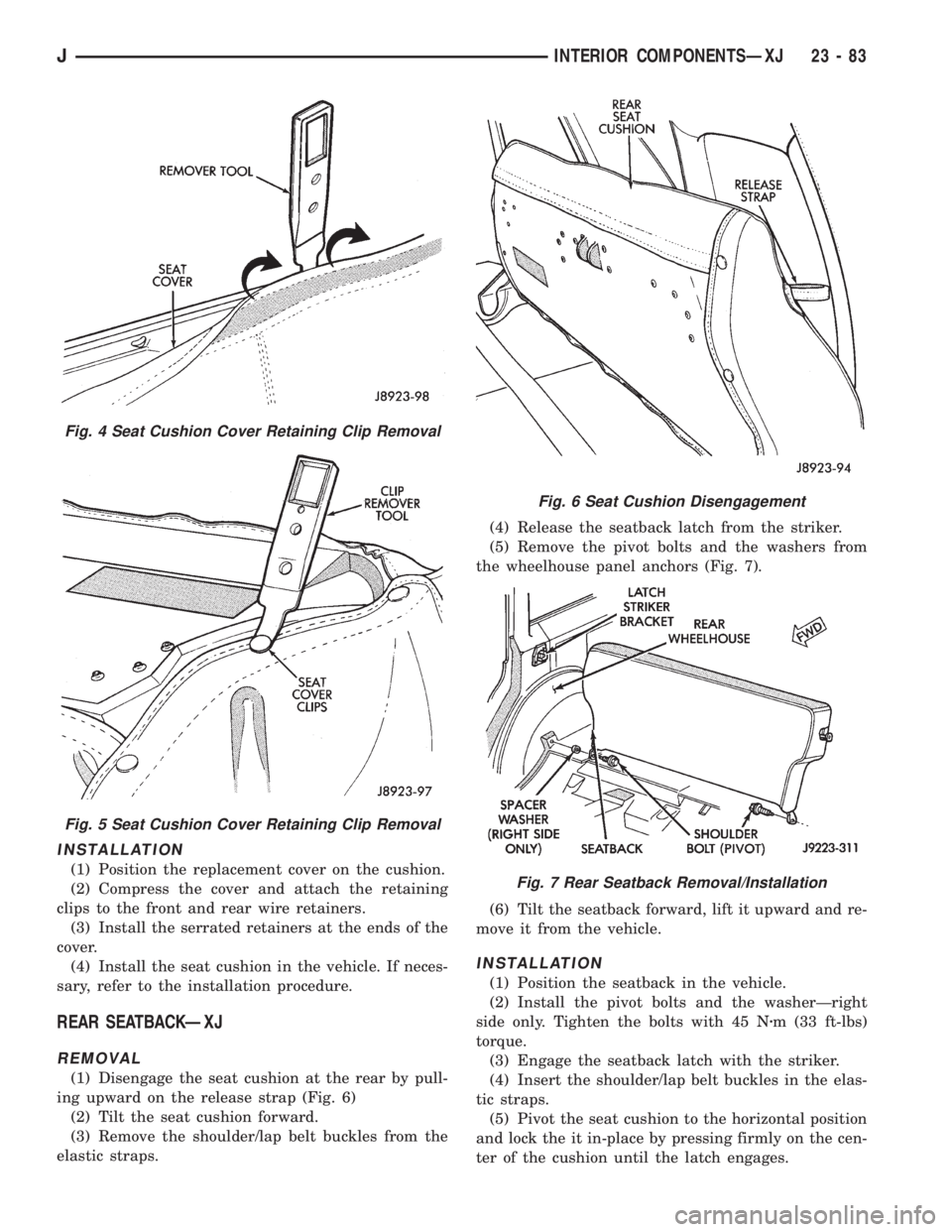

(1) Disengage the seat cushion at the rear by pull-

ing upward on the release strap (Fig. 6)

(2) Tilt the seat cushion forward.

(3) Remove the shoulder/lap belt buckles from the

elastic straps.(4) Release the seatback latch from the striker.

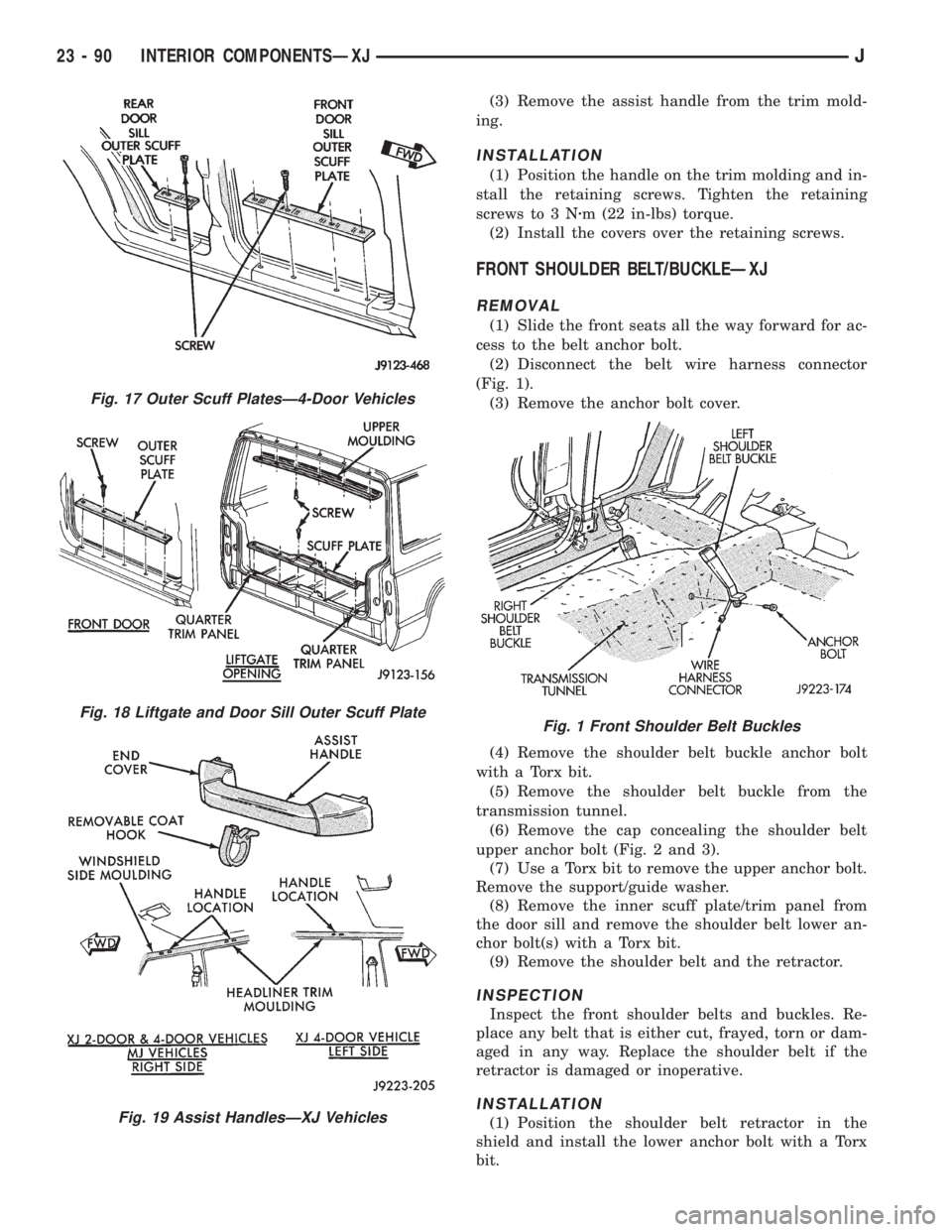

(5) Remove the pivot bolts and the washers from

the wheelhouse panel anchors (Fig. 7).

(6) Tilt the seatback forward, lift it upward and re-

move it from the vehicle.

INSTALLATION

(1) Position the seatback in the vehicle.

(2) Install the pivot bolts and the washerÐright

side only. Tighten the bolts with 45 Nzm (33 ft-lbs)

torque.

(3) Engage the seatback latch with the striker.

(4) Insert the shoulder/lap belt buckles in the elas-

tic straps.

(5) Pivot the seat cushion to the horizontal position

and lock the it in-place by pressing firmly on the cen-

ter of the cushion until the latch engages.

Fig. 4 Seat Cushion Cover Retaining Clip Removal

Fig. 5 Seat Cushion Cover Retaining Clip Removal

Fig. 6 Seat Cushion Disengagement

Fig. 7 Rear Seatback Removal/Installation

JINTERIOR COMPONENTSÐXJ 23 - 83

Page 2008 of 2158

(3) Remove the assist handle from the trim mold-

ing.

INSTALLATION

(1) Position the handle on the trim molding and in-

stall the retaining screws. Tighten the retaining

screws to 3 Nzm (22 in-lbs) torque.

(2) Install the covers over the retaining screws.

FRONT SHOULDER BELT/BUCKLEÐXJ

REMOVAL

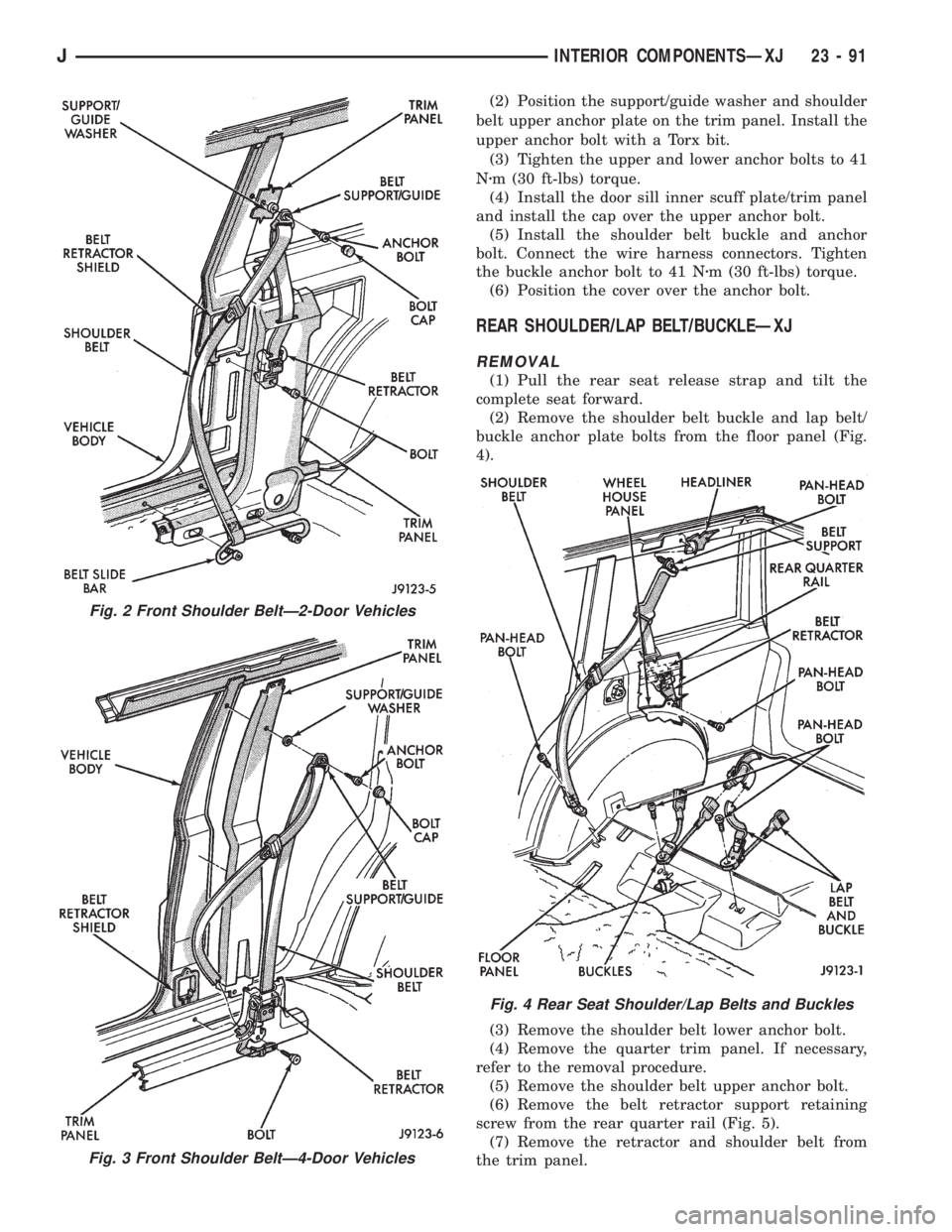

(1) Slide the front seats all the way forward for ac-

cess to the belt anchor bolt.

(2) Disconnect the belt wire harness connector

(Fig. 1).

(3) Remove the anchor bolt cover.

(4) Remove the shoulder belt buckle anchor bolt

with a Torx bit.

(5) Remove the shoulder belt buckle from the

transmission tunnel.

(6) Remove the cap concealing the shoulder belt

upper anchor bolt (Fig. 2 and 3).

(7) Use a Torx bit to remove the upper anchor bolt.

Remove the support/guide washer.

(8) Remove the inner scuff plate/trim panel from

the door sill and remove the shoulder belt lower an-

chor bolt(s) with a Torx bit.

(9) Remove the shoulder belt and the retractor.

INSPECTION

Inspect the front shoulder belts and buckles. Re-

place any belt that is either cut, frayed, torn or dam-

aged in any way. Replace the shoulder belt if the

retractor is damaged or inoperative.

INSTALLATION

(1) Position the shoulder belt retractor in the

shield and install the lower anchor bolt with a Torx

bit.

Fig. 17 Outer Scuff PlatesÐ4-Door Vehicles

Fig. 18 Liftgate and Door Sill Outer Scuff Plate

Fig. 19 Assist HandlesÐXJ Vehicles

Fig. 1 Front Shoulder Belt Buckles

23 - 90 INTERIOR COMPONENTSÐXJJ

Page 2009 of 2158

(2) Position the support/guide washer and shoulder

belt upper anchor plate on the trim panel. Install the

upper anchor bolt with a Torx bit.

(3) Tighten the upper and lower anchor bolts to 41

Nzm (30 ft-lbs) torque.

(4) Install the door sill inner scuff plate/trim panel

and install the cap over the upper anchor bolt.

(5) Install the shoulder belt buckle and anchor

bolt. Connect the wire harness connectors. Tighten

the buckle anchor bolt to 41 Nzm (30 ft-lbs) torque.

(6) Position the cover over the anchor bolt.

REAR SHOULDER/LAP BELT/BUCKLEÐXJ

REMOVAL

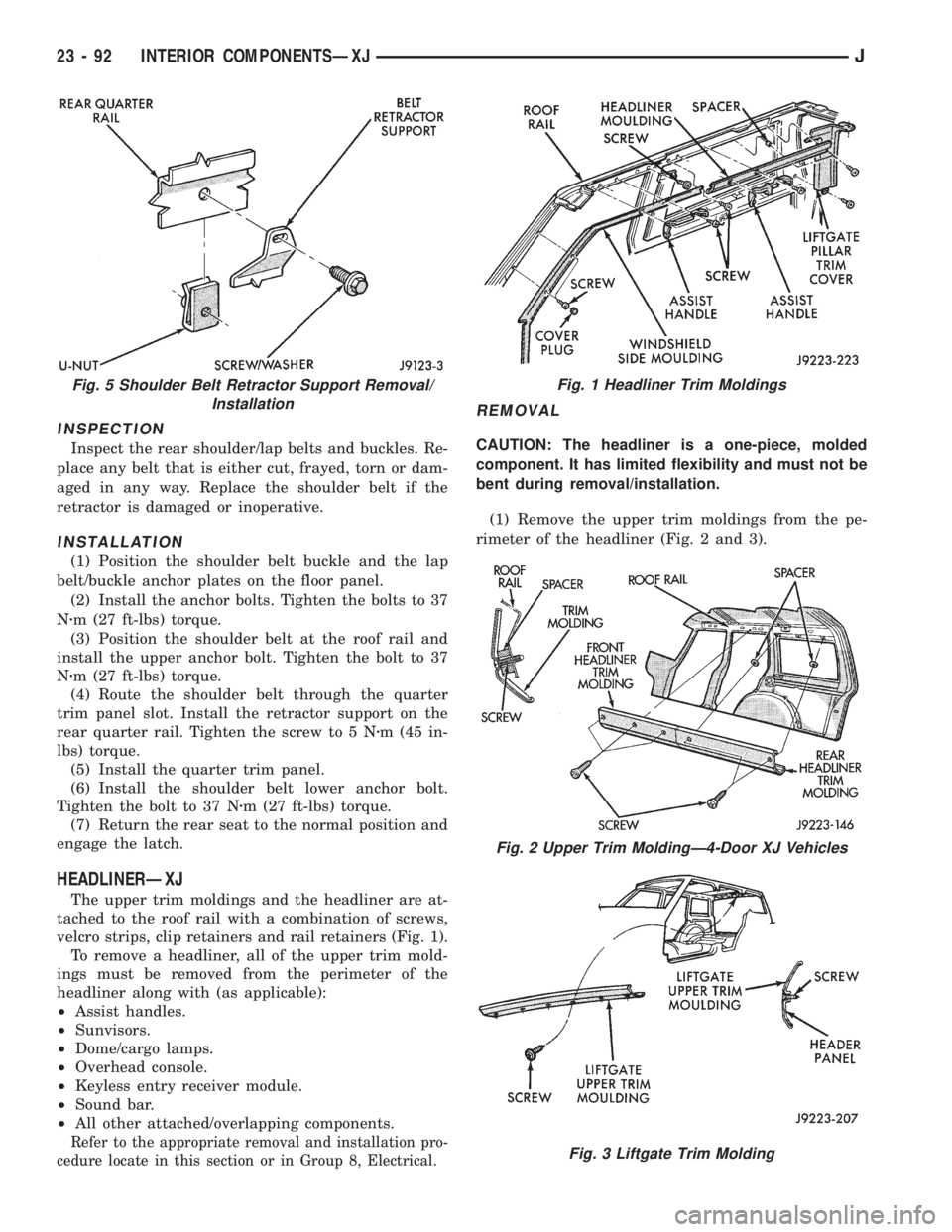

(1) Pull the rear seat release strap and tilt the

complete seat forward.

(2) Remove the shoulder belt buckle and lap belt/

buckle anchor plate bolts from the floor panel (Fig.

4).

(3) Remove the shoulder belt lower anchor bolt.

(4) Remove the quarter trim panel. If necessary,

refer to the removal procedure.

(5) Remove the shoulder belt upper anchor bolt.

(6) Remove the belt retractor support retaining

screw from the rear quarter rail (Fig. 5).

(7) Remove the retractor and shoulder belt from

the trim panel.

Fig. 2 Front Shoulder BeltÐ2-Door Vehicles

Fig. 3 Front Shoulder BeltÐ4-Door Vehicles

Fig. 4 Rear Seat Shoulder/Lap Belts and Buckles

JINTERIOR COMPONENTSÐXJ 23 - 91

Page 2010 of 2158

INSPECTION

Inspect the rear shoulder/lap belts and buckles. Re-

place any belt that is either cut, frayed, torn or dam-

aged in any way. Replace the shoulder belt if the

retractor is damaged or inoperative.

INSTALLATION

(1) Position the shoulder belt buckle and the lap

belt/buckle anchor plates on the floor panel.

(2) Install the anchor bolts. Tighten the bolts to 37

Nzm (27 ft-lbs) torque.

(3) Position the shoulder belt at the roof rail and

install the upper anchor bolt. Tighten the bolt to 37

Nzm (27 ft-lbs) torque.

(4) Route the shoulder belt through the quarter

trim panel slot. Install the retractor support on the

rear quarter rail. Tighten the screw to 5 Nzm (45 in-

lbs) torque.

(5) Install the quarter trim panel.

(6) Install the shoulder belt lower anchor bolt.

Tighten the bolt to 37 Nzm (27 ft-lbs) torque.

(7) Return the rear seat to the normal position and

engage the latch.

HEADLINERÐXJ

The upper trim moldings and the headliner are at-

tached to the roof rail with a combination of screws,

velcro strips, clip retainers and rail retainers (Fig. 1).

To remove a headliner, all of the upper trim mold-

ings must be removed from the perimeter of the

headliner along with (as applicable):

²Assist handles.

²Sunvisors.

²Dome/cargo lamps.

²Overhead console.

²Keyless entry receiver module.

²Sound bar.

²All other attached/overlapping components.

Refer to the appropriate removal and installation pro-

cedure locate in this section or in Group 8, Electrical.

REMOVAL

CAUTION: The headliner is a one-piece, molded

component. It has limited flexibility and must not be

bent during removal/installation.

(1) Remove the upper trim moldings from the pe-

rimeter of the headliner (Fig. 2 and 3).

Fig. 5 Shoulder Belt Retractor Support Removal/

InstallationFig. 1 Headliner Trim Moldings

Fig. 2 Upper Trim MoldingÐ4-Door XJ Vehicles

Fig. 3 Liftgate Trim Molding

23 - 92 INTERIOR COMPONENTSÐXJJ

Page 2044 of 2158

(4) Apply weatherstrip adhesive to the hard top

weatherstrip seal (Fig. 4).

(5) Carefully position the weatherstrip seal on the

rear panels and the hard top.

(6) Press the seal onto the hard top flange and en-

sure that it is correctly seated on the flange.

(7) Install the seal retaining screws in the rear

panels and tighten them securely.

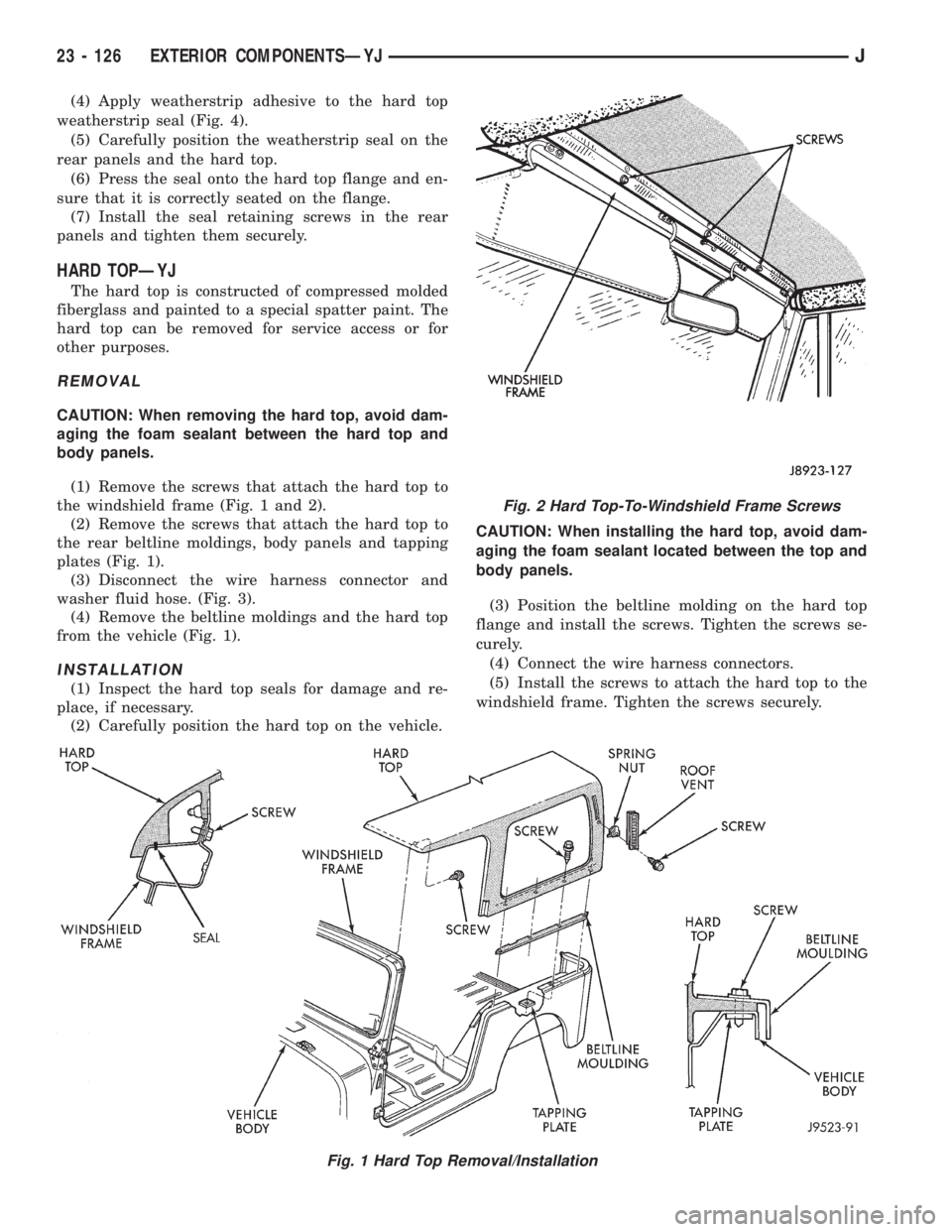

HARD TOPÐYJ

The hard top is constructed of compressed molded

fiberglass and painted to a special spatter paint. The

hard top can be removed for service access or for

other purposes.

REMOVAL

CAUTION: When removing the hard top, avoid dam-

aging the foam sealant between the hard top and

body panels.

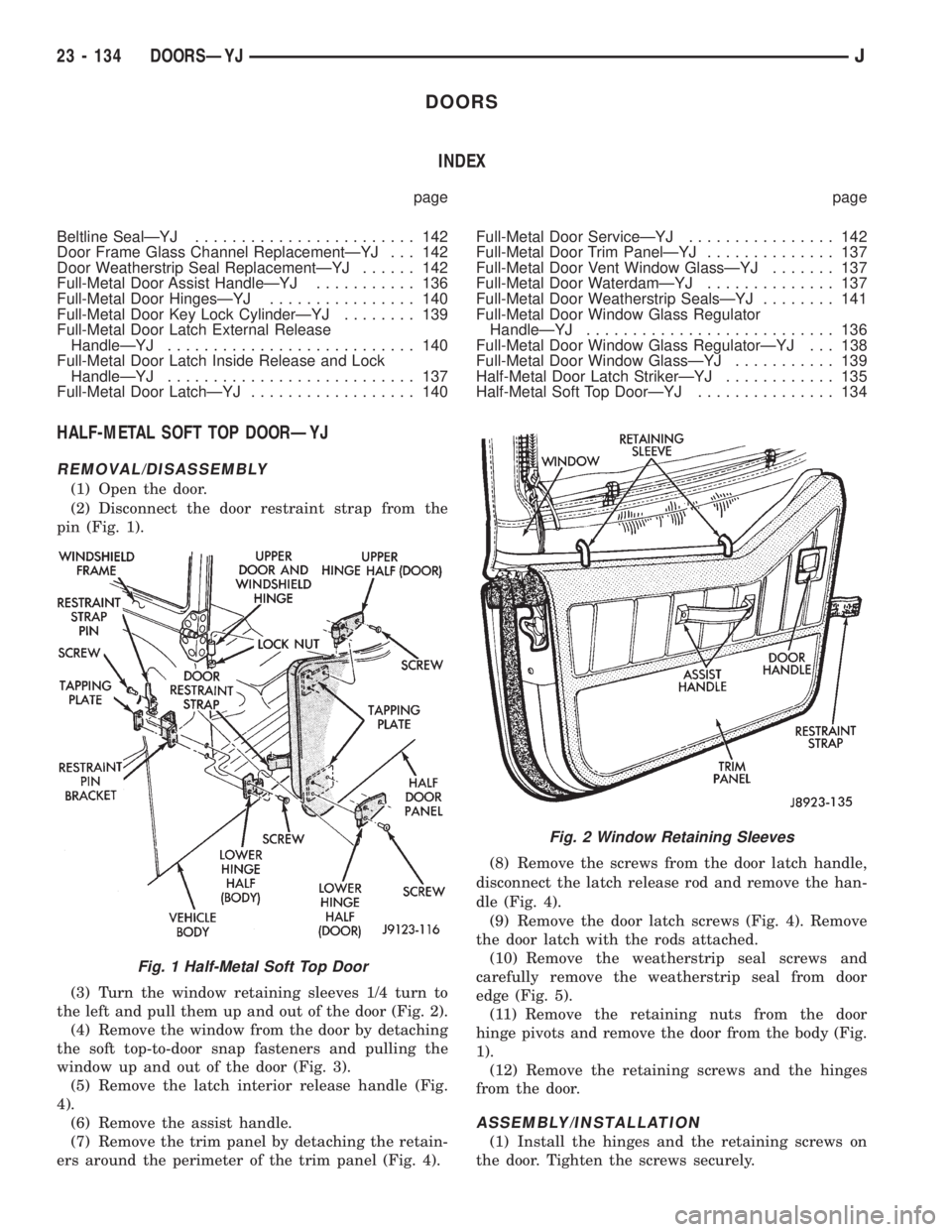

(1) Remove the screws that attach the hard top to

the windshield frame (Fig. 1 and 2).

(2) Remove the screws that attach the hard top to

the rear beltline moldings, body panels and tapping

plates (Fig. 1).

(3) Disconnect the wire harness connector and

washer fluid hose. (Fig. 3).

(4) Remove the beltline moldings and the hard top

from the vehicle (Fig. 1).

INSTALLATION

(1) Inspect the hard top seals for damage and re-

place, if necessary.

(2) Carefully position the hard top on the vehicle.CAUTION: When installing the hard top, avoid dam-

aging the foam sealant located between the top and

body panels.

(3) Position the beltline molding on the hard top

flange and install the screws. Tighten the screws se-

curely.

(4) Connect the wire harness connectors.

(5) Install the screws to attach the hard top to the

windshield frame. Tighten the screws securely.

Fig. 1 Hard Top Removal/Installation

Fig. 2 Hard Top-To-Windshield Frame Screws

23 - 126 EXTERIOR COMPONENTSÐYJJ

Page 2052 of 2158

DOORS

INDEX

page page

Beltline SealÐYJ........................ 142

Door Frame Glass Channel ReplacementÐYJ . . . 142

Door Weatherstrip Seal ReplacementÐYJ...... 142

Full-Metal Door Assist HandleÐYJ........... 136

Full-Metal Door HingesÐYJ................ 140

Full-Metal Door Key Lock CylinderÐYJ........ 139

Full-Metal Door Latch External Release

HandleÐYJ........................... 140

Full-Metal Door Latch Inside Release and Lock

HandleÐYJ........................... 137

Full-Metal Door LatchÐYJ.................. 140Full-Metal Door ServiceÐYJ................ 142

Full-Metal Door Trim PanelÐYJ.............. 137

Full-Metal Door Vent Window GlassÐYJ....... 137

Full-Metal Door WaterdamÐYJ.............. 137

Full-Metal Door Weatherstrip SealsÐYJ........ 141

Full-Metal Door Window Glass Regulator

HandleÐYJ........................... 136

Full-Metal Door Window Glass RegulatorÐYJ . . . 138

Full-Metal Door Window GlassÐYJ........... 139

Half-Metal Door Latch StrikerÐYJ............ 135

Half-Metal Soft Top DoorÐYJ............... 134

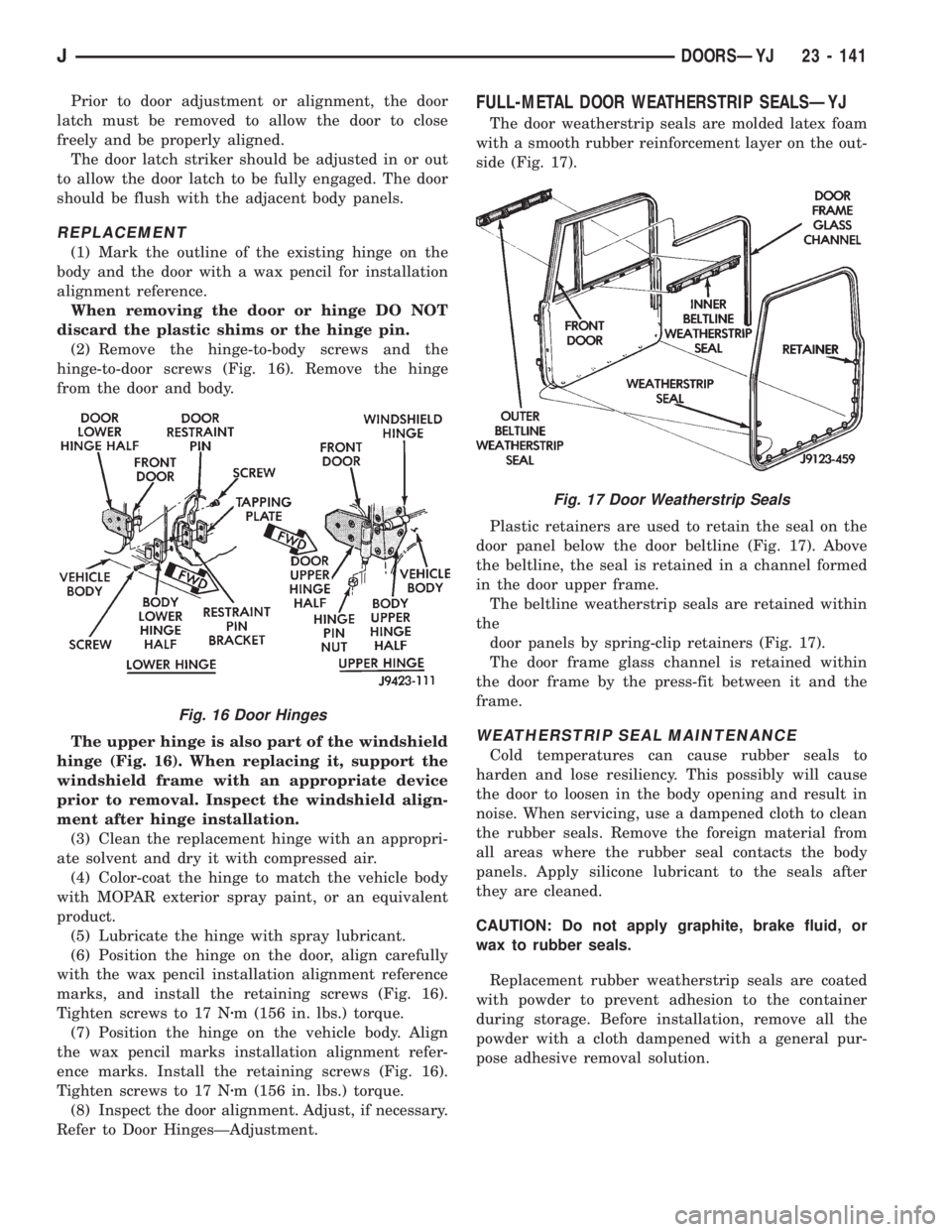

HALF-METAL SOFT TOP DOORÐYJ

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Disconnect the door restraint strap from the

pin (Fig. 1).

(3) Turn the window retaining sleeves 1/4 turn to

the left and pull them up and out of the door (Fig. 2).

(4) Remove the window from the door by detaching

the soft top-to-door snap fasteners and pulling the

window up and out of the door (Fig. 3).

(5) Remove the latch interior release handle (Fig.

4).

(6) Remove the assist handle.

(7) Remove the trim panel by detaching the retain-

ers around the perimeter of the trim panel (Fig. 4).(8) Remove the screws from the door latch handle,

disconnect the latch release rod and remove the han-

dle (Fig. 4).

(9) Remove the door latch screws (Fig. 4). Remove

the door latch with the rods attached.

(10) Remove the weatherstrip seal screws and

carefully remove the weatherstrip seal from door

edge (Fig. 5).

(11) Remove the retaining nuts from the door

hinge pivots and remove the door from the body (Fig.

1).

(12) Remove the retaining screws and the hinges

from the door.

ASSEMBLY/INSTALLATION

(1) Install the hinges and the retaining screws on

the door. Tighten the screws securely.

Fig. 1 Half-Metal Soft Top Door

Fig. 2 Window Retaining Sleeves

23 - 134 DOORSÐYJJ

Page 2059 of 2158

Prior to door adjustment or alignment, the door

latch must be removed to allow the door to close

freely and be properly aligned.

The door latch striker should be adjusted in or out

to allow the door latch to be fully engaged. The door

should be flush with the adjacent body panels.

REPLACEMENT

(1) Mark the outline of the existing hinge on the

body and the door with a wax pencil for installation

alignment reference.

When removing the door or hinge DO NOT

discard the plastic shims or the hinge pin.

(2) Remove the hinge-to-body screws and the

hinge-to-door screws (Fig. 16). Remove the hinge

from the door and body.

The upper hinge is also part of the windshield

hinge (Fig. 16). When replacing it, support the

windshield frame with an appropriate device

prior to removal. Inspect the windshield align-

ment after hinge installation.

(3) Clean the replacement hinge with an appropri-

ate solvent and dry it with compressed air.

(4) Color-coat the hinge to match the vehicle body

with MOPAR exterior spray paint, or an equivalent

product.

(5) Lubricate the hinge with spray lubricant.

(6) Position the hinge on the door, align carefully

with the wax pencil installation alignment reference

marks, and install the retaining screws (Fig. 16).

Tighten screws to 17 Nzm (156 in. lbs.) torque.

(7) Position the hinge on the vehicle body. Align

the wax pencil marks installation alignment refer-

ence marks. Install the retaining screws (Fig. 16).

Tighten screws to 17 Nzm (156 in. lbs.) torque.

(8) Inspect the door alignment. Adjust, if necessary.

Refer to Door HingesÐAdjustment.

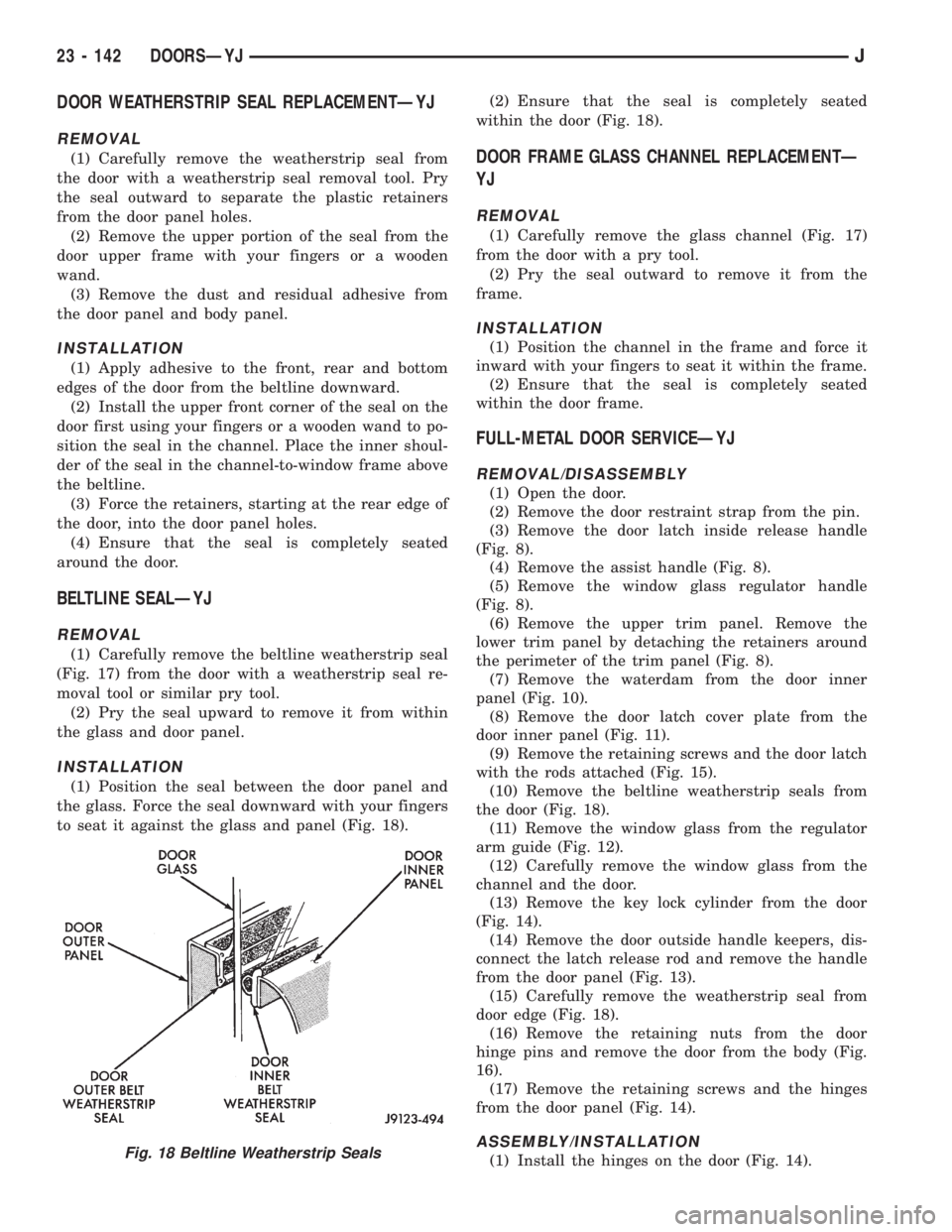

FULL-METAL DOOR WEATHERSTRIP SEALSÐYJ

The door weatherstrip seals are molded latex foam

with a smooth rubber reinforcement layer on the out-

side (Fig. 17).

Plastic retainers are used to retain the seal on the

door panel below the door beltline (Fig. 17). Above

the beltline, the seal is retained in a channel formed

in the door upper frame.

The beltline weatherstrip seals are retained within

the

door panels by spring-clip retainers (Fig. 17).

The door frame glass channel is retained within

the door frame by the press-fit between it and the

frame.

WEATHERSTRIP SEAL MAINTENANCE

Cold temperatures can cause rubber seals to

harden and lose resiliency. This possibly will cause

the door to loosen in the body opening and result in

noise. When servicing, use a dampened cloth to clean

the rubber seals. Remove the foreign material from

all areas where the rubber seal contacts the body

panels. Apply silicone lubricant to the seals after

they are cleaned.

CAUTION: Do not apply graphite, brake fluid, or

wax to rubber seals.

Replacement rubber weatherstrip seals are coated

with powder to prevent adhesion to the container

during storage. Before installation, remove all the

powder with a cloth dampened with a general pur-

pose adhesive removal solution.

Fig. 16 Door Hinges

Fig. 17 Door Weatherstrip Seals

JDOORSÐYJ 23 - 141

Page 2060 of 2158

DOOR WEATHERSTRIP SEAL REPLACEMENTÐYJ

REMOVAL

(1) Carefully remove the weatherstrip seal from

the door with a weatherstrip seal removal tool. Pry

the seal outward to separate the plastic retainers

from the door panel holes.

(2) Remove the upper portion of the seal from the

door upper frame with your fingers or a wooden

wand.

(3) Remove the dust and residual adhesive from

the door panel and body panel.

INSTALLATION

(1) Apply adhesive to the front, rear and bottom

edges of the door from the beltline downward.

(2) Install the upper front corner of the seal on the

door first using your fingers or a wooden wand to po-

sition the seal in the channel. Place the inner shoul-

der of the seal in the channel-to-window frame above

the beltline.

(3) Force the retainers, starting at the rear edge of

the door, into the door panel holes.

(4) Ensure that the seal is completely seated

around the door.

BELTLINE SEALÐYJ

REMOVAL

(1) Carefully remove the beltline weatherstrip seal

(Fig. 17) from the door with a weatherstrip seal re-

moval tool or similar pry tool.

(2) Pry the seal upward to remove it from within

the glass and door panel.

INSTALLATION

(1) Position the seal between the door panel and

the glass. Force the seal downward with your fingers

to seat it against the glass and panel (Fig. 18).(2) Ensure that the seal is completely seated

within the door (Fig. 18).

DOOR FRAME GLASS CHANNEL REPLACEMENTÐ

YJ

REMOVAL

(1) Carefully remove the glass channel (Fig. 17)

from the door with a pry tool.

(2) Pry the seal outward to remove it from the

frame.

INSTALLATION

(1) Position the channel in the frame and force it

inward with your fingers to seat it within the frame.

(2) Ensure that the seal is completely seated

within the door frame.

FULL-METAL DOOR SERVICEÐYJ

REMOVAL/DISASSEMBLY

(1) Open the door.

(2) Remove the door restraint strap from the pin.

(3) Remove the door latch inside release handle

(Fig. 8).

(4) Remove the assist handle (Fig. 8).

(5) Remove the window glass regulator handle

(Fig. 8).

(6) Remove the upper trim panel. Remove the

lower trim panel by detaching the retainers around

the perimeter of the trim panel (Fig. 8).

(7) Remove the waterdam from the door inner

panel (Fig. 10).

(8) Remove the door latch cover plate from the

door inner panel (Fig. 11).

(9) Remove the retaining screws and the door latch

with the rods attached (Fig. 15).

(10) Remove the beltline weatherstrip seals from

the door (Fig. 18).

(11) Remove the window glass from the regulator

arm guide (Fig. 12).

(12) Carefully remove the window glass from the

channel and the door.

(13) Remove the key lock cylinder from the door

(Fig. 14).

(14) Remove the door outside handle keepers, dis-

connect the latch release rod and remove the handle

from the door panel (Fig. 13).

(15) Carefully remove the weatherstrip seal from

door edge (Fig. 18).

(16) Remove the retaining nuts from the door

hinge pins and remove the door from the body (Fig.

16).

(17) Remove the retaining screws and the hinges

from the door panel (Fig. 14).

ASSEMBLY/INSTALLATION

(1) Install the hinges on the door (Fig. 14).Fig. 18 Beltline Weatherstrip Seals

23 - 142 DOORSÐYJJ

Page 2061 of 2158

(2) Position the door at the body opening, insert

the hinge pins in the hinge receptacles and install

the retaining nuts (Fig. 16). Tighten the nuts se-

curely.

(3) Install the weatherstrip seal on the door edge

(Fig. 18).

(4) Install the door outside handle and the keepers.

Connect the latch release rod to the handle (Fig. 13).

(5) Install the key lock cylinder (Fig. 14).

(6) Position the window glass in the channel and

the door.

(7) Attach the window glass to the regulator arm

guide (Fig. 12).

(8) Install the beltline weatherstrip seals in the

door (Fig. 18).

(9) Position the latch in the door and install the re-

taining screws (Fig. 15). Tighten the screws securely.

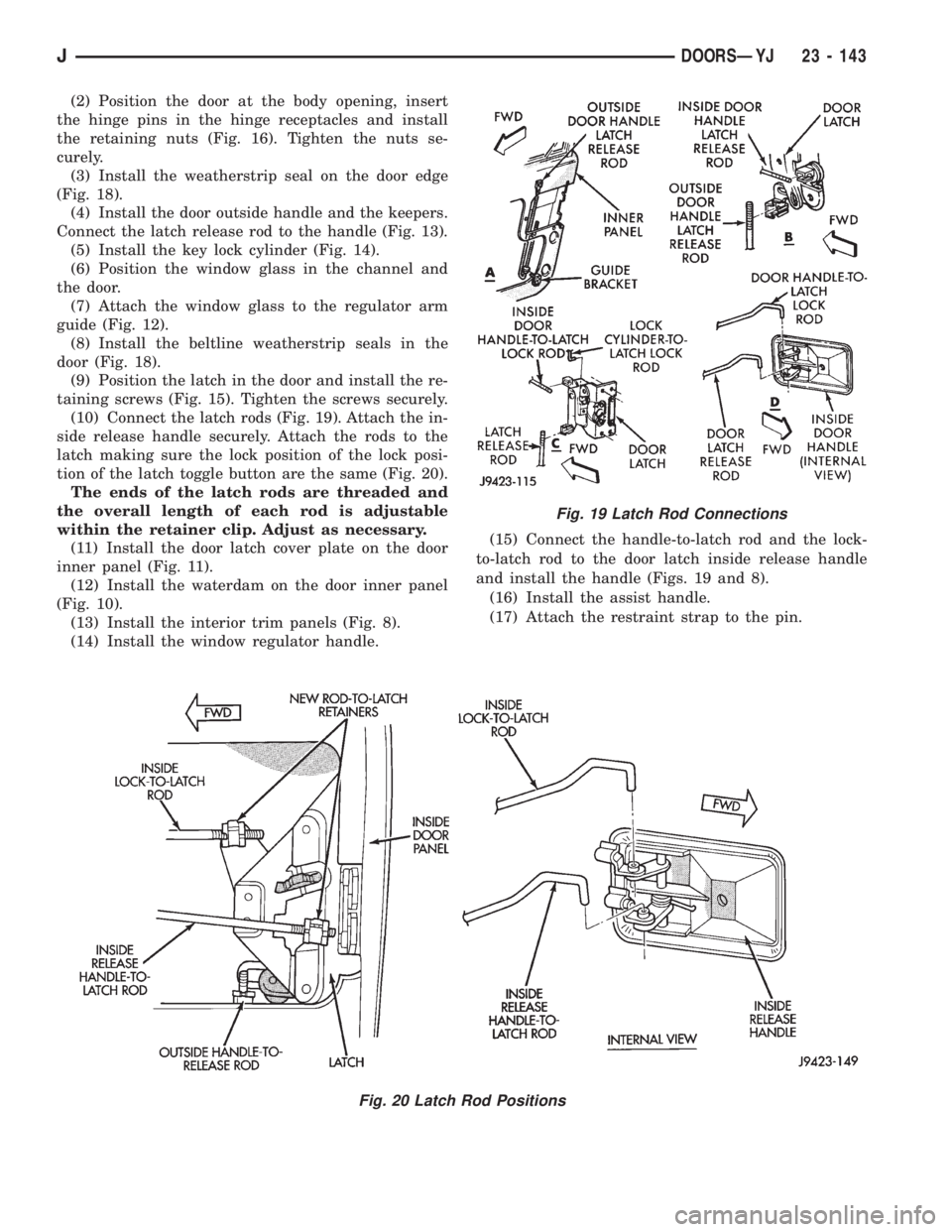

(10) Connect the latch rods (Fig. 19). Attach the in-

side release handle securely. Attach the rods to the

latch making sure the lock position of the lock posi-

tion of the latch toggle button are the same (Fig. 20).

The ends of the latch rods are threaded and

the overall length of each rod is adjustable

within the retainer clip. Adjust as necessary.

(11) Install the door latch cover plate on the door

inner panel (Fig. 11).

(12) Install the waterdam on the door inner panel

(Fig. 10).

(13) Install the interior trim panels (Fig. 8).

(14) Install the window regulator handle.(15) Connect the handle-to-latch rod and the lock-

to-latch rod to the door latch inside release handle

and install the handle (Figs. 19 and 8).

(16) Install the assist handle.

(17) Attach the restraint strap to the pin.

Fig. 19 Latch Rod Connections

Fig. 20 Latch Rod Positions

JDOORSÐYJ 23 - 143

Page 2069 of 2158

INTERIOR COMPONENTS

INDEX

page page

Add-A-TrunkÐYJ........................ 157

Bucket SeatsÐYJ........................ 153

CarpetÐYJ............................. 156

Floor ConsolesÐYJ...................... 155

Front Shoulder BeltsÐYJ.................. 154

Glove BoxÐYJ.......................... 152

Instrument Cluster and Gauge HousingsÐYJ.... 151Instrument Cluster BezelÐYJ............... 151

Instrument Panel ComponentsÐYJ........... 152

Instrument PanelÐYJ..................... 151

Rear Bench SeatÐYJ..................... 153

Rear Shoulder BeltsÐYJ................... 154

SeatsÐYJ............................. 153

SunvisorsÐYJ.......................... 155

INSTRUMENT PANELÐYJ

The instrument panel is constructed of sheet metal

and is attached to cowl panel with screws. The in-

strument panel and defroster grille pad is attached

to the instrument panel with screws.

INSTRUMENT CLUSTER AND GAUGE HOUSINGSÐ

YJ

REMOVAL

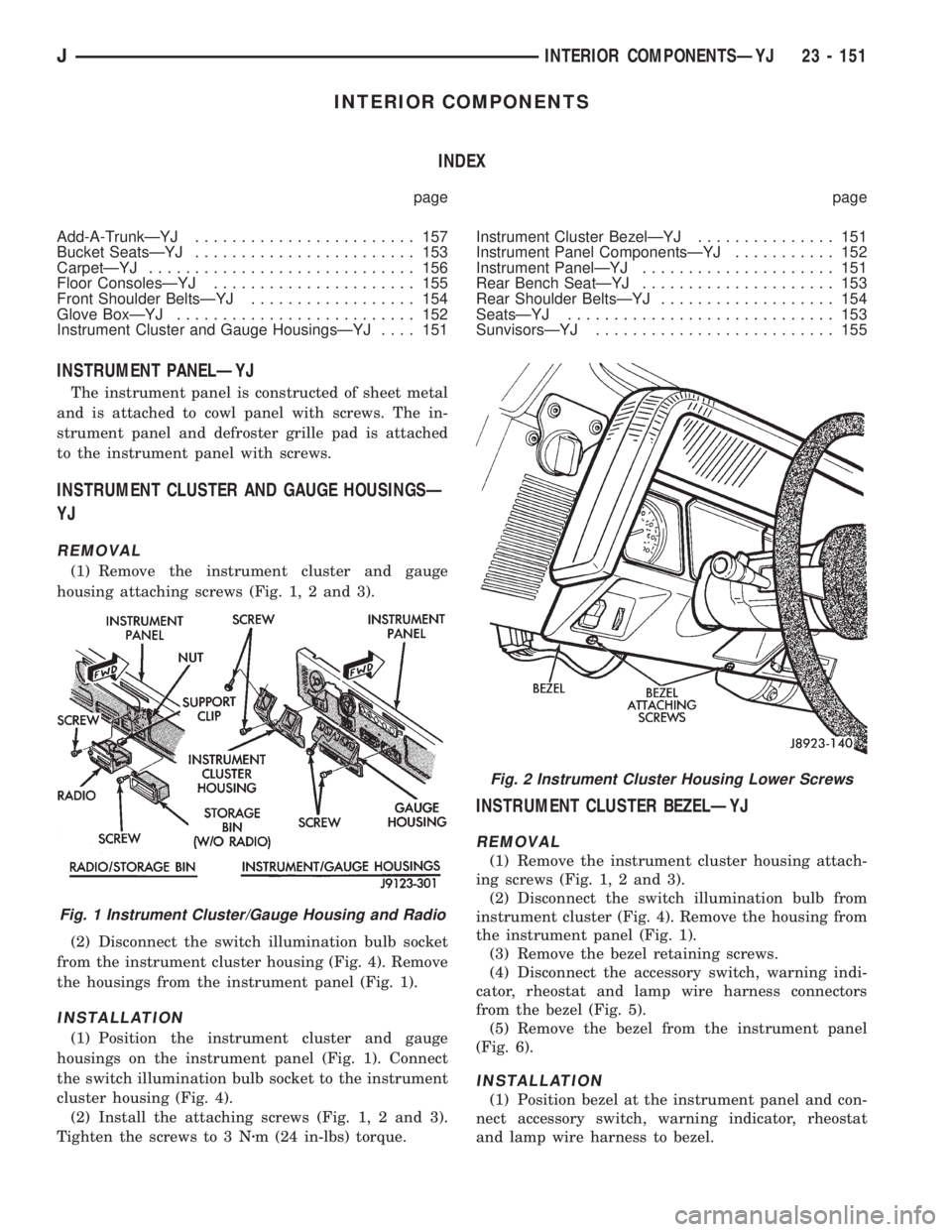

(1) Remove the instrument cluster and gauge

housing attaching screws (Fig. 1, 2 and 3).

(2) Disconnect the switch illumination bulb socket

from the instrument cluster housing (Fig. 4). Remove

the housings from the instrument panel (Fig. 1).

INSTALLATION

(1) Position the instrument cluster and gauge

housings on the instrument panel (Fig. 1). Connect

the switch illumination bulb socket to the instrument

cluster housing (Fig. 4).

(2) Install the attaching screws (Fig. 1, 2 and 3).

Tighten the screws to 3 Nzm (24 in-lbs) torque.

INSTRUMENT CLUSTER BEZELÐYJ

REMOVAL

(1) Remove the instrument cluster housing attach-

ing screws (Fig. 1, 2 and 3).

(2) Disconnect the switch illumination bulb from

instrument cluster (Fig. 4). Remove the housing from

the instrument panel (Fig. 1).

(3) Remove the bezel retaining screws.

(4) Disconnect the accessory switch, warning indi-

cator, rheostat and lamp wire harness connectors

from the bezel (Fig. 5).

(5) Remove the bezel from the instrument panel

(Fig. 6).

INSTALLATION

(1) Position bezel at the instrument panel and con-

nect accessory switch, warning indicator, rheostat

and lamp wire harness to bezel.

Fig. 1 Instrument Cluster/Gauge Housing and Radio

Fig. 2 Instrument Cluster Housing Lower Screws

JINTERIOR COMPONENTSÐYJ 23 - 151