belt JEEP YJ 1995 Service And Owners Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1561 of 2158

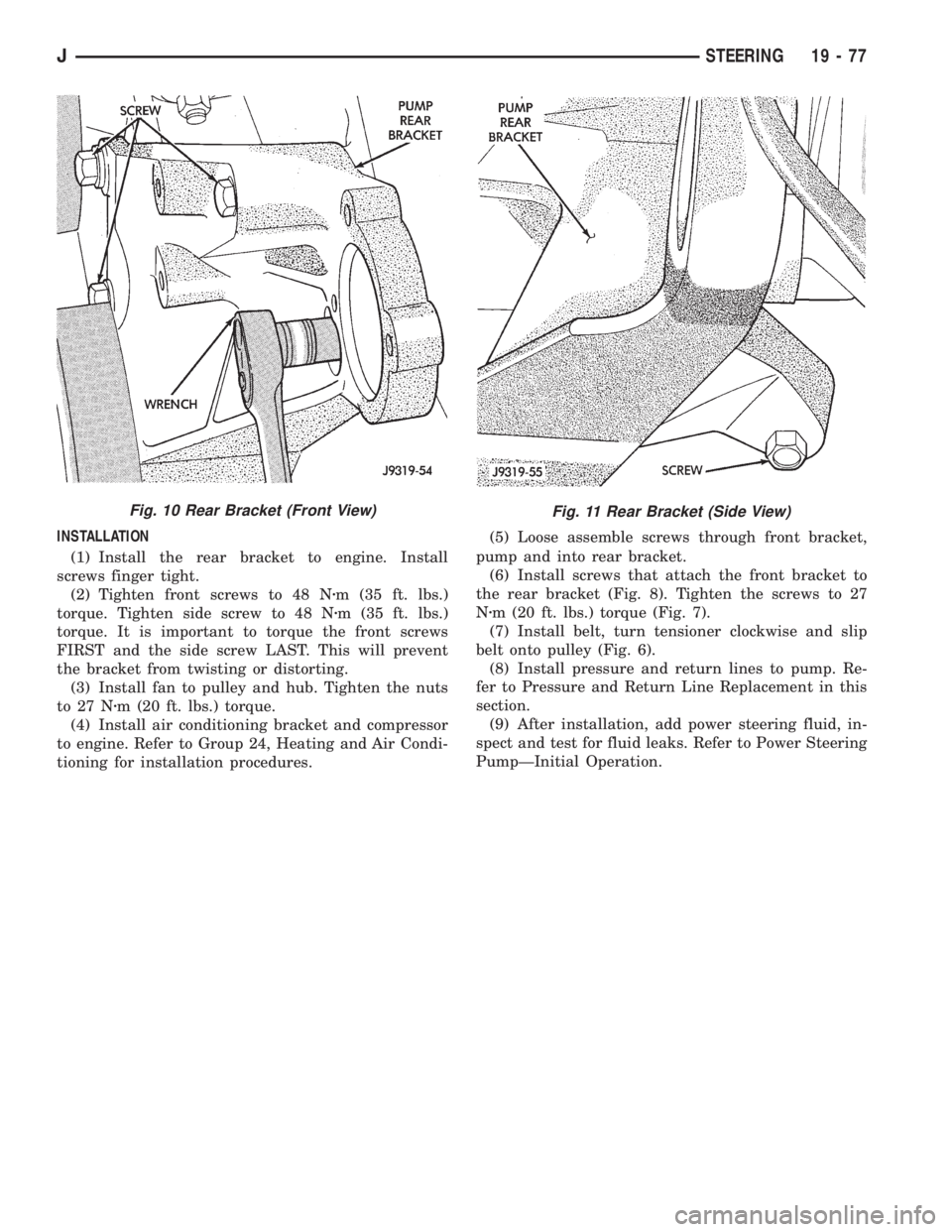

INSTALLATION

(1) Install the rear bracket to engine. Install

screws finger tight.

(2) Tighten front screws to 48 Nzm (35 ft. lbs.)

torque. Tighten side screw to 48 Nzm (35 ft. lbs.)

torque. It is important to torque the front screws

FIRST and the side screw LAST. This will prevent

the bracket from twisting or distorting.

(3) Install fan to pulley and hub. Tighten the nuts

to 27 Nzm (20 ft. lbs.) torque.

(4) Install air conditioning bracket and compressor

to engine. Refer to Group 24, Heating and Air Condi-

tioning for installation procedures.(5) Loose assemble screws through front bracket,

pump and into rear bracket.

(6) Install screws that attach the front bracket to

the rear bracket (Fig. 8). Tighten the screws to 27

Nzm (20 ft. lbs.) torque (Fig. 7).

(7) Install belt, turn tensioner clockwise and slip

belt onto pulley (Fig. 6).

(8) Install pressure and return lines to pump. Re-

fer to Pressure and Return Line Replacement in this

section.

(9) After installation, add power steering fluid, in-

spect and test for fluid leaks. Refer to Power Steering

PumpÐInitial Operation.

Fig. 11 Rear Bracket (Side View)Fig. 10 Rear Bracket (Front View)

JSTEERING 19 - 77

Page 1917 of 2158

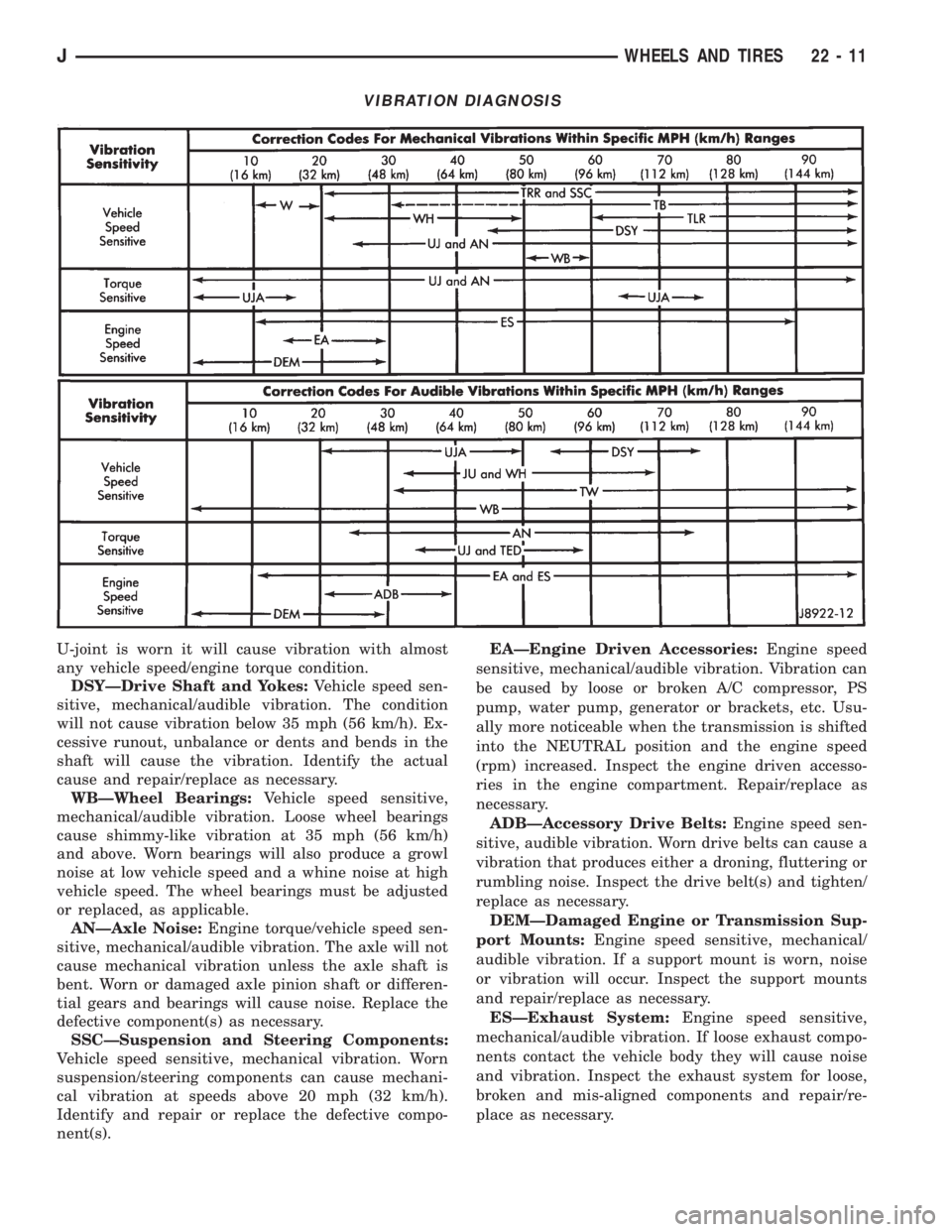

U-joint is worn it will cause vibration with almost

any vehicle speed/engine torque condition.

DSYÐDrive Shaft and Yokes:Vehicle speed sen-

sitive, mechanical/audible vibration. The condition

will not cause vibration below 35 mph (56 km/h). Ex-

cessive runout, unbalance or dents and bends in the

shaft will cause the vibration. Identify the actual

cause and repair/replace as necessary.

WBÐWheel Bearings:Vehicle speed sensitive,

mechanical/audible vibration. Loose wheel bearings

cause shimmy-like vibration at 35 mph (56 km/h)

and above. Worn bearings will also produce a growl

noise at low vehicle speed and a whine noise at high

vehicle speed. The wheel bearings must be adjusted

or replaced, as applicable.

ANÐAxle Noise:Engine torque/vehicle speed sen-

sitive, mechanical/audible vibration. The axle will not

cause mechanical vibration unless the axle shaft is

bent. Worn or damaged axle pinion shaft or differen-

tial gears and bearings will cause noise. Replace the

defective component(s) as necessary.

SSCÐSuspension and Steering Components:

Vehicle speed sensitive, mechanical vibration. Worn

suspension/steering components can cause mechani-

cal vibration at speeds above 20 mph (32 km/h).

Identify and repair or replace the defective compo-

nent(s).EAÐEngine Driven Accessories:Engine speed

sensitive, mechanical/audible vibration. Vibration can

be caused by loose or broken A/C compressor, PS

pump, water pump, generator or brackets, etc. Usu-

ally more noticeable when the transmission is shifted

into the NEUTRAL position and the engine speed

(rpm) increased. Inspect the engine driven accesso-

ries in the engine compartment. Repair/replace as

necessary.

ADBÐAccessory Drive Belts:Engine speed sen-

sitive, audible vibration. Worn drive belts can cause a

vibration that produces either a droning, fluttering or

rumbling noise. Inspect the drive belt(s) and tighten/

replace as necessary.

DEMÐDamaged Engine or Transmission Sup-

port Mounts:Engine speed sensitive, mechanical/

audible vibration. If a support mount is worn, noise

or vibration will occur. Inspect the support mounts

and repair/replace as necessary.

ESÐExhaust System:Engine speed sensitive,

mechanical/audible vibration. If loose exhaust compo-

nents contact the vehicle body they will cause noise

and vibration. Inspect the exhaust system for loose,

broken and mis-aligned components and repair/re-

place as necessary.

VIBRATION DIAGNOSIS

JWHEELS AND TIRES 22 - 11

Page 1961 of 2158

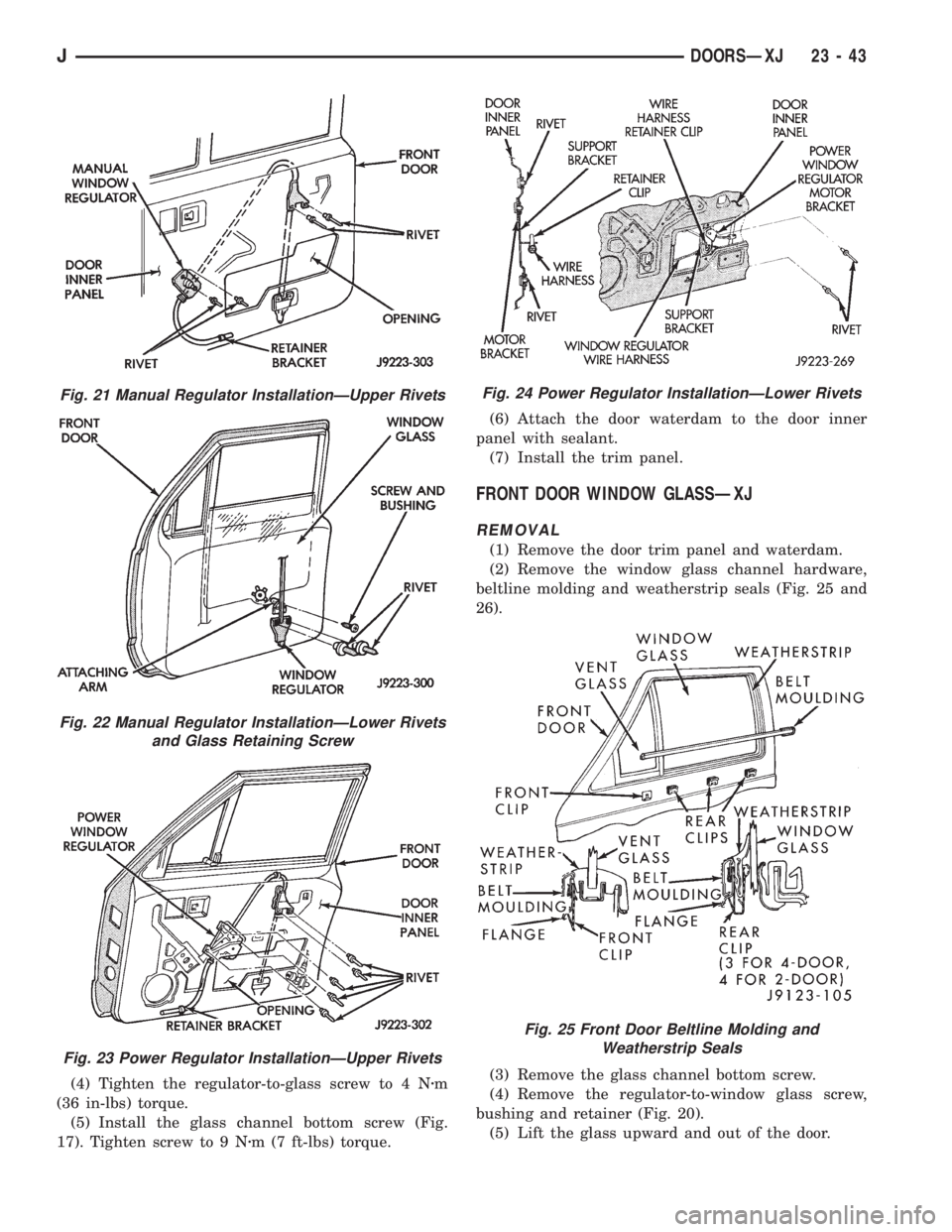

(4) Tighten the regulator-to-glass screw to 4 Nzm

(36 in-lbs) torque.

(5) Install the glass channel bottom screw (Fig.

17). Tighten screw to 9 Nzm (7 ft-lbs) torque.(6) Attach the door waterdam to the door inner

panel with sealant.

(7) Install the trim panel.

FRONT DOOR WINDOW GLASSÐXJ

REMOVAL

(1) Remove the door trim panel and waterdam.

(2) Remove the window glass channel hardware,

beltline molding and weatherstrip seals (Fig. 25 and

26).

(3) Remove the glass channel bottom screw.

(4) Remove the regulator-to-window glass screw,

bushing and retainer (Fig. 20).

(5) Lift the glass upward and out of the door.

Fig. 21 Manual Regulator InstallationÐUpper Rivets

Fig. 22 Manual Regulator InstallationÐLower Rivets

and Glass Retaining Screw

Fig. 23 Power Regulator InstallationÐUpper Rivets

Fig. 24 Power Regulator InstallationÐLower Rivets

Fig. 25 Front Door Beltline Molding and

Weatherstrip Seals

JDOORSÐXJ 23 - 43

Page 1962 of 2158

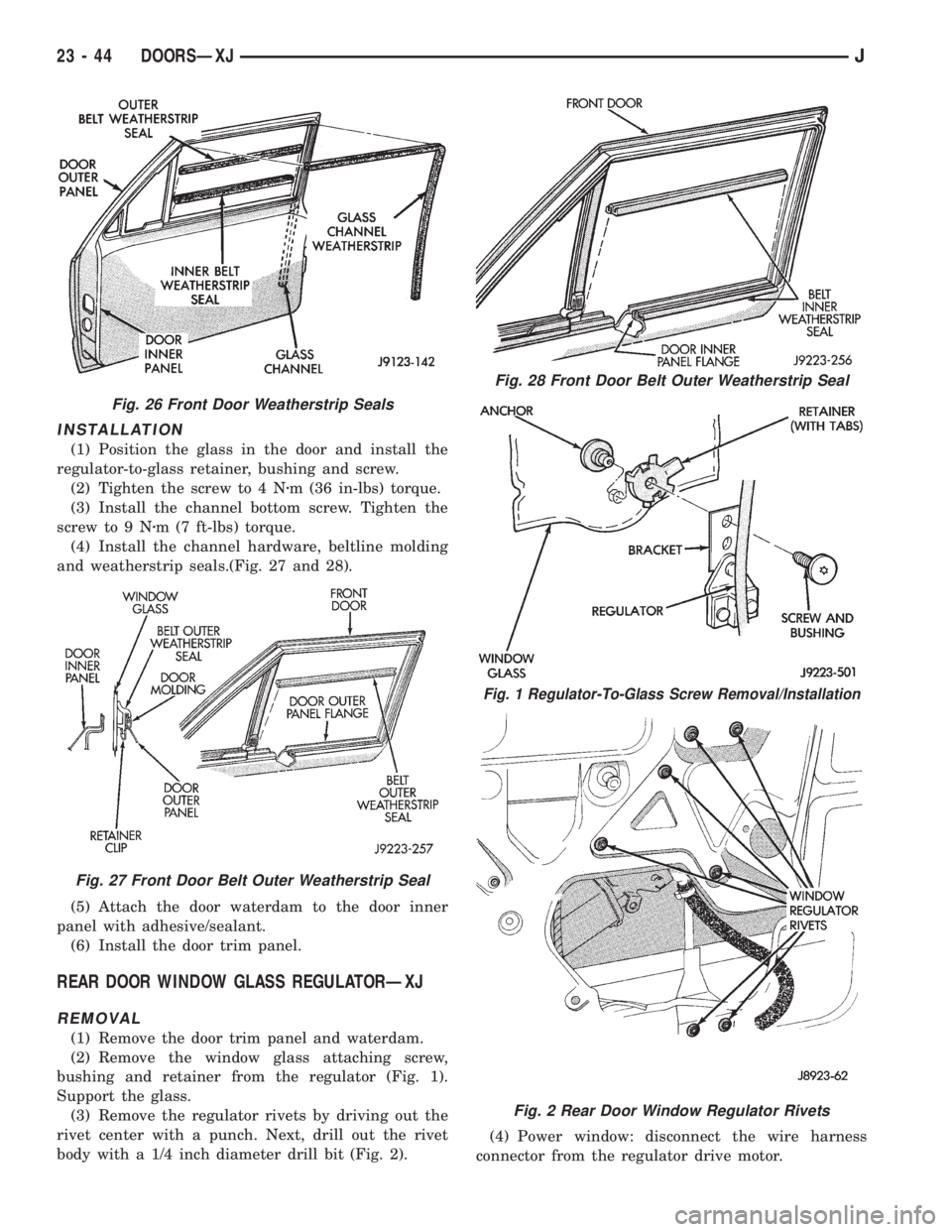

INSTALLATION

(1) Position the glass in the door and install the

regulator-to-glass retainer, bushing and screw.

(2) Tighten the screw to 4 Nzm (36 in-lbs) torque.

(3) Install the channel bottom screw. Tighten the

screw to 9 Nzm (7 ft-lbs) torque.

(4) Install the channel hardware, beltline molding

and weatherstrip seals.(Fig. 27 and 28).

(5) Attach the door waterdam to the door inner

panel with adhesive/sealant.

(6) Install the door trim panel.

REAR DOOR WINDOW GLASS REGULATORÐXJ

REMOVAL

(1) Remove the door trim panel and waterdam.

(2) Remove the window glass attaching screw,

bushing and retainer from the regulator (Fig. 1).

Support the glass.

(3) Remove the regulator rivets by driving out the

rivet center with a punch. Next, drill out the rivet

body with a 1/4 inch diameter drill bit (Fig. 2).(4) Power window: disconnect the wire harness

connector from the regulator drive motor.

Fig. 26 Front Door Weatherstrip Seals

Fig. 27 Front Door Belt Outer Weatherstrip Seal

Fig. 28 Front Door Belt Outer Weatherstrip Seal

Fig. 1 Regulator-To-Glass Screw Removal/Installation

Fig. 2 Rear Door Window Regulator Rivets

23 - 44 DOORSÐXJJ

Page 1963 of 2158

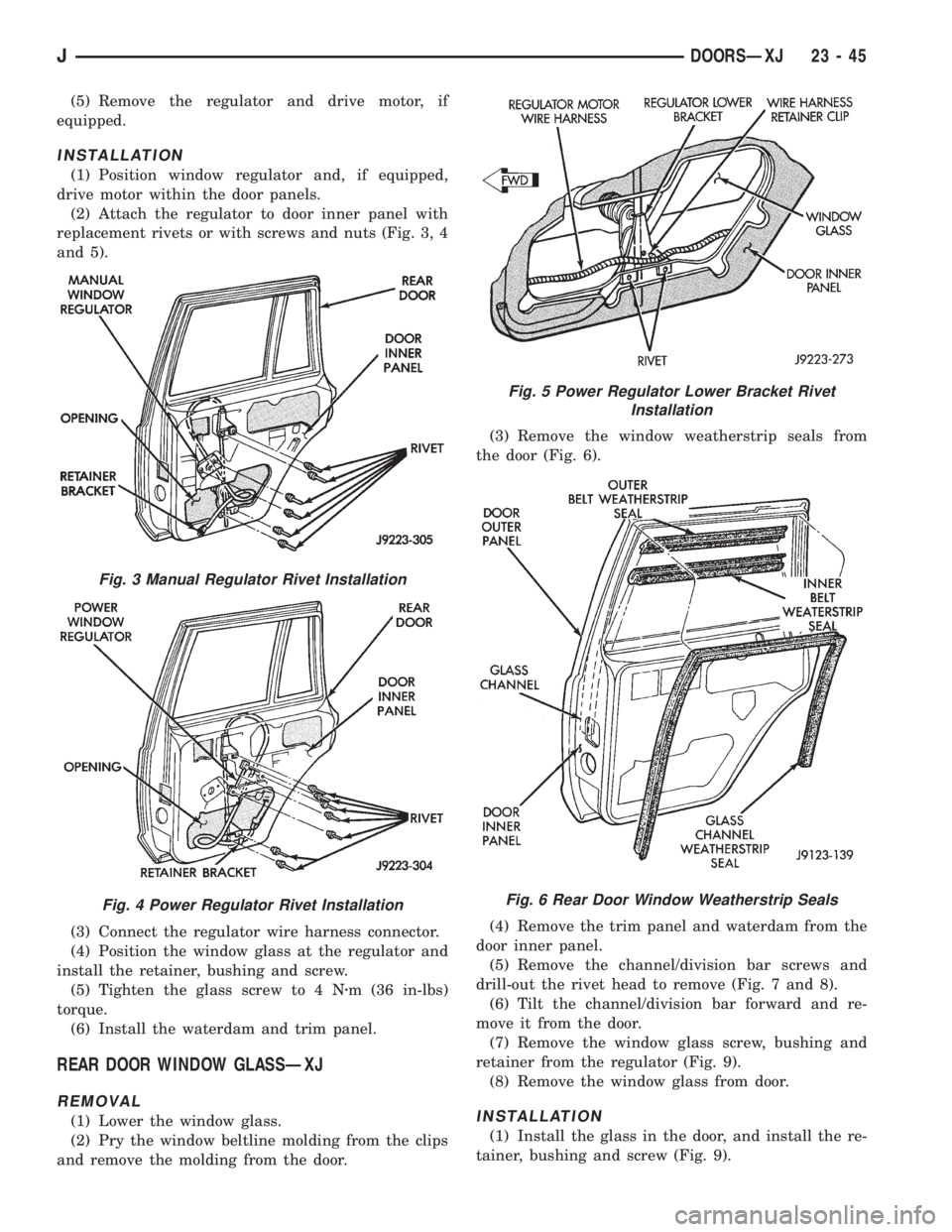

(5) Remove the regulator and drive motor, if

equipped.

INSTALLATION

(1) Position window regulator and, if equipped,

drive motor within the door panels.

(2) Attach the regulator to door inner panel with

replacement rivets or with screws and nuts (Fig. 3, 4

and 5).

(3) Connect the regulator wire harness connector.

(4) Position the window glass at the regulator and

install the retainer, bushing and screw.

(5) Tighten the glass screw to 4 Nzm (36 in-lbs)

torque.

(6) Install the waterdam and trim panel.

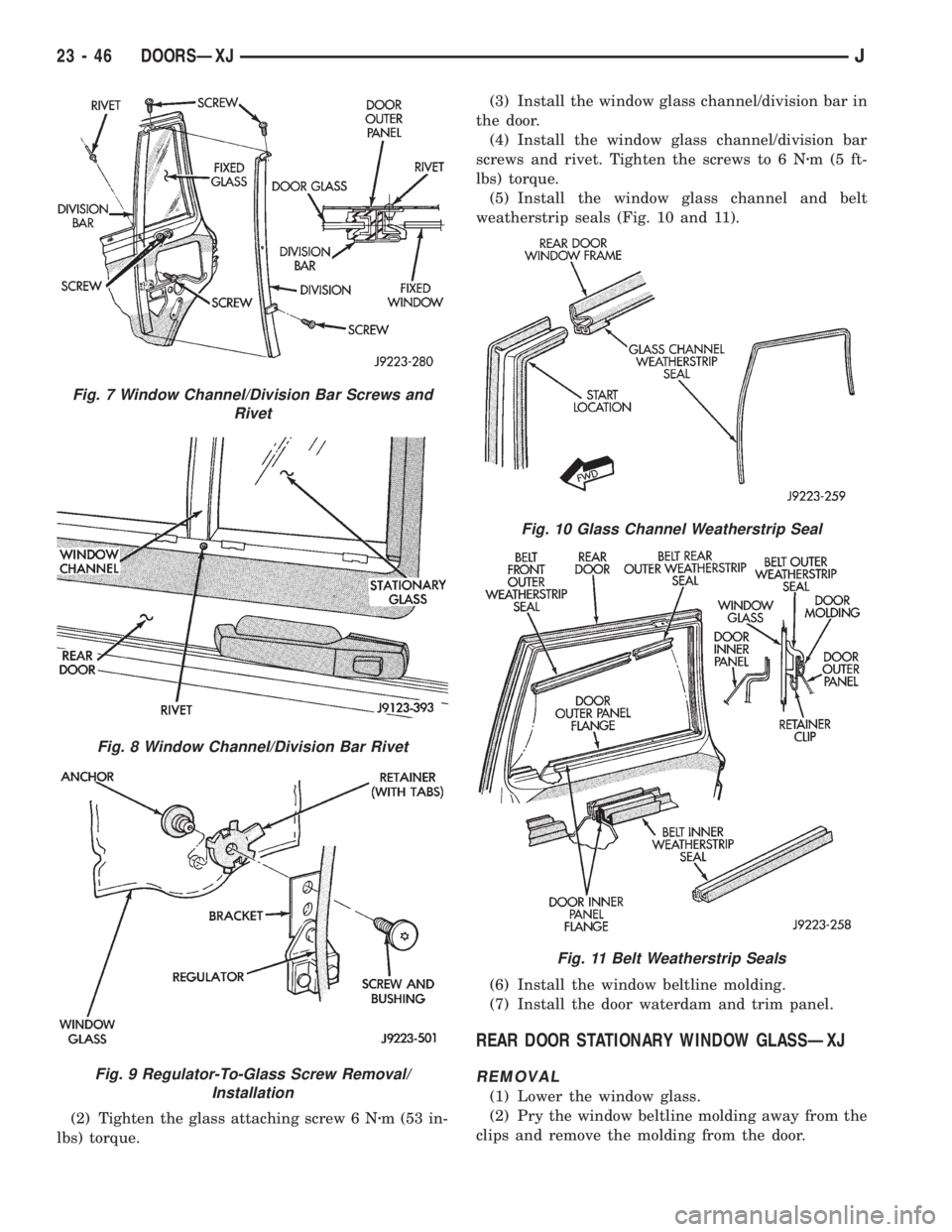

REAR DOOR WINDOW GLASSÐXJ

REMOVAL

(1) Lower the window glass.

(2) Pry the window beltline molding from the clips

and remove the molding from the door.(3) Remove the window weatherstrip seals from

the door (Fig. 6).

(4) Remove the trim panel and waterdam from the

door inner panel.

(5) Remove the channel/division bar screws and

drill-out the rivet head to remove (Fig. 7 and 8).

(6) Tilt the channel/division bar forward and re-

move it from the door.

(7) Remove the window glass screw, bushing and

retainer from the regulator (Fig. 9).

(8) Remove the window glass from door.INSTALLATION

(1) Install the glass in the door, and install the re-

tainer, bushing and screw (Fig. 9).

Fig. 3 Manual Regulator Rivet Installation

Fig. 4 Power Regulator Rivet Installation

Fig. 5 Power Regulator Lower Bracket Rivet

Installation

Fig. 6 Rear Door Window Weatherstrip Seals

JDOORSÐXJ 23 - 45

Page 1964 of 2158

(2) Tighten the glass attaching screw 6 Nzm (53 in-

lbs) torque.(3) Install the window glass channel/division bar in

the door.

(4) Install the window glass channel/division bar

screws and rivet. Tighten the screws to 6 Nzm(5ft-

lbs) torque.

(5) Install the window glass channel and belt

weatherstrip seals (Fig. 10 and 11).

(6) Install the window beltline molding.

(7) Install the door waterdam and trim panel.

REAR DOOR STATIONARY WINDOW GLASSÐXJ

REMOVAL

(1) Lower the window glass.

(2) Pry the window beltline molding away from the

clips and remove the molding from the door.

Fig. 7 Window Channel/Division Bar Screws and

Rivet

Fig. 8 Window Channel/Division Bar Rivet

Fig. 9 Regulator-To-Glass Screw Removal/

Installation

Fig. 10 Glass Channel Weatherstrip Seal

Fig. 11 Belt Weatherstrip Seals

23 - 46 DOORSÐXJJ

Page 1965 of 2158

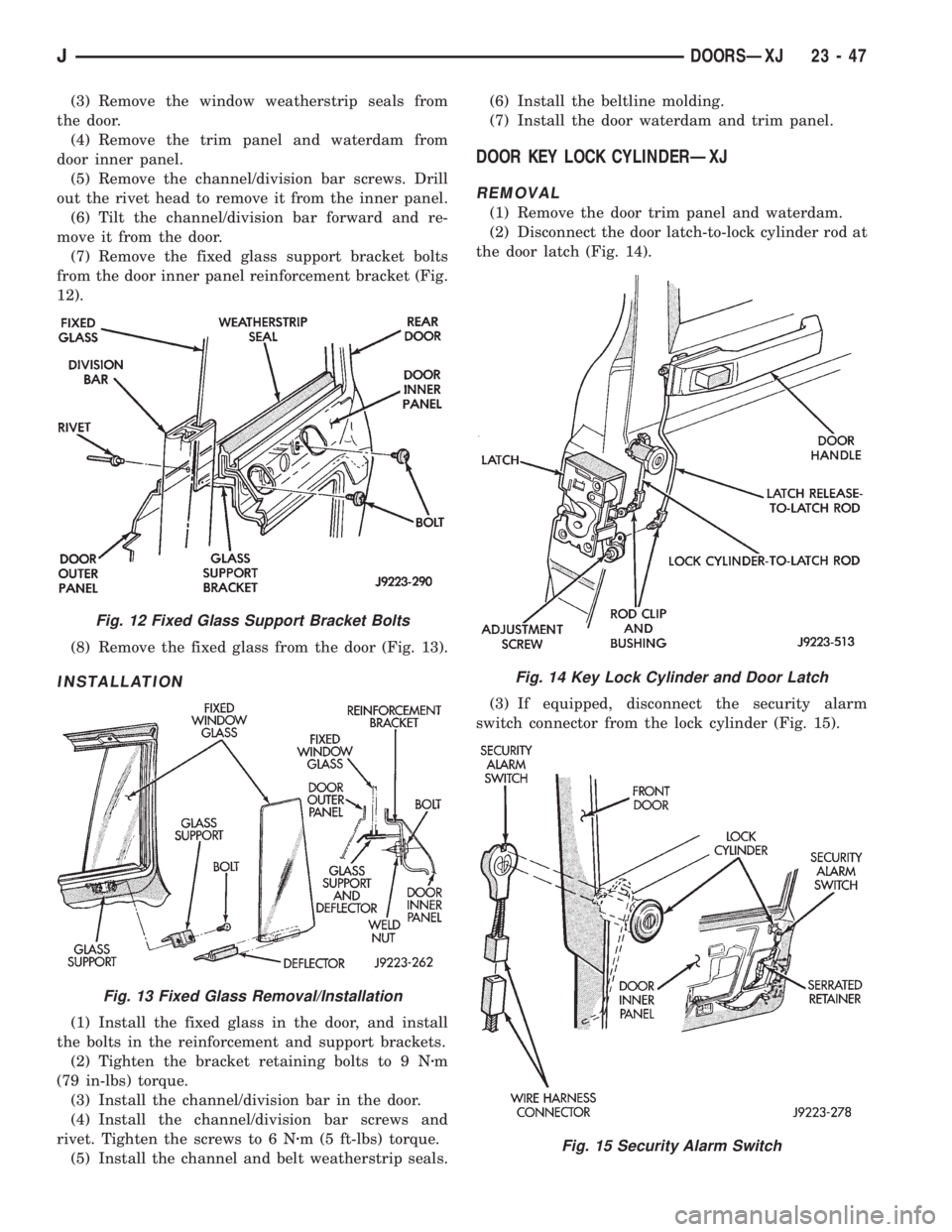

(3) Remove the window weatherstrip seals from

the door.

(4) Remove the trim panel and waterdam from

door inner panel.

(5) Remove the channel/division bar screws. Drill

out the rivet head to remove it from the inner panel.

(6) Tilt the channel/division bar forward and re-

move it from the door.

(7) Remove the fixed glass support bracket bolts

from the door inner panel reinforcement bracket (Fig.

12).

(8) Remove the fixed glass from the door (Fig. 13).

INSTALLATION

(1) Install the fixed glass in the door, and install

the bolts in the reinforcement and support brackets.

(2) Tighten the bracket retaining bolts to 9 Nzm

(79 in-lbs) torque.

(3) Install the channel/division bar in the door.

(4) Install the channel/division bar screws and

rivet. Tighten the screws to 6 Nzm (5 ft-lbs) torque.

(5) Install the channel and belt weatherstrip seals.(6) Install the beltline molding.

(7) Install the door waterdam and trim panel.

DOOR KEY LOCK CYLINDERÐXJ

REMOVAL

(1) Remove the door trim panel and waterdam.

(2) Disconnect the door latch-to-lock cylinder rod at

the door latch (Fig. 14).

(3) If equipped, disconnect the security alarm

switch connector from the lock cylinder (Fig. 15).

Fig. 12 Fixed Glass Support Bracket Bolts

Fig. 13 Fixed Glass Removal/Installation

Fig. 14 Key Lock Cylinder and Door Latch

Fig. 15 Security Alarm Switch

JDOORSÐXJ 23 - 47

Page 1975 of 2158

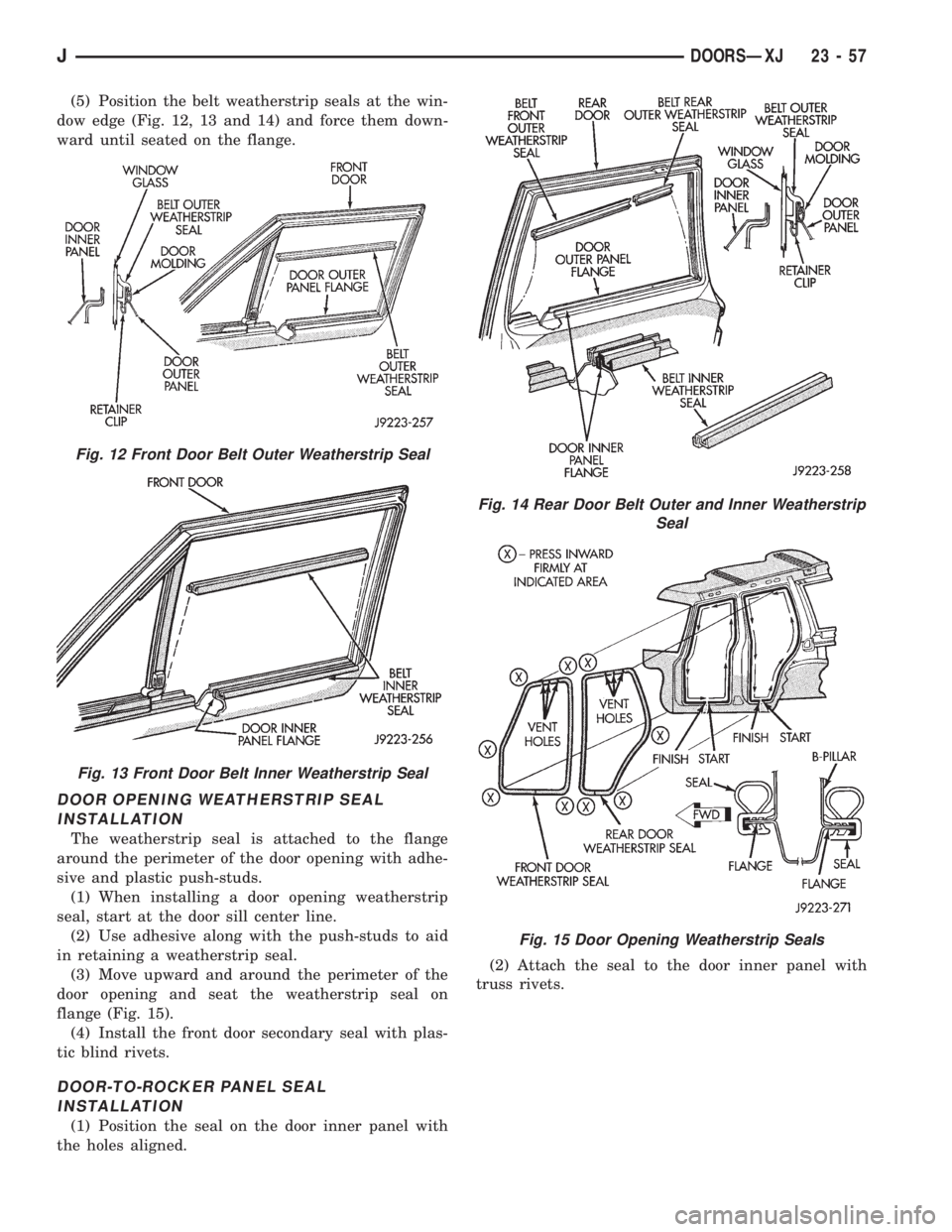

(5) Position the belt weatherstrip seals at the win-

dow edge (Fig. 12, 13 and 14) and force them down-

ward until seated on the flange.

DOOR OPENING WEATHERSTRIP SEAL

INSTALLATION

The weatherstrip seal is attached to the flange

around the perimeter of the door opening with adhe-

sive and plastic push-studs.

(1) When installing a door opening weatherstrip

seal, start at the door sill center line.

(2) Use adhesive along with the push-studs to aid

in retaining a weatherstrip seal.

(3) Move upward and around the perimeter of the

door opening and seat the weatherstrip seal on

flange (Fig. 15).

(4) Install the front door secondary seal with plas-

tic blind rivets.

DOOR-TO-ROCKER PANEL SEAL

INSTALLATION

(1) Position the seal on the door inner panel with

the holes aligned.(2) Attach the seal to the door inner panel with

truss rivets.

Fig. 12 Front Door Belt Outer Weatherstrip Seal

Fig. 13 Front Door Belt Inner Weatherstrip Seal

Fig. 14 Rear Door Belt Outer and Inner Weatherstrip

Seal

Fig. 15 Door Opening Weatherstrip Seals

JDOORSÐXJ 23 - 57

Page 1990 of 2158

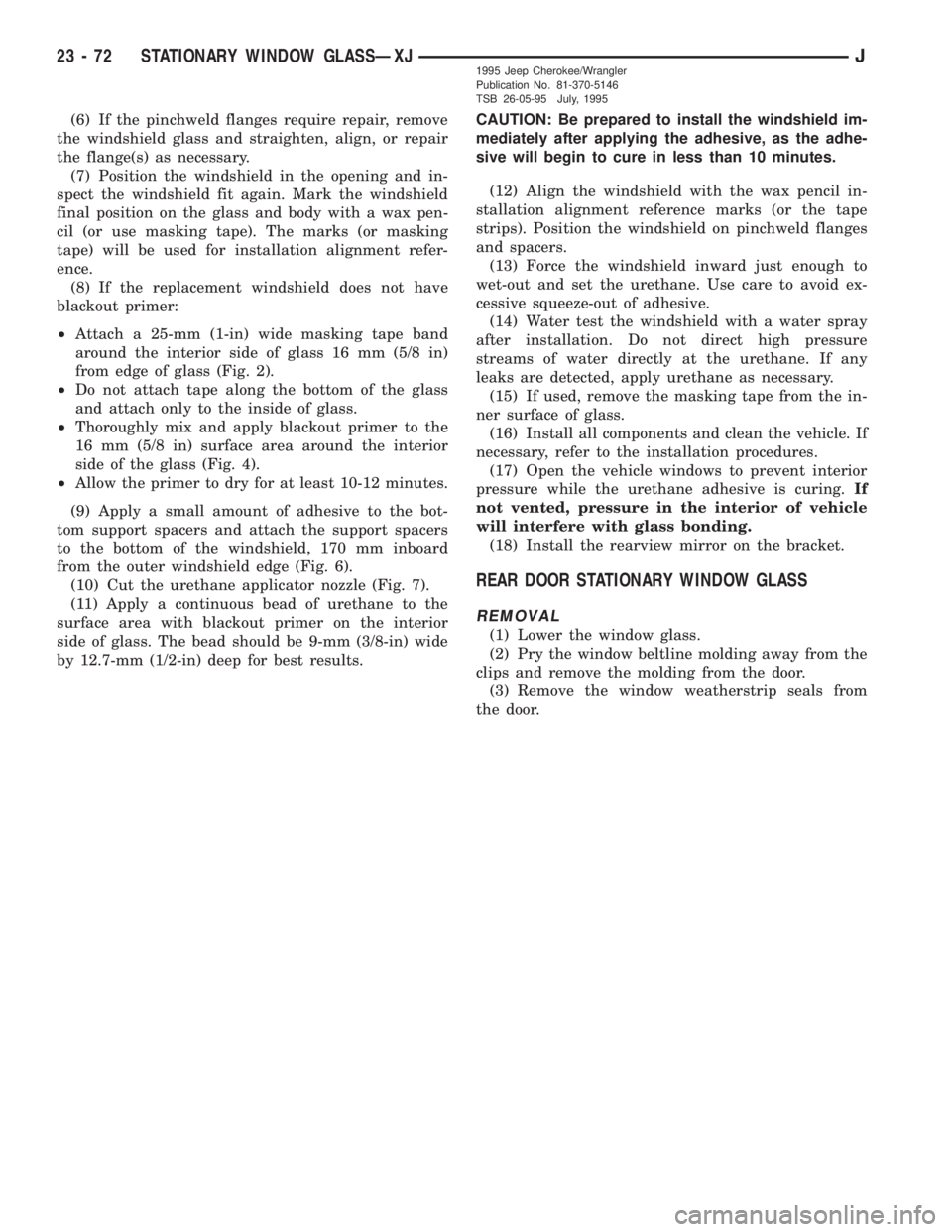

(6) If the pinchweld flanges require repair, remove

the windshield glass and straighten, align, or repair

the flange(s) as necessary.

(7) Position the windshield in the opening and in-

spect the windshield fit again. Mark the windshield

final position on the glass and body with a wax pen-

cil (or use masking tape). The marks (or masking

tape) will be used for installation alignment refer-

ence.

(8) If the replacement windshield does not have

blackout primer:

²Attach a 25-mm (1-in) wide masking tape band

around the interior side of glass 16 mm (5/8 in)

from edge of glass (Fig. 2).

²Do not attach tape along the bottom of the glass

and attach only to the inside of glass.

²Thoroughly mix and apply blackout primer to the

16 mm (5/8 in) surface area around the interior

side of the glass (Fig. 4).

²Allow the primer to dry for at least 10-12 minutes.

(9) Apply a small amount of adhesive to the bot-

tom support spacers and attach the support spacers

to the bottom of the windshield, 170 mm inboard

from the outer windshield edge (Fig. 6).

(10) Cut the urethane applicator nozzle (Fig. 7).

(11) Apply a continuous bead of urethane to the

surface area with blackout primer on the interior

side of glass. The bead should be 9-mm (3/8-in) wide

by 12.7-mm (1/2-in) deep for best results.CAUTION: Be prepared to install the windshield im-

mediately after applying the adhesive, as the adhe-

sive will begin to cure in less than 10 minutes.

(12) Align the windshield with the wax pencil in-

stallation alignment reference marks (or the tape

strips). Position the windshield on pinchweld flanges

and spacers.

(13) Force the windshield inward just enough to

wet-out and set the urethane. Use care to avoid ex-

cessive squeeze-out of adhesive.

(14) Water test the windshield with a water spray

after installation. Do not direct high pressure

streams of water directly at the urethane. If any

leaks are detected, apply urethane as necessary.

(15) If used, remove the masking tape from the in-

ner surface of glass.

(16) Install all components and clean the vehicle. If

necessary, refer to the installation procedures.

(17) Open the vehicle windows to prevent interior

pressure while the urethane adhesive is curing.If

not vented, pressure in the interior of vehicle

will interfere with glass bonding.

(18) Install the rearview mirror on the bracket.

REAR DOOR STATIONARY WINDOW GLASS

REMOVAL

(1) Lower the window glass.

(2) Pry the window beltline molding away from the

clips and remove the molding from the door.

(3) Remove the window weatherstrip seals from

the door.

23 - 72 STATIONARY WINDOW GLASSÐXJJ1995 Jeep Cherokee/Wrangler

Publication No. 81-370-5146

TSB 26-05-95 July, 1995

Page 1998 of 2158

INTERIOR COMPONENTS

INDEX

page page

Assist HandleÐXJ........................ 89

B/C-Pillar and Liftgate Pillar Trim CoversÐXJ.... 88

Bucket Seat Cushion and CoverÐXJ........... 81

Bucket Seat PlatformÐXJ................... 82

Bucket Seatback Cover and FrameÐXJ........ 81

Cargo BarrierÐXJ........................ 101

Cargo LampÐXJ......................... 94

Carpets and Floor MatsÐXJ................. 99

Dome LampÐXJ......................... 93

Front Bucket SeatsÐXJ.................... 81

Front Carpet/MatÐXJ...................... 99

Front Inner Scuff Plate/Cowl Side Trim PanelÐXJ . 86

Front Shoulder Belt/BuckleÐXJ............... 90

Full Floor ConsoleÐXJ..................... 95

HeadlinerÐXJ............................ 92

I/P Ash Receiver Tray LampÐXJ.............. 80

Instrument Cluster BezelÐXJ................ 80

Interior Trim Panels and Scuff PlatesÐXJ....... 84

Jack StorageÐXJ......................... 97

Keyless Entry ReceiverÐXJ................. 93Mini-Console with Floor ShiftÐXJ............. 94

Mini-Floor ConsoleÐXJ..................... 94

Outer Scuff PlatesÐXJ..................... 89

Overhead ConsoleÐXJ..................... 93

Parking Brake Handle CoverÐXJ............. 94

Quarter and Wheelhouse Trim PanelsÐXJ...... 87

Quarter Trim Panel ExtensionÐXJ............. 87

Rear Carpet/MatÐXJ..................... 100

Rear Seat Cushion CoverÐXJ............... 82

Rear Seat CushionÐXJ.................... 82

Rear Seatback CoverÐXJ................... 84

Rear Seatback Latch Striker and BumperÐXJ.... 84

Rear SeatbackÐXJ........................ 83

Rear Shoulder/Lap Belt/BuckleÐXJ............ 91

Sound BarÐXJ........................... 94

Spare Tire/Wheel Holddown and Floor

BracketsÐXJ........................... 98

SunvisorsÐXJ........................... 93

Windshield Side MoldingÐXJ................ 86

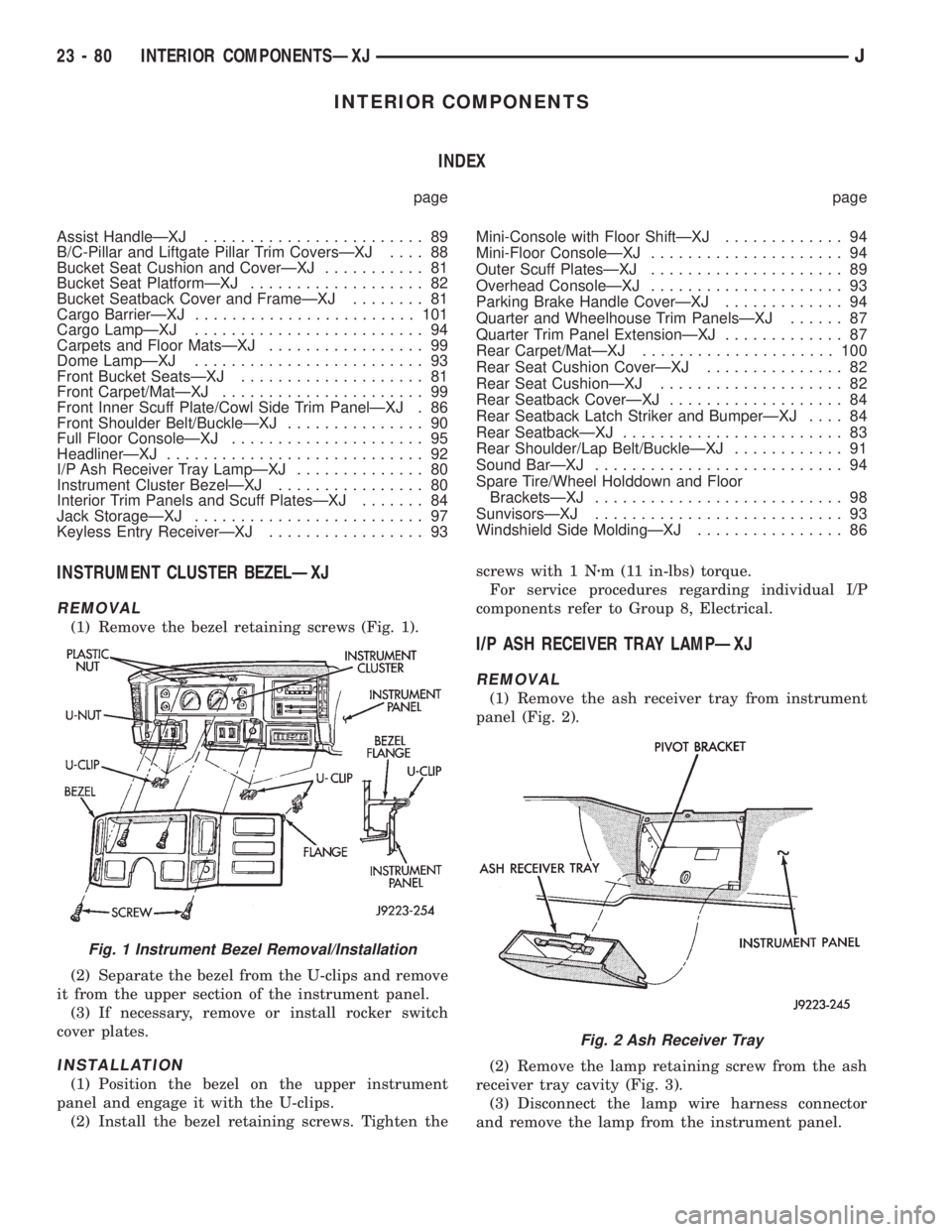

INSTRUMENT CLUSTER BEZELÐXJ

REMOVAL

(1) Remove the bezel retaining screws (Fig. 1).

(2) Separate the bezel from the U-clips and remove

it from the upper section of the instrument panel.

(3) If necessary, remove or install rocker switch

cover plates.

INSTALLATION

(1) Position the bezel on the upper instrument

panel and engage it with the U-clips.

(2) Install the bezel retaining screws. Tighten thescrews with 1 Nzm (11 in-lbs) torque.

For service procedures regarding individual I/P

components refer to Group 8, Electrical.

I/P ASH RECEIVER TRAY LAMPÐXJ

REMOVAL

(1) Remove the ash receiver tray from instrument

panel (Fig. 2).

(2) Remove the lamp retaining screw from the ash

receiver tray cavity (Fig. 3).

(3) Disconnect the lamp wire harness connector

and remove the lamp from the instrument panel.

Fig. 1 Instrument Bezel Removal/Installation

Fig. 2 Ash Receiver Tray

23 - 80 INTERIOR COMPONENTSÐXJJ