stop start JEEP YJ 1995 Service And User Guide

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 336 of 2158

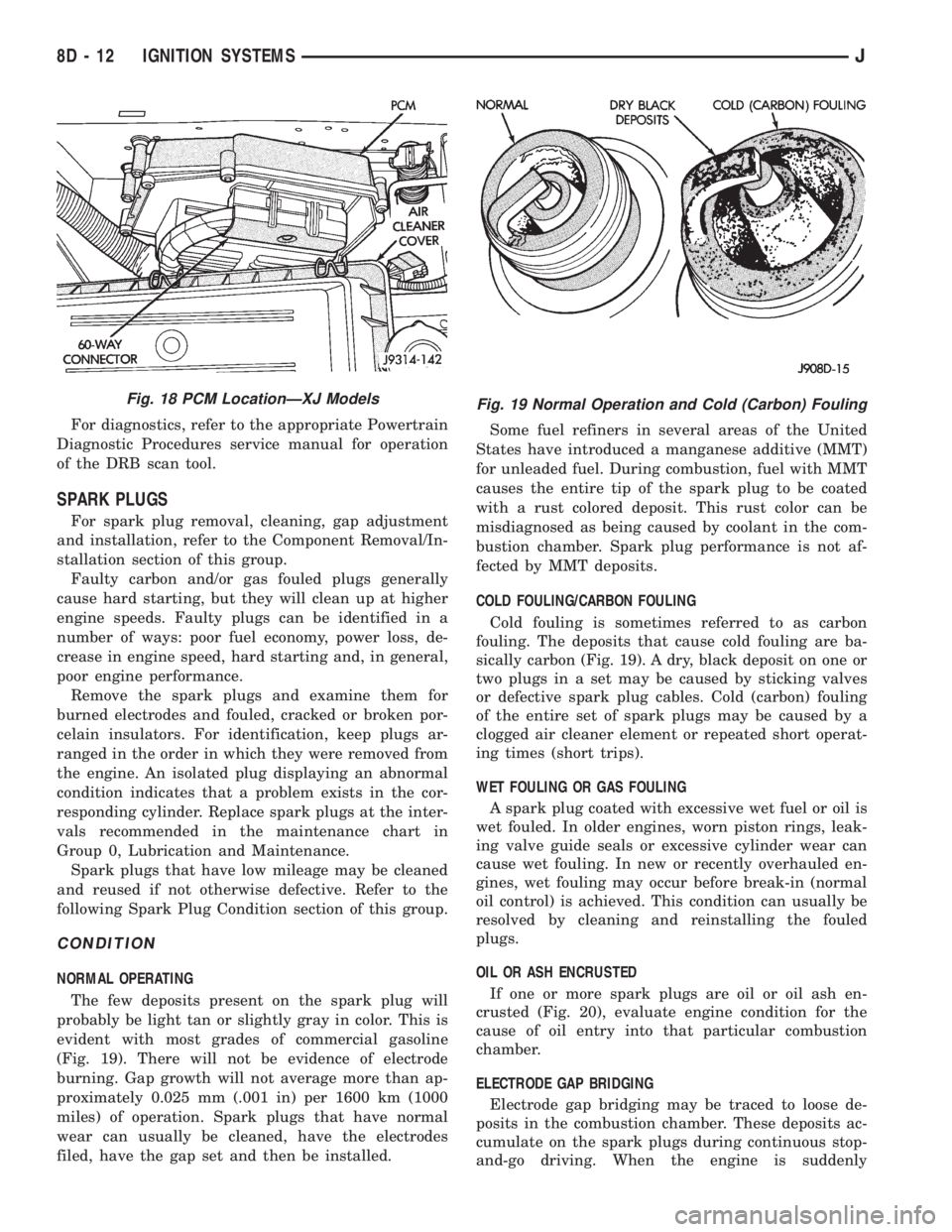

For diagnostics, refer to the appropriate Powertrain

Diagnostic Procedures service manual for operation

of the DRB scan tool.

SPARK PLUGS

For spark plug removal, cleaning, gap adjustment

and installation, refer to the Component Removal/In-

stallation section of this group.

Faulty carbon and/or gas fouled plugs generally

cause hard starting, but they will clean up at higher

engine speeds. Faulty plugs can be identified in a

number of ways: poor fuel economy, power loss, de-

crease in engine speed, hard starting and, in general,

poor engine performance.

Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. For identification, keep plugs ar-

ranged in the order in which they were removed from

the engine. An isolated plug displaying an abnormal

condition indicates that a problem exists in the cor-

responding cylinder. Replace spark plugs at the inter-

vals recommended in the maintenance chart in

Group 0, Lubrication and Maintenance.

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

following Spark Plug Condition section of this group.

CONDITION

NORMAL OPERATING

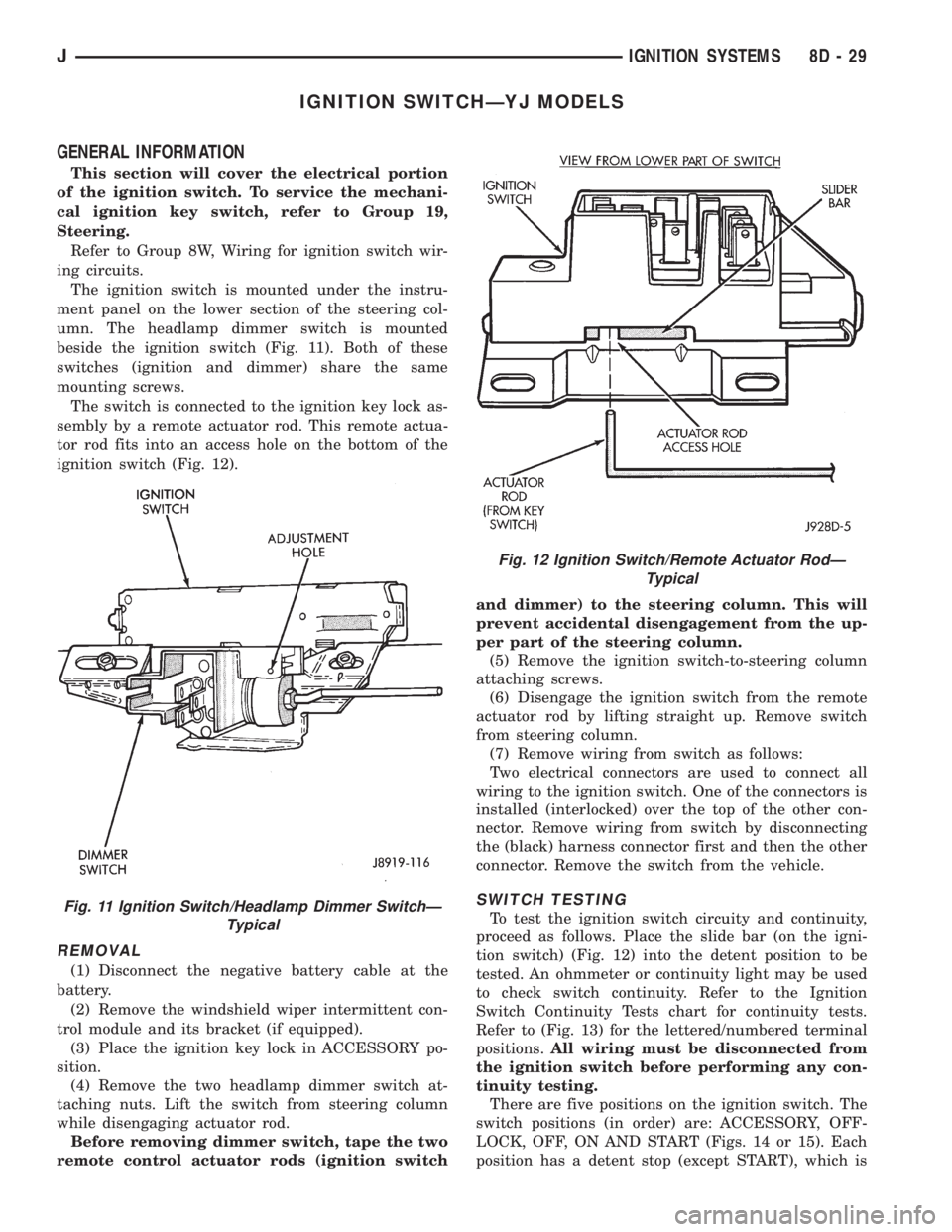

The few deposits present on the spark plug will

probably be light tan or slightly gray in color. This is

evident with most grades of commercial gasoline

(Fig. 19). There will not be evidence of electrode

burning. Gap growth will not average more than ap-

proximately 0.025 mm (.001 in) per 1600 km (1000

miles) of operation. Spark plugs that have normal

wear can usually be cleaned, have the electrodes

filed, have the gap set and then be installed.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

causes the entire tip of the spark plug to be coated

with a rust colored deposit. This rust color can be

misdiagnosed as being caused by coolant in the com-

bustion chamber. Spark plug performance is not af-

fected by MMT deposits.

COLD FOULING/CARBON FOULING

Cold fouling is sometimes referred to as carbon

fouling. The deposits that cause cold fouling are ba-

sically carbon (Fig. 19). A dry, black deposit on one or

two plugs in a set may be caused by sticking valves

or defective spark plug cables. Cold (carbon) fouling

of the entire set of spark plugs may be caused by a

clogged air cleaner element or repeated short operat-

ing times (short trips).

WET FOULING OR GAS FOULING

A spark plug coated with excessive wet fuel or oil is

wet fouled. In older engines, worn piston rings, leak-

ing valve guide seals or excessive cylinder wear can

cause wet fouling. In new or recently overhauled en-

gines, wet fouling may occur before break-in (normal

oil control) is achieved. This condition can usually be

resolved by cleaning and reinstalling the fouled

plugs.

OIL OR ASH ENCRUSTED

If one or more spark plugs are oil or oil ash en-

crusted (Fig. 20), evaluate engine condition for the

cause of oil entry into that particular combustion

chamber.

ELECTRODE GAP BRIDGING

Electrode gap bridging may be traced to loose de-

posits in the combustion chamber. These deposits ac-

cumulate on the spark plugs during continuous stop-

and-go driving. When the engine is suddenly

Fig. 18 PCM LocationÐXJ ModelsFig. 19 Normal Operation and Cold (Carbon) Fouling

8D - 12 IGNITION SYSTEMSJ

Page 353 of 2158

IGNITION SWITCHÐYJ MODELS

GENERAL INFORMATION

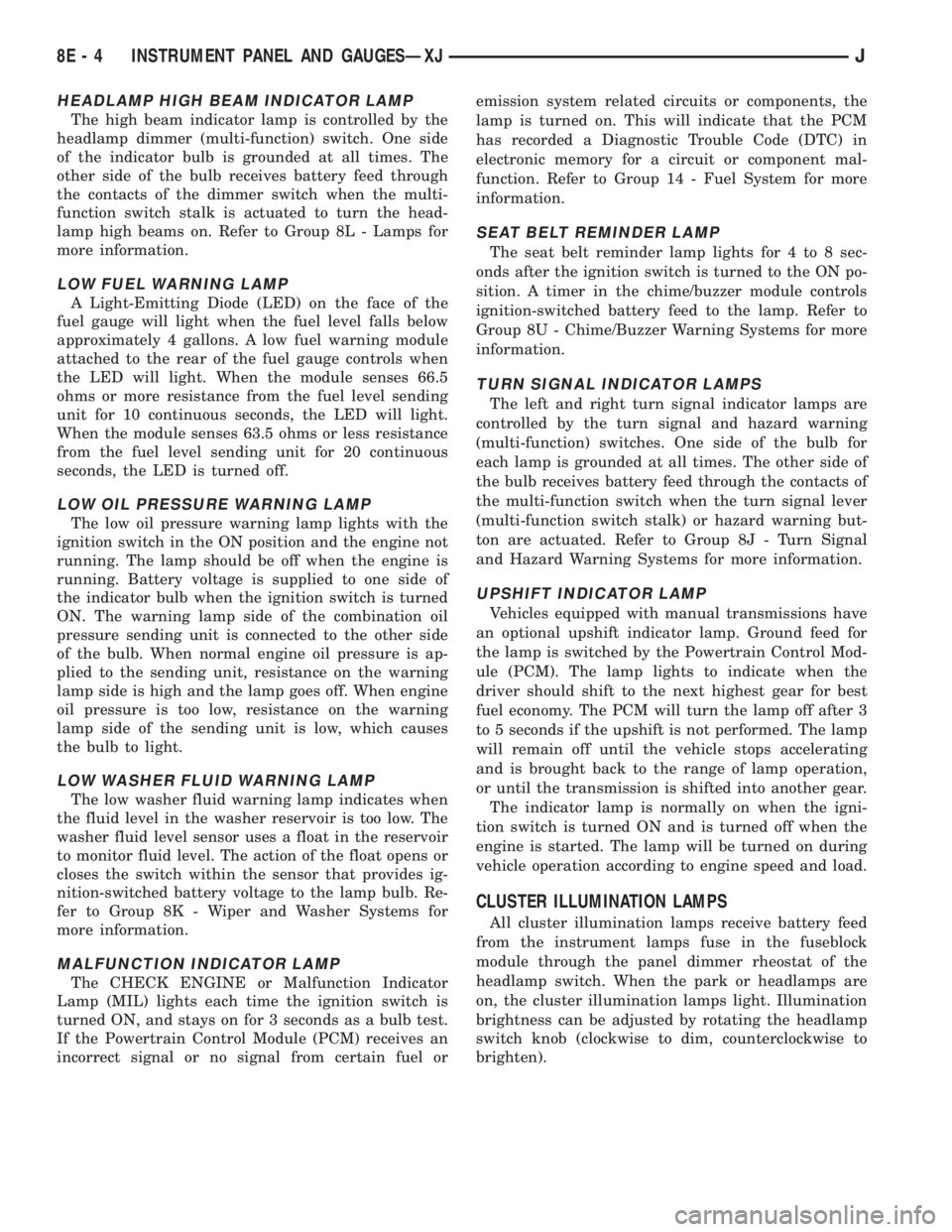

This section will cover the electrical portion

of the ignition switch. To service the mechani-

cal ignition key switch, refer to Group 19,

Steering.

Refer to Group 8W, Wiring for ignition switch wir-

ing circuits.

The ignition switch is mounted under the instru-

ment panel on the lower section of the steering col-

umn. The headlamp dimmer switch is mounted

beside the ignition switch (Fig. 11). Both of these

switches (ignition and dimmer) share the same

mounting screws.

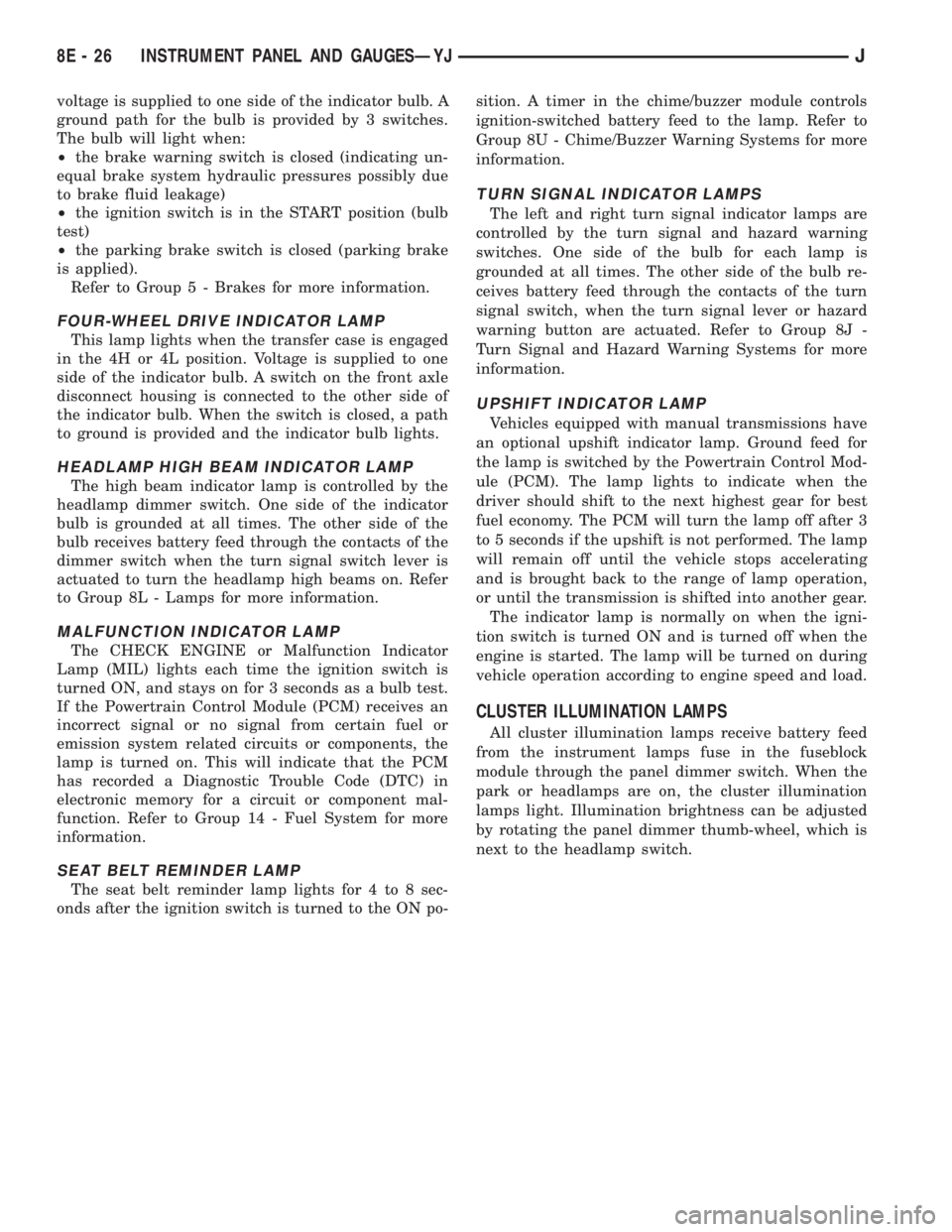

The switch is connected to the ignition key lock as-

sembly by a remote actuator rod. This remote actua-

tor rod fits into an access hole on the bottom of the

ignition switch (Fig. 12).

REMOVAL

(1) Disconnect the negative battery cable at the

battery.

(2) Remove the windshield wiper intermittent con-

trol module and its bracket (if equipped).

(3) Place the ignition key lock in ACCESSORY po-

sition.

(4) Remove the two headlamp dimmer switch at-

taching nuts. Lift the switch from steering column

while disengaging actuator rod.

Before removing dimmer switch, tape the two

remote control actuator rods (ignition switchand dimmer) to the steering column. This will

prevent accidental disengagement from the up-

per part of the steering column.

(5) Remove the ignition switch-to-steering column

attaching screws.

(6) Disengage the ignition switch from the remote

actuator rod by lifting straight up. Remove switch

from steering column.

(7) Remove wiring from switch as follows:

Two electrical connectors are used to connect all

wiring to the ignition switch. One of the connectors is

installed (interlocked) over the top of the other con-

nector. Remove wiring from switch by disconnecting

the (black) harness connector first and then the other

connector. Remove the switch from the vehicle.

SWITCH TESTING

To test the ignition switch circuity and continuity,

proceed as follows. Place the slide bar (on the igni-

tion switch) (Fig. 12) into the detent position to be

tested. An ohmmeter or continuity light may be used

to check switch continuity. Refer to the Ignition

Switch Continuity Tests chart for continuity tests.

Refer to (Fig. 13) for the lettered/numbered terminal

positions.All wiring must be disconnected from

the ignition switch before performing any con-

tinuity testing.

There are five positions on the ignition switch. The

switch positions (in order) are: ACCESSORY, OFF-

LOCK, OFF, ON AND START (Figs. 14 or 15). Each

position has a detent stop (except START), which isFig. 11 Ignition Switch/Headlamp Dimmer SwitchÐ

Typical

Fig. 12 Ignition Switch/Remote Actuator RodÐ

Typical

JIGNITION SYSTEMS 8D - 29

Page 360 of 2158

HEADLAMP HIGH BEAM INDICATOR LAMP

The high beam indicator lamp is controlled by the

headlamp dimmer (multi-function) switch. One side

of the indicator bulb is grounded at all times. The

other side of the bulb receives battery feed through

the contacts of the dimmer switch when the multi-

function switch stalk is actuated to turn the head-

lamp high beams on. Refer to Group 8L - Lamps for

more information.

LOW FUEL WARNING LAMP

A Light-Emitting Diode (LED) on the face of the

fuel gauge will light when the fuel level falls below

approximately 4 gallons. A low fuel warning module

attached to the rear of the fuel gauge controls when

the LED will light. When the module senses 66.5

ohms or more resistance from the fuel level sending

unit for 10 continuous seconds, the LED will light.

When the module senses 63.5 ohms or less resistance

from the fuel level sending unit for 20 continuous

seconds, the LED is turned off.

LOW OIL PRESSURE WARNING LAMP

The low oil pressure warning lamp lights with the

ignition switch in the ON position and the engine not

running. The lamp should be off when the engine is

running. Battery voltage is supplied to one side of

the indicator bulb when the ignition switch is turned

ON. The warning lamp side of the combination oil

pressure sending unit is connected to the other side

of the bulb. When normal engine oil pressure is ap-

plied to the sending unit, resistance on the warning

lamp side is high and the lamp goes off. When engine

oil pressure is too low, resistance on the warning

lamp side of the sending unit is low, which causes

the bulb to light.

LOW WASHER FLUID WARNING LAMP

The low washer fluid warning lamp indicates when

the fluid level in the washer reservoir is too low. The

washer fluid level sensor uses a float in the reservoir

to monitor fluid level. The action of the float opens or

closes the switch within the sensor that provides ig-

nition-switched battery voltage to the lamp bulb. Re-

fer to Group 8K - Wiper and Washer Systems for

more information.

MALFUNCTION INDICATOR LAMP

The CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch is

turned ON, and stays on for 3 seconds as a bulb test.

If the Powertrain Control Module (PCM) receives an

incorrect signal or no signal from certain fuel oremission system related circuits or components, the

lamp is turned on. This will indicate that the PCM

has recorded a Diagnostic Trouble Code (DTC) in

electronic memory for a circuit or component mal-

function. Refer to Group 14 - Fuel System for more

information.

SEAT BELT REMINDER LAMP

The seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-

sition. A timer in the chime/buzzer module controls

ignition-switched battery feed to the lamp. Refer to

Group 8U - Chime/Buzzer Warning Systems for more

information.

TURN SIGNAL INDICATOR LAMPS

The left and right turn signal indicator lamps are

controlled by the turn signal and hazard warning

(multi-function) switches. One side of the bulb for

each lamp is grounded at all times. The other side of

the bulb receives battery feed through the contacts of

the multi-function switch when the turn signal lever

(multi-function switch stalk) or hazard warning but-

ton are actuated. Refer to Group 8J - Turn Signal

and Hazard Warning Systems for more information.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed for

the lamp is switched by the Powertrain Control Mod-

ule (PCM). The lamp lights to indicate when the

driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3

to 5 seconds if the upshift is not performed. The lamp

will remain off until the vehicle stops accelerating

and is brought back to the range of lamp operation,

or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-

tion switch is turned ON and is turned off when the

engine is started. The lamp will be turned on during

vehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPS

All cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblock

module through the panel dimmer rheostat of the

headlamp switch. When the park or headlamps are

on, the cluster illumination lamps light. Illumination

brightness can be adjusted by rotating the headlamp

switch knob (clockwise to dim, counterclockwise to

brighten).

8E - 4 INSTRUMENT PANEL AND GAUGESÐXJJ

Page 382 of 2158

voltage is supplied to one side of the indicator bulb. A

ground path for the bulb is provided by 3 switches.

The bulb will light when:

²the brake warning switch is closed (indicating un-

equal brake system hydraulic pressures possibly due

to brake fluid leakage)

²the ignition switch is in the START position (bulb

test)

²the parking brake switch is closed (parking brake

is applied).

Refer to Group 5 - Brakes for more information.

FOUR-WHEEL DRIVE INDICATOR LAMP

This lamp lights when the transfer case is engaged

in the 4H or 4L position. Voltage is supplied to one

side of the indicator bulb. A switch on the front axle

disconnect housing is connected to the other side of

the indicator bulb. When the switch is closed, a path

to ground is provided and the indicator bulb lights.

HEADLAMP HIGH BEAM INDICATOR LAMP

The high beam indicator lamp is controlled by the

headlamp dimmer switch. One side of the indicator

bulb is grounded at all times. The other side of the

bulb receives battery feed through the contacts of the

dimmer switch when the turn signal switch lever is

actuated to turn the headlamp high beams on. Refer

to Group 8L - Lamps for more information.

MALFUNCTION INDICATOR LAMP

The CHECK ENGINE or Malfunction Indicator

Lamp (MIL) lights each time the ignition switch is

turned ON, and stays on for 3 seconds as a bulb test.

If the Powertrain Control Module (PCM) receives an

incorrect signal or no signal from certain fuel or

emission system related circuits or components, the

lamp is turned on. This will indicate that the PCM

has recorded a Diagnostic Trouble Code (DTC) in

electronic memory for a circuit or component mal-

function. Refer to Group 14 - Fuel System for more

information.

SEAT BELT REMINDER LAMP

The seat belt reminder lamp lights for 4 to 8 sec-

onds after the ignition switch is turned to the ON po-sition. A timer in the chime/buzzer module controls

ignition-switched battery feed to the lamp. Refer to

Group 8U - Chime/Buzzer Warning Systems for more

information.

TURN SIGNAL INDICATOR LAMPS

The left and right turn signal indicator lamps are

controlled by the turn signal and hazard warning

switches. One side of the bulb for each lamp is

grounded at all times. The other side of the bulb re-

ceives battery feed through the contacts of the turn

signal switch, when the turn signal lever or hazard

warning button are actuated. Refer to Group 8J -

Turn Signal and Hazard Warning Systems for more

information.

UPSHIFT INDICATOR LAMP

Vehicles equipped with manual transmissions have

an optional upshift indicator lamp. Ground feed for

the lamp is switched by the Powertrain Control Mod-

ule (PCM). The lamp lights to indicate when the

driver should shift to the next highest gear for best

fuel economy. The PCM will turn the lamp off after 3

to 5 seconds if the upshift is not performed. The lamp

will remain off until the vehicle stops accelerating

and is brought back to the range of lamp operation,

or until the transmission is shifted into another gear.

The indicator lamp is normally on when the igni-

tion switch is turned ON and is turned off when the

engine is started. The lamp will be turned on during

vehicle operation according to engine speed and load.

CLUSTER ILLUMINATION LAMPS

All cluster illumination lamps receive battery feed

from the instrument lamps fuse in the fuseblock

module through the panel dimmer switch. When the

park or headlamps are on, the cluster illumination

lamps light. Illumination brightness can be adjusted

by rotating the panel dimmer thumb-wheel, which is

next to the headlamp switch.

8E - 26 INSTRUMENT PANEL AND GAUGESÐYJJ

Page 422 of 2158

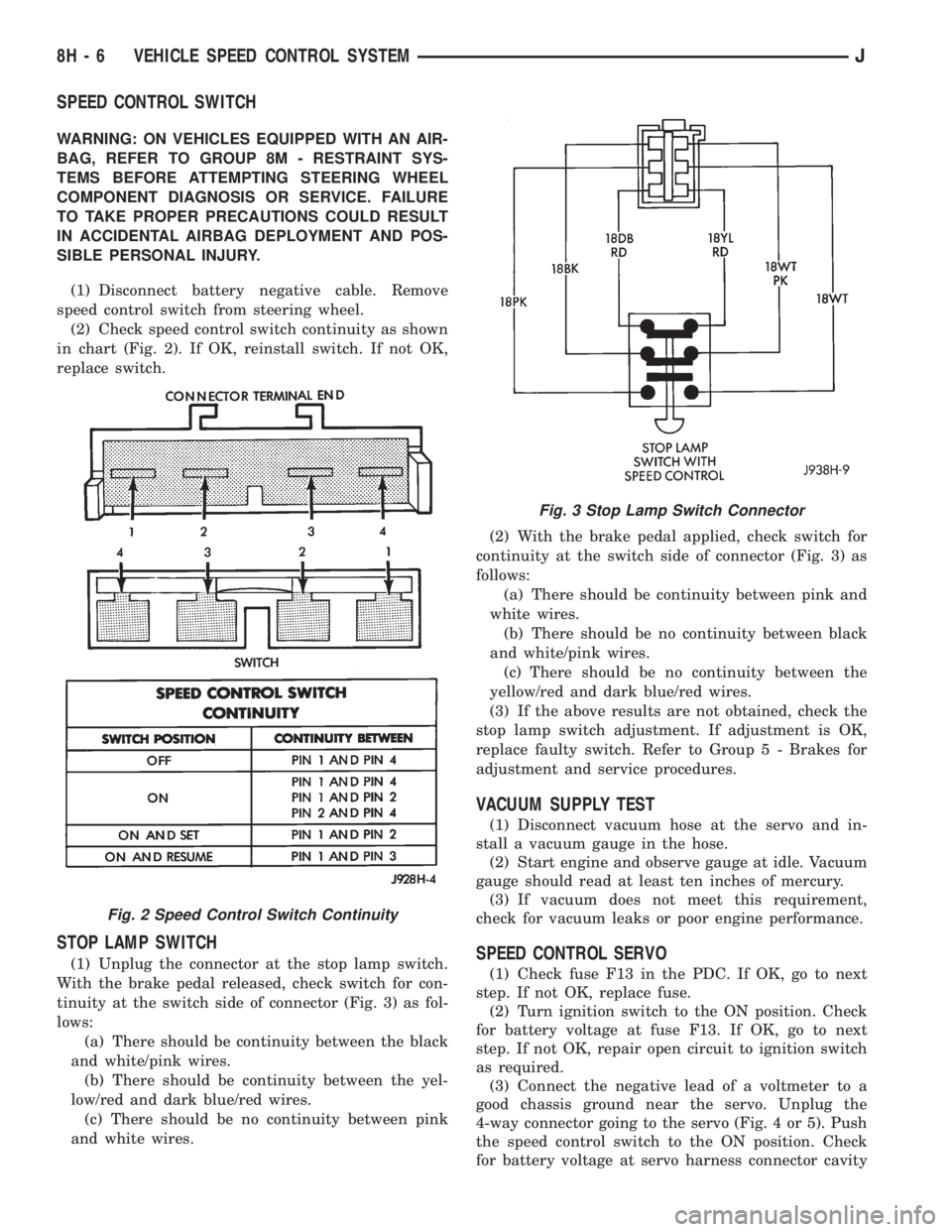

SPEED CONTROL SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AN AIR-

BAG, REFER TO GROUP 8M - RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE PROPER PRECAUTIONS COULD RESULT

IN ACCIDENTAL AIRBAG DEPLOYMENT AND POS-

SIBLE PERSONAL INJURY.

(1) Disconnect battery negative cable. Remove

speed control switch from steering wheel.

(2) Check speed control switch continuity as shown

in chart (Fig. 2). If OK, reinstall switch. If not OK,

replace switch.

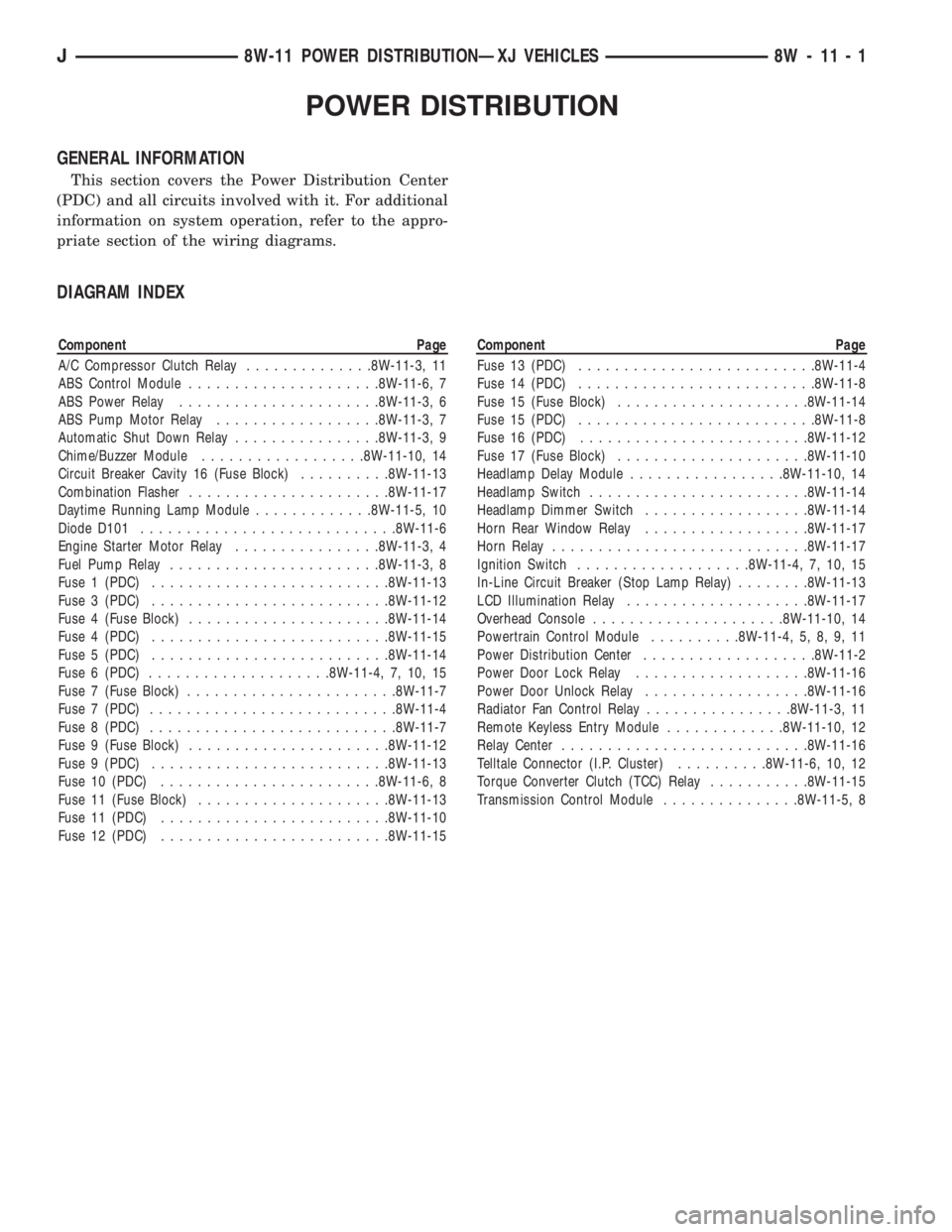

STOP LAMP SWITCH

(1) Unplug the connector at the stop lamp switch.

With the brake pedal released, check switch for con-

tinuity at the switch side of connector (Fig. 3) as fol-

lows:

(a) There should be continuity between the black

and white/pink wires.

(b) There should be continuity between the yel-

low/red and dark blue/red wires.

(c) There should be no continuity between pink

and white wires.(2) With the brake pedal applied, check switch for

continuity at the switch side of connector (Fig. 3) as

follows:

(a) There should be continuity between pink and

white wires.

(b) There should be no continuity between black

and white/pink wires.

(c) There should be no continuity between the

yellow/red and dark blue/red wires.

(3) If the above results are not obtained, check the

stop lamp switch adjustment. If adjustment is OK,

replace faulty switch. Refer to Group 5 - Brakes for

adjustment and service procedures.

VACUUM SUPPLY TEST

(1) Disconnect vacuum hose at the servo and in-

stall a vacuum gauge in the hose.

(2) Start engine and observe gauge at idle. Vacuum

gauge should read at least ten inches of mercury.

(3) If vacuum does not meet this requirement,

check for vacuum leaks or poor engine performance.

SPEED CONTROL SERVO

(1) Check fuse F13 in the PDC. If OK, go to next

step. If not OK, replace fuse.

(2) Turn ignition switch to the ON position. Check

for battery voltage at fuse F13. If OK, go to next

step. If not OK, repair open circuit to ignition switch

as required.

(3) Connect the negative lead of a voltmeter to a

good chassis ground near the servo. Unplug the

4-way connector going to the servo (Fig. 4 or 5). Push

the speed control switch to the ON position. Check

for battery voltage at servo harness connector cavity

Fig. 2 Speed Control Switch Continuity

Fig. 3 Stop Lamp Switch Connector

8H - 6 VEHICLE SPEED CONTROL SYSTEMJ

Page 557 of 2158

POWER DISTRIBUTION

GENERAL INFORMATION

This section covers the Power Distribution Center

(PDC) and all circuits involved with it. For additional

information on system operation, refer to the appro-

priate section of the wiring diagrams.

DIAGRAM INDEX

Component Page

A/C Compressor Clutch Relay..............8W-11-3, 11

ABS Control Module.....................8W-11-6, 7

ABS Power Relay......................8W-11-3, 6

ABS Pump Motor Relay..................8W-11-3, 7

Automatic Shut Down Relay................8W-11-3, 9

Chime/Buzzer Module..................8W-11-10, 14

Circuit Breaker Cavity 16 (Fuse Block)..........8W-11-13

Combination Flasher......................8W-11-17

Daytime Running Lamp Module.............8W-11-5, 10

Diode D101............................8W-11-6

Engine Starter Motor Relay................8W-11-3, 4

Fuel Pump Relay.......................8W-11-3, 8

Fuse 1 (PDC)..........................8W-11-13

Fuse 3 (PDC)..........................8W-11-12

Fuse 4 (Fuse Block)......................8W-11-14

Fuse 4 (PDC)..........................8W-11-15

Fuse 5 (PDC)..........................8W-11-14

Fuse 6 (PDC)....................8W-11-4, 7, 10, 15

Fuse 7 (Fuse Block).......................8W-11-7

Fuse 7 (PDC)...........................8W-11-4

Fuse 8 (PDC)...........................8W-11-7

Fuse 9 (Fuse Block)......................8W-11-12

Fuse 9 (PDC)..........................8W-11-13

Fuse 10 (PDC)........................8W-11-6, 8

Fuse 11 (Fuse Block).....................8W-11-13

Fuse 11 (PDC).........................8W-11-10

Fuse 12 (PDC).........................8W-11-15Component Page

Fuse 13 (PDC)..........................8W-11-4

Fuse 14 (PDC)..........................8W-11-8

Fuse 15 (Fuse Block).....................8W-11-14

Fuse 15 (PDC)..........................8W-11-8

Fuse 16 (PDC).........................8W-11-12

Fuse 17 (Fuse Block).....................8W-11-10

Headlamp Delay Module.................8W-11-10, 14

Headlamp Switch........................8W-11-14

Headlamp Dimmer Switch..................8W-11-14

Horn Rear Window Relay..................8W-11-17

Horn Relay............................8W-11-17

Ignition Switch...................8W-11-4, 7, 10, 15

In-Line Circuit Breaker (Stop Lamp Relay)........8W-11-13

LCD Illumination Relay....................8W-11-17

Overhead Console.....................8W-11-10, 14

Powertrain Control Module..........8W-11-4, 5, 8, 9, 11

Power Distribution Center...................8W-11-2

Power Door Lock Relay...................8W-11-16

Power Door Unlock Relay..................8W-11-16

Radiator Fan Control Relay................8W-11-3, 11

Remote Keyless Entry Module.............8W-11-10, 12

Relay Center...........................8W-11-16

Telltale Connector (I.P. Cluster)..........8W-11-6, 10, 12

Torque Converter Clutch (TCC) Relay...........8W-11-15

Transmission Control Module...............8W-11-5, 8

J8W-11 POWER DISTRIBUTIONÐXJ VEHICLES 8W - 11 - 1

Page 609 of 2158

TRANSMISSION CONTROLS

UPSHIFT LAMP

On vehicles equipped with a manual transmission,

the PCM grounds the up-shift lamp on circuit K54.

Circuit K54 connects to cavity 54 of the PCM.

FOUR-WHEEL DRIVE (4WD) SWITCH

When the 4WD switch closes, circuit Z1 provides

ground for the 4WD indicator lamp in the instrument

cluster. Circuit F87 connects to the instrument clus-

ter and supplies battery voltage to the 4WD indicator

lamp. Circuit 107 connects the indicator lamp to the

4WD switch. Circuit 106 connects the lamp to the in-

strument cluster and circuit F87.

TRANSMISSION CONTROL MODULEÐ4.0L

ENGINE ONLY

Vehicles equipped with the 4.0L engine have elec-

tronically controlled solenoids in the automatic trans-

mission valve body.

The Transmission Control Module (TCM) receives

inputs from the Throttle Position Sensor (TPS) on

circuit K22 and the stop lamp switch on circuit K29.

Circuit K4 connects to the TCM to provide ground for

the TPS signal. The TCM receives the transmission

output speed sensor signal on circuit T505. Circuit

A14 from fuse 2 in the Power Distribution Center

supplies battery voltage to the TCM. Circuit Z12 pro-

vides ground for the TCM.

The TCM powers the S1 solenoid on circuit T510,

the S2 solenoid on circuit T509, and the S3 solenoid

on circuit T508. Circuit Z12 provides ground for the

S1, S2, and S3 solenoids.

TORQUE CONVERTER CLUTCH (TCC) SOLENOID

AND RELAYÐ2.5L ENGINE ONLY

The TCC solenoid is only used on 2.5L engines

with the three-speed automatic transmissions. The

Powertrain Control Module (PCM) operates the TCC

solenoid by energizing the TCC relay.

Circuit T17 from fuse 12 in the Power Distribution

Center (PDC) supplies voltage to the coil and contact

sides of the TCC relay. When the PCM provides a

ground path on circuit K54 for the coil side of the re-

lay, the relay contacts close.

When the relay contacts close, they connect circuit

T17 with circuit T22. Circuit T22 supplies battery

voltage to the case grounded TCC solenoid. Circuit

K54 connects to PCM cavity 54.

HELPFUL INFORMATION

²In the RUN or START position, the ignition switch

connects circuit A1 from fuse 6 in the PDC to circuit

A21.

DIAGRAM INDEX

Component Page

4-WD Indicator Lamp......................8W-31-4

4-WD Indicator Switch.....................8W-31-4

Back-Up Lamp Switch.....................8W-31-3

Fuse 2 (PDC)...........................8W-31-4

Fuse 6 (PDC).........................8W-31-2, 3

Fuse 11 (PDC)..........................8W-31-3

Fuse 12 (PDC)..........................8W-31-2

Ignition Switch........................8W-31-2, 3

Powertrain Control Module..................8W-31-2

Park/Neutral Position Switch.................8W-31-3

TCC Relay.............................8W-31-2

TCC Solenoid...........................8W-31-2

Transmission Control Module.................8W-31-2

J8W-31 TRANSMISSION CONTROLSÐXJ VEHICLES 8W - 31 - 1

Page 621 of 2158

VEHICLE SPEED CONTROL

VEHICLE SPEED CONTROL

The vehicle speed control system is operated by the

Powertrain Control Module (PCM). Circuit F12 from

fuse 11 in the Power Distribution Center (PDC) sup-

plies battery voltage to the vehicle speed control ON/

OFF switch. Circuit A21 supplies voltage to fuse 11

when the ignition switch is in the START or RUN po-

sitions. In the START or RUN position the ignition

switch connects circuit A21 with circuit A1. Fuse 6 in

the PDC protects circuit A1.

The vehicle speed control ON/OFF switch supplies

voltage to the SET/COAST and RESUME/ACCEL

switches. Both switches send signals to the PCM

(which supplies the ground path for the switches).

The PCM controls the vent and vacuum functions

of the speed control servo on circuits V35 and V36.

Depending on the signal it receives from the vehicle

speed control switches, the PCM either applies vac-

uum to, or vents vacuum from, the servo. Circuit V36

from cavity 33 of the PCM sends the vacuum signal

to the servo. Circuit V35 from cavity 53 sends the

vent signal.

Circuit V32 signals to the PCM that the speed con-

trol switch is in the ON position. The V32 circuit con-

nects to cavity 49 of the PCM. Circuit V32 also

connects to the stop lamp switch.

In the CLOSED position, the stop lamp switch con-

nects circuit V32 with circuit V30 to power the speed

control servo. Circuit Z1 provides ground for the

speed control servo.

Circuit V31 provides the SET/COAST signal to cav-

ity 48 of the PCM. Circuit V33 sends the RESUME/

ACCEL signal to cavity 50 of the PCM.

Circuit K29 connects to cavity 29 of the PCM and

to ground through the stop lamp switch. The stop

lamp switch OPENS when the operator depresses the

brake pedal. The PCM disables speed control when

the stop lamp switch opens. From the stop lamp

switch, circuit Z1 provides ground for circuit K29.

HELPFUL INFORMATION

²Circuit K29 also connects to the ABS control mod-

ule on vehicles with all wheel anti-lock brakes.

²On vehicles with the 4.0L Engine and Automatic

Transmission, Circuit K29 connects to the Transmis-

sion Control Module (TCM).

DIAGRAM INDEX

Component Page

ABS Control Module..................8W-32-4 thru 8

ABS Hydraulic Unit.......................8W-32-6

ABS Power Relay........................8W-32-4

ABS Pump Motor........................8W-32-5

ABS Pump Motor Relay....................8W-32-4

Data Link Connector......................8W-32-8

Diode................................8W-32-6

Fuse 6 (PDC)...........................8W-32-5

Fuse 7 (Fuse Block).......................8W-32-5

Fuse 7 (PDC)...........................8W-32-8

Fuse 8 (PDC)...........................8W-32-5

Fuse 10 (PDC)..........................8W-32-4

Fuse 13 (PDC)..........................8W-32-8

G-Sensor..............................8W-32-8

Ignition Switch..........................8W-32-5

Powertrain Control Module..................8W-32-8

Telltale Connector (Instrument Cluster)...........8W-32-6

Transmission Control Module.................8W-32-8

Wheel Speed Sensors......................8W-32-7

J8W-33 VEHICLE SPEED CONTROLÐXJ VEHICLES 8W - 33 - 1

Page 677 of 2158

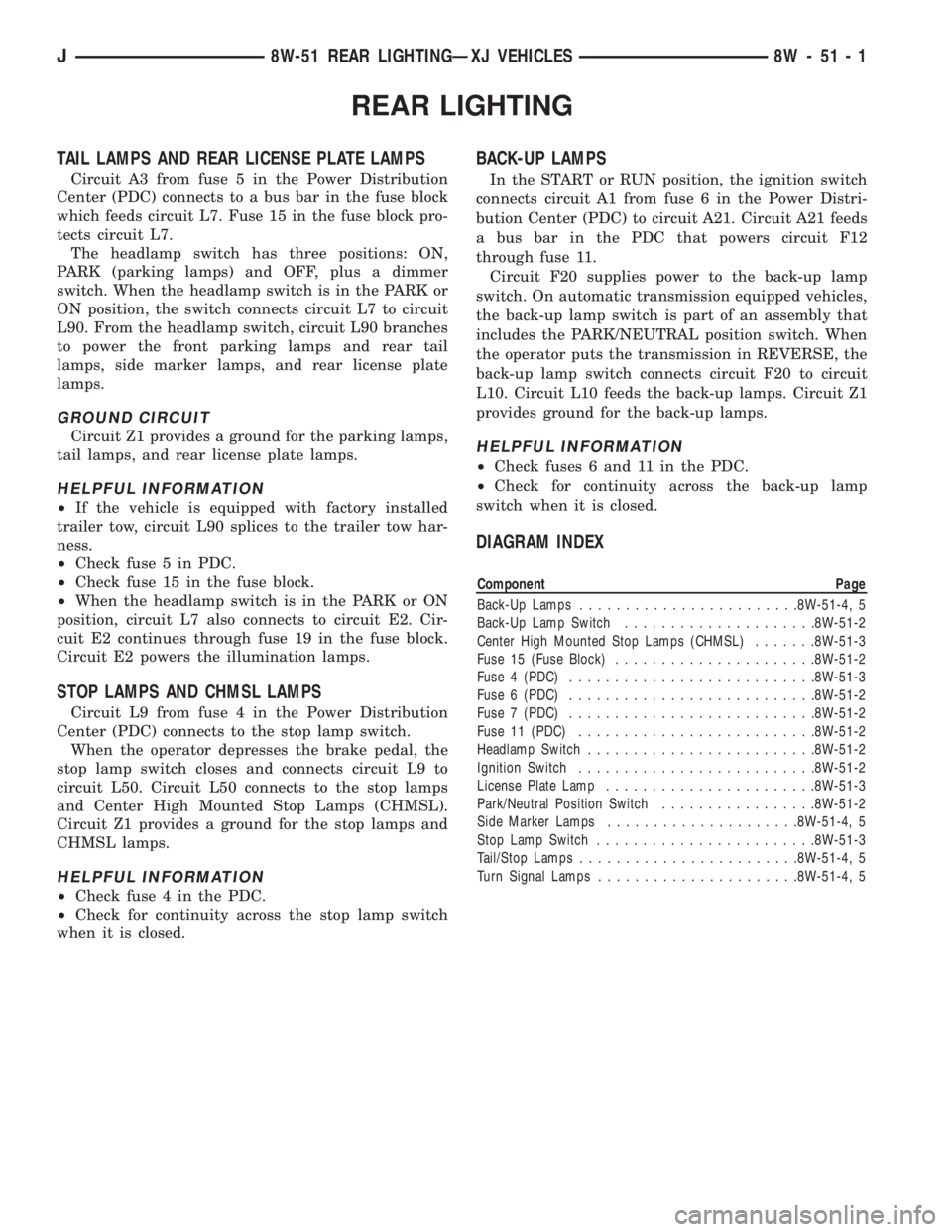

REAR LIGHTING

TAIL LAMPS AND REAR LICENSE PLATE LAMPS

Circuit A3 from fuse 5 in the Power Distribution

Center (PDC) connects to a bus bar in the fuse block

which feeds circuit L7. Fuse 15 in the fuse block pro-

tects circuit L7.

The headlamp switch has three positions: ON,

PARK (parking lamps) and OFF, plus a dimmer

switch. When the headlamp switch is in the PARK or

ON position, the switch connects circuit L7 to circuit

L90. From the headlamp switch, circuit L90 branches

to power the front parking lamps and rear tail

lamps, side marker lamps, and rear license plate

lamps.

GROUND CIRCUIT

Circuit Z1 provides a ground for the parking lamps,

tail lamps, and rear license plate lamps.

HELPFUL INFORMATION

²If the vehicle is equipped with factory installed

trailer tow, circuit L90 splices to the trailer tow har-

ness.

²Check fuse 5 in PDC.

²Check fuse 15 in the fuse block.

²When the headlamp switch is in the PARK or ON

position, circuit L7 also connects to circuit E2. Cir-

cuit E2 continues through fuse 19 in the fuse block.

Circuit E2 powers the illumination lamps.

STOP LAMPS AND CHMSL LAMPS

Circuit L9 from fuse 4 in the Power Distribution

Center (PDC) connects to the stop lamp switch.

When the operator depresses the brake pedal, the

stop lamp switch closes and connects circuit L9 to

circuit L50. Circuit L50 connects to the stop lamps

and Center High Mounted Stop Lamps (CHMSL).

Circuit Z1 provides a ground for the stop lamps and

CHMSL lamps.

HELPFUL INFORMATION

²Check fuse 4 in the PDC.

²Check for continuity across the stop lamp switch

when it is closed.

BACK-UP LAMPS

In the START or RUN position, the ignition switch

connects circuit A1 from fuse 6 in the Power Distri-

bution Center (PDC) to circuit A21. Circuit A21 feeds

a bus bar in the PDC that powers circuit F12

through fuse 11.

Circuit F20 supplies power to the back-up lamp

switch. On automatic transmission equipped vehicles,

the back-up lamp switch is part of an assembly that

includes the PARK/NEUTRAL position switch. When

the operator puts the transmission in REVERSE, the

back-up lamp switch connects circuit F20 to circuit

L10. Circuit L10 feeds the back-up lamps. Circuit Z1

provides ground for the back-up lamps.

HELPFUL INFORMATION

²Check fuses 6 and 11 in the PDC.

²Check for continuity across the back-up lamp

switch when it is closed.

DIAGRAM INDEX

Component Page

Back-Up Lamps........................8W-51-4, 5

Back-Up Lamp Switch.....................8W-51-2

Center High Mounted Stop Lamps (CHMSL).......8W-51-3

Fuse 15 (Fuse Block)......................8W-51-2

Fuse 4 (PDC)...........................8W-51-3

Fuse 6 (PDC)...........................8W-51-2

Fuse 7 (PDC)...........................8W-51-2

Fuse 11 (PDC)..........................8W-51-2

Headlamp Switch.........................8W-51-2

Ignition Switch..........................8W-51-2

License Plate Lamp.......................8W-51-3

Park/Neutral Position Switch.................8W-51-2

Side Marker Lamps.....................8W-51-4, 5

Stop Lamp Switch........................8W-51-3

Tail/Stop Lamps........................8W-51-4, 5

Turn Signal Lamps......................8W-51-4, 5

J8W-51 REAR LIGHTINGÐXJ VEHICLES 8W - 51 - 1

Page 833 of 2158

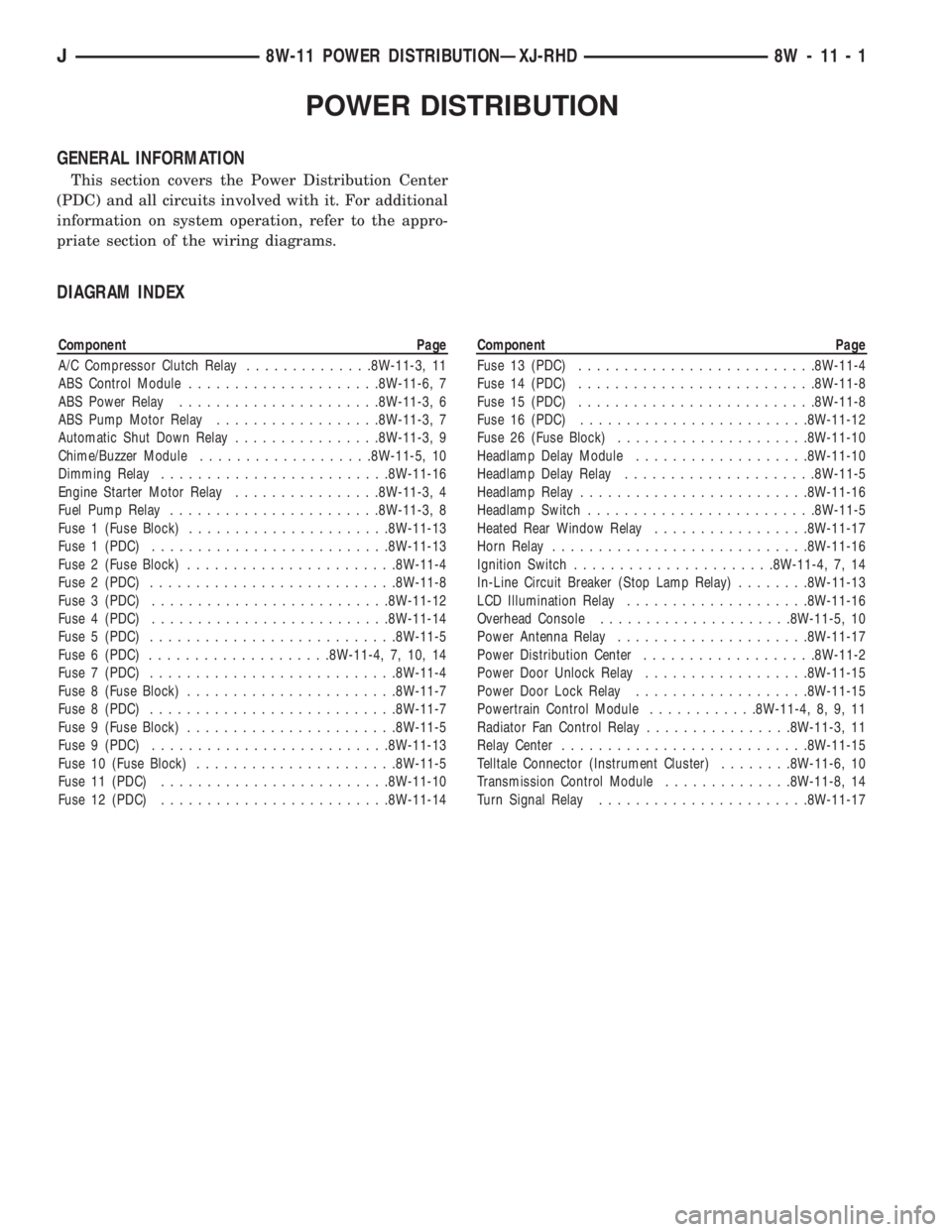

POWER DISTRIBUTION

GENERAL INFORMATION

This section covers the Power Distribution Center

(PDC) and all circuits involved with it. For additional

information on system operation, refer to the appro-

priate section of the wiring diagrams.

DIAGRAM INDEX

Component Page

A/C Compressor Clutch Relay..............8W-11-3, 11

ABS Control Module.....................8W-11-6, 7

ABS Power Relay......................8W-11-3, 6

ABS Pump Motor Relay..................8W-11-3, 7

Automatic Shut Down Relay................8W-11-3, 9

Chime/Buzzer Module...................8W-11-5, 10

Dimming Relay.........................8W-11-16

Engine Starter Motor Relay................8W-11-3, 4

Fuel Pump Relay.......................8W-11-3, 8

Fuse 1 (Fuse Block)......................8W-11-13

Fuse 1 (PDC)..........................8W-11-13

Fuse 2 (Fuse Block).......................8W-11-4

Fuse 2 (PDC)...........................8W-11-8

Fuse 3 (PDC)..........................8W-11-12

Fuse 4 (PDC)..........................8W-11-14

Fuse 5 (PDC)...........................8W-11-5

Fuse 6 (PDC)....................8W-11-4, 7, 10, 14

Fuse 7 (PDC)...........................8W-11-4

Fuse 8 (Fuse Block).......................8W-11-7

Fuse 8 (PDC)...........................8W-11-7

Fuse 9 (Fuse Block).......................8W-11-5

Fuse 9 (PDC)..........................8W-11-13

Fuse 10 (Fuse Block)......................8W-11-5

Fuse 11 (PDC).........................8W-11-10

Fuse 12 (PDC).........................8W-11-14Component Page

Fuse 13 (PDC)..........................8W-11-4

Fuse 14 (PDC)..........................8W-11-8

Fuse 15 (PDC)..........................8W-11-8

Fuse 16 (PDC).........................8W-11-12

Fuse 26 (Fuse Block).....................8W-11-10

Headlamp Delay Module...................8W-11-10

Headlamp Delay Relay.....................8W-11-5

Headlamp Relay.........................8W-11-16

Headlamp Switch.........................8W-11-5

Heated Rear Window Relay.................8W-11-17

Horn Relay............................8W-11-16

Ignition Switch......................8W-11-4, 7, 14

In-Line Circuit Breaker (Stop Lamp Relay)........8W-11-13

LCD Illumination Relay....................8W-11-16

Overhead Console.....................8W-11-5, 10

Power Antenna Relay.....................8W-11-17

Power Distribution Center...................8W-11-2

Power Door Unlock Relay..................8W-11-15

Power Door Lock Relay...................8W-11-15

Powertrain Control Module............8W-11-4, 8, 9, 11

Radiator Fan Control Relay................8W-11-3, 11

Relay Center...........................8W-11-15

Telltale Connector (Instrument Cluster)........8W-11-6, 10

Transmission Control Module..............8W-11-8, 14

Turn Signal Relay.......................8W-11-17

J8W-11 POWER DISTRIBUTIONÐXJ-RHD 8W - 11 - 1