stop start JEEP YJ 1995 Service And Service Manual

[x] Cancel search | Manufacturer: JEEP, Model Year: 1995, Model line: YJ, Model: JEEP YJ 1995Pages: 2158, PDF Size: 81.9 MB

Page 1719 of 2158

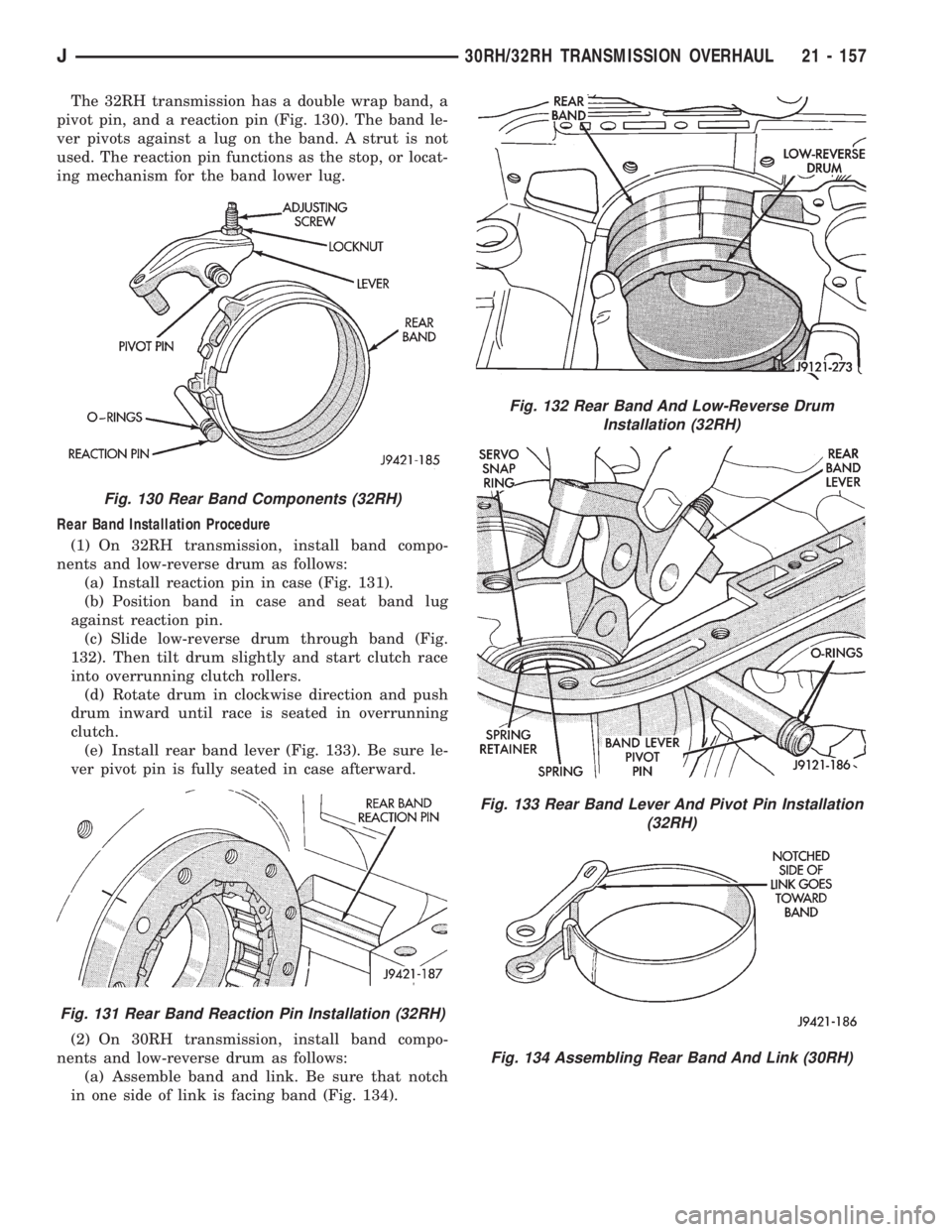

The 32RH transmission has a double wrap band, a

pivot pin, and a reaction pin (Fig. 130). The band le-

ver pivots against a lug on the band. A strut is not

used. The reaction pin functions as the stop, or locat-

ing mechanism for the band lower lug.

Rear Band Installation Procedure

(1) On 32RH transmission, install band compo-

nents and low-reverse drum as follows:

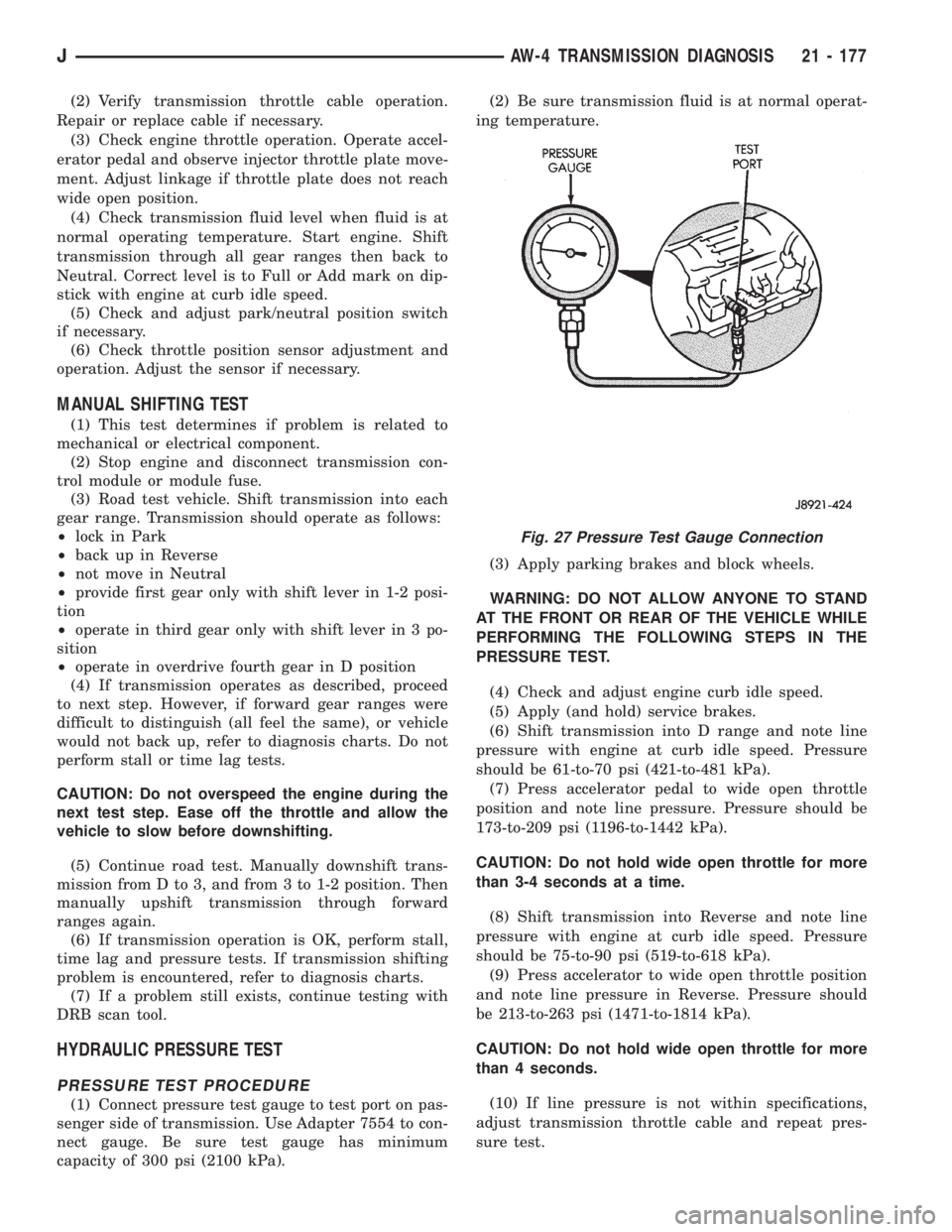

(a) Install reaction pin in case (Fig. 131).

(b) Position band in case and seat band lug

against reaction pin.

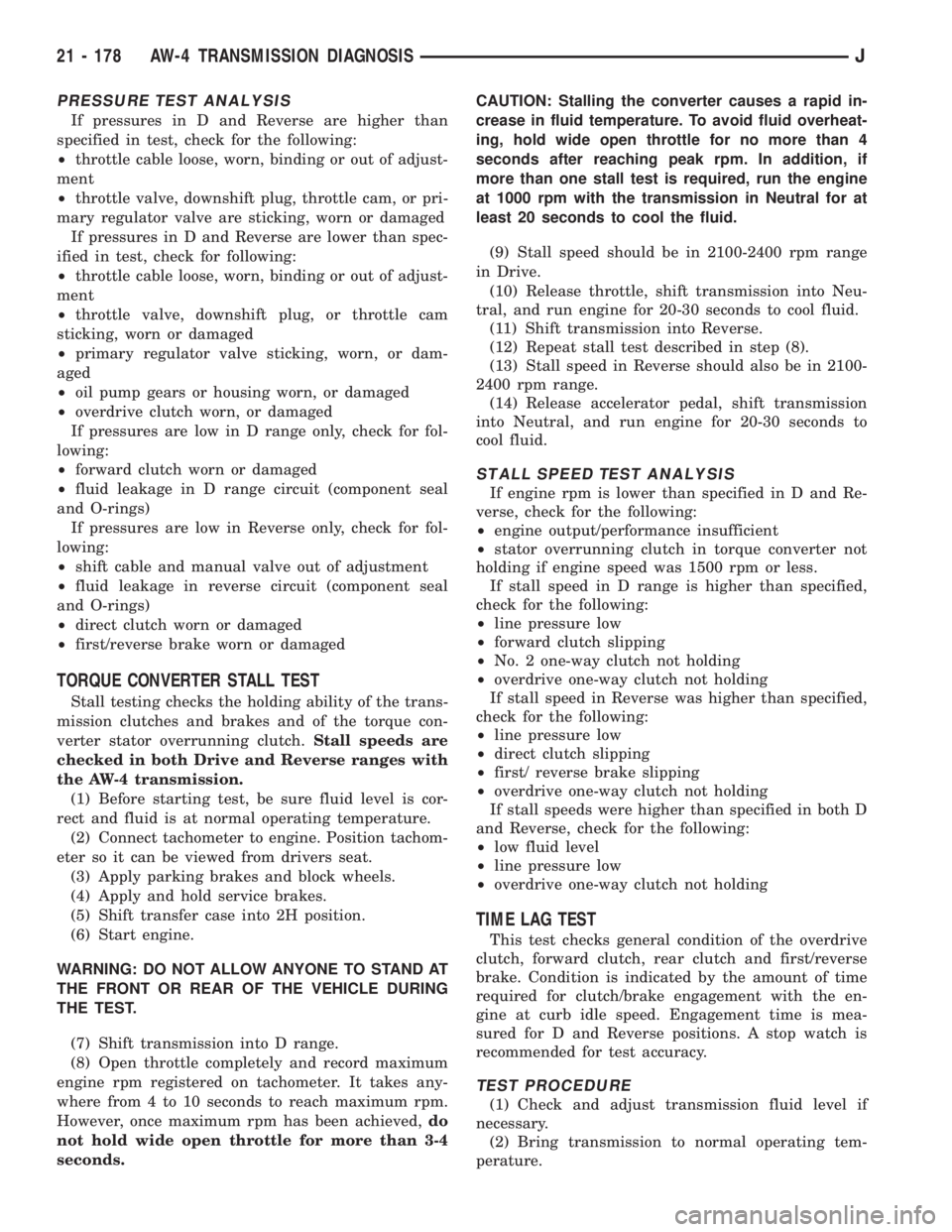

(c) Slide low-reverse drum through band (Fig.

132). Then tilt drum slightly and start clutch race

into overrunning clutch rollers.

(d) Rotate drum in clockwise direction and push

drum inward until race is seated in overrunning

clutch.

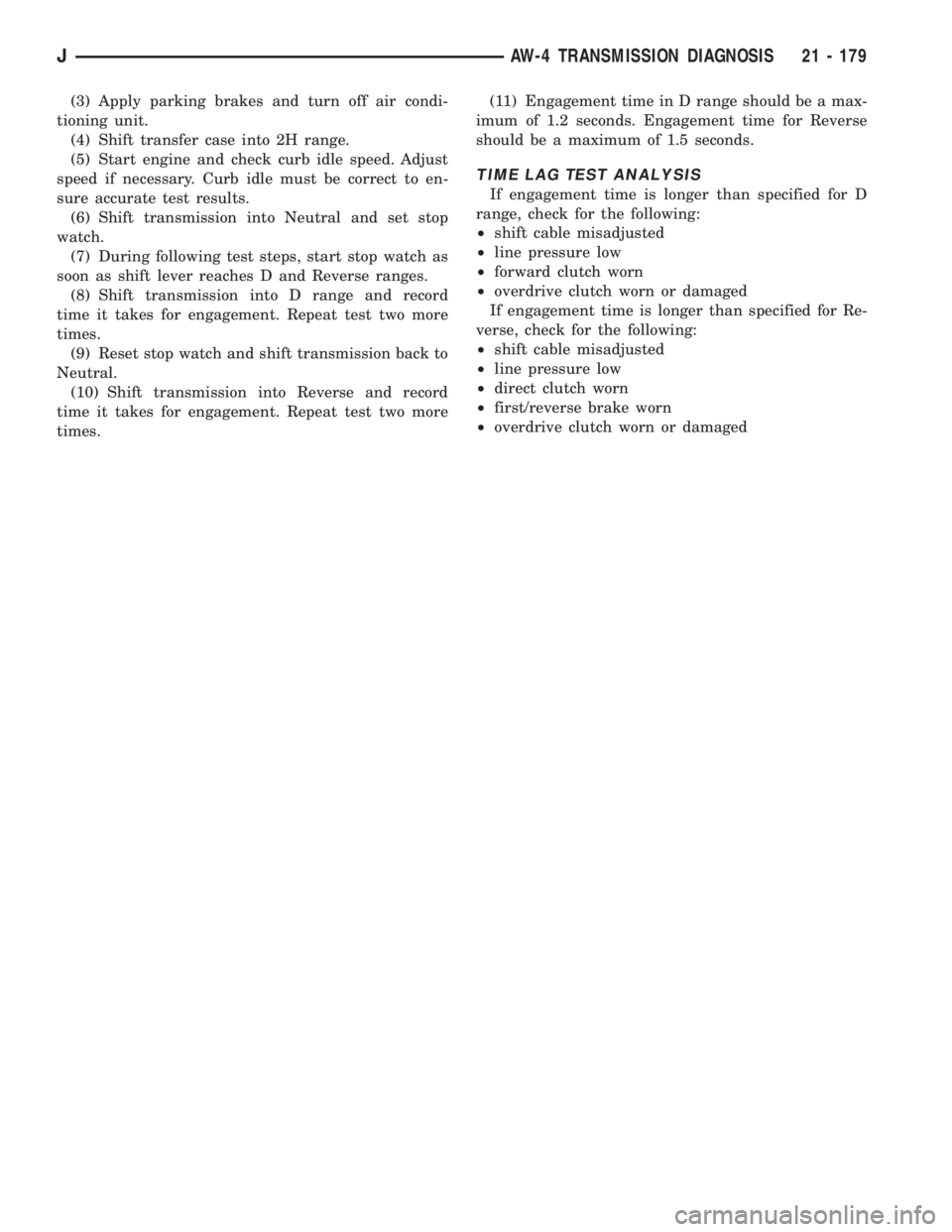

(e) Install rear band lever (Fig. 133). Be sure le-

ver pivot pin is fully seated in case afterward.

(2) On 30RH transmission, install band compo-

nents and low-reverse drum as follows:

(a) Assemble band and link. Be sure that notch

in one side of link is facing band (Fig. 134).

Fig. 130 Rear Band Components (32RH)

Fig. 131 Rear Band Reaction Pin Installation (32RH)

Fig. 132 Rear Band And Low-Reverse Drum

Installation (32RH)

Fig. 133 Rear Band Lever And Pivot Pin Installation

(32RH)

Fig. 134 Assembling Rear Band And Link (30RH)

J30RH/32RH TRANSMISSION OVERHAUL 21 - 157

Page 1739 of 2158

(2) Verify transmission throttle cable operation.

Repair or replace cable if necessary.

(3) Check engine throttle operation. Operate accel-

erator pedal and observe injector throttle plate move-

ment. Adjust linkage if throttle plate does not reach

wide open position.

(4) Check transmission fluid level when fluid is at

normal operating temperature. Start engine. Shift

transmission through all gear ranges then back to

Neutral. Correct level is to Full or Add mark on dip-

stick with engine at curb idle speed.

(5) Check and adjust park/neutral position switch

if necessary.

(6) Check throttle position sensor adjustment and

operation. Adjust the sensor if necessary.

MANUAL SHIFTING TEST

(1) This test determines if problem is related to

mechanical or electrical component.

(2) Stop engine and disconnect transmission con-

trol module or module fuse.

(3) Road test vehicle. Shift transmission into each

gear range. Transmission should operate as follows:

²lock in Park

²back up in Reverse

²not move in Neutral

²provide first gear only with shift lever in 1-2 posi-

tion

²operate in third gear only with shift lever in 3 po-

sition

²operate in overdrive fourth gear in D position

(4) If transmission operates as described, proceed

to next step. However, if forward gear ranges were

difficult to distinguish (all feel the same), or vehicle

would not back up, refer to diagnosis charts. Do not

perform stall or time lag tests.

CAUTION: Do not overspeed the engine during the

next test step. Ease off the throttle and allow the

vehicle to slow before downshifting.

(5) Continue road test. Manually downshift trans-

mission from D to 3, and from 3 to 1-2 position. Then

manually upshift transmission through forward

ranges again.

(6) If transmission operation is OK, perform stall,

time lag and pressure tests. If transmission shifting

problem is encountered, refer to diagnosis charts.

(7) If a problem still exists, continue testing with

DRB scan tool.

HYDRAULIC PRESSURE TEST

PRESSURE TEST PROCEDURE

(1) Connect pressure test gauge to test port on pas-

senger side of transmission. Use Adapter 7554 to con-

nect gauge. Be sure test gauge has minimum

capacity of 300 psi (2100 kPa).(2) Be sure transmission fluid is at normal operat-

ing temperature.

(3) Apply parking brakes and block wheels.

WARNING: DO NOT ALLOW ANYONE TO STAND

AT THE FRONT OR REAR OF THE VEHICLE WHILE

PERFORMING THE FOLLOWING STEPS IN THE

PRESSURE TEST.

(4) Check and adjust engine curb idle speed.

(5) Apply (and hold) service brakes.

(6) Shift transmission into D range and note line

pressure with engine at curb idle speed. Pressure

should be 61-to-70 psi (421-to-481 kPa).

(7) Press accelerator pedal to wide open throttle

position and note line pressure. Pressure should be

173-to-209 psi (1196-to-1442 kPa).

CAUTION: Do not hold wide open throttle for more

than 3-4 seconds at a time.

(8) Shift transmission into Reverse and note line

pressure with engine at curb idle speed. Pressure

should be 75-to-90 psi (519-to-618 kPa).

(9) Press accelerator to wide open throttle position

and note line pressure in Reverse. Pressure should

be 213-to-263 psi (1471-to-1814 kPa).

CAUTION: Do not hold wide open throttle for more

than 4 seconds.

(10) If line pressure is not within specifications,

adjust transmission throttle cable and repeat pres-

sure test.

Fig. 27 Pressure Test Gauge Connection

JAW-4 TRANSMISSION DIAGNOSIS 21 - 177

Page 1740 of 2158

PRESSURE TEST ANALYSIS

If pressures in D and Reverse are higher than

specified in test, check for the following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, throttle cam, or pri-

mary regulator valve are sticking, worn or damaged

If pressures in D and Reverse are lower than spec-

ified in test, check for following:

²throttle cable loose, worn, binding or out of adjust-

ment

²throttle valve, downshift plug, or throttle cam

sticking, worn or damaged

²primary regulator valve sticking, worn, or dam-

aged

²oil pump gears or housing worn, or damaged

²overdrive clutch worn, or damaged

If pressures are low in D range only, check for fol-

lowing:

²forward clutch worn or damaged

²fluid leakage in D range circuit (component seal

and O-rings)

If pressures are low in Reverse only, check for fol-

lowing:

²shift cable and manual valve out of adjustment

²fluid leakage in reverse circuit (component seal

and O-rings)

²direct clutch worn or damaged

²first/reverse brake worn or damaged

TORQUE CONVERTER STALL TEST

Stall testing checks the holding ability of the trans-

mission clutches and brakes and of the torque con-

verter stator overrunning clutch.Stall speeds are

checked in both Drive and Reverse ranges with

the AW-4 transmission.

(1) Before starting test, be sure fluid level is cor-

rect and fluid is at normal operating temperature.

(2) Connect tachometer to engine. Position tachom-

eter so it can be viewed from drivers seat.

(3) Apply parking brakes and block wheels.

(4) Apply and hold service brakes.

(5) Shift transfer case into 2H position.

(6) Start engine.

WARNING: DO NOT ALLOW ANYONE TO STAND AT

THE FRONT OR REAR OF THE VEHICLE DURING

THE TEST.

(7) Shift transmission into D range.

(8) Open throttle completely and record maximum

engine rpm registered on tachometer. It takes any-

where from 4 to 10 seconds to reach maximum rpm.

However, once maximum rpm has been achieved,do

not hold wide open throttle for more than 3-4

seconds.CAUTION: Stalling the converter causes a rapid in-

crease in fluid temperature. To avoid fluid overheat-

ing, hold wide open throttle for no more than 4

seconds after reaching peak rpm. In addition, if

more than one stall test is required, run the engine

at 1000 rpm with the transmission in Neutral for at

least 20 seconds to cool the fluid.

(9) Stall speed should be in 2100-2400 rpm range

in Drive.

(10) Release throttle, shift transmission into Neu-

tral, and run engine for 20-30 seconds to cool fluid.

(11) Shift transmission into Reverse.

(12) Repeat stall test described in step (8).

(13) Stall speed in Reverse should also be in 2100-

2400 rpm range.

(14) Release accelerator pedal, shift transmission

into Neutral, and run engine for 20-30 seconds to

cool fluid.

STALL SPEED TEST ANALYSIS

If engine rpm is lower than specified in D and Re-

verse, check for the following:

²engine output/performance insufficient

²stator overrunning clutch in torque converter not

holding if engine speed was 1500 rpm or less.

If stall speed in D range is higher than specified,

check for the following:

²line pressure low

²forward clutch slipping

²No. 2 one-way clutch not holding

²overdrive one-way clutch not holding

If stall speed in Reverse was higher than specified,

check for the following:

²line pressure low

²direct clutch slipping

²first/ reverse brake slipping

²overdrive one-way clutch not holding

If stall speeds were higher than specified in both D

and Reverse, check for the following:

²low fluid level

²line pressure low

²overdrive one-way clutch not holding

TIME LAG TEST

This test checks general condition of the overdrive

clutch, forward clutch, rear clutch and first/reverse

brake. Condition is indicated by the amount of time

required for clutch/brake engagement with the en-

gine at curb idle speed. Engagement time is mea-

sured for D and Reverse positions. A stop watch is

recommended for test accuracy.

TEST PROCEDURE

(1) Check and adjust transmission fluid level if

necessary.

(2) Bring transmission to normal operating tem-

perature.

21 - 178 AW-4 TRANSMISSION DIAGNOSISJ

Page 1741 of 2158

(3) Apply parking brakes and turn off air condi-

tioning unit.

(4) Shift transfer case into 2H range.

(5) Start engine and check curb idle speed. Adjust

speed if necessary. Curb idle must be correct to en-

sure accurate test results.

(6) Shift transmission into Neutral and set stop

watch.

(7) During following test steps, start stop watch as

soon as shift lever reaches D and Reverse ranges.

(8) Shift transmission into D range and record

time it takes for engagement. Repeat test two more

times.

(9) Reset stop watch and shift transmission back to

Neutral.

(10) Shift transmission into Reverse and record

time it takes for engagement. Repeat test two more

times.(11) Engagement time in D range should be a max-

imum of 1.2 seconds. Engagement time for Reverse

should be a maximum of 1.5 seconds.

TIME LAG TEST ANALYSIS

If engagement time is longer than specified for D

range, check for the following:

²shift cable misadjusted

²line pressure low

²forward clutch worn

²overdrive clutch worn or damaged

If engagement time is longer than specified for Re-

verse, check for the following:

²shift cable misadjusted

²line pressure low

²direct clutch worn

²first/reverse brake worn

²overdrive clutch worn or damaged

JAW-4 TRANSMISSION DIAGNOSIS 21 - 179

Page 1759 of 2158

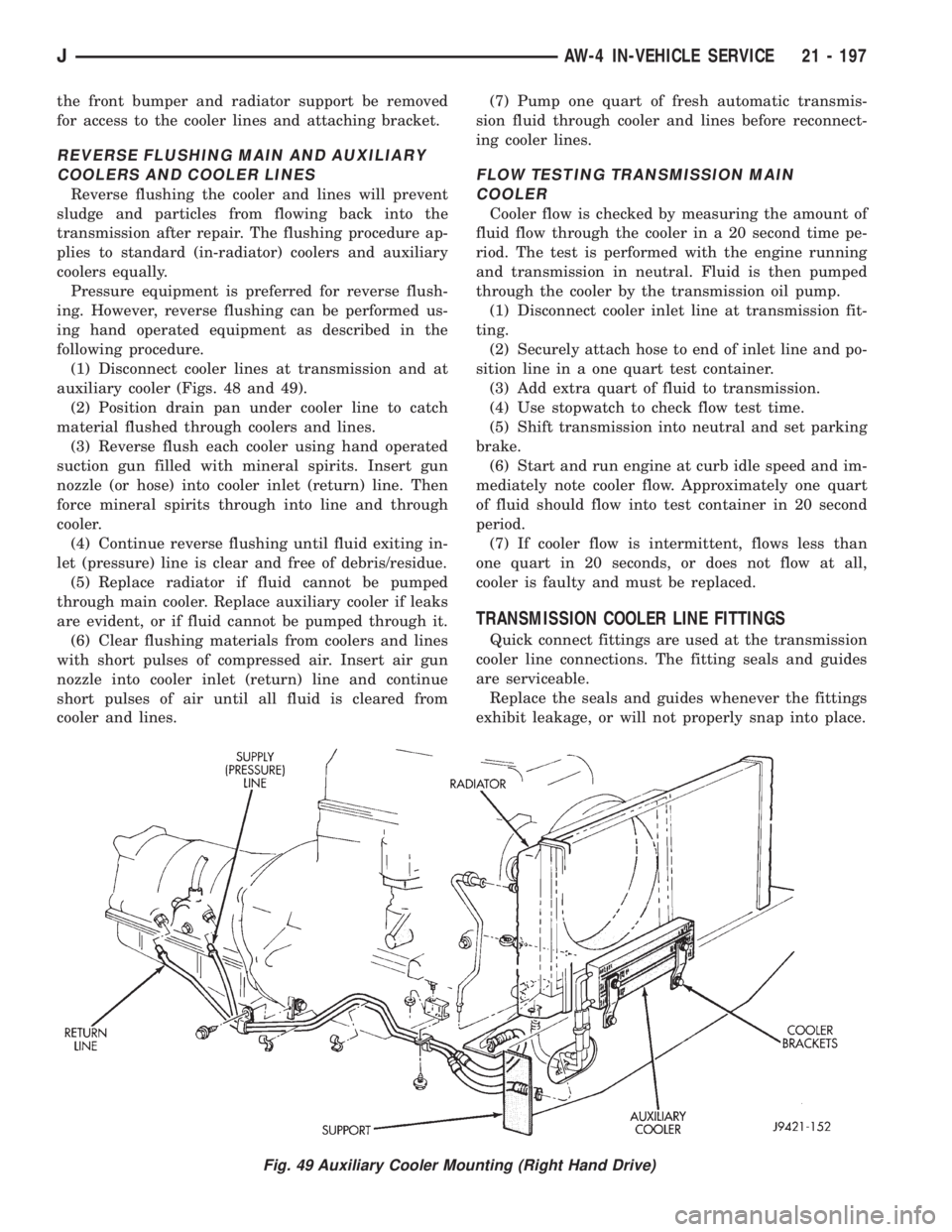

the front bumper and radiator support be removed

for access to the cooler lines and attaching bracket.

REVERSE FLUSHING MAIN AND AUXILIARY

COOLERS AND COOLER LINES

Reverse flushing the cooler and lines will prevent

sludge and particles from flowing back into the

transmission after repair. The flushing procedure ap-

plies to standard (in-radiator) coolers and auxiliary

coolers equally.

Pressure equipment is preferred for reverse flush-

ing. However, reverse flushing can be performed us-

ing hand operated equipment as described in the

following procedure.

(1) Disconnect cooler lines at transmission and at

auxiliary cooler (Figs. 48 and 49).

(2) Position drain pan under cooler line to catch

material flushed through coolers and lines.

(3) Reverse flush each cooler using hand operated

suction gun filled with mineral spirits. Insert gun

nozzle (or hose) into cooler inlet (return) line. Then

force mineral spirits through into line and through

cooler.

(4) Continue reverse flushing until fluid exiting in-

let (pressure) line is clear and free of debris/residue.

(5) Replace radiator if fluid cannot be pumped

through main cooler. Replace auxiliary cooler if leaks

are evident, or if fluid cannot be pumped through it.

(6) Clear flushing materials from coolers and lines

with short pulses of compressed air. Insert air gun

nozzle into cooler inlet (return) line and continue

short pulses of air until all fluid is cleared from

cooler and lines.(7) Pump one quart of fresh automatic transmis-

sion fluid through cooler and lines before reconnect-

ing cooler lines.

FLOW TESTING TRANSMISSION MAIN

COOLER

Cooler flow is checked by measuring the amount of

fluid flow through the cooler in a 20 second time pe-

riod. The test is performed with the engine running

and transmission in neutral. Fluid is then pumped

through the cooler by the transmission oil pump.

(1) Disconnect cooler inlet line at transmission fit-

ting.

(2) Securely attach hose to end of inlet line and po-

sition line in a one quart test container.

(3) Add extra quart of fluid to transmission.

(4) Use stopwatch to check flow test time.

(5) Shift transmission into neutral and set parking

brake.

(6) Start and run engine at curb idle speed and im-

mediately note cooler flow. Approximately one quart

of fluid should flow into test container in 20 second

period.

(7) If cooler flow is intermittent, flows less than

one quart in 20 seconds, or does not flow at all,

cooler is faulty and must be replaced.

TRANSMISSION COOLER LINE FITTINGS

Quick connect fittings are used at the transmission

cooler line connections. The fitting seals and guides

are serviceable.

Replace the seals and guides whenever the fittings

exhibit leakage, or will not properly snap into place.

Fig. 49 Auxiliary Cooler Mounting (Right Hand Drive)

JAW-4 IN-VEHICLE SERVICE 21 - 197

Page 1761 of 2158

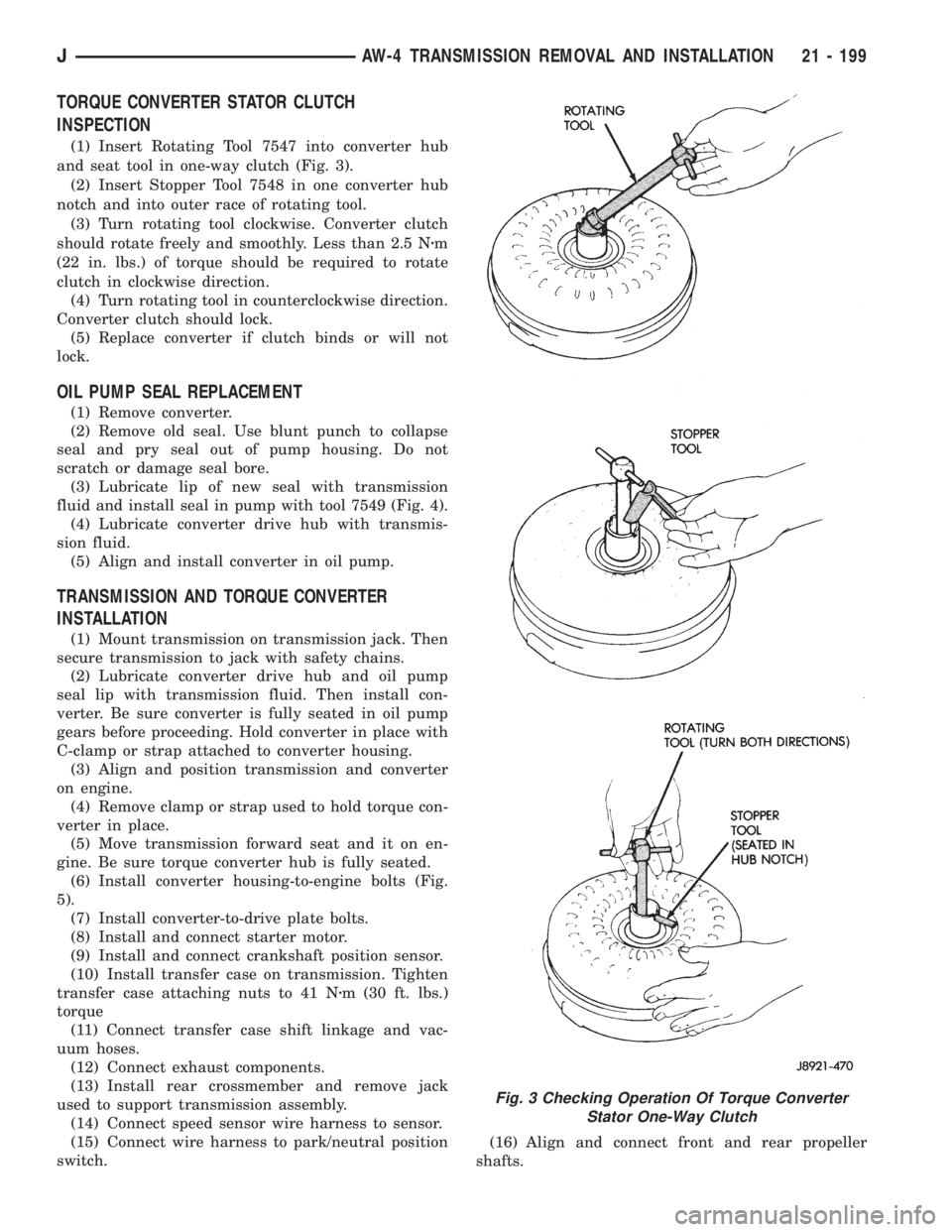

TORQUE CONVERTER STATOR CLUTCH

INSPECTION

(1) Insert Rotating Tool 7547 into converter hub

and seat tool in one-way clutch (Fig. 3).

(2) Insert Stopper Tool 7548 in one converter hub

notch and into outer race of rotating tool.

(3) Turn rotating tool clockwise. Converter clutch

should rotate freely and smoothly. Less than 2.5 Nzm

(22 in. lbs.) of torque should be required to rotate

clutch in clockwise direction.

(4) Turn rotating tool in counterclockwise direction.

Converter clutch should lock.

(5) Replace converter if clutch binds or will not

lock.

OIL PUMP SEAL REPLACEMENT

(1) Remove converter.

(2) Remove old seal. Use blunt punch to collapse

seal and pry seal out of pump housing. Do not

scratch or damage seal bore.

(3) Lubricate lip of new seal with transmission

fluid and install seal in pump with tool 7549 (Fig. 4).

(4) Lubricate converter drive hub with transmis-

sion fluid.

(5) Align and install converter in oil pump.

TRANSMISSION AND TORQUE CONVERTER

INSTALLATION

(1) Mount transmission on transmission jack. Then

secure transmission to jack with safety chains.

(2) Lubricate converter drive hub and oil pump

seal lip with transmission fluid. Then install con-

verter. Be sure converter is fully seated in oil pump

gears before proceeding. Hold converter in place with

C-clamp or strap attached to converter housing.

(3) Align and position transmission and converter

on engine.

(4) Remove clamp or strap used to hold torque con-

verter in place.

(5) Move transmission forward seat and it on en-

gine. Be sure torque converter hub is fully seated.

(6) Install converter housing-to-engine bolts (Fig.

5).

(7) Install converter-to-drive plate bolts.

(8) Install and connect starter motor.

(9) Install and connect crankshaft position sensor.

(10) Install transfer case on transmission. Tighten

transfer case attaching nuts to 41 Nzm (30 ft. lbs.)

torque

(11) Connect transfer case shift linkage and vac-

uum hoses.

(12) Connect exhaust components.

(13) Install rear crossmember and remove jack

used to support transmission assembly.

(14) Connect speed sensor wire harness to sensor.

(15) Connect wire harness to park/neutral position

switch.(16) Align and connect front and rear propeller

shafts.

Fig. 3 Checking Operation Of Torque Converter

Stator One-Way Clutch

JAW-4 TRANSMISSION REMOVAL AND INSTALLATION 21 - 199

Page 1823 of 2158

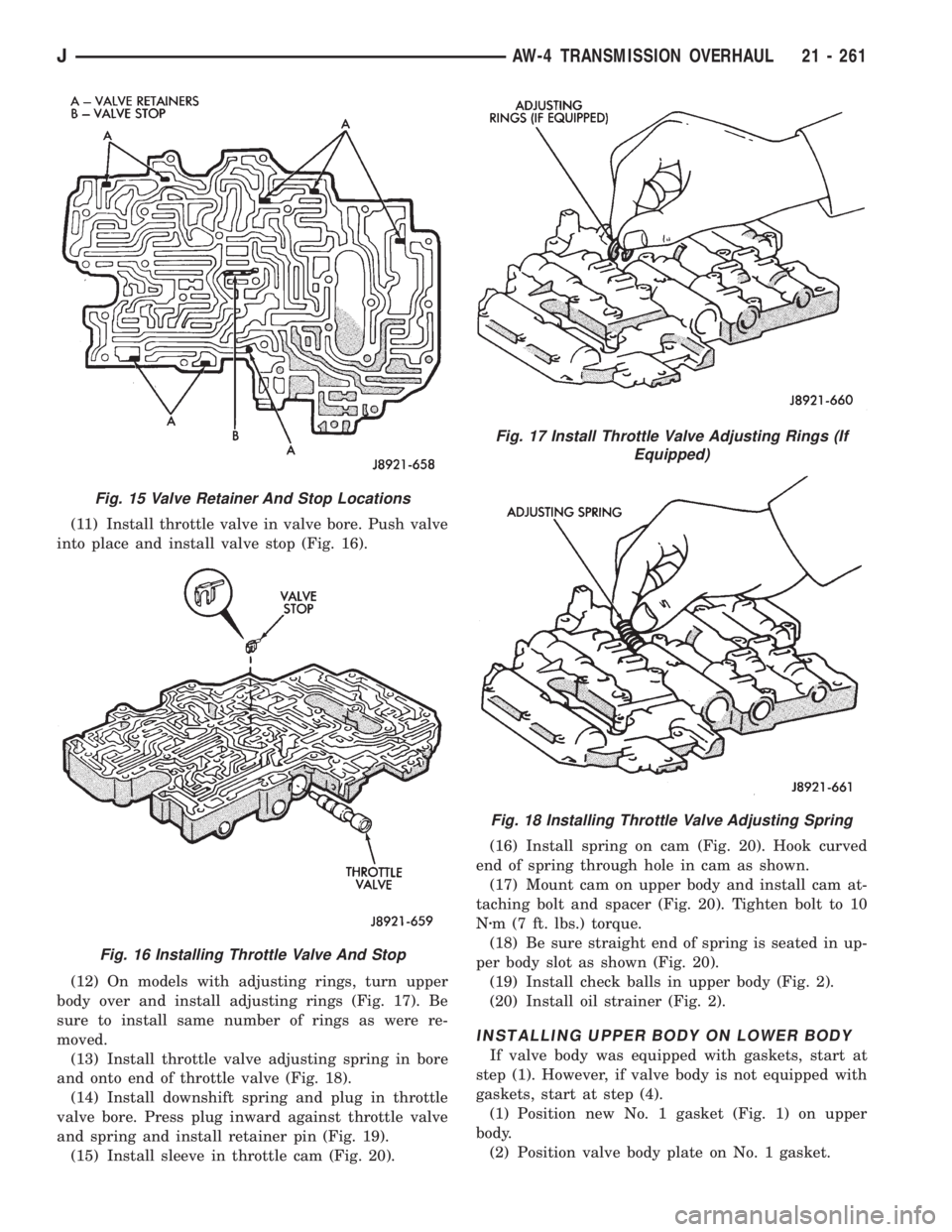

(11) Install throttle valve in valve bore. Push valve

into place and install valve stop (Fig. 16).

(12) On models with adjusting rings, turn upper

body over and install adjusting rings (Fig. 17). Be

sure to install same number of rings as were re-

moved.

(13) Install throttle valve adjusting spring in bore

and onto end of throttle valve (Fig. 18).

(14) Install downshift spring and plug in throttle

valve bore. Press plug inward against throttle valve

and spring and install retainer pin (Fig. 19).

(15) Install sleeve in throttle cam (Fig. 20).(16) Install spring on cam (Fig. 20). Hook curved

end of spring through hole in cam as shown.

(17) Mount cam on upper body and install cam at-

taching bolt and spacer (Fig. 20). Tighten bolt to 10

Nzm (7 ft. lbs.) torque.

(18) Be sure straight end of spring is seated in up-

per body slot as shown (Fig. 20).

(19) Install check balls in upper body (Fig. 2).

(20) Install oil strainer (Fig. 2).

INSTALLING UPPER BODY ON LOWER BODY

If valve body was equipped with gaskets, start at

step (1). However, if valve body is not equipped with

gaskets, start at step (4).

(1) Position new No. 1 gasket (Fig. 1) on upper

body.

(2) Position valve body plate on No. 1 gasket.

Fig. 15 Valve Retainer And Stop Locations

Fig. 16 Installing Throttle Valve And Stop

Fig. 17 Install Throttle Valve Adjusting Rings (If

Equipped)

Fig. 18 Installing Throttle Valve Adjusting Spring

JAW-4 TRANSMISSION OVERHAUL 21 - 261

Page 2128 of 2158

BUMPERÐXJ, LIFTGATE LICENSE PLATE

SCREW ANCHOR.....................23-65

BUMPERÐXJ, REAR SEATBACK LATCH

STRIKER...........................23-84

BUMPERS......................13-16,13-5

BUS, CCD; FUEL/IGNITION (XJ).......8W-30-5

BUSHING AND PISTON CLEARANCE,

AW-4 .............................21-339

BUSHING REPLACEMENT, AXLE......2-12,2-34

BUSHING REPLACEMENT, LEAF SPRING

EYE; FRONT SUSPENSION AND AXLE.....2-17

BUSHING REPLACEMENT, LEAF SPRING

EYE; REAR SUSPENSION AND AXLES . . . 3-5,3-7

BUSHINGS, CLUTCH AND BRAKE PEDAL . . . 0-22

BUZZER, COMBINATION; INTERIOR

LIGHTING (YJ)....................8W-44-1

BUZZER MODULE.................8U-1,8U-2

BUZZER MODULE SCHEMATIC - YJ.......8U-4

CABLE, ACCELERATOR PEDAL AND

THROTTLE.....................14-17,14-58

CABLE ADJUSTMENT, PARK INTERLOCK . 21-195

CABLE ADJUSTMENT, SHIFT...........21-195

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE.........................21-194

CABLE ADJUSTMENT, TRANSMISSION

THROTTLE VALVE....................21-71

CABLE ADJUSTMENT (XJ), PARK

INTERLOCK........................21-101

CABLE ADJUSTMENT (XJ), SHIFT.......21-100

CABLE ADJUSTMENT (XJ/YJ), THROTTLE

VALVE..............................21-101

CABLE REMOVE/INSTALL, SERVO.......8H-10

CABLE REPLACEMENT, TRANSMISSION

THROTTLE.........................21-193

CABLE REPLACEMENT (XJ), PARKING

BRAKE REAR.........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE FRONT........................5-67

CABLE REPLACEMENT (YJ), PARKING

BRAKE REAR.........................5-68

CABLE REPLACEMENTÐXJ, LATCH

RELEASE...........................23-11

CABLE RESISTANCE, SPARK PLUG......8D-14

CABLE, SERVO.......................8H-1

CABLE, SPEEDOMETER.................0-33

CABLE TENSIONER ADJUSTMENT

(XJ/YJ), PARKING BRAKE...............5-69

CABLE TENSIONER REPLACEMENT (XJ),

PARKING BRAKE......................5-66

CABLE, THROTTLE...................14-17

CABLE/LINKAGE ADJUSTMENT,

GEARSHIFT.........................21-71

CABLES, DISTRIBUTOR CAP AND

ROTOR, IGNITION.....................0-20

CABLES, SPARK PLUG SECONDARY.....8D-14,

8D-24

CABLES, VENT DOOR CONTROL.........24-32

CALIBRATION, COMPASS...............8C-5

CALIPER ASSEMBLY...................5-50

CALIPER CLEANING AND INSPECTION.....5-50

CALIPER DISASSEMBLY................5-48

CALIPER INSTALLATION................5-51

CALIPER OPERATION AND WEAR

COMPENSATION......................5-45

CALIPER REMOVAL....................5-48

CAMSHAFT......................9-32,9-74

CAMSHAFT PIN REPLACEMENT......9-34,9-75

CAMSHAFT POSITION SENSOR; FUEL

SYSTEM............................14-60

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (YJ)................8W-30-3

CAMSHAFT POSITION SENSOR;

IGNITION SYSTEMS..............8D-17,8D-2

CAMSHAFT POSITION SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-3

CAMSHAFT POSITION SENSOR TEST;

FUEL SYSTEM.......................14-46

CAMSHAFT POSITION SENSOR TEST;

IGNITION SYSTEMS

...................8D-6

CAMSHAFT POSITION SENSORÐPCM

INPUT

.............................14-22

(CANADA ONLY)ÐXJ, DAYTIME

RUNNING LIGHTS

....................8L-15

(CANADA ONLY)ÐYJ, DAYTIME

RUNNING LIGHTS

....................8L-30

CANISTER, EVAP

..................25-4,25-7CAP AND ROTOR, IGNITION CABLES,

DISTRIBUTOR........................0-20

CAP, DISTRIBUTOR....................8D-7

CAP, FUEL TANK FILLER TUBE;

EMISSION CONTROL SYSTEMS......25-4,25-7

CAP, FUEL TANK FILLER TUBE; FUEL

SYSTEM............................14-13

CAP, RADIATOR PRESSURE.............7-25

CAPACITIES, COOLING SYSTEM..........7-45

CAPACITIES, FLUID.....................0-3

CAPACITIES, FUEL TANK..........14-13,14-67

CAPACITY TEST, FUEL PUMP............14-7

CAR REPLACEMENT, PITMAN SHAFT

SEALSÐIN.........................19-23

CARDAN (CV), DOUBLE................16-11

CARDAN, SINGLE....................16-10

CARGO BARRIERÐXJ................23-101

CARGO LAMP AND DOME LAMP;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

CARGO LAMP, COURTESY LAMPS AND

DOME LAMP; INTERIOR LIGHTING (XJ) . 8W-44-1

CARGO LAMPÐXJ...................23-94

CARPET/MATÐXJ, FRONT.............23-99

CARPET/MATÐXJ, REAR.............23-100

CARPETÐYJ.......................23-156

CARPETS AND FLOOR MATSÐXJ.......23-99

CARRIERÐYJ, EXTERNAL SPARE/

WHEEL TIRE.......................23-133

CASE (4WD VEHICLES), TRANSFER........0-24

CASE ASSEMBLY, TRANSFER....21-294,21-319

CASE CHANGES, TRANSFER...........21-307

CASE CLEANING AND INSPECTION,

TRANSMISSION.....................21-125

CASE COVER OIL SEAL REPLACEMENT,

TIMING.........................9-30,9-73

CASE COVER, TIMING..............9-31,9-72

CASE DISASSEMBLY AND OVERHAUL,

TRANSFER...................21-289,21-310

CASE IDENTIFICATION, TRANSFER.....21-284,

21-307

CASE INSTALLATION, TRANSFER . 21-288,21-309

CASE LUBRICANT AND FILL LEVEL,

TRANSFER.........................21-284

CASE, NP231 TRANSFER.......21-283,21-305

CASE, NP242 TRANSFER.......21-307,21-331

CASE OVERHAUL, FIRST-REVERSE

BRAKE PISTON AND TRANSMISSION....21-247

CASE REMOVAL, TRANSFER.....21-287,21-309

CASE SKID PLATE, TRANSFER......13-15,13-3

CASE SPECIFICATIONS, TRANSMISSION/

TRANSFER.........................21-333

CATALYTIC CONVERTER............11-1,11-4

CATALYTIC CONVERTOR................25-1

CAUTIONS, AND WARNINGS, NOTES;

WIRING DIAGRAMSÐGENERAL

INFORMATION (XJ)...................8W-1

CCD BUS; FUEL/IGNITION (XJ)........8W-30-5

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ.......................8L-12

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ.......................8L-28

CERTIFICATION LABEL, VEHICLE SAFETY . Intro.-4

CHAIN AND SPROCKETS, TIMING....9-31,9-73

CHANGE AND FILTER REPLACEMENT,

ENGINE OIL

..........................0-16

CHANGE, LUBRICANT; FRONT

SUSPENSION AND AXLE

................2-23

CHANGE, LUBRICANT; REAR

SUSPENSION AND AXLES

...........3-13,3-31

CHANGE, REFILLING AFTER OVERHAUL

OR FLUID/FILTER

..............21-100,21-182

CHANGES AND PARTS

INTERCHANGEABILITY, TRANSMISSION

. . . 21-67

CHANGES, TRANSFER CASE

...........21-307

CHANNEL REPLACEMENTÐYJ, DOOR

FRAME GLASS

......................23-142

CHARGING, BATTERY

..................8A-7

CHARGING REFRIGERANT SYSTEM

......24-11

CHARGING SYSTEM; BATTERY/

STARTING/CHARGING SYSTEMS

DIAGNOSTICS

.......................8A-17

CHARGING SYSTEM; CHARGING

SYSTEM (XJ)

.....................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (XJ-RHD)

.................8W-20-1

CHARGING SYSTEM; CHARGING

SYSTEM (YJ)

.....................8W-20-1CHARGING SYSTEM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-3

CHARGING SYSTEM SPECIFICATIONS....8A-23

CHARGING TIME TABLE, BATTERY........8A-8

CHART, MAIN BEARING FITTING......9-48,9-90

CHART, XJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHART, YJ PERFORMANCE

TEMPERATURE AND PRESSURE.........24-13

CHARTÐAX 15 MANUAL

TRANSMISSION, SELECTIVE SNAP

RING.............................21-334

CHARTS, BRAKELINE..................5-12

CHARTS, DIAGNOSIS GUIDES...........21-77

CHARTS, GEARTRAIN OPERATION AND

APPLICATION.......................21-169

CHARTS, INSPECTION AND DIAGNOSIS.....6-4

CHASSIS AND BODY COMPONENTS.......0-28

CHASSIS COMPONENT AND WHEEL

BEARING LUBRICANTS.................0-28

CHECK VALVE TEST, POWER BOOSTER.....5-9

CHECKING FLUID LEVEL AND

CONDITION........................21-182

CHECKS, PRELIMINARY.................7-5

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ)....................8W-44-2

CHIME/BUZZER MODULE; INTERIOR

LIGHTING (XJ-RHD)................8W-44-2

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ)....................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (XJ-RHD)................8W-51-1

CHMSL LAMPS, STOP LAMPS; REAR

LIGHTING (YJ)....................8W-51-1

(CHMSL)ÐXJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-12

(CHMSL)ÐYJ, CENTER HIGH MOUNTED

STOP LAMP.........................8L-28

CIGAR LIGHTER; HORN/CIGAR LIGHTER . . . 8E-1

CIGAR LIGHTER; HORN/CIGAR LIGHTER

(YJ).............................8W-41-1

CIGAR LIGHTER; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

CIRCUIT IDENTIFICATION; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

CIRCUIT REMOVE/INSTALL, PRINTED....8E-19,

8E-40

CIRCUIT SENSEÐPCM INPUT, IGNITION . . 14-23

CIRCUIT VOLTAGE, OPEN...............8A-6

CLAMPS, FUEL TUBES/LINES/HOSES . 14-62,14-9

CLASSIFICATION OF LUBRICANTS.........0-2

CLASSIFICATIONS AND RATINGS,

BATTERY...........................8A-23

CLEANER, AIR.......................14-29

CLEANER ELEMENT, AIR; EMISSION

CONTROL SYSTEMS...................25-7

CLEANER ELEMENT, AIR; FUEL SYSTEM . . 14-59

CLEANER ELEMENT, AIR; LUBRICATION

AND MAINTENANCE...................0-18

CLEANER HOUSING, AIR...............14-58

CLEANING AND INSPECTION, CALIPER....5-50

CLEANING AND INSPECTION, GEAR......19-42

CLEANING AND INSPECTION,

TRANSMISSION CASE................21-125

CLEANING OF TIRES...................22-2

CLEANING/INSPECTION; FRONT

SUSPENSION AND AXLE

................2-37

CLEANING/INSPECTION; REAR

SUSPENSION AND AXLES

...............3-20

CLEANING/REVERSE FLUSHING,

COOLING SYSTEM

....................7-22

CLEARANCE AND RAMP ANGLE,

GROUND

............................0-11

CLEARANCE, AW-4 BUSHING AND

PISTON

...........................21-339

CLOCKSPRING

.......................19-51

CLUSTER AND GAUGE HOUSINGSÐYJ,

INSTRUMENT

......................23-151

CLUSTER ASSEMBLY REMOVE/INSTALL

. . 8E-17,

8E-35

CLUSTER BEZELÐXJ, INSTRUMENT

.....23-80

CLUSTER BEZELÐYJ, INSTRUMENT

....23-151

CLUSTER CONNECTORS (RHD)

.........8E-11

CLUSTER, GAUGE PACKAGE

.......8E-31,8E-43

CLUSTER GROUND; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-3

4 INDEXJ

Description Group-Page Description Group-Page Description Group-Page

Page 2137 of 2158

HEATER AND A/C CONTROL

REPLACEMENT......................24-23

HEATER AND A/C OPERATION...........24-1

HEATER AND AIR CONDITIONING; AIR

CONDITIONING/HEATER (YJ).........8W-42-2

HEATER CONTROL PANEL LAMP,

ACCESSORY LAMP; INTERIOR

LIGHTING (YJ)....................8W-44-1

HEATER CONTROL REPLACEMENT.......24-32

HEATER CORE.......................24-26

HEATER CORE AND HOUSING..........24-33

HEATER DIAGNOSIS..................24-17

HEATER ELEMENTS; POWER MIRRORS

(XJ-RHD).........................8W-62-1

HEATER, ENGINE BLOCK................7-44

HEATER HOUSING REPLACEMENT.......24-26

HEATER SYSTEM; AIR CONDITIONING/

HEATER (XJ)......................8W-42-1

HEATER SYSTEM; AIR CONDITIONING/

HEATER (XJ-RHD)..................8W-42-1

HEATER SYSTEM; AIR CONDITIONING/

HEATER (YJ)......................8W-42-1

HEATER/DEFROSTER/INSTRUMENT

PANEL OUTLET VACUUM MOTOR

REPLACEMENT......................24-26

HEATING AND AIR CONDITIONING TEST

PROCEDURES.......................24-15

HEATING ELEMENT TEST, OXYGEN

SENSOR (O2S)......................14-48

HEATING SCHEMATICÐXJ..............24-2

HEATING SYSTEM DIAGNOSIS..........24-18

HELPFUL INFORMATION; CHARGING

SYSTEM (XJ).....................8W-20-1

HELPFUL INFORMATION; CHARGING

SYSTEM (XJ-RHD).................8W-20-1

HELPFUL INFORMATION; CHARGING

SYSTEM (YJ).....................8W-20-1

HELPFUL INFORMATION; POWER SEAT

(XJ).............................8W-63-1

HELPFUL INFORMATION; POWER

WINDOWS (XJ)....................8W-60-2

HELPFUL INFORMATION; POWER

WINDOWS (XJ-RHD)...............8W-60-2

HELPFUL INFORMATION; TRAILER TOW

(XJ).............................8W-54-1

HELPFUL INFORMATION; TRAILER TOW

(XJ-RHD).........................8W-54-1

HIGH MOUNTED STOP LAMP

(CHMSL)ÐXJ, CENTER................8L-12

HIGH MOUNTED STOP LAMP

(CHMSL)ÐYJ, CENTER................8L-28

HIGH PEDAL EFFORT, HARD PEDAL OR.....5-6

HIGH-BEAM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ).........8W-40-2

HIGH-BEAM INDICATOR LAMP;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

HIGH-LINE GAUGE CLUSTER (LHD).......8E-9

HIGH-PRESSURE CUT-OFF SWITCH,

LOW-PRESSURE................24-15,24-16

HINGE REPLACEMENTÐXJ, HOOD.......23-10

HINGE/HINGE PIN REPLACEMENTÐXJ,

DOOR.............................23-52

HINGEÐXJ, LIFTGATE.................23-60

HINGEÐYJ, TAILGATE................23-121

HINGESÐYJ, FULL-METAL DOOR.......23-140

HITCH, TRAILER.....................23-77

HITCHÐXJ, TRAILER.................23-77

HOISTING, JUMP STARTING, TOWING......0-9

HOISTING RECOMMENDATIONS..........0-10

HOLD AFTER DRIVING THROUGH DEEP

WATER PUDDLES, BRAKES DO NOT.......5-7

HOLDDOWN AND FLOOR BRACKETSÐ

XJ, SPARE TIRE/WHEEL...............23-98

HONING CYLINDER BORES...............9-2

HOOD ADJUSTMENTÐXJ..............23-10

HOOD ALIGNMENTÐYJ..............23-107

HOOD HINGE REPLACEMENTÐXJ.......23-10

HOOD INSULATOR PANELÐYJ.........23-107

HOOD LATCH REPLACEMENTÐXJ.......23-11

HOOD LATCH STRIKER REPLACEMENTÐ

XJ ................................23-11

HOOD SAFETY LATCHÐYJ............23-109

HOODÐXJ...........................23-7

HOODÐYJ

.........................23-107

HOOK, REAR TOW

.....................13-9

HOOKS, FRONT TOW

..................13-7

HOOKS, TOW

........................13-13

HORN; HORN/CIGAR LIGHTER

...........8E-1HORN; HORN/CIGAR LIGHTER (YJ)....8W-41-1

HORN; INSTRUMENT CLUSTER (XJ) . . . 8W-40-1

HORN CONTACT/CLOCKSPRING..........8G-4

HORN RELAY........................8G-1

HORN REMOVE/INSTALL...............8G-3

HORN SWITCH.......................8G-1

HORN SWITCH REMOVE/INSTALL........8G-3

HORNS.............................8G-1

HOSE REPLACEMENT, PRESSURE AND

RETURN............................19-11

HOSE ROUTING SCHEMATICS, VACUUM . . . 25-2

HOSE SPLASH SHIELDÐXJ VEHICLES,

FUEL FILLER.........................13-4

HOSES, BRAKE FLUIDÐBRAKE

BLEEDINGÐBRAKELINES...............5-10

HOSES, BRAKELINES..................5-12

HOSES, COOLING SYSTEM..............7-32

HOSES/TUBES PRECAUTIONS,

REFRIGERANT.......................24-10

HOSES/TUBING, RUBBER AND PLASTIC....0-26

HOUSING, AIR CLEANER...............14-58

HOUSING COMPONENTSÐYJ,

EVAPORATIVE........................24-6

HOUSING END PLUG..................19-28

HOUSING, EVAPORATOR...............24-35

HOUSING, EVAPORATOR/BLOWER.......24-29

HOUSING, HEATER CORE..............24-33

HOUSING INSPECTION AND PARK LOCK

COMPONENT OVERHAUL, ADAPTER/

EXTENSION........................21-127

HOUSING LEAK DIAGNOSIS,

CONVERTER........................21-75

HOUSING MISALIGNMENT, CLUTCH........6-4

HOUSING REPLACEMENT, CLUTCH.......6-13

HOUSING REPLACEMENT, HEATER.......24-26

HOUSING SEAL REPLACEMENT,

ADAPTER..........................21-191

HOUSINGÐXJ, LIFTGATE LICENSE

PLATE LAMP........................23-65

HOUSINGSÐYJ, INSTRUMENT CLUSTER

AND GAUGE........................23-151

HOW TO USE THIS GROUP; WIRING

DIAGRAMS (XJ)......................8W-1

HOW TO USE THIS GROUP; WIRING

DIAGRAMS (XJ-RHD)..................8W-1

HOW TO USE THIS GROUP; WIRING

DIAGRAMS (YJ)......................8W-1

HUB BEARING AND AXLE SHAFT.........2-25

HYDRAULIC CONTROL UNIT; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

HYDRAULIC CONTROL UNIT; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

HYDRAULIC CONTROL UNIT; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

HYDRAULIC CONTROL UNIT (HCU).......5-33

HYDRAULIC LINKAGE COMPONENTS.......6-1

HYDRAULIC LINKAGE INSTALLATION,

CLUTCH.............................6-14

HYDRAULIC LINKAGE REMOVAL,

CLUTCH.............................6-13

HYDRAULIC PRESSURE TEST.....21-177,21-72

HYDRAULIC SYSTEM................21-169

HYDRAULIC TAPPETS..............9-24,9-66

HYDROSTATIC LOCK

....................9-4

IDENTIFICATION, AW-4 ACCUMULATOR

COMPONENT

.......................21-342

IDENTIFICATION, AW-4 VALVE AND

SPRING

...........................21-343

IDENTIFICATION, BOLT

..............Intro.-14

IDENTIFICATION, CIRCUIT; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)

...............................8W-1

IDENTIFICATION, ENGINE AND

TRANSMISSION/TRANSFER CASE

......Intro.-5

IDENTIFICATION, MAJOR COMPONENT

. . Intro.-5

IDENTIFICATION NUMBER (VIN)

DECODING, VEHICLE

................Intro.-4

IDENTIFICATION NUMBER (VIN) PLATE,

VEHICLE

..........................Intro.-4

IDENTIFICATION, SECTION; WIRING

DIAGRAMS (XJ)

......................8W-1

IDENTIFICATION, SECTION; WIRING

DIAGRAMS (XJ-RHD)

..................8W-1

IDENTIFICATION, SECTION; WIRING

DIAGRAMS (YJ)

......................8W-1

IDENTIFICATION, TRANSFER CASE

.....21-284,

21-307IDENTIFICATION, TRANSMISSION . 21-166,21-33,

21-67,21-2

IDENTIFICATION, WIRE CODE; WIRING

DIAGRAMSÐGENERAL INFORMATION

(XJ)...............................8W-1

IDENTIFICATION/SYSTEM OPERATION,

COMPONENT.........................8D-1

IDLE AIR CONTROL (IAC) MOTOR; FUEL

SYSTEM............................14-62

IDLE AIR CONTROL (IAC) MOTOR;

FUEL/IGNITION (XJ)................8W-30-2

IDLE AIR CONTROL (IAC) MOTOR;

FUEL/IGNITION (YJ)................8W-30-2

IDLE AIR CONTROL (IAC) MOTOR;

FUEL/IGNITION (XJ-RHD)............8W-30-2

IDLE AIR CONTROL (IAC) MOTORÐPCM

OUTPUT............................14-27

IDLE AIR CONTROL MOTOR TEST.......14-49

IDLE SWITCH, EXTENDED...........8W-30-5

IDLE SWITCH TEST, EXTENDED.........14-48

IDLE SWITCHÐPCM INPUT, EXTENDED . . . 14-23

IGNITION CABLES, DISTRIBUTOR CAP

AND ROTOR.........................0-20

IGNITION CIRCUIT SENSEÐPCM INPUT . . 14-23

IGNITION COIL; FUEL SYSTEM..........14-62

IGNITION COIL; FUEL/IGNITION (XJ) . . . 8W-30-2

IGNITION COIL; FUEL/IGNITION (YJ) . . . 8W-30-2

IGNITION COIL; IGNITION SYSTEMS.....8D-22,

8D-4,8D-9

IGNITION COIL; FUEL/IGNITION

(XJ-RHD).........................8W-30-2

IGNITION COIL RESISTANCE............8D-9

IGNITION COILÐPCM OUTPUT..........14-28

IGNITION FEED; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

IGNITION KEY-IN SWITCH..........8U-1,8U-2

IGNITION SECONDARY CIRCUIT

DIAGNOSIS.........................8D-10

IGNITION SWITCH; BRAKES.............5-35

IGNITION SWITCH; FUEL/IGNITION (XJ) . 8W-30-1

IGNITION SWITCH; FUEL/IGNITION (YJ) . 8W-30-1

IGNITION SWITCH; FUEL/IGNITION

(XJ-RHD).........................8W-30-1

IGNITION SWITCH AND KEY CYLINDER

SERVICE...........................8D-26

IGNITION SWITCH CONTINUITY TESTS . . . 8D-30

IGNITION SWITCH LAMP; INTERIOR

LIGHTING (XJ)....................8W-44-1

IGNITION SWITCH LAMP; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

IGNITION SWITCH SERVICE............19-54

IGNITION SWITCHÐXJ MODELS........8D-26

IGNITION SWITCHÐYJ MODELS........8D-29

IGNITION TIMING....................8D-11

ILLUMINATION LAMPS, CLUSTER . . 8E-16,8E-26,

8E-34,8E-4

ILLUMINATION LAMPS, INSTRUMENT

PANEL; INTERIOR LIGHTING (XJ).....8W-44-1

ILLUMINATION LAMPS, INSTRUMENT

PANEL; INTERIOR LIGHTING (XJ-RHD) . 8W-44-1

ILLUMINATION, RADIO; RADIO (XJ)....8W-47-1

ILLUMINATION, RADIO; RADIO

(XJ-RHD).........................8W-47-1

ILLUMINATION, RADIO; RADIO (YJ)....8W-47-1

ILLUMINATION RELAY CONNECTIONS,

RADIO

..............................8F-4

ILLUMINATION RELAY, RADIO

........8F-1,8F-4

IMPACT SENSOR/INFLATOR ASSEMBLY

. . . 8M-2

INCORRECT FLUID LEVEL, EFFECTS OF

. . . 21-71

INDEX, DIAGRAM; AIR CONDITIONING/

HEATER (XJ)

......................8W-42-2

INDEX, DIAGRAM; AIR CONDITIONING/

HEATER (XJ-RHD)

..................8W-42-2

INDEX, DIAGRAM; AIR CONDITIONING/

HEATER (YJ)

...............8W-42-1,8W-42-2

INDEX, DIAGRAM; ANTI-LOCK BRAKES

(XJ)

.............................8W-32-3

INDEX, DIAGRAM; ANTI-LOCK BRAKES

(XJ-RHD)

.........................8W-32-3

INDEX, DIAGRAM; ANTI-LOCK BRAKES

(YJ)

.............................8W-32-2

INDEX, DIAGRAM; CHARGING SYSTEM

(XJ)

.............................8W-20-1

INDEX, DIAGRAM; CHARGING SYSTEM

(XJ-RHD)

.........................8W-20-1

INDEX, DIAGRAM; CHARGING SYSTEM

(YJ)

.............................8W-20-1

JINDEX 13

Description Group-Page Description Group-Page Description Group-Page

Page 2139 of 2158

INSTALLATION, DRUM BRAKESHOE.......5-55

INSTALLATION, FRONT WHEEL SENSOR . . . 5-38

INSTALLATION METHODS AND PARTS

USAGE...............................6-4

INSTALLATION (NON-ABS), MASTER

CYLINDER...........................5-16

INSTALLATION, ROTOR.................5-51

INSTALLATION, TRANSFER CASE . 21-288,21-309

INSTALLATION, TRANSMISSION.....21-36,21-5

INSTALLATION, TRANSMISSION AND

CONVERTER.......................21-117

INSTALLATION, TRANSMISSION AND

TORQUE CONVERTER................21-199

INSTALLATION, TRANSMISSION VALVE

BODY.............................21-187

INSTALLATION, VALVE BODY..........21-104

INSTALLATION, WHEEL.................22-6

INSTALLATION, WHEEL CYLINDER........5-58

INSTALLATION (WITH ABS), MASTER

CYLINDER AND COMBINATION VALVE.....5-20

INSTALLATION (XJ), HCU...............5-43

INSTALLATION (XJ MODELS), ECU........5-40

INSTALLATION (XJ), SHIFT LEVER......21-286,

21-309

INSTALLATION (XJ WITH ABS), POWER

BRAKE BOOSTER.....................5-27

INSTALLATION (XJ WITH FULL

CONSOLE), PARKING BRAKE LEVER.......5-64

INSTALLATION (XJ WITH MINI

CONSOLE), PARKING BRAKE LEVER.......5-63

INSTALLATION (XJ WITHOUT ABS),

POWER BRAKE BOOSTER...............5-30

INSTALLATION (XJ WITHOUT CONSOLE),

PARKING BRAKE LEVER................5-65

INSTALLATION (YJ), HCU...............5-44

INSTALLATION (YJ), PARKING BRAKE

PEDAL..............................5-66

INSTALLATION (YJ), POWER BRAKE

BOOSTER............................5-30

INSTALLATION (YJ), SHIFT LEVER......21-286

INSTRUMENT CLUSTER; INSTRUMENT

CLUSTER (XJ).....................8W-40-1

INSTRUMENT CLUSTER; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-1

INSTRUMENT CLUSTER; INSTRUMENT

CLUSTER (YJ).....................8W-40-1

INSTRUMENT CLUSTER AND GAUGE

HOUSINGSÐYJ.....................23-151

INSTRUMENT CLUSTER BEZELÐXJ......23-80

INSTRUMENT CLUSTER BEZELÐYJ.....23-151

INSTRUMENT CLUSTERS..........8E-24,8E-1

INSTRUMENT PANEL.............8E-24,8E-1

INSTRUMENT PANEL AND GAUGESÐYJ . . 8E-24

INSTRUMENT PANEL COMPONENTSÐYJ . 23-152

INSTRUMENT PANEL ILLUMINATION

LAMPS; INTERIOR LIGHTING (XJ).....8W-44-1

INSTRUMENT PANEL ILLUMINATION

LAMPS; INTERIOR LIGHTING (XJ-RHD) . 8W-44-1

INSTRUMENT PANEL REMOVE/INSTALL . . . 8E-20

INSTRUMENT PANELÐYJ.............23-151

INSULATOR PANELÐXJ, DASH PANEL....23-12

INSULATOR PANELÐYJ, HOOD........23-107

INTAKE AIR TEMPERATURE SENSOR;

FUEL/IGNITION (XJ)................8W-30-4

INTAKE AIR TEMPERATURE SENSOR;

FUEL/IGNITION (YJ)................8W-30-4

INTAKE AIR TEMPERATURE SENSOR;

FUEL/IGNITION (XJ-RHD)............8W-30-4

INTAKE DUCT, FRESH AIR..............24-34

INTAKE MANIFOLD...................14-63

INTAKE MANIFOLD AIR TEMPERATURE

SENSOR; FUEL SYSTEM...............14-60

INTAKE MANIFOLD AIR TEMPERATURE

SENSOR; IGNITION SYSTEMS......8D-23,8D-5

INTAKE MANIFOLD AIR TEMPERATURE

SENSOR TEST; FUEL SYSTEM..........14-46

INTAKE MANIFOLD AIR TEMPERATURE

SENSOR TEST; IGNITION SYSTEMS......8D-11

INTAKE MANIFOLD AIR TEMPERATURE

SENSORÐPCM INPUT................14-22

INTAKE MANIFOLD LEAKAGE DIAGNOSIS . . . 9-5

INTAKE MANIFOLDÐ2.5L ENGINE........11-7

INTAKE MANIFOLDÐ4.0L ENGINE

........11-8

INTERCHANGEABILITY, TRANSMISSION

CHANGES AND PARTS

................21-67

INTERFERENCE, RADIO FREQUENCY

......8F-5

INTERIOR COMPONENTS

........23-151,23-80

INTERIOR LAMPS

...............8L-16,8L-31INTERIOR LAMPSÐXJ................8L-18

INTERIOR LAMPSÐYJ................8L-32

INTERIOR REARVIEW MIRROR

SUPPORT BRACKET REPLACEMENTÐ

XJ ................................23-68

INTERIOR REARVIEW MIRRORÐXJ......23-66

INTERIOR TRIM PANELS AND SCUFF

PLATESÐXJ........................23-84

INTERLOCK CABLE ADJUSTMENT, PARK . 21-195

INTERLOCK CABLE ADJUSTMENT (XJ),

PARK .............................21-101

INTERLOCK MECHANISM, AUTOMATIC

TRANSMISSION SHIFTER/IGNITION......19-55

INTERMEDIATE (COUPLER) SHAFT.......19-45

INTERMEDIATEÐCOUPLING SHAFT......19-23

INTERMITTENT AND POOR

CONNECTIONS; WIRING DIAGRAMSÐ

GENERAL INFORMATION (XJ)...........8W-4

INTERMITTENT WIPE MODULE..........8K-4

INTERMITTENT WIPE SWITCH TESTING . . 8K-15

INTERMITTENT WIPERS; WIPERS

(XJ-RHD).........................8W-53-1

INTERNATIONAL SYMBOLS...............0-1

INTERNATIONAL VEHICLE CONTROL

AND DISPLAY SYMBOLS.............Intro.-5

INTRODUCTION; BODY COMPONENTSÐ

XJ VEHICLES.......................23-158

INTRODUCTION; LUBRICATION AND

MAINTENANCE.....................0-1,0-4

IN-VEHICLE SERVICE, 30RH/32RH.......21-99

IN-VEHICLE SERVICE, AW-4.............21-182

I/P ASH RECEIVER TRAY LAMPÐXJ.....23-80

JACK STORAGEÐXJ..................23-97

JAMB SWITCH, DRIVER'S DOOR.....8U-1,8U-2

JEEP BODY CODE LETTERS..............5-2

JOINT ANGLE MEASUREMENT,

UNIVERSAL..........................16-4

JOINT REPLACEMENT, UNIVERSAL.......16-10

JOINTS, UNIVERSAL...................16-2

JUMP STARTING PROCEDURE............0-9

JUMP STARTING, TOWING AND

HOISTING............................0-9

KEY CYLINDER SERVICE, IGNITION

SWITCH............................8D-26

KEY LOCK CYLINDERÐXJ, DOOR.......23-47

KEY LOCK CYLINDERÐYJ, FULL-METAL

DOOR............................23-139

KEY-IN SWITCH, IGNITION..........8U-1,8U-2

KEYLESS ENTRY MODULE..........8P-1,8P-7

KEYLESS ENTRY MODULE, REMOTE . . . 8W-61-1

KEYLESS ENTRY MODULE REMOVE/

INSTALL...........................8P-10

KEYLESS ENTRY RECEIVER.............8C-1

KEYLESS ENTRY RECEIVERÐXJ........23-93

KEYLESS ENTRY TRANSMITTER . 8P-1,8P-7,8P-8

KEYS ARE NOT AVAILABLE, TOWING

WHEN..............................0-13

KNOCK, LOW SPEED; FRONT

SUSPENSION AND AXLE................2-19

KNOCK, LOW SPEED; REAR

SUSPENSION AND AXLES...............3-10

KNUCKLE AND BALL STUDS, STEERING . . . 2-32

LABEL, VEHICLE EMISSION CONTROL

INFORMATION (VECI)..................25-1

LABEL, VEHICLE SAFETY CERTIFICATION . Intro.-4

LABELS AND PLATESÐXJ, VEHICLE....Intro.-2

LABELS AND PLATESÐYJ, VEHICLE....Intro.-3

LABELS/DECALS/PLATESÐXJ............23-1

LABELS/DECALS/PLATESÐYJ..........23-102

LABELS/PLATES, CODES AND

DIMENSIONS, DESIGNATIONS.........Intro.-1

LAG TEST, TIME....................21-178

LAMP, ABS WARNING; ANTI-LOCK

BRAKES (XJ)......................8W-32-2

LAMP, ABS WARNING; ANTI-LOCK

BRAKES (XJ-RHD).................8W-32-2

LAMP, ABS WARNING; ANTI-LOCK

BRAKES (YJ)......................8W-32-2

LAMP, ABS WARNING; INSTRUMENT

CLUSTER (XJ)

.....................8W-40-2

LAMP, ABS WARNING; INSTRUMENT

CLUSTER (XJ-RHD)

................8W-40-2

LAMP, ABS WARNING; INSTRUMENT

CLUSTER (YJ)

.....................8W-40-2

LAMP, ACCESSORY LAMP AND HEATER

CONTROL PANEL

..................8W-44-1

LAMP ADJUSTMENT USING ALIGNMENT

SCREENÐXJ, HEADLAMP/FOG

...........8L-7LAMP ADJUSTMENT USING ALIGNMENT

SCREENÐYJ, HEADLAMP/FOG..........8L-23

LAMP AND DOME LAMP, CARGO......8W-44-1

LAMP AND HEATER CONTROL PANEL

LAMP, ACCESSORY.................8W-44-1

LAMP, BRAKE WARNING; INSTRUMENT

CLUSTER (XJ).....................8W-40-2

LAMP, BRAKE WARNING; INSTRUMENT

CLUSTER (XJ-RHD)................8W-40-2

LAMP, BRAKE WARNING; INSTRUMENT

CLUSTER (YJ).....................8W-40-2

LAMP BULB REMOVE/INSTALL,

READING/COURTESY..................8C-8

LAMP BULB REPLACEMENTÐXJ,

BACK-UP/REAR TURN SIGNAL/TAIL......8L-12

LAMP BULB REPLACEMENTÐXJ, FRONT

PARK/TURN SIGNAL...................8L-9

LAMP BULB REPLACEMENTÐXJ, SIDE

MARKER...........................8L-10

LAMP BULB REPLACEMENTÐXJ,

UNDERHOOD........................8L-13

LAMP BULB REPLACEMENTÐYJ,

BACK-UP/REAR TURN SIGNAL/TAIL......8L-28

LAMP BULB REPLACEMENTÐYJ, FRONT

PARK/TURN SIGNAL..................8L-25

LAMP BULB REPLACEMENTÐYJ, SIDE

MARKER...........................8L-25

LAMP BULB REPLACEMENTÐYJ,

UNDERHOOD........................8L-29

LAMP BULB REPLACEMENTÐYJ

VEHICLES, HARDTOP DOME/CARGO.....8L-31

LAMP, CARGO LAMP AND DOME;

INTERIOR LIGHTING (XJ-RHD)........8W-44-1

LAMP, CARGO LAMP, COURTESY LAMPS

AND DOME; INTERIOR LIGHTING (XJ) . . 8W-44-1

LAMP, CHARGING SYSTEM INDICATOR;

INSTRUMENT CLUSTER (XJ).........8W-40-3

LAMP (CHMSL)ÐXJ, CENTER HIGH

MOUNTED STOP.....................8L-12

LAMP (CHMSL)ÐYJ, CENTER HIGH

MOUNTED STOP.....................8L-28

LAMP, COURTESY LAMPS AND DOME

LAMP, CARGO; INTERIOR LIGHTING

(XJ).............................8W-44-1

LAMP DIAGNOSIS, FOG...........8L-21,8L-3

LAMP (DRL) MODULE, DAYTIME

RUNNING; FRONT LIGHTING (XJ).....8W-50-2

LAMP (DRL) MODULEÐCANADIAN

VEHICLES ONLY, DAYTIME RUNNING;

FRONT LIGHTING (YJ)..............8W-50-2

LAMP, ENGINE COOLANT TEMPERATURE

WARNING; INSTRUMENT CLUSTER

(XJ).............................8W-40-1

LAMP, ENGINE COOLANT TEMPERATURE

WARNING; INSTRUMENT CLUSTER

(XJ-RHD).........................8W-40-1

LAMP, GLOVE BOX; INTERIOR LIGHTING

(XJ).............................8W-44-1

LAMP, GLOVE BOX; INTERIOR LIGHTING

(XJ-RHD).........................8W-44-1

LAMP, HIGH-BEAM INDICATOR;

INSTRUMENT CLUSTER (XJ).........8W-40-2

LAMP, HIGH-BEAM INDICATOR;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

LAMP HOUSINGÐXJ, LIFTGATE LICENSE

PLATE .............................23-65

LAMP, IGNITION SWITCH; INTERIOR

LIGHTING (XJ)....................8W-44-1

LAMP, IGNITION SWITCH; INTERIOR

LIGHTING (XJ-RHD)................8W-44-1

LAMP, LOW FUEL WARNING;

INSTRUMENT CLUSTER (XJ).........8W-40-1

LAMP, LOW WASHER FLUID WARNING;

INSTRUMENT CLUSTER (XJ).........8W-40-2

LAMP, LOW WASHER FLUID WARNING;

INSTRUMENT CLUSTER (XJ-RHD).....8W-40-2

LAMP, MANUAL TRANSMISSION

UP-SHIFT; INSTRUMENT CLUSTER (XJ) . 8W-40-2

LAMP (MIL), MALFUNCTION INDICATOR;

FUEL/IGNITION (XJ)

................8W-30-5

LAMP (MIL), MALFUNCTION INDICATOR;

FUEL/IGNITION (YJ)

................8W-30-5

LAMP (MIL), MALFUNCTION INDICATOR;

INSTRUMENT CLUSTER (XJ)

.........8W-40-2

LAMP (MIL), MALFUNCTION INDICATOR;

INSTRUMENT CLUSTER (XJ-RHD)

.....8W-40-1

LAMP (MIL), MALFUNCTION INDICATOR;

FUEL/IGNITION (XJ-RHD)

............8W-30-4

JINDEX 15

Description Group-Page Description Group-Page Description Group-Page