KIA Amanti 2008 1.G Owner's Manual

Manufacturer: KIA, Model Year: 2008, Model line: Amanti, Model: KIA Amanti 2008 1.GPages: 283, PDF Size: 20.47 MB

Page 231 of 283

In case of an emergency

186

The compact spare should be inflat-

ed to 420 kPa (60 psi).

✽NOTICE

Check the inflation pressure after

installing the spare tire. Adjust it to

the specified pressure, as necessary.

When using a compact spare tire,

observe the following precautions:

• Under no circumstances should

you exceed 80 km/h (50 mph); a

higher speed could damage the

tire.

• Ensure that you drive slowly enough for the road conditions to

avoid all hazards. Any road hazard,

such as a pothole or debris, could

seriously damage the compact

spare.

• Any continuous road use of this tire could result in tire failure, loss of

vehicle control, and possible per-

sonal injury.

• Do not exceed the vehicle’s maxi- mum load rating or the load-carry-

ing capacity shown on the sidewall

of the compact spare tire.

• Avoid driving over obstacles. The compact spare tire diameter is

smaller than the diameter of a con-

ventional tire and reduces the

ground clearance approximately

25 mm (1 inch), which could result

in damage to the vehicle. • Do not take the vehicle through an

automatic car wash with a compact

spare.

• Do not use tire chains on this tire. Because of the smaller size, a tire

chain will not fit properly. This could

damage the vehicle and result in

loss of the chain.

• This tire should not be installed on the front axle if the vehicle must be

driven in snow or on ice.

• Do not use the compact spare tire on any other vehicle because this

tire has been designed especially

for your vehicle.

• The compact spare tire’s tread life is shorter than a regular tire.

Inspect your compact spare tire

regularly and replace worn com-

pact spare tires with the same size

and design, mounted on the same

wheel.

WARNING - Compact spare

This spare tire should be used

only for VERY short distances.

Compact spares should NEVER

be us ed for long drives or

extended distances.

Page 232 of 283

619

In case of an emergency

Changing tires

Jacking instructions

The jack is provided for emergency

tire changing only.

Follow jacking instructions to reduce

the possibility of personal injury.

Tire replacement

1. Park on a level surface and apply

the parking brake firmly.

2. Shift the shift lever into P (Park).

3. Activate the hazard warning flash- er.

WARNING- Changing tire s

• Never attempt vehicle repair s

in the traffic lanes of a public

road or highway.

•Alway s move the vehicle com-

pletely off the road and onto

the shoulder before trying to

change a tire. The jack should

be used on level firm ground

whenever possible. If you can-

not find a firm, level place off

the road, call a towing service

company for assistance.

• Be sure to use the correct

front and rear jacking po si-

tions on the vehicle; never use

the bumper s or any other part

of the vehicle for jack support.

(Continued)

(Continued)

• The vehicle can easily roll off the jack caus ing serious

injury or death. No per son

should place any portion of

their body under a vehicle that

is supported only by a jack ;

use vehicle support stands.

• Do not start or run the engine while the vehicle i s on the

jack.

• Do not allow anyone to remain in the vehicle while it i s on the

jack.

• Make sure any children pres-

ent are in a secure place away

from the road and from the

vehicle to be rai sed with the

jack.

1JBA6021

Page 233 of 283

In case of an emergency

206

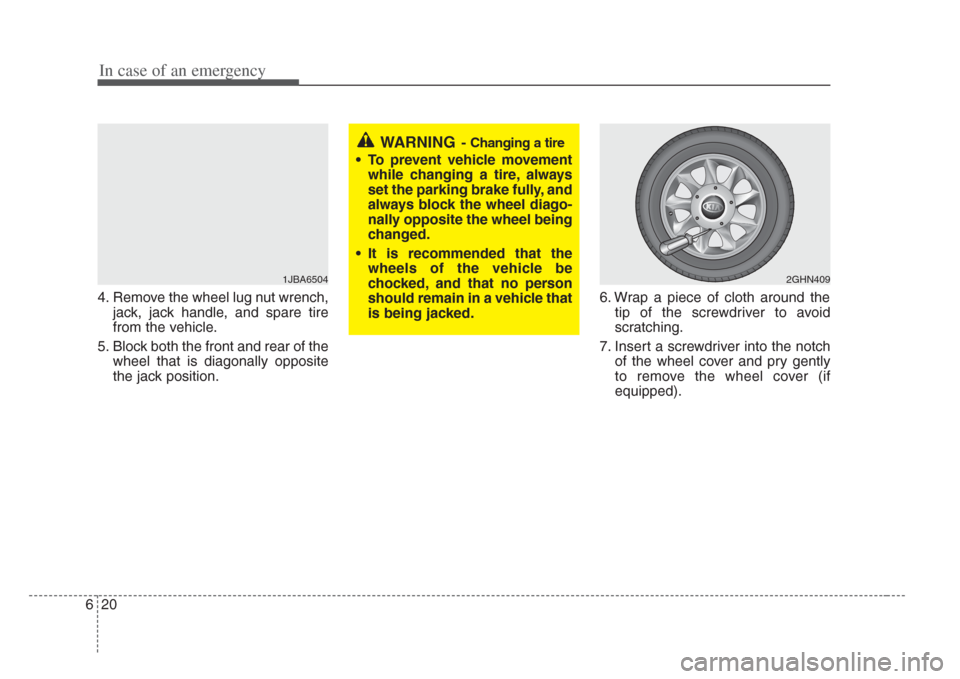

4. Remove the wheel lug nut wrench,jack, jack handle, and spare tire

from the vehicle.

5. Block both the front and rear of the wheel that is diagonally opposite

the jack position. 6. Wrap a piece of cloth around the

tip of the screwdriver to avoid

scratching.

7. Insert a screwdriver into the notch of the wheel cover and pry gently

to remove the wheel cover (if

equipped).

WARNING-Changing a tire

• To prevent vehicle movementwhile changing a tire, alway s

set the parking brake fully, and

always block the wheel diago-

nally opposite the wheel being

changed.

• It is recommended that the wheels of the vehicle be

chocked, and that no per son

should remain in a vehicle that

is being jacked.

1JBA65042GHN409

Page 234 of 283

621

In case of an emergency

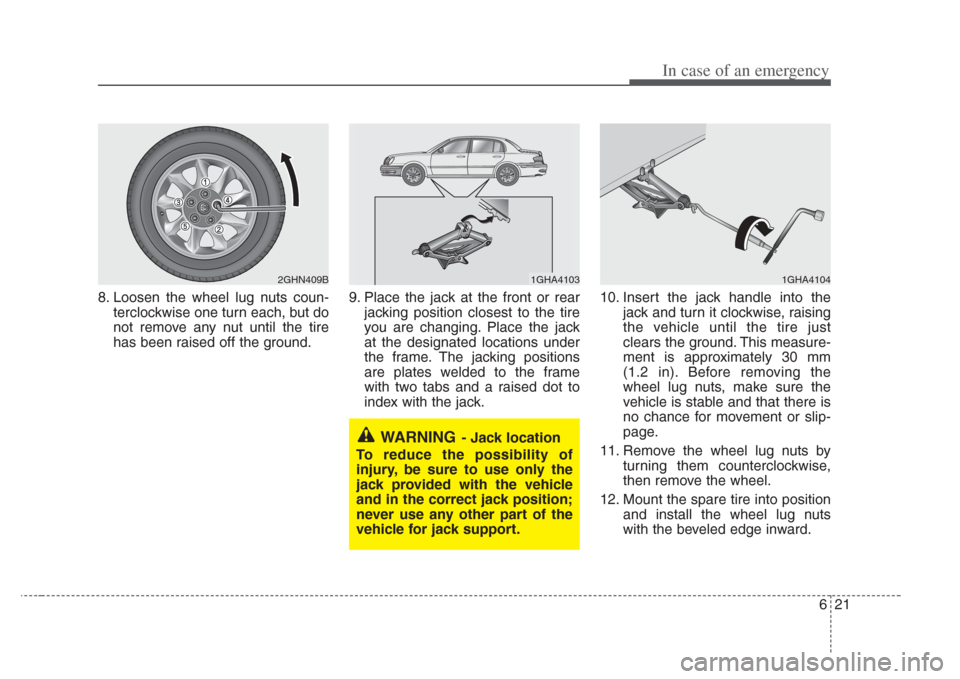

8. Loosen the wheel lug nuts coun-terclockwise one turn each, but do

not remove any nut until the tire

has been raised off the ground. 9. Place the jack at the front or rear

jacking position closest to the tire

you are changing. Place the jack

at the designated locations under

the frame. The jacking positions

are plates welded to the frame

with two tabs and a raised dot to

index with the jack. 10. Insert the jack handle into the

jack and turn it clockwise, raising

the vehicle until the tire just

clears the ground. This measure-

ment is approximately 30 mm

(1.2 in). Before removing the

wheel lug nuts, make sure the

vehicle is stable and that there is

no chance for movement or slip-

page.

11. Remove the wheel lug nuts by turning them counterclockwise,

then remove the wheel.

12. Mount the spare tire into position and install the wheel lug nuts

with the beveled edge inward.

WARNING- Jack location

To reduce the possibility of

injury, be sure to use only the

jack provided with the vehicle

and in the correct jack position;

never use any other part of the

vehicle for jack support.

1GHA41041GHA41032GHN409B

Page 235 of 283

In case of an emergency

226

13. Once the wheel lug nuts havebeen tightened, lower the vehicle

fully to the ground and continue to

tighten the lug nuts until they are

fully secured. Tighten the wheel

lug nuts firmly in a “star” pattern.

If you are unsure of the tightness

of the wheel lug nuts, have them

checked at the nearest service

station. The specified tightening

torque is 9~11 kg•m (65-79 lb•ft,

88-107 N•m). Improperly tight-

ened wheel lug nuts could cause

brake pedal vibration while brak-

ing. 14. Reinstall the wheel cover by fit-

ting the boss of the wheel cover

in the groove of the wheel.

To prevent the jack, jack handle,

wheel lug nut, wrench and spare tire

from rattling while the vehicle is in

motion, store them properly.

2GHN409A

CAUTION

Your vehicle has metric threadson the wheel studs and nuts.Make certain during wheelremoval that the s ame nuts

removed are reinstalled - or, if replaced, that nut s with metric

threads and the same chamfer configuration are used.

Ins tallation of a non-metric

thread nut on a metric stud or

vice-ver sa will not secure the

wheel to the hub properly and will damage the stud so that it

mu st be replaced.

Note that most lug nuts do not have metric threads. Be sure to

use extreme care in checking for thread style before in stalling

aftermarket lug nut s or wheels.

If in doubt, cons ult an

Authorized Kia Dealer.

WARNING- Wheel studs

If the studs are damaged, they

may lose their ability to retain

the wheel. Thi s could lead to the

loss of the wheel and a colli-

sion.

WARNING

Check the inflation pressures as

s oon as possible after ins talling

the spare tire. Adjus t it to the

s pecified pre ssure, if necessary.

Refer to Section 8, Specifications .

Page 236 of 283

7

Maintenance services / 7-2

Maintenance schedule / 7-3

Owner maintenance / 7-7

Engine compartment / 7-10

Engine oil and oil filter / 7-11

Engine cooling system / 7-12

Brakes / 7-14

Power steering / 7-15

Automatic transaxle / 7-16

Lubricants and fluids / 7-18

Air cleaner / 7-19

Climate control air filter / 7-19

Wiper blades / 7-20

Battery / 7-22

Tires and wheels / 7-25

Lubricant specifications / 7-36

Exterior care / 7-38

Interior care / 7-41

Maintenance

Page 237 of 283

Maintenance

27

MAINTENANCE SERVICES

You should exercise the utmost care to

prevent damage to your vehicle and

injury to yourself whenever performing

any maintenance or inspection proce-

dures.

Should you have any doubts concerning

the inspection or servicing of your vehi-

cle, we strongly recommend that you

have an Authorized Kia Dealer perform

this work.

An Authorized Kia Dealer has factory-

trained technicians and genuine Kia

parts to service your vehicle properly. For

expert advice and quality service, see an

Authorized Kia Dealer.

Inadequate, incomplete or insufficient

servicing may result in operational prob-

lems with your vehicle that could lead to

vehicle damage, an accident, or person-

al injury.Owner’s responsibility

✽

NOTICE

Maintenance Service and Record

Retention are the owner's responsibility.

You should retain documents that show

proper maintenance has been performed

on your vehicle in accordance with the

scheduled maintenance service charts

shown on the following pages. You need

this information to establish your compli-

ance with the servicing and maintenance

requirements of your Kia warranties.

Detailed warranty information is provided

in your Warranty & Consumer

Information manual. Repairs and adjustments required as a

result of improper maintenance or a lack

of required maintenance are not covered.

We strongly recommend that all vehicle

maintenance be performed by an author-

ized Kia dealer using genuine Kia parts.

Page 238 of 283

73

Maintenance

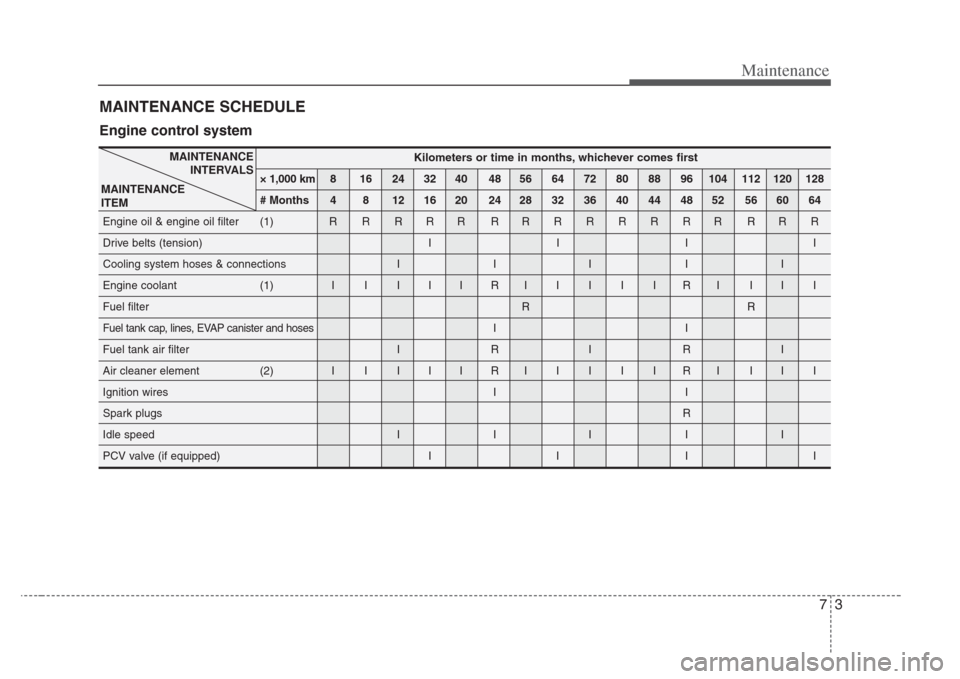

MAINTENANCE SCHEDULE

Kilometers or time in months, whichever come s first

× 1,000 km 8 16 24 32 40 48 56 64 72 80 88 96 104 112 120 128

# Months 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64

Engine oil & engine oil filter (1) R R R R R R RRRRRRR RRR

Drive belts (tension) I I I I

Cooling system hoses & connections I I I I I

Engine coolant (1) I I I I I R IIIIIRI III

Fuel filter RR

Fuel tank cap, lines, EVAP canister and hosesII

Fuel tank air filter I R I R I

Air cleaner element (2) I I I I I R IIIIIRI III

Ignition wires I I

Spark plugs R

Idle speed I I I I I

PCV valve (if equipped) I I I I

MAINTENANCE INTERVALS

MAINTENANCE

ITEM

Engine control system

Page 239 of 283

Maintenance

47

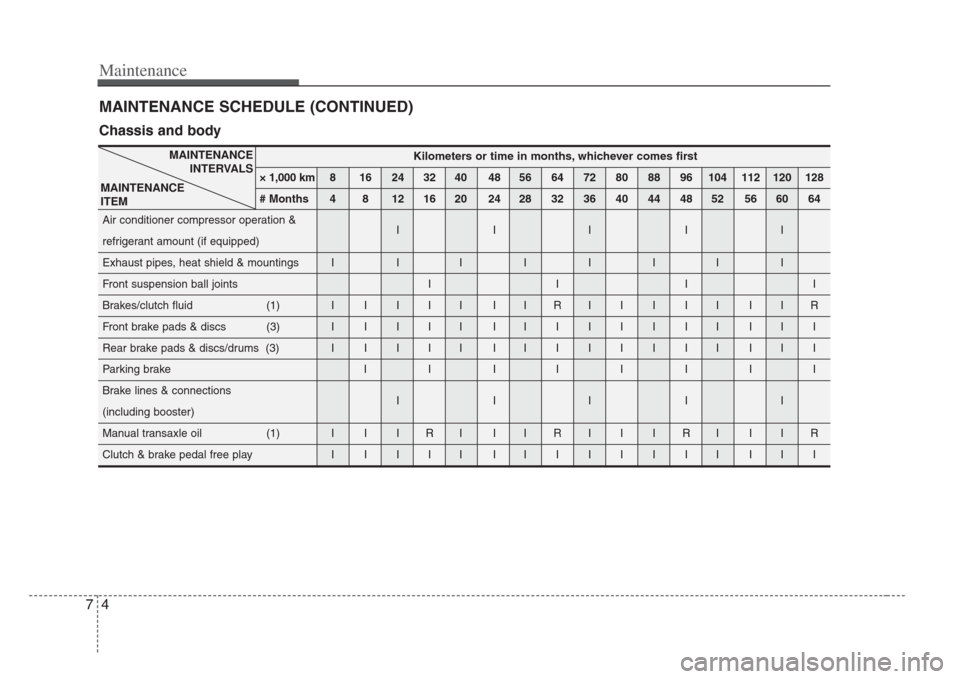

MAINTENANCE SCHEDULE (CONTINUED)

Kilometers or time in months, whichever come s first

× 1,000 km 8 16 24 32 40 48 56 64 72 80 88 96 104 112 120 128

# Months 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64

Air conditioner compressor operation & IIIII

refrigerant amount (if equipped)

Exhaust pipes, heat shield & mountings I I IIIIII

Front suspension ball joints I I I I

Brakes/clutch fluid (1) I I I I I I I R IIIII IIR

Front brake pads & discs (3) I I I I I I IIIIIII III

Rear brake pads & discs/drums (3) I I I I I I IIIIIII III

Parking brake I I I IIIII

Brake lines & connections IIIII

(including booster)

Manual transaxle oil (1) I I I R I I I R I I I R I I I R

Clutch & brake pedal free play I I I I I I IIIIIII III

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Chassis and body

Page 240 of 283

75

Maintenance

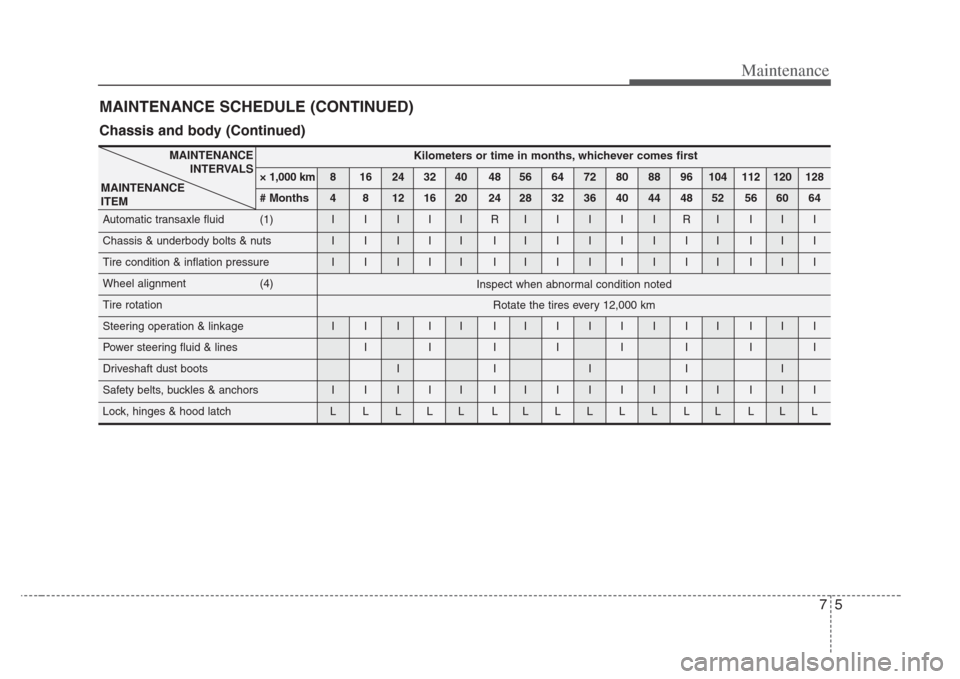

MAINTENANCE SCHEDULE (CONTINUED)

Kilometers or time in months, whichever come s first

× 1,000 km 8 16 24 32 40 48 56 64 72 80 88 96 104 112 120 128

# Months 4 8 12 16 20 24 28 32 36 40 44 48 52 56 60 64

Automatic transaxle fluid (1) I I I I I R IIIIIRI III

Chassis & underbody bolts & nuts I I I I I I IIIIIII III

Tire condition & inflation pressure I I I I I I IIIIIII III

Wheel alignment (4)

Tire rotation

Steering operation & linkage I I I I I I IIIIIII III

Power steering fluid & lines I I I IIIII

Driveshaft dust boots I I I I I

Safety belts, buckles & anchors I I I I I I IIIIIII III

Lock, hinges & hood latch L L L L L L LLLLLLL LLL

MAINTENANCE

INTERVALS

MAINTENANCE

ITEM

Inspect when abnormal condition noted

Rotate the tires every 12,000 km

Chassis and body (Continued)