engine KIA CARENS RHD 2017 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2017, Model line: CARENS RHD, Model: KIA CARENS RHD 2017Pages: 723, PDF Size: 40.8 MB

Page 579 of 723

729

What to do in an emergency

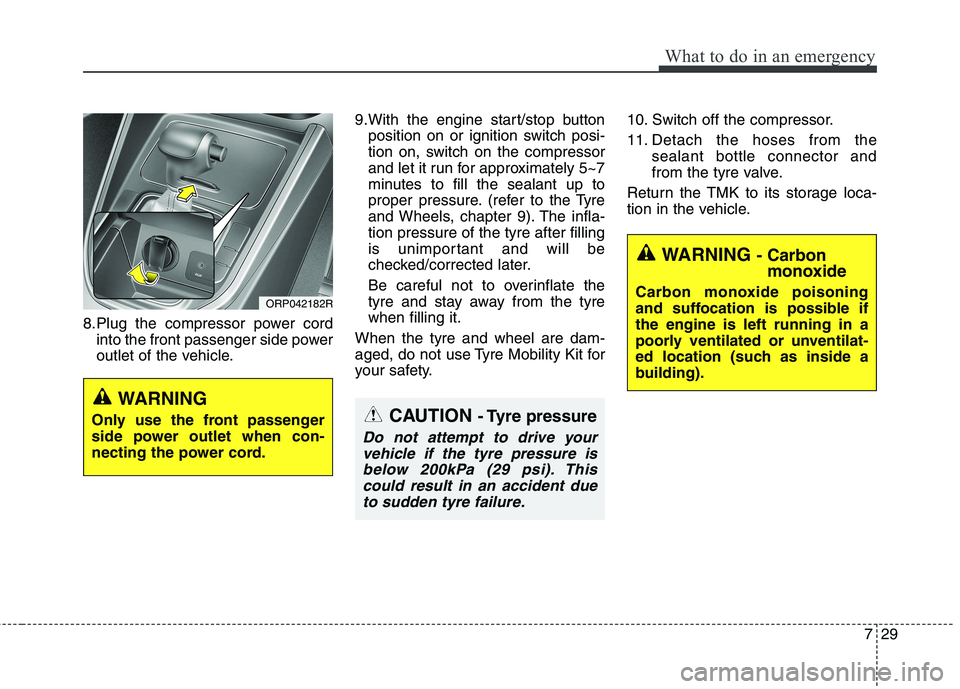

8.Plug the compressor power cordinto the front passenger side power

outlet of the vehicle. 9.With the engine start/stop button

position on or ignition switch posi-

tion on, switch on the compressor

and let it run for approximately 5~7

minutes to fill the sealant up to

proper pressure. (refer to the Tyre

and Wheels, chapter 9). The infla-tion pressure of the tyre after filling

is unimportant and will be

checked/corrected later.

Be careful not to overinflate the

tyre and stay away from the tyrewhen filling it.

When the tyre and wheel are dam-

aged, do not use Tyre Mobility Kit for

your safety. 10. Switch off the compressor.

11. Detach the hoses from the

sealant bottle connector and

from the tyre valve.

Return the TMK to its storage loca-

tion in the vehicle.

WARNING - Carbon

monoxide

Carbon monoxide poisoning

and suffocation is possible ifthe engine is left running in a

poorly ventilated or unventilat-

ed location (such as inside a

building).

WARNING

Only use the front passenger

side power outlet when con-

necting the power cord.

CAUTION - Tyre pressure

Do not attempt to drive your

vehicle if the tyre pressure is below 200kPa (29 psi). Thiscould result in an accident dueto sudden tyre failure.

ORP042182R

Page 581 of 723

731

What to do in an emergency

Notes on the safe use of the

Tyre Mobility Kit

Park your car at the side of theroad so that you can work with the

TMK away from moving traffic.

Place your warning triangle in a

prominent place to make passing

vehicles aware of your location.

To be sure your vehicle will not move, even when you're on fairly

level ground, always set your park-

ing brake.

Only use the TMK for sealing/infla- tion passenger car tyres. Do not

use on motorcycles, bicycles or

any other type of tyres.

Do not remove any foreign objects- such as nails or screws -that have

penetrated the tyre.

Before using the TMK, read the precautionary advice printed onthe sealant bottle!

Provided the car is outdoors, leave the engine running. Otherwise

operating the compressor may

eventually drain the car battery. Never leave the TMK unattended

whilst it is being used.

Do not leave the compressor run- ning for more than 10 min. at a time

or it may overheat.

Do not use the TMK if the ambient temperature is below -30┬░C (-22┬░F).

When the tyre and wheel are dam- aged, do not use Tyre Mobility Kit

for your safety. Technical Data

System voltage: DC 12 V

Working voltage: DC 10 - 15 V

Amperage rating: max. 15 A

Suitable for use at temperatures:

-30 ~ +70┬░C (-22 ~ +158┬░F)

Max. working pressure: 6 bar (87 psi)

Size

Compressor: 170 x 150 x 60 mm (6.7 x 5.9 x 2.4 in.)

Sealant bottle: 85 x 77 ├Ė mm (3.3 x 3.0 ├Ė in.)

Compressor weight: 0.8 kg (1.8 lbs)

Sealant volume: 200 ml (12.2 cu. in.)

ŌØł Sealant and spare parts can be obtained and replaced at an

authorised vehicle or tyre dealer.

Empty sealant bottles may be dis-

posed of at home. Liquid residuefrom the sealant should be dis-

posed of by your vehicle or tyredealer or in accordance with local

waste disposal regulations.

Page 588 of 723

Maintenance

Engine compartment . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Maintenance services . . . . . . . . . . . . . . . . . . . . . . . . 8-6ŌĆó OwnerŌĆÖs responsibility . . . . . . . . . . . . . . . . . . . . . . . . 8-6

. . . . . . . . . . . . . . . . 8-6

. . . . . . . . . . . . . . . . 8-7

Owner maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 8-9 . . . . . . . . . . . . . . . . . . . 8-9

Scheduled maintenance service . . . . . . . . . . . . . 8-11

Explanation of scheduled maintenance items . . . 8-28

Engine oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-32 . . . . . . . . . . . . . . . . . . . 8-32

. . . . . . . . . . . . . . . 8-33

Engine coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-34 . . . . . . . . . . . . . . . . . . 8-34

. . . . . . . . . . . . . . . . . . . . . . . . . 8-37

Brake/clutch fluid . . . . . . . . . . . . . . . . . . . . . . . . . . 8-38 . . . . . . . . . . . . 8-38

Washer fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-39 . . . . . . . . . . . . . . . . 8-39

Parking brake - hand type . . . . . . . . . . . . . . . . . . 8-39 . . . . . . . . . . . . . . . . . . 8-39

Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40 . . . . . . . . . . . . . . . . . 8-40 Air cleaner air cleaner . . . . . . . . . . . . . . . . . . . . . . 8-40

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-40

Climate control air filter . . . . . . . . . . . . . . . . . . . . 8-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-42

Wiper blades . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-44

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-48 . . . . . . . . . . . . . . . . . . . . . . . 8-48

. . . . . . . . . . . . . . . . . . . . . . . . . 8-50

. . . . . . . . . . . . . . . . . . . . . . . . . . 8-50

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-51

Tyres and wheels . . . . . . . . . . . . . . . . . . . . . . . . . . 8-52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-52

. . . . . . . 8-52

. . . . . . . . . . . . . . . . 8-53

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-54

. . . . . . . . . . . . . 8-55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-56

. . . . . . . . . . . . . . . . . . . . . . . . . . . 8-57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-57

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-57

. . . . . . . . . . . . . . . . . . . . . . . . . 8-58

. . . . . . . . . . . . . . . . . . . . . . . . . 8-62

8

Page 590 of 723

83

Maintenance

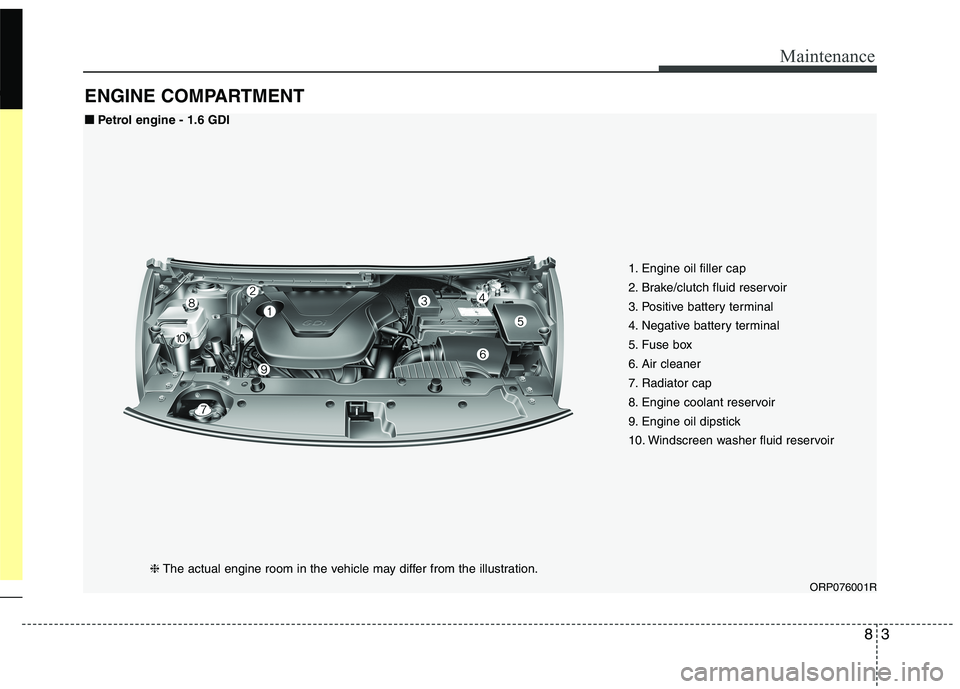

ENGINE COMPARTMENT

ORP076001R

ŌØł

The actual engine room in the vehicle may differ from the illustration. 1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

Ō¢ĀŌ¢Ā

Petrol engine - 1.6 GDI

Page 591 of 723

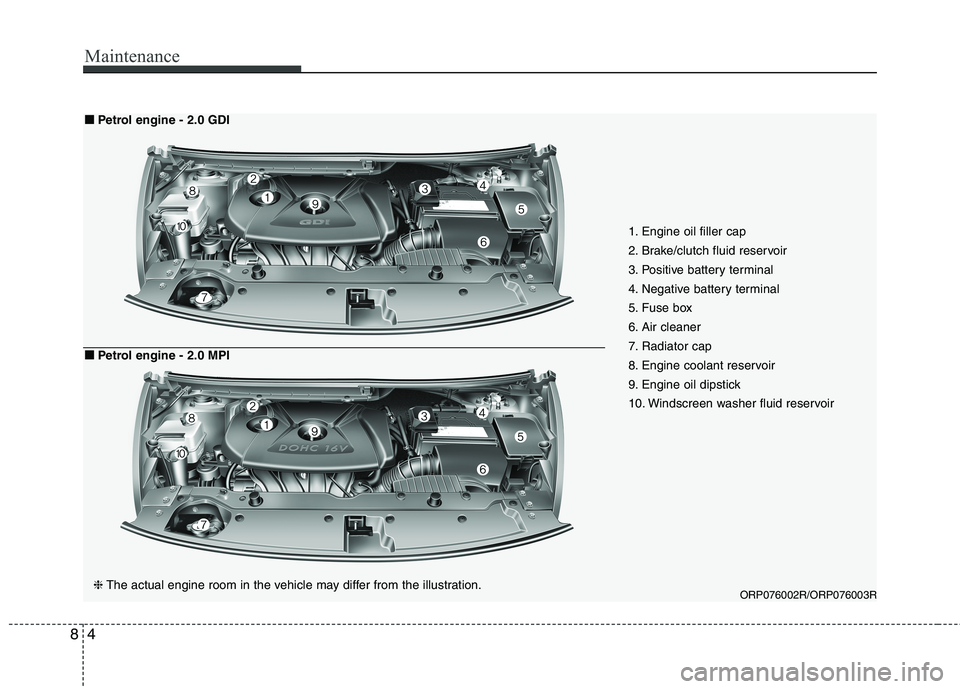

Maintenance

4

8

ORP076002R/ORP076003R

1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

Ō¢ĀŌ¢Ā

Petrol engine - 2.0 GDI

Ō¢ĀŌ¢ĀPetrol engine - 2.0 MPI

ŌØł The actual engine room in the vehicle may differ from the illustration.

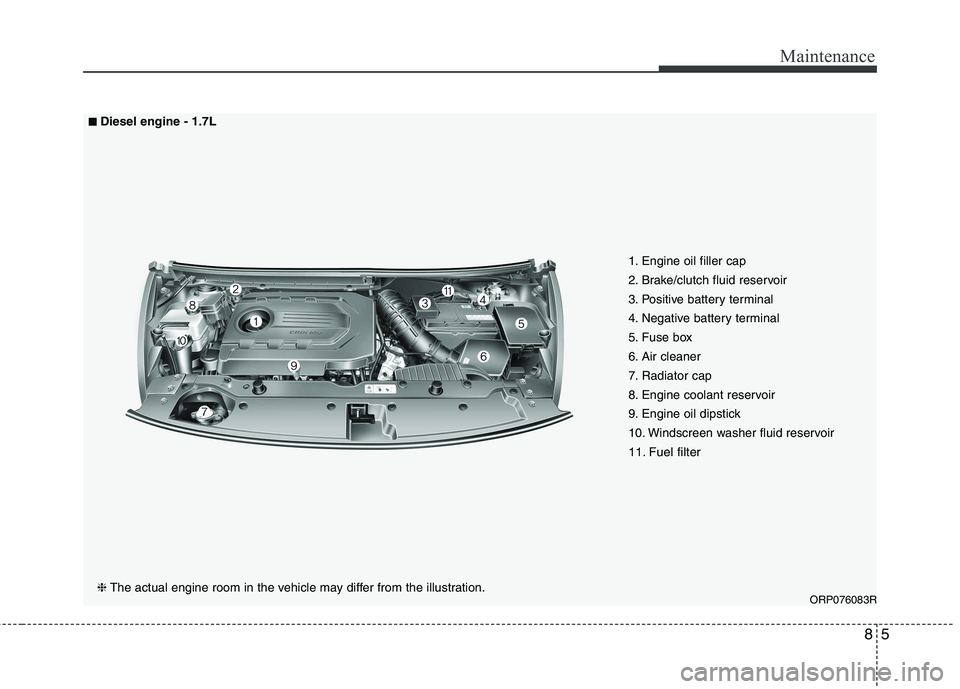

Page 592 of 723

85

Maintenance

1. Engine oil filler cap

2. Brake/clutch fluid reservoir

3. Positive battery terminal

4. Negative battery terminal

5. Fuse box

6. Air cleaner

7. Radiator cap

8. Engine coolant reservoir

9. Engine oil dipstick

10. Windscreen washer fluid reservoir

11. Fuel filter

ORP076083R

ŌØł

The actual engine room in the vehicle may differ from the illustration.

Ō¢ĀŌ¢Ā

Diesel engine - 1.7L

Page 594 of 723

87

Maintenance

Engine compartment precau- tions (Diesel engine)

ŌĆó The injector operates at high volt-age (maximum 200v). Therefore,

the following accidents may occur.

- Direct contact with the injector orinjector wiring may cause electric

shock or damage your muscle or

nerve system.

- The electromagnetic wave from the operating injector may cause

the artificial heart pacemaker tomalfunction.

Follow the safety tips provided below, when you are checking theengine room whilst the engine is

running.

- Do not touch the injector, injectorwirings, and the engine computer

whilst the engine is running.

- Do not remove the injector con- nector whilst the engine is run-ning.

- People using pacemakers must not go near the engine whilst the

engine is starting or running.WARNING - Maintenance

work

Performing maintenance work on a vehicle can be danger-

ous. You can be seriously

injured whilst performing

some maintenance proce-

dures. If you lack sufficient

knowledge and experience or

the proper tools and equip-

ment to do the work, we rec-ommend that the system be

serviced by an authorised Kia

dealer.

Working under the bonnet with the engine running is

dangerous. It becomes even

more dangerous when you

wear jewelry or loose cloth-

ing. These can become entan-

gled in moving parts and

result in injury.

(Continued)(Continued)

Therefore, if you must run the

engine whilst working under

the bonnet, make certain that

you remove all jewelry (espe-

cially rings, bracelets, watch-

es, and necklaces) and all

neckties, scarves, and similar

loose clothing before gettingnear the engine or coolingfans.

Page 595 of 723

Maintenance

8

8

WARNING - Diesel Engine

Never work on injection system with engine running or within 30seconds after shutting off

engine. High-pressure pump,

rail, injectors and high-pressurepipes are subject to high pres-

sure even after the engine

stopped. The fuel jet produced by

fuel leaks may cause serious

injury, if it touches the body.

People using pacemakers

should not move than 30cm clos-er to the ECU or wiring harness

within the engine room whilst

engine is running, since the high

currents in the electronic engine

control system produce consid-

erable magnetic fields.CAUTION

Do not put heavy objects or apply excessive force on top ofthe engine cover (if equipped)or fuel related parts.

When you inspect the fuel system (fuel lines and fuelinjection devices), we recom- mend that you contact anauthorised Kia dealer.

Do not drive long time with the engine cover (if equipped)removed.

When checking the engine room, do not go near fire.

Fuel, washer fluid, etc. areflammable oils that may cause fire.

Before touching the battery, ignition cables and electricalwiring, you should disconnectthe battery "-" terminal. You may get an electric shockfrom the electric current.

(Continued)

(Continued) When you remove the interior trim cover with a flat head (-)driver, be careful not to dam-age the cover.

Be careful when you replace and clean bulbs to avoidburns or electrical shock.

Page 596 of 723

89

Maintenance

OWNER MAINTENANCE

We recommend that the following

lists are vehicle checks and inspec-

tions that should be performed by the

owner or an authorised Kia dealer atthe frequencies indicated to help

ensure safe, dependable operation

of your vehicle.

If you have any question, we recom-

mend that you consult an authorised

Kia dealer.

These Owner Maintenance Checks

are generally not covered by war-

ranties and you may be charged for

labour, parts and lubricants used. Owner maintenance schedule

When you stop for fuel:

Check the engine oil level.

Check coolant level in coolant

reservoir.

Check the windscreen washer fluid level.

Look for low or under-inflated tyres.

Check the radiator and condenser. Check if the front of the radiator and condenser are clean and not

blocked with leaves, dirt or insectsetc.

If any of the above parts are

extremely dirty or you are not sure

of their condition, we recommend

that you contact an authorised Kia

dealer.

Whilst operating your vehicle:

Note any changes in the sound ofthe exhaust or any smell of

exhaust fumes in the vehicle.

Check for vibrations in the steering wheel. Notice any increased steer-

ing effort or looseness in the steer-

ing wheel, or change in its straight-ahead position.

Notice if your vehicle constantly turns slightly or ŌĆ£pullsŌĆØ to one side

when travelling on smooth, levelroad.

When stopping, listen and check for unusual sounds, pulling to one

side, increased brake pedal travel

or ŌĆ£hard-to-pushŌĆØ brake pedal.

If any slipping or changes in the operation of your transaxle occurs,

check the transaxle fluid level.

Check manual transaxle operation, including clutch operation.

WARNING

Be careful when checking your

engine coolant level when the

engine is hot. Scalding hot

coolant and steam may blow out

under pressure. This could cause

burns or other serious injury.

Page 597 of 723

Maintenance

10

8

Check automatic transaxle / dual

clutch transmission P (Park) func- tion.

Check parking brake.

Check for fluid leaks under your vehicle (water dripping from the air

conditioning system during or after

use is normal).

At least monthly:

Check coolant level in the enginecoolant reservoir.

Check the operation of all exterior lights, including the stoplights, turn

signals and hazard warning flash-

ers.

Check the inflation pressures of all tyres including the spare.

At least twice a year

(i.e., every Spring and Fall) :

Check radiator, heater and air con- ditioning hoses for leaks or dam-

age.

Check windscreen washer spray and wiper operation. Clean wiper

blades with clean cloth dampened

with washer fluid.

Check headlight alignment.

Check muffler, exhaust pipes, shields and clamps.

Check the lap/shoulder belts for wear and function.

Check for worn tyres and loose wheel lug nuts.

At least once a year :

Clean body and door drain holes.

Lubricate door hinges and checks,and bonnet hinges.

Lubricate door and bonnet locks and latches.

Lubricate door rubber weather- strips.

Check the air conditioning system.

Inspect and lubricate automatic transaxle / dual clutch transmission

linkage and controls.

Clean battery and terminals.

Check the brake (and clutch) fluid level.