brake KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 926 of 1575

18Voltage for hybrid ECU 1 A500 mA 60200

5,10,17,19 signal wheel speed sensor FL,

FR, RL,RR

6 mA

16 mA 250200 to

ground 1.5M to bat

16,9,6,8 Voltage supply for the active

wheel speed sensor FL,FR,

RL, RR 6 mA

16 mA 250200 to

ground 1.5M to bat

14,24 wheel speed sensor output

(FR, RL) 20 mA

10 mA 250200

11 Diagnostic wire K 6 mA3 mA 250200

22 ABS - warning lamp actuation 30 mA5 mA 250200

12 EBD- warning lamp actuation 30 mA5 mA 250200

20 brake light switch 10 mA5 mA 250200

15 CAN Low 30 mA20 mA 250200

26 CAN High 30 mA20 mA 250200

ABS HECU CONNECTOR Connector terminal SpecificationCondition

Number Description

1 Ground for recirculation pump Current range: Min.10A

Max.20~39A Always

4 Ground for solenoid valves and

ECU Current range: Min.2.5A

Max.5~15A Always

2 Voltage supply for pump motor

Battery voltageAlways

3 Voltage supply for solenoid valves

16 Voltage supply for the active

wheel speed sensor FL,FR, RL, RR Battery voltage

IG ON

9

6

8

5

signal wheel speed sensor FL, FR, RL,RR Voltage(High) : 0.89~1.26 V

Voltage (Low) : 0.44~0.63 V On driving

10

17

19

11

Diagnostic wire K Voltage (High)

≥ 0.8 * IG ON

Voltage (Low) ≤ 0.2 * IG ON On SCAN TOOL

communication

18 Voltage for hybrid ECU Battery voltageKEY ON/OFF

20 Brake light switch Voltage (High)

≥ 0.8 * IG ON

Voltage (Low) ≤ 0.3 * IG ON BRAKE ON/OFF

SENSOR OUTPUT ON SCAN TOOL(ABS) Description AbbreviationUnitRemarks

1 Vehicle speed sensor VEH. SPDKm/h

2 Battery voltage BATT. VOLV

3 FL Wheel speed sensor FL WHEELKm/h

Page 927 of 1575

4FR Wheel speed sensor FR WHEELKm/h

5 RL Wheel speed sensor RL WHEELKm/h

6 RR Wheel speed sensor RR WHEELKm/h

7 ABS Warning lamp ABS LAMP-

8 EBD Warning lamp EBD LAMP-

9 Brake Lamp B/LAMP-

10 Pump relay state PUMP RLY-

11 Valve relay state VALVE RLY-

12 Motor MOTOR-

13 Front Left valve(IN) FL INLET-

14 Front Right valve (IN) FR INLET-

15 Rear Left valve (IN) RL INLET-

16 Rear Right valve (IN) RR INLET-

17 Front Left valve (OUT) FL OUTLET-

18 Front Right valve (OUT) FR OUTLET-

19 Rear Left valve(OUT) RL OUTLET-

20 Rear Right valve (OUT) RR OUTLET-

Page 928 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

This specification applies to HCU(Hydraulic Control Unit) and ECU(Electronic Control Unit) of the HECU.(Hydraulic and

Electronic Control Unit)

This specification is for the wiring design and installation of ABS/TCS/ESC ECU.

This unit has the functions as follows.

a. Input of signal from Pressure sensor, Steering angle sensor, Yaw & Lateral G sensor, the wheel speed sensors

attached to each wheel.

b. Control of braking force / traction force/ yaw moment.

c. Failsafe function.

d. Self diagnosis function.

e. Interface with the external diagnosis tester.

Installation position : engine compartment a. Brake tube length from Master cylinder port to HECU inlet port should be max. 1m

b. The position should not be close to the engine block and not lower than the wheel.

OPERATION

The ECU shall be put into operation by switching on the operating voltage (IGN).

On completion of the initialization phase, the ECU shall be ready for operation.

In the operating condition, the ECU shall be ready, within the specified limits (voltage and temperature), to process the

signals offered by the various sensors and switches in accordance with the control algorithm defined by the software

and to control the hydraulic and electrical actuators.

Wheel Sensor signal processing

The ECU shall receive wheel speed signal from the four active wheel sensors.

The wheel signals are converted to voltage signal by the signal conditioning circuit after receiving current signal from

active wheel sensors and given as input to the MCU.

Solenoid Valve Control

When one side of the valve coil is connected to the positive voltage that is provided through the valve relay and the

other side is connected to the ground by the semiconductor circuit, the solenoid valve goes into operation.

The electrical function of the coils are always monitored by the valve test pulse under normal operation conditions.

Voltage limits

a.Overvoltage

When overvoltage is detected(above 16.8 V), the ECU switches off the valve relay and shuts down the system.

When voltage is returned to operating range, the system goes back to the normal condition after the initialization

phase.

b. Undervoltage

In the event of undervoltage(below 9.3 V), ABS control shall be inhibited and the warning lamp shall be turned on.

When voltage is returned to operating range, the warning lamp is switched off and ECU returns to normal operating

mode.

Pump Motor Checking

The ECU performs a pump motor test at a speed of 15km/h once after IGN is switched on.

Diagnostic Interface

Failures detected by the ECU are encoded on the ECU, stored in a EEPROM and read out by diagnostic equipment

when the ignition switch is turned on.

The diagnosis interface can also be used for testing the ECU during production of the ECU and for actuating the HCU

(Air - bleeding line or Roll and Brake Test line).

Warning Lamp module

Page 929 of 1575

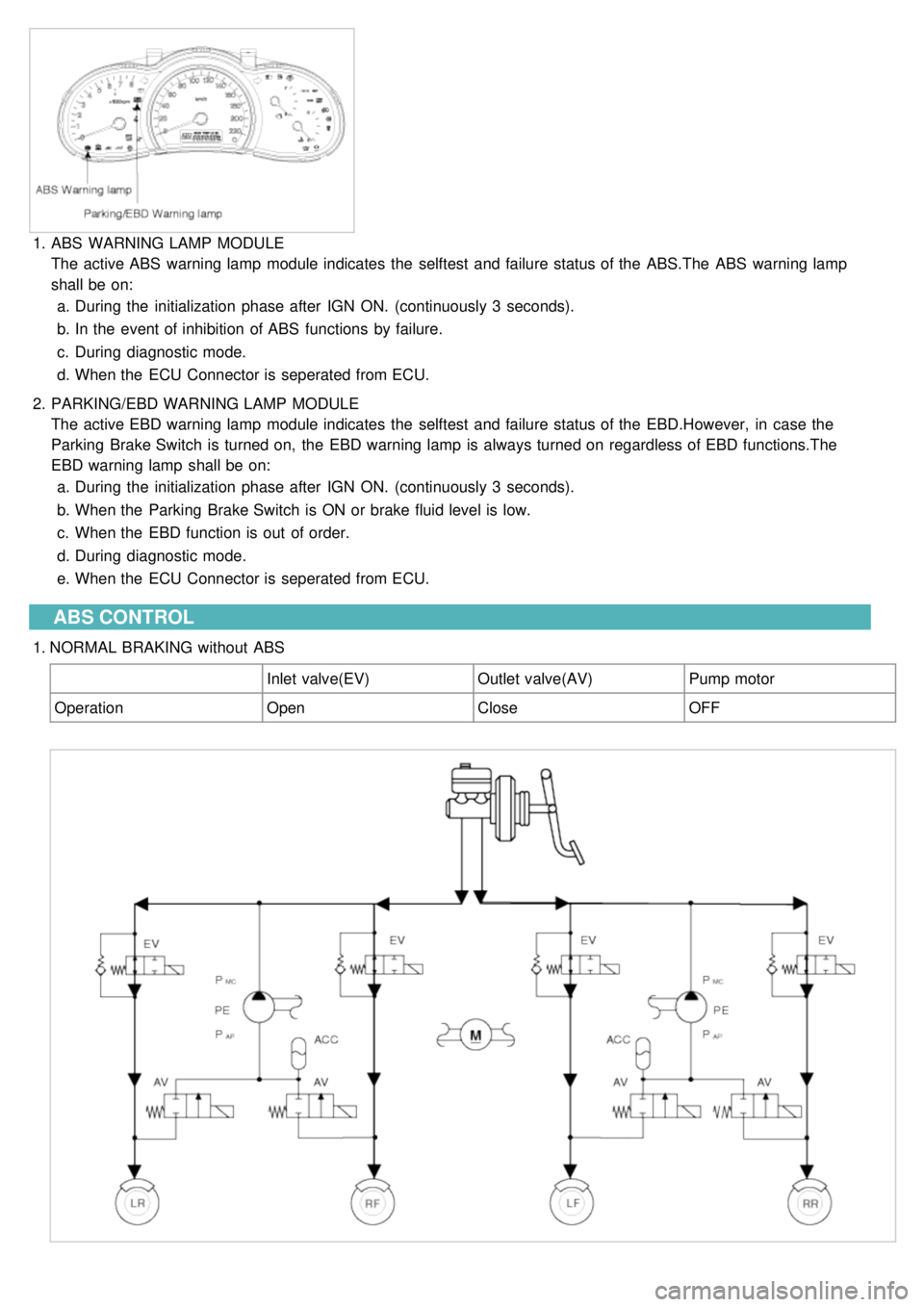

1.ABS WARNING LAMP MODULE

The active ABS warning lamp module indicates the selftest and failure status of the ABS.The ABS warning lamp

shall be on:

a. During the initialization phase after IGN ON. (continuously 3 seconds).

b. In the event of inhibition of ABS functions by failure.

c. During diagnostic mode.

d. When the ECU Connector is seperated from ECU.

2. PARKING/EBD WARNING LAMP MODULE

The active EBD warning lamp module indicates the selftest and failure status of the EBD.However, in case the

Parking Brake Switch is turned on, the EBD warning lamp is always turned on regardless of EBD functions.The

EBD warning lamp shall be on:

a. During the initialization phase after IGN ON. (continuously 3 seconds).

b. When the Parking Brake Switch is ON or brake fluid level is low.

c. When the EBD function is out of order.

d. During diagnostic mode.

e. When the ECU Connector is seperated from ECU.

ABS CONTROL

1.NORMAL BRAKING without ABS

Inlet valve(EV)Outlet valve(AV)Pump motor

Operation OpenCloseOFF

Page 934 of 1575

2007 > 2.7L V6 GASOLINE >

STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

NOTES WITH REGARD TO DIAGNOSIS

The phenomena listed in the following table are not abnormal.

Phenomenon Explanation

System check sound When starting the engine, a thudding sound can sometimes be heard coming

from inside the engine compartment. This is because the system operation check

is being performed.

ABS operation sound a.Sound of the motor inside the ABS hydraulic unit operation (whine).

b. Sound is generated along with vibration of the brake pedal (scraping).

c. When ABS operates, sound is generated from the vehicle chassis due to

repeated brake application and release

(Thump : suspension; squeak: tires)

ABS operation (Long braking

distance) For road surfaces such as snow- covered and gravel roads, the braking distance

for vehicles with ABS can sometimes be longer than that for other vehicles.

Accordingly, advise the customer to drive safely on such roads by lowering the

vehicle speed.

Diagnosis detection conditions can vary depending on the diagnosis code. When checking the trouble symptom after

the diagnosis code has been erased, ensure that the requirements listed in "Comment" are met.

SCAN TOOL (PRO) CHECK

1. Turn the ignition switch OFF.

2. Connector the Scan tool to the 16P data link connector located the driver's side kick panel.

Page 937 of 1575

c.Stop lamp switch circuit.

d. Check the hydraulic circuit for leakage.

Communication with Scan tool is not possible.

(Communication with any system is not possible) a.

Power source circuit

b. Diagnosis line

Communication with Scan tool is not possible.

(Communication with ABS only is not possible) a.

Power source circuit

b. Diagnosis line

c. HECU

When ignition key is turned ON (engine OFF), the ABS

warning lamp does not light up. a.

ABS warning lamp circuit

b. HECU

Even after the engine is started, the ABS warning lamp

remains ON. a.

ABS warning lamp circuit

b. HECU

During ABS operation, the brake pedal may vibrate or may not be able to be depressed. Such phenomena are

due to intermittent changes in hydraulic pressure inside the brake line to prevent the wheels from locking and is

not an abnormality.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Brake operation varies depending on driving conditions and road

surface conditions, so diagnosis can be difficult.However if a normal

DTC is displayed, check the following probable cause. When the

problem is still occurring, replace the ABS control module. a.

Inoperative power source circuit

b. Inoperative wheel speed sensor circuit

c. Inoperative hydraulic circuit for leakage

d. Inoperative HECU

INSPECTION PROCEDURES

DTC INSPECTION

1. Connect the Scan Tool with the data link connector and turn the ignition switch ON.

2. Verify that the system is operating to specifications.

Is the system operating to specifications ?

▶ Check the power source circuit.

▶ Erase the DTC and recheck using Scan Tool.

CHECK THE POWER SOURCE CIRCUIT.

1. Disconnect the connector from the ABS control module.

2. Turn the ignition switch ON, measure the voltage between terminal 18 of the ABS control module harness side

connector and body ground.

Specification: approximately B+

Is the voltage within specification?

▶ Check the ground circuit.

▶ Check the harness or connector between the fuse (10A) in the engine compartment junction block and the ABS

control module. Repair if necessary.

Page 938 of 1575

control module. Repair if necessary.

CHECK THE GROUND CIRCUIT.

1.Disconnect the connector from the ABS control module.

2. Check for continuity between terminals 1,4 of the ABS control module harness side connector and ground point.

Is there continuity?

▶ Check the wheel speed sensor circuit.

▶ Repair an open in the wire and ground point.

CHECK THE WHEEL SPEED SENSOR CIRCUIT.

Refer to the DTC troubleshooting procedures.

Is the system operating to specifications ?

▶ Check the hydraulic circuit for leakage.

▶ Repair or replace the wheel speed sensor.

CHECK THE HYDRAULIC CIRCUIT FOR LEAKAGE.

Refer to the hydraulic lines.

Inspect leakage of the hydraulic lines.

Is the system operating to specifications ?

▶ The problem is still occurring, replace the ABS control module.

▶ Replace the leaking hydraulic lines.

DETECTING CONDITION

Trouble Symptoms Possible Cause

Brake operation varies depending on driving conditions and road

surface conditions, so diagnosis can be difficult.However if a normal

DTC is displayed, check the following probable cause. When the a.

Inoperative power source circuit

b. Inoperative wheel speed sensor circuit

Page 939 of 1575

DTC is displayed, check the following probable cause. When the

problem is still occurring, replace the ABS control module.b.

Inoperative wheel speed sensor circuit

c. Inoperative hydraulic circuit for leakage

d. Inoperative HECU

INSPECTION PROCEDURES

DTC INSPECTION

1. Connect the Scan Tool with the data link connector and turn the ignition switch ON.

2. Verify that the system is operating to specifications.

Is the system operating to specifications ?

▶ Check the wheel speed sensor circuit.

▶ Erase the DTC and recheck using Scan Tool.

CHECK THE WHEEL SPEED SENSOR CIRCUIT.

Refer to the DTC troubleshooting procedures.

Is the system operating to specifications ?

▶ Check the stop lamp switch circuit.

▶ Repair or replace the wheel speed sensor.

CHECK THE STOP LAMP SWITCH CIRCUIT.

1. Check that stop lamp lights up when brake pedal is depressed and turns off when brake pedal is released.

2. Measure the voltage between terminal 20 of the ABS control module harness side connector and body ground

when brake pedal is depressed.

Specification: approximately B+

Is the voltage within specification?

▶ Check the hydraulic circuit for leakage.

▶ Repair the stop lamp switch. Repair an open in the wire between the ABS control module and the stop lamp

switch.

CHECK THE HYDRAULIC CIRCUIT FOR LEAKAGE.

Refer to the hydraulic lines.

Inspect leakage of the hydraulic lines.

Is the system operating to specifications ?

▶ The problem is still occurring, replace the ABS control module.

Page 943 of 1575

CHECK FOR BLOWN FUSE

Check continuity of fuse (10A) from the engine compartment junction block.

Is there continuity?

▶ Repair an open in the wire between ABS fuse and 1 of cluster connector.

▶ Replace the blown fuse.

DETECTING CONDITION

Trouble Symptoms Possible Cause

If the HECU detects trouble, it lights the ABS warning lamp while at

the same time prohibiting ABS control. At this time, the HECU

records a DTC in memory.Even though the normal code is output, the

ABS warning lamp remains ON, then the cause may be probably an

open or short in the ABS warning lamp circuit. a.

An open in the wire

b. Inoperative instrument cluster assembly

c. Inoperative ABS warning lamp module

d. Inoperative HECU

INSPECTION PROCEDURES

CHECK DTC OUTPUT.

1. Connect the Scan Tool to the 16P data link connector located behind the driver's side kick panel.

2. Check the DTC output using Scan Tool.

Is DTC output ?

▶ Repair circuit indicated by code output.

▶ Check instrument cluster.

CHECK INSTRUMENT CLUSTER

Disconnect the cluster connector and turn the ignition switch ON.

Does the ABS warning lamp remains ON?

▶ Replace the instrument cluster.

▶ Check for open the wire.

CHECK FOR OPEN IN THE WIRE

Check for continuity in the wire between cluster and ABS control module.

Is there continuity?

▶ Replace the ABS control module and recheck.

▶ Repair an open in the wire between cluster and ABS control module.

BLEEDING OF BRAKE SYSTEM

1. Remove the reservoir cap and fill the brake reservoir with brake fluid.

If there is any brake fluid on any painted surface, wash it off immediately.

Page 944 of 1575

When pressure bleeding, do not depress the brake pedal.

Recommended fluid........ DOT3 or DOT4

2. Connect a clear plastic tube to the brake caliper bleeder plug and insert the other end of the tube into a half filled

clear plastic bottle.

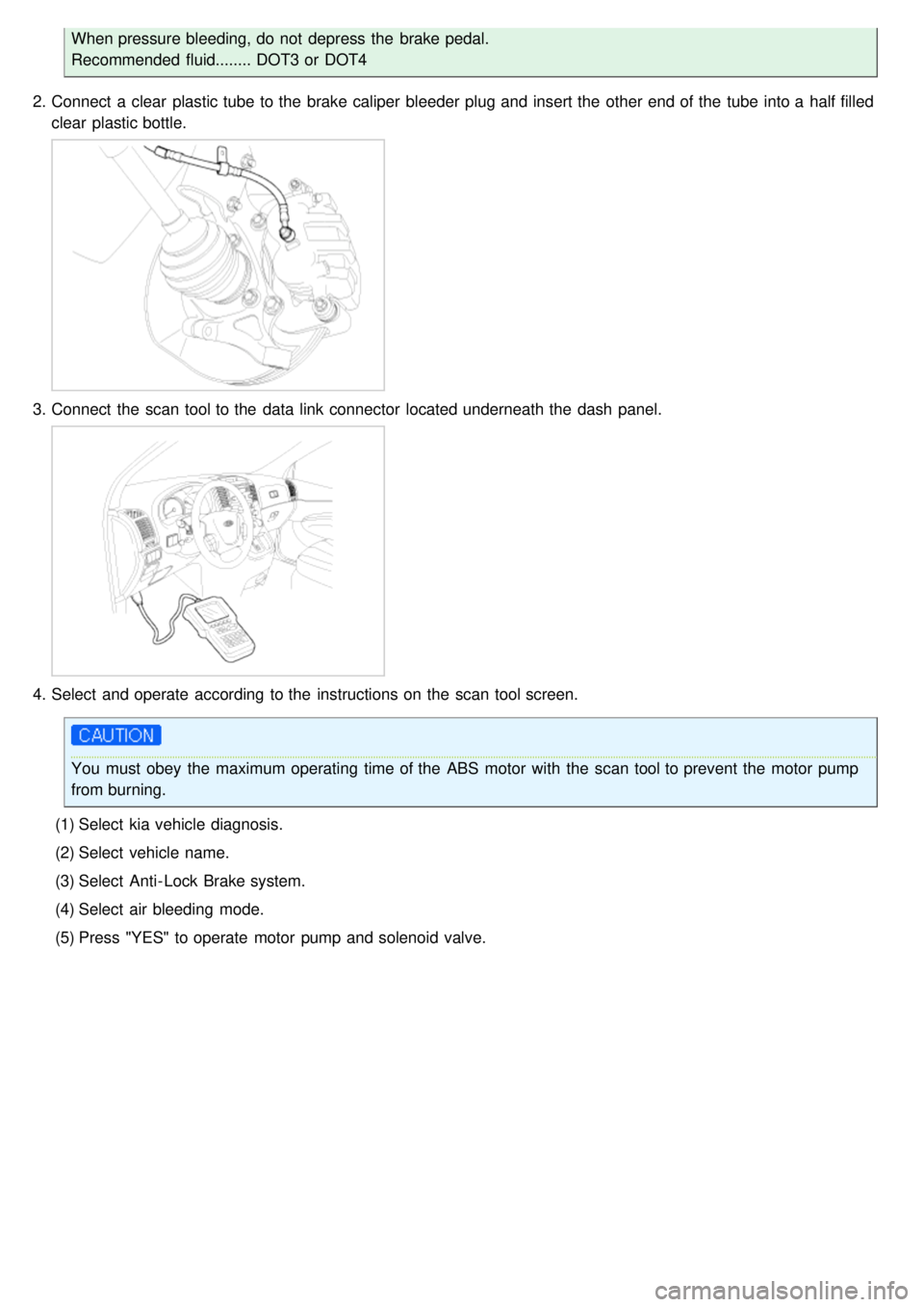

3.Connect the scan tool to the data link connector located underneath the dash panel.

4.Select and operate according to the instructions on the scan tool screen.

You must obey the maximum operating time of the ABS motor with the scan tool to prevent the motor pump

from burning.

(1) Select kia vehicle diagnosis.

(2) Select vehicle name.

(3) Select Anti- Lock Brake system.

(4) Select air bleeding mode.

(5) Press "YES" to operate motor pump and solenoid valve.