KIA CARNIVAL 2007 Workshop Manual

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Workshop Manual

Trending: oil level, air filter, window, airbag off, four wheel drive, steering wheel, keyless entry

Page 171 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

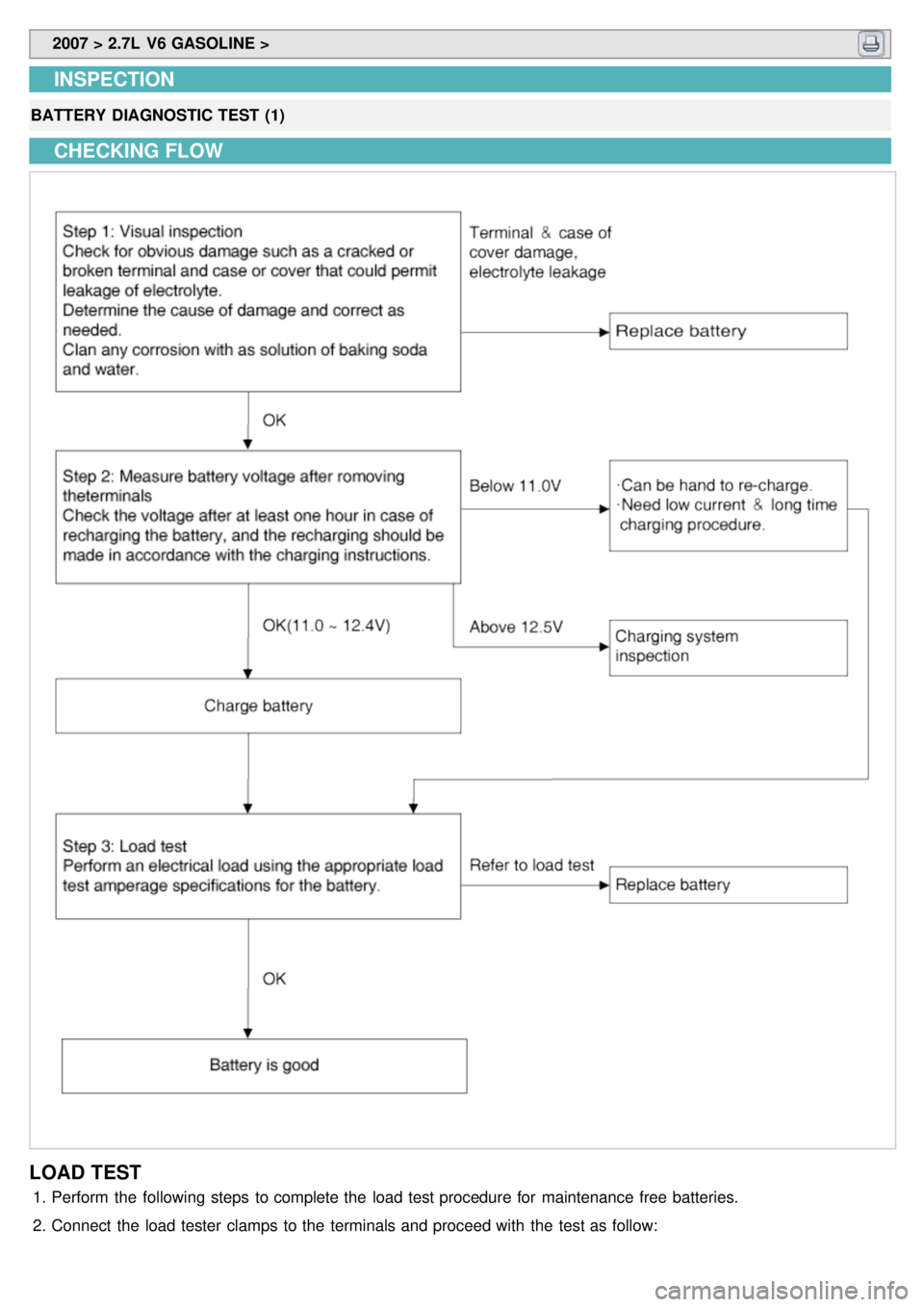

BATTERY DIAGNOSTIC TEST (1)

CHECKING FLOW

LOAD TEST

1.Perform the following steps to complete the load test procedure for maintenance free batteries.

2. Connect the load tester clamps to the terminals and proceed with the test as follow:

Page 172 of 1575

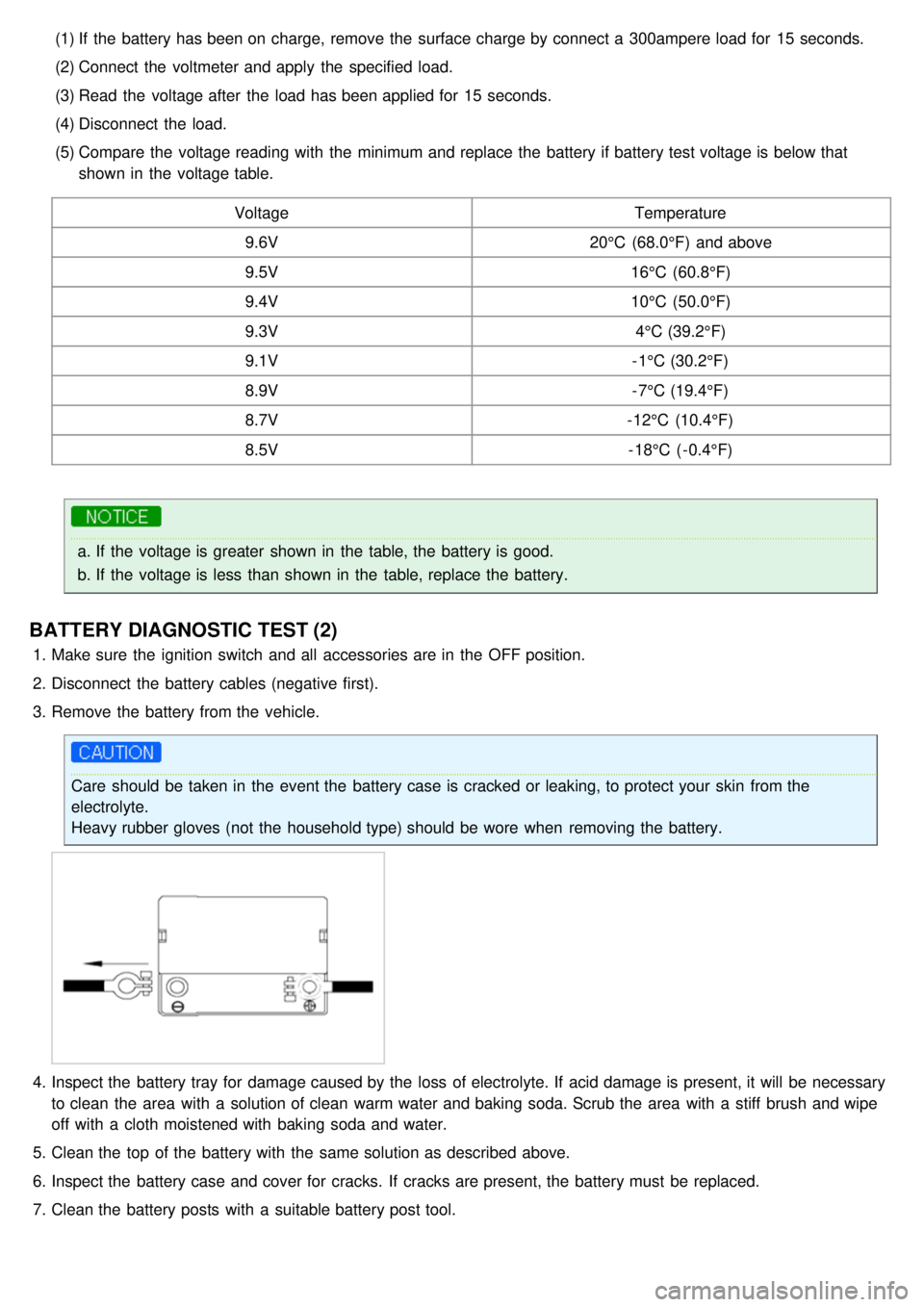

(1)If the battery has been on charge, remove the surface charge by connect a 300ampere load for 15 seconds.

(2) Connect the voltmeter and apply the specified load.

(3) Read the voltage after the load has been applied for 15 seconds.

(4) Disconnect the load.

(5) Compare the voltage reading with the minimum and replace the battery if battery test voltage is below that

shown in the voltage table.

Voltage Temperature

9.6V 20°C (68.0°F) and above

9.5V 16°C (60.8°F)

9.4V 10°C (50.0°F)

9.3V 4°C (39.2°F)

9.1V - 1°C (30.2°F)

8.9V - 7°C (19.4°F)

8.7V - 12°C (10.4°F)

8.5V - 18°C ( - 0.4°F)

a.If the voltage is greater shown in the table, the battery is good.

b. If the voltage is less than shown in the table, replace the battery.

BATTERY DIAGNOSTIC TEST (2)

1.Make sure the ignition switch and all accessories are in the OFF position.

2. Disconnect the battery cables (negative first).

3. Remove the battery from the vehicle.

Care should be taken in the event the battery case is cracked or leaking, to protect your skin from the

electrolyte.

Heavy rubber gloves (not the household type) should be wore when removing the battery.

4.Inspect the battery tray for damage caused by the loss of electrolyte. If acid damage is present, it will be necessary

to clean the area with a solution of clean warm water and baking soda. Scrub the area with a stiff brush and wipe

off with a cloth moistened with baking soda and water.

5. Clean the top of the battery with the same solution as described above.

6. Inspect the battery case and cover for cracks. If cracks are present, the battery must be replaced.

7. Clean the battery posts with a suitable battery post tool.

Page 173 of 1575

8.Clean the inside surface of the terminal clamps with a suitable battery cleaning tool. Replace damaged or frayed

cables and broken terminal clamps.

9. Install the battery in the vehicle.

10. Connect the cable terminals to the battery post, making sure tops of the terminals are flush with the tops of the

posts.

11. Tighten the terminal nuts securely.

12. Coat all connections with light mineral grease after tightening.

When batteries are being charged, an explosive gas forms beneath the cover of each cell. Do not smoke

near batteries being charged or which have recently been charged. Do not break live circuit at the terminals

of batteries being charged.

A spark will occur when the circuit is broken. Keep open flames away form battery.

Page 174 of 1575

Page 175 of 1575

2007 > 2.7L V6 GASOLINE >

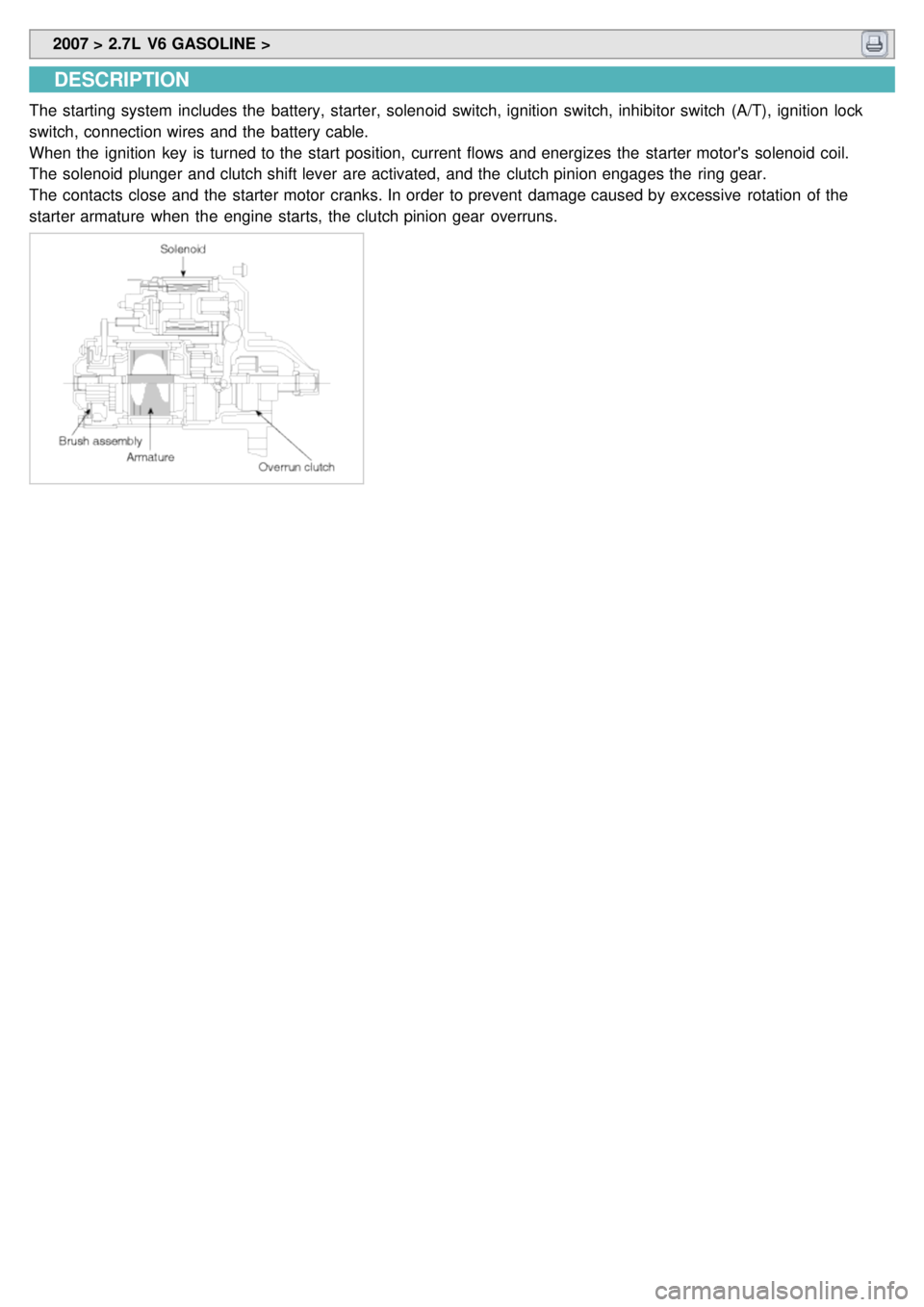

DESCRIPTION

The starting system includes the battery, starter, solenoid switch, ignition switch, inhibitor switch (A/T), ignition lock

switch, connection wires and the battery cable.

When the ignition key is turned to the start position, current flows and energizes the starter motor's solenoid coil.

The solenoid plunger and clutch shift lever are activated, and the clutch pinion engages the ring gear.

The contacts close and the starter motor cranks. In order to prevent damage caused by excessive rotation of the

starter armature when the engine starts, the clutch pinion gear overruns.

Page 176 of 1575

2007 > 2.7L V6 GASOLINE >

STARTER CIRCUIT TROUBLESHOOTING

The battery must be in good condition and fully charged.

1. Remove the fuel pump relay(A) from the fuse box.

2. With the shift lever in N or P (A/T) or clutch pedal pressed (M/T), turn the ignition switch to "START"

If the starter normally cranks the engine, starting system is OK. If the starter will not crank the engine at all, go to

next step.

If it won't disengage from the ring gear when you release key, check for the following until you find the cause.

a. Solenoid plunger and switch malfunction.

b. Dirty pinion gear or damaged overrunning clutch.

3. Check the battery condition. Check electrical connections at the battery, battery negative cable connected to the

body, engine ground cables, and the starter for looseness and corrosion. Then try starting the engine again.

If the starter cranks normally the engine, repairing the loose connection repaired the problem. The starting system

is now OK.

If the starter still does not crank the engine, go to next step.

4. Disconnect the connector from the S- terminal of solenoid. Connect a jumper wire from the B- terminal of solenoid to

the S- terminal of solenoid.

If the starter cranks the engine, go to next step.

If the starter still does not crank the engine, remove the starter, and repair or replace as necessary.

5. Check the following items in the order listed until you find the open circuit.

a. Check the wire and connectors between the driver's under - dash fuse/relay box and the ignition switch, and

between the driver's under - dash fuse/relay box and the starter.

b. Check the ignition switch (Refer to BE group - ignition system)

c. Check the transaxle range switch connector or ignition lock switch connector.

d. Inspect the starter relay.

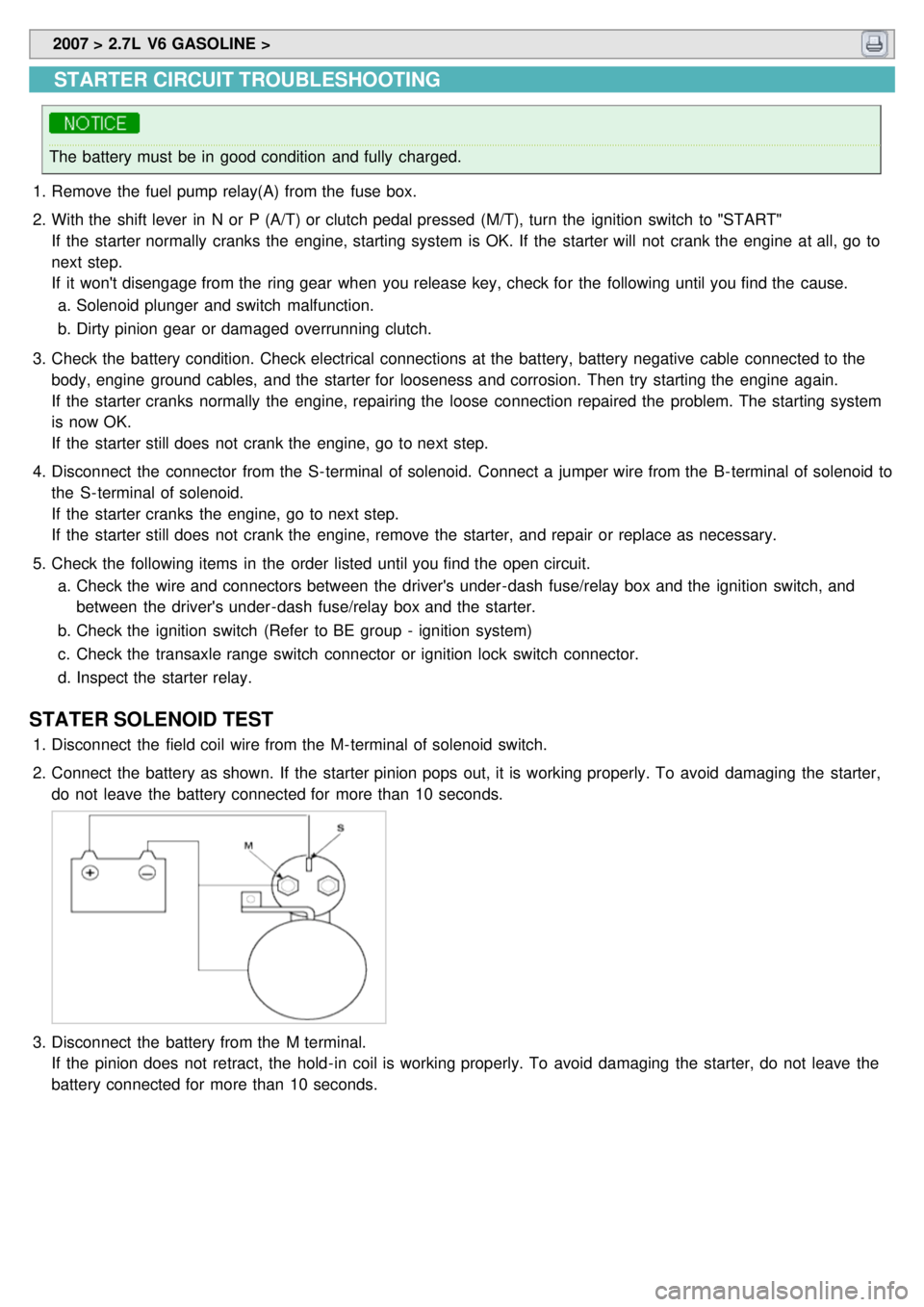

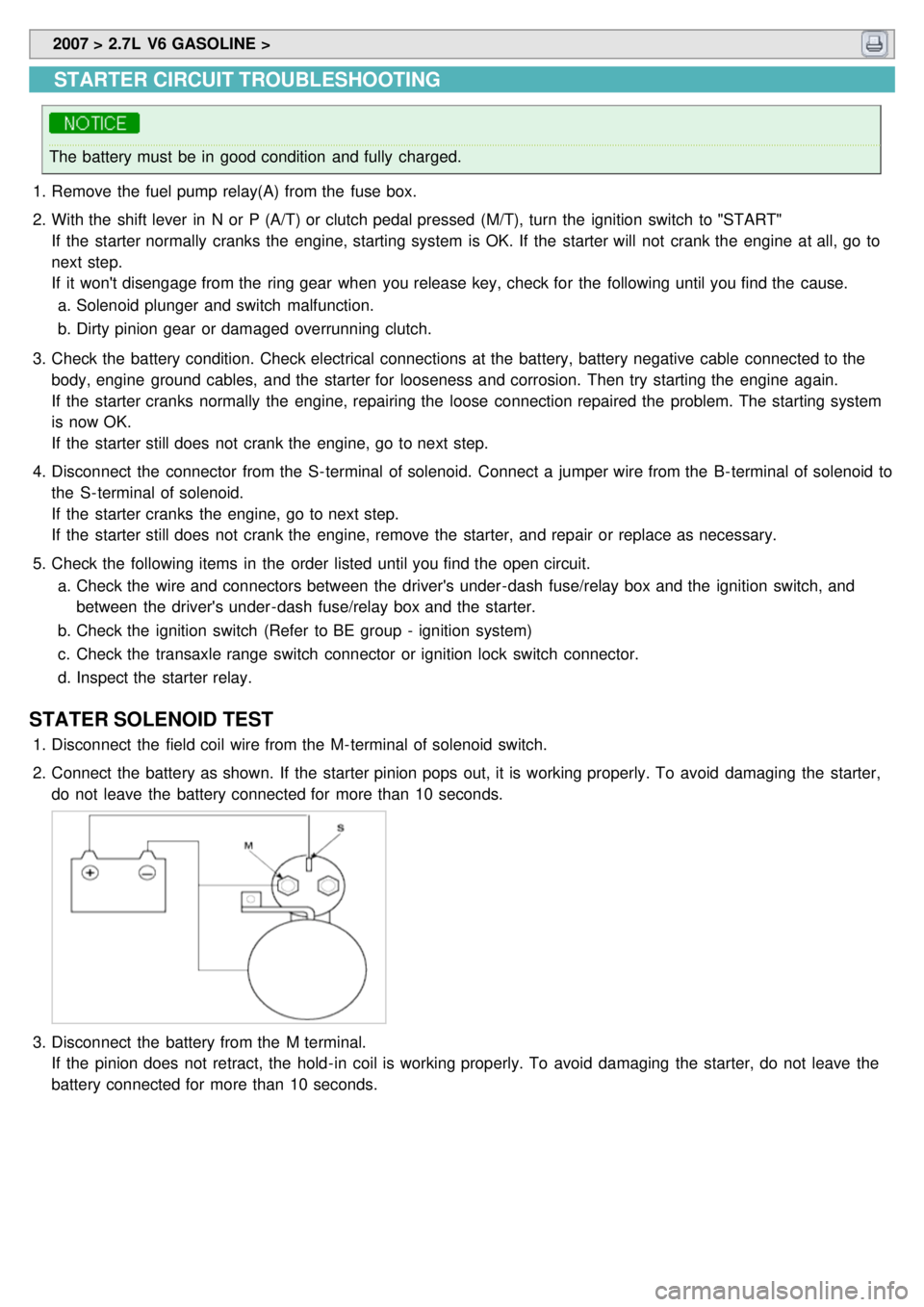

STATER SOLENOID TEST

1.Disconnect the field coil wire from the M- terminal of solenoid switch.

2. Connect the battery as shown. If the starter pinion pops out, it is working properly. To avoid damaging the starter,

do not leave the battery connected for more than 10 seconds.

3.Disconnect the battery from the M terminal.

If the pinion does not retract, the hold- in coil is working properly. To avoid damaging the starter, do not leave the

battery connected for more than 10 seconds.

Page 177 of 1575

4.Disconnect the battery also from the body. If the pinion retracts immediately, it is working properly. To avoid

damaging the starter, do not leave the battery connected for more than 10 seconds.

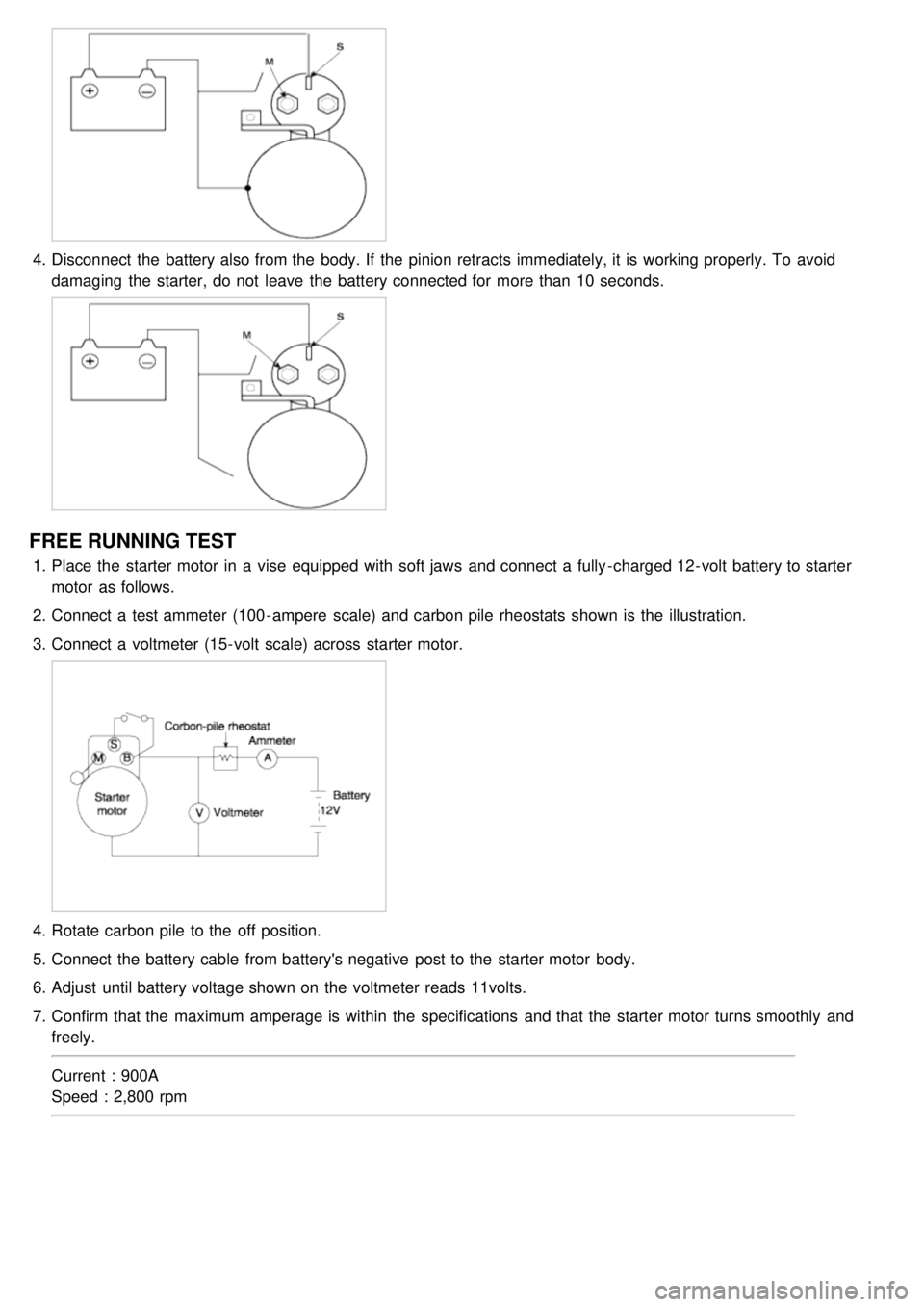

FREE RUNNING TEST

1.Place the starter motor in a vise equipped with soft jaws and connect a fully - charged 12- volt battery to starter

motor as follows.

2. Connect a test ammeter (100 - ampere scale) and carbon pile rheostats shown is the illustration.

3. Connect a voltmeter (15- volt scale) across starter motor.

4.Rotate carbon pile to the off position.

5. Connect the battery cable from battery's negative post to the starter motor body.

6. Adjust until battery voltage shown on the voltmeter reads 11volts.

7. Confirm that the maximum amperage is within the specifications and that the starter motor turns smoothly and

freely.

Current : 900A

Speed : 2,800 rpm

Page 178 of 1575

Page 179 of 1575

2007 > 2.7L V6 GASOLINE >

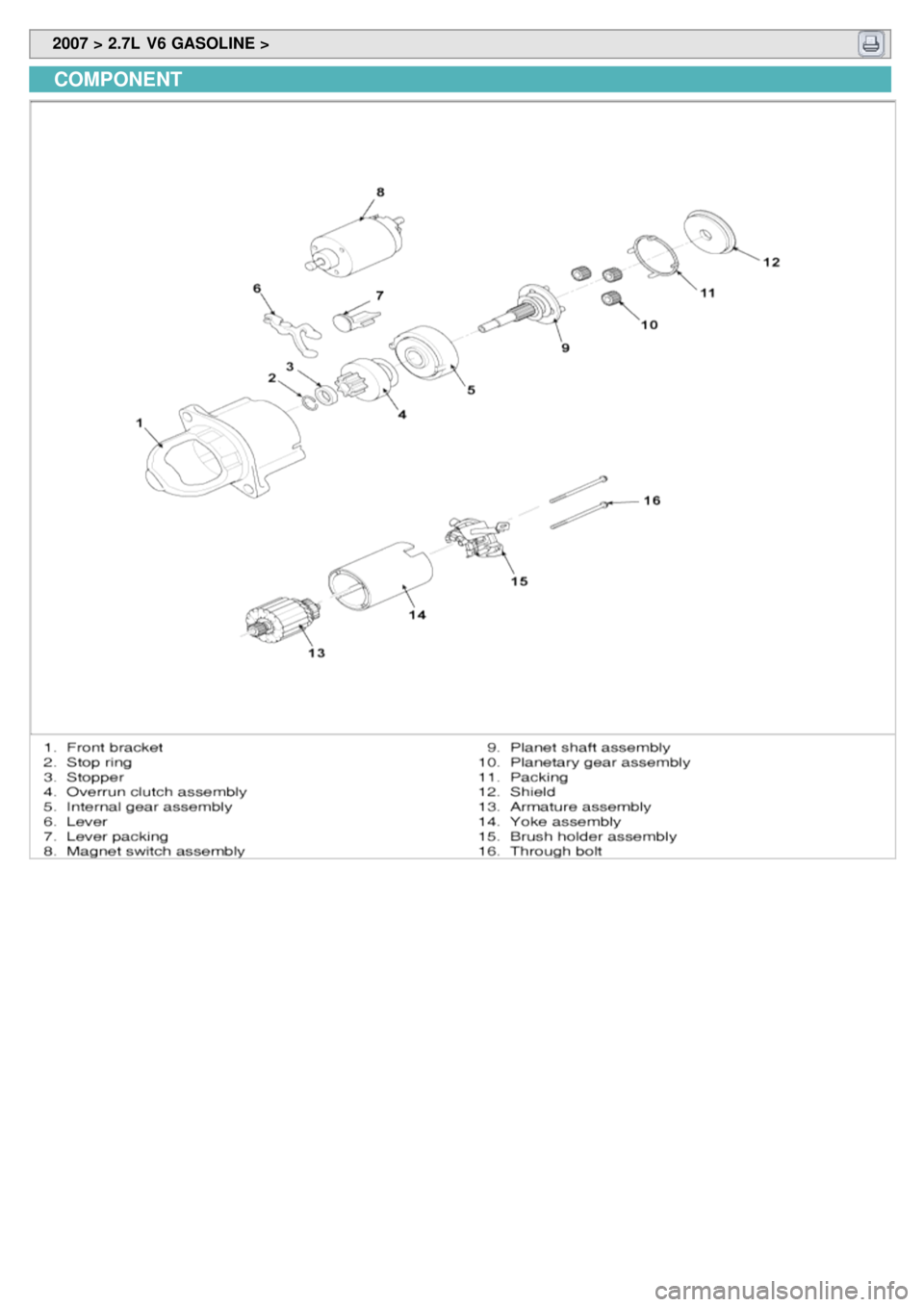

COMPONENT

Page 180 of 1575

2007 > 2.7L V6 GASOLINE >

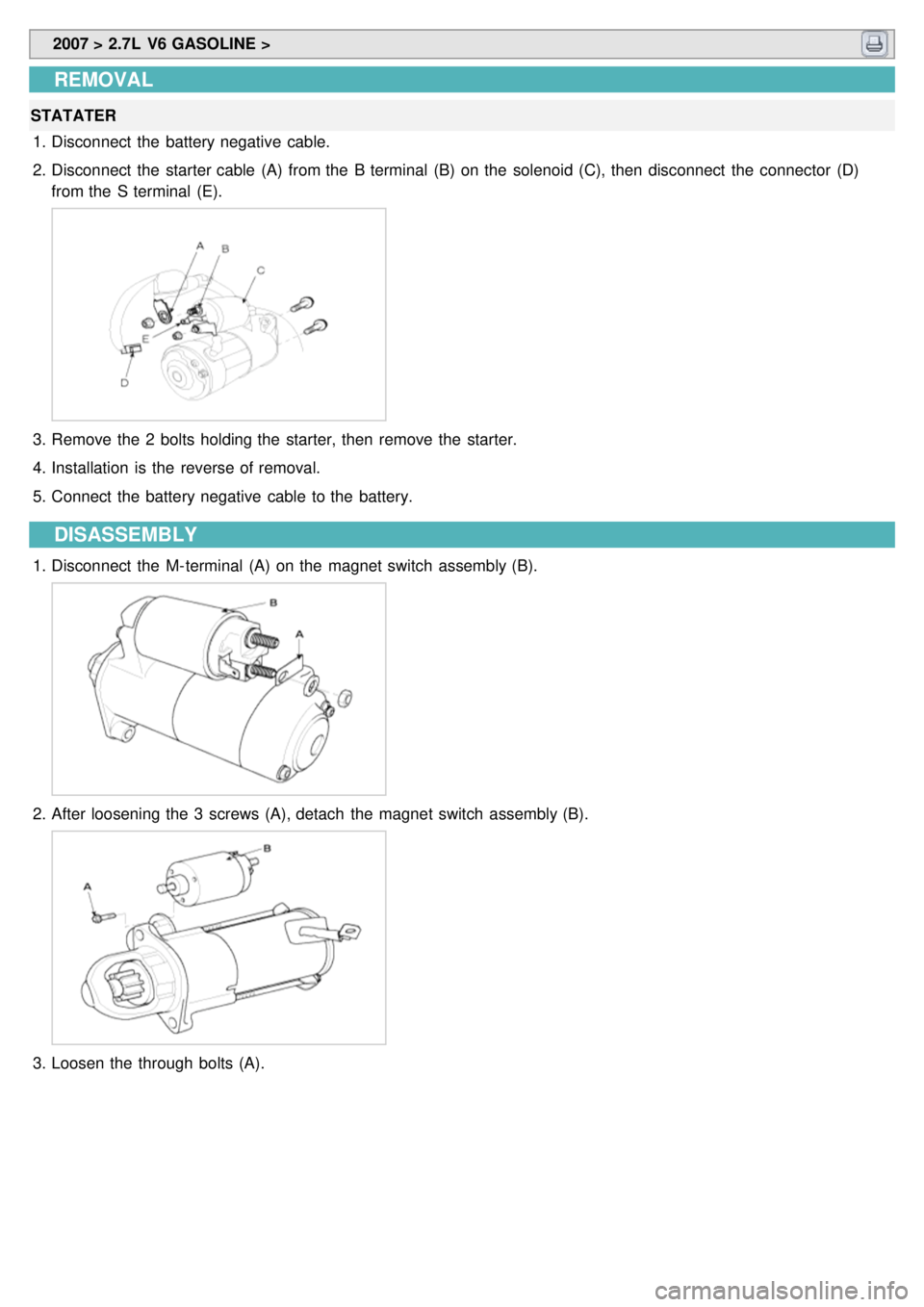

REMOVAL

STATATER

1. Disconnect the battery negative cable.

2. Disconnect the starter cable (A) from the B terminal (B) on the solenoid (C), then disconnect the connector (D)

from the S terminal (E).

3.Remove the 2 bolts holding the starter, then remove the starter.

4. Installation is the reverse of removal.

5. Connect the battery negative cable to the battery.

DISASSEMBLY

1.Disconnect the M- terminal (A) on the magnet switch assembly (B).

2.After loosening the 3 screws (A), detach the magnet switch assembly (B).

3.Loosen the through bolts (A).

Trending: remove seats, rear view mirror, battery location, refrigerant type, checking oil, engine, brake fluid