CYLINDER 6 KIA CARNIVAL 2007 User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 23 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the engine cover.

2. Remove the front right wheel and tire.

3. Remove the right side cover.

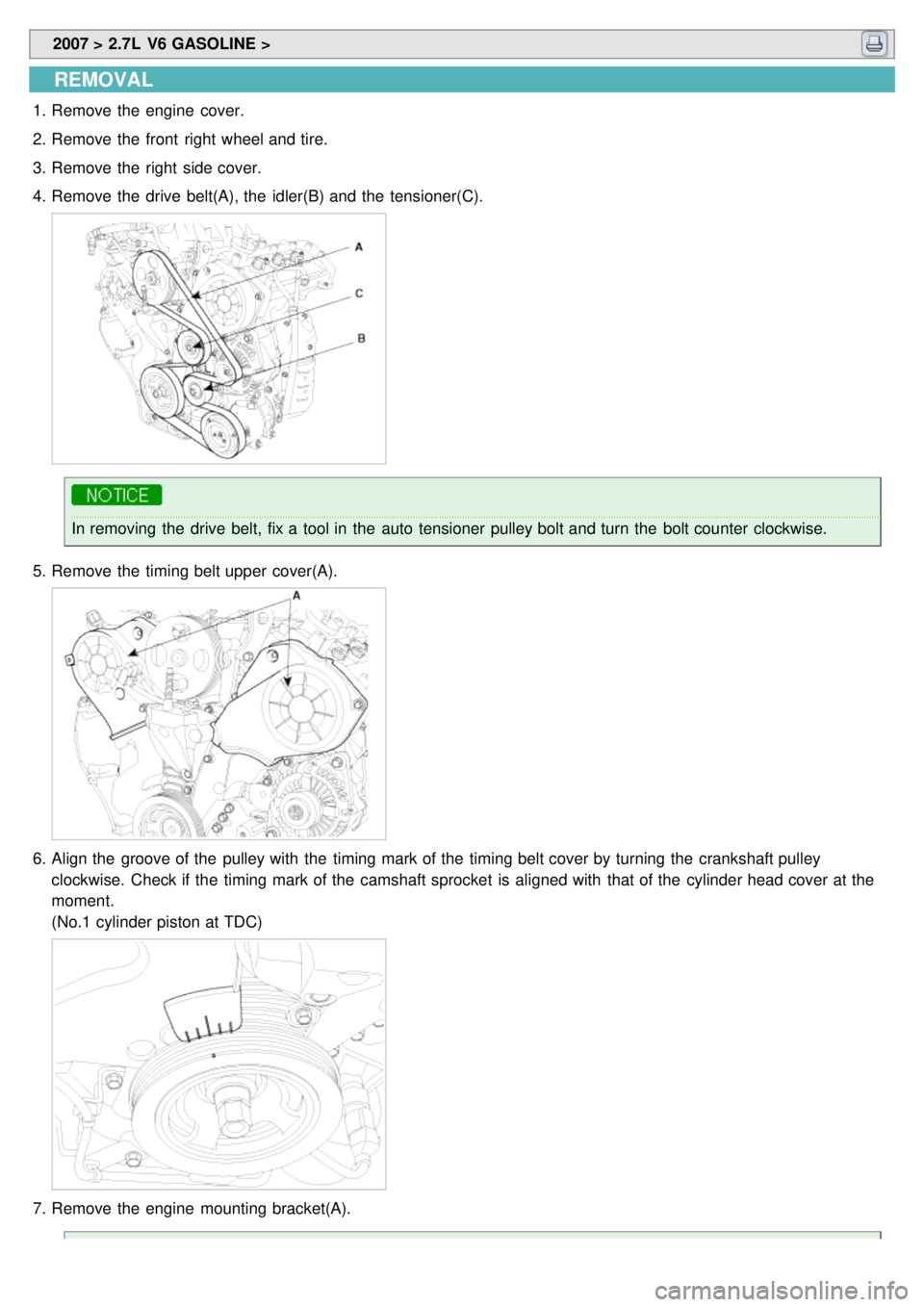

4. Remove the drive belt(A), the idler(B) and the tensioner(C).

In removing the drive belt, fix a tool in the auto tensioner pulley bolt and turn the bolt counter clockwise.

5. Remove the timing belt upper cover(A).

6.Align the groove of the pulley with the timing mark of the timing belt cover by turning the crankshaft pulley

clockwise. Check if the timing mark of the camshaft sprocket is aligned with that of the cylinder head cover at the

moment.

(No.1 cylinder piston at TDC)

7.Remove the engine mounting bracket(A).

Page 28 of 1575

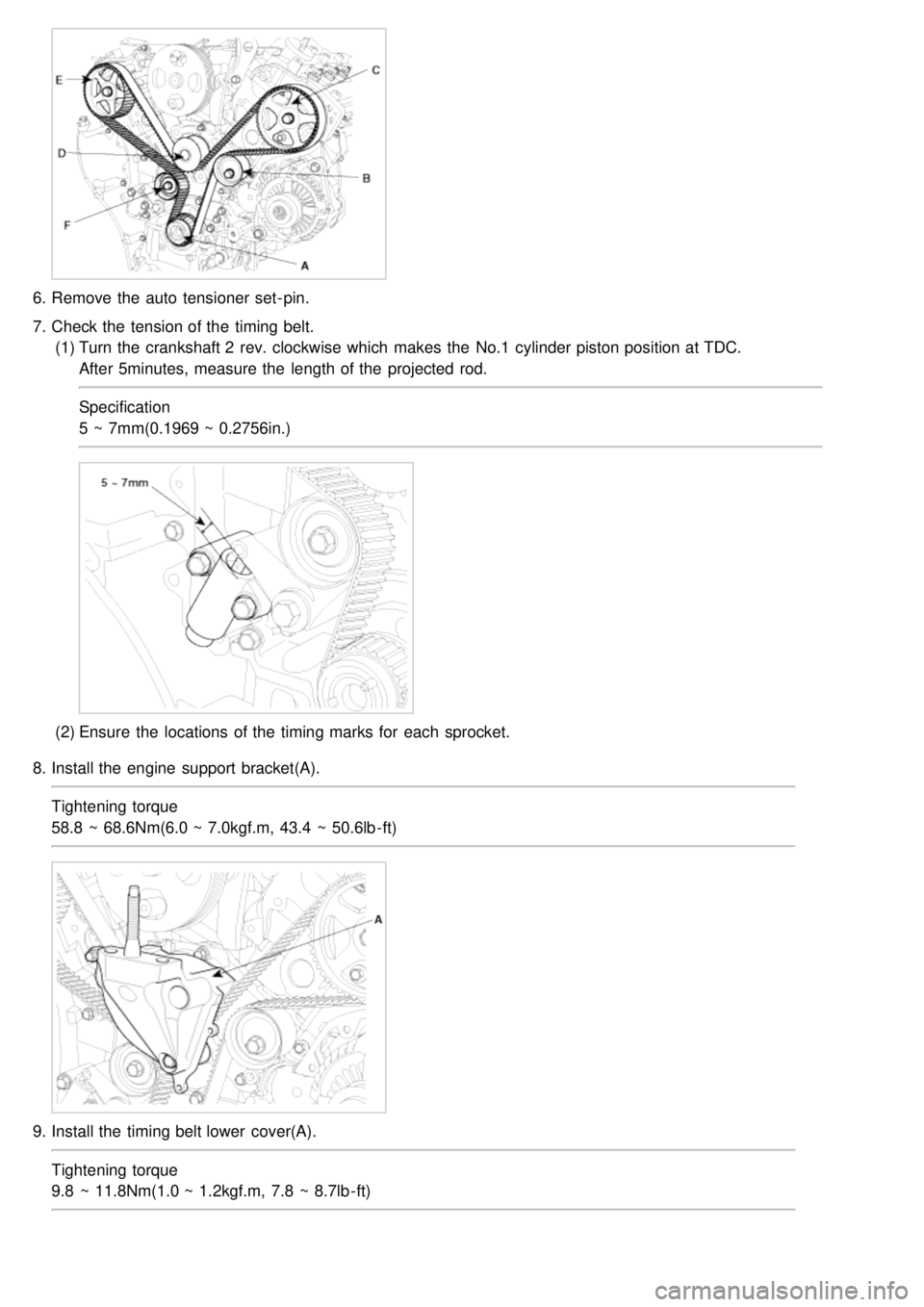

6.Remove the auto tensioner set- pin.

7. Check the tension of the timing belt.

(1) Turn the crankshaft 2 rev. clockwise which makes the No.1 cylinder piston position at TDC.

After 5minutes, measure the length of the projected rod.

Specification

5 ~ 7mm(0.1969 ~ 0.2756in.)

(2)Ensure the locations of the timing marks for each sprocket.

8. Install the engine support bracket(A).

Tightening torque

58.8 ~ 68.6Nm(6.0 ~ 7.0kgf.m, 43.4 ~ 50.6lb- ft)

9.Install the timing belt lower cover(A).

Tightening torque

9.8 ~ 11.8Nm(1.0 ~ 1.2kgf.m, 7.8 ~ 8.7lb - ft)

Page 32 of 1575

Cylinder Head Assembly

Page 35 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

a.Use fender covers to avoid damaging painted surfaces.

b. To avoid damaging the cylinder head, wait until the engine coolant temperature drops below normal

temperature before removing it.

c. When handling a metal gasket, take care not to fold the gasket or damage the contact surface of the gasket.

d. To avoid damage, unplug the wiring connectors carefully while holding the connector portion.

a.Mark all wiring and hoses to avoid misconnection.

b. Turn the crankshaft pulley so that the No. 1 piston is at top dead center.

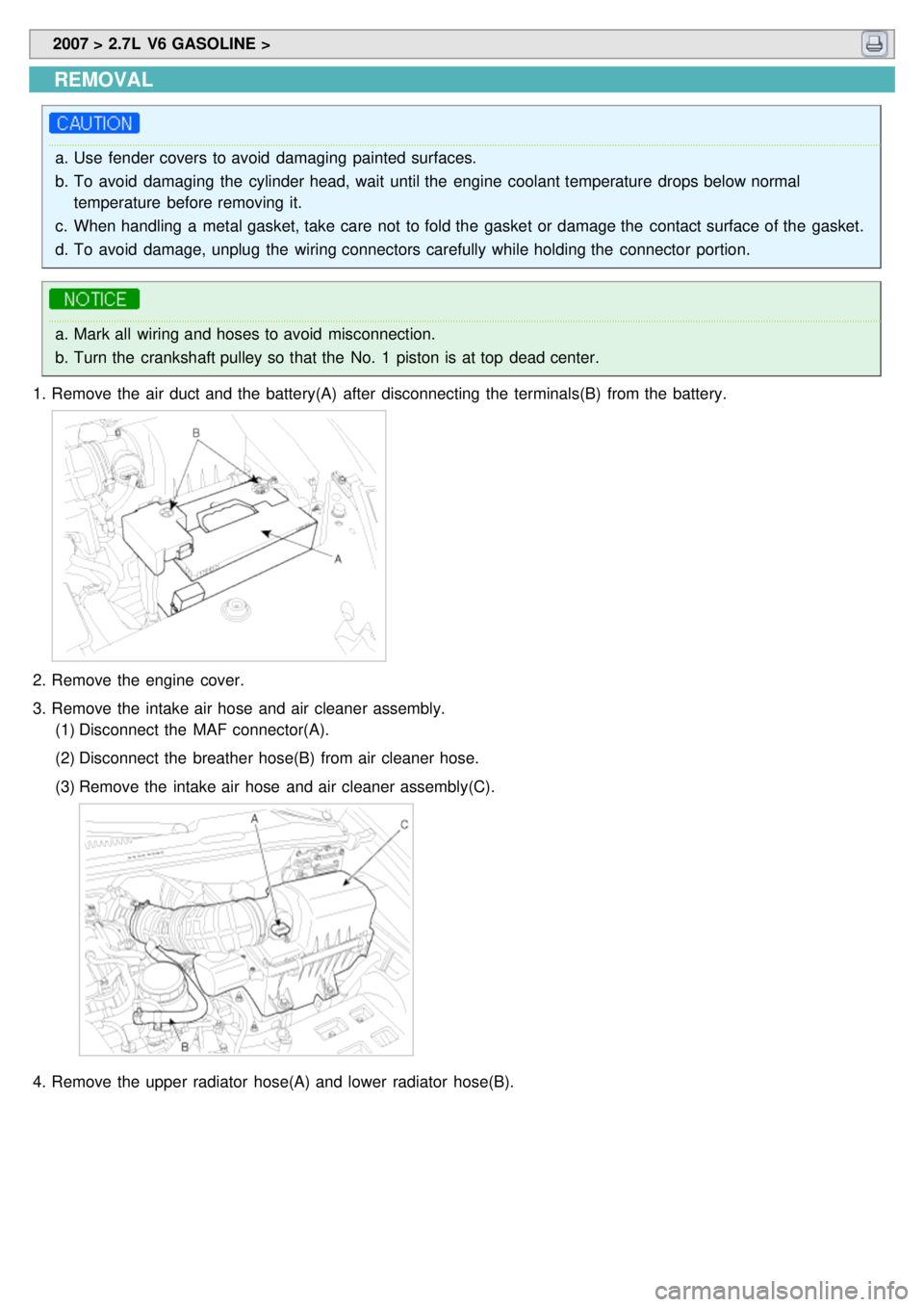

1. Remove the air duct and the battery(A) after disconnecting the terminals(B) from the battery.

2.Remove the engine cover.

3. Remove the intake air hose and air cleaner assembly.

(1) Disconnect the MAF connector(A).

(2) Disconnect the breather hose(B) from air cleaner hose.

(3) Remove the intake air hose and air cleaner assembly(C).

4.Remove the upper radiator hose(A) and lower radiator hose(B).

Page 39 of 1575

8.Disconnect the brake vaccume hose(A).

9.Remove the heater hoses.

10. Remove the drive belt(A).

11.Remove the power steering pump.(Refer to 'ST' group).

12. Remove the exhaust manifold assembly.(Refer to 'Intake and exhause system').

13. Remove the intake manifold assembly.(Refer to 'Intake and exhause system').

14. Remove the timing belt.(Refer to 'Timing system').

15. Remove the ignition coils.

16. Remove the water temp. control assembly.

17. Remove the cylinder head cover(A).

Page 41 of 1575

23.Remove the CKP sensor connector bracket(A).

24.Remove the cylinder head assembly.

(1) Remove the bolts in 2~3 steps as following orders.

If the bolts are not removed as the order, the deformation of the head assembly can be occurred.

(2) Put the cylinder head assembly on a wooden block after removal from the cylinder block.

Ensure that the surface between the cylinder head and the block is not damaged.

REPLACEMENT

Valve guide

1. Using the SST(09221- 3F100A), remove the valve guide from the downside of the cylinder head assembly.

Page 42 of 1575

2.Reprocess the valve guide hole for the oversized valve guide newly installed.

3. Using the SST(09221- 3F100A/B), insert the valve guide in the upside of the cylinder head assembly. Be aware of

the difference in length between the intake and the exhaust valve guides.

Specification

Intake valve guide: 45.8 ~ 46.2mm(1.8031 ~ 1.8189in.)

Exhaust valve guide: 46.8 ~ 47.2mm(1.8425 ~ 1.8583in.)

4.After installing the valve guides, insert new valves and check the clearance between the valve stems and the valve

guides.

5. After replacing the valve guides, check if they are properly installed with the valve seats. Reprocess valve seats if

necessary.

INSTALLATION

a.Thoroughly clean all parts to be assembled.

b. Always use a new head and manifold gasket.

c. The cylinder head gasket is a metal gasket. Take care not to bend it.

d. Rotate the crankshaft to set the No.1 cylinder piston at TDC.

1. After putting the cylinder head gasket on the cylinder block, install the cylinder head.

Page 43 of 1575

Ensure the LH/RH classification of the cylinder head gasket when installing.

2. Tighten the cylinder head bolts with the plain washers in several steps as following order.

a.In assembling washers, the marked surface should face upward.

b. In installing the cylinder head bolts, apply engine oil on the thread of the bolts and the surface of the

washers.

Tightening torque

22.6~26.5Nm(2.3~2.7kgf.m, 16.6~19.5lb - ft) + (60° + 2°) + (45° + 2°)

Using the SST(09221- 4A000), tighten the bolts which need to be tightened with the angular tightening method.

3. Install the CVVT assembly and camshaft chain sprocket with the dowel pin in the CVVT installed to the intake

camshaft. Ensure that the pin will not be installed in the hole for oil feeding.

Page 44 of 1575

camshaft. Ensure that the pin will not be installed in the hole for oil feeding.

Tightening torque

66.7~78.5Nm(6.8~8.0kgf.m, 49.2~57.9lb - ft)

After tightening the CVVT bolts, rotate the CVVT assembly housing counterclockwise by hand to seat the lock

pin in the CVVT assembly in good position.

Fix the hexagonal part of the camshaft in a vice when tightening the CVVT bolts. Do not fix the CVVT housing

or sprocket in a vice.

4. Install the camshaft in the cylinder head assembly.

(1) Align the timing mark of the camshaft timinig chain.

LH camshaft chain timing mark

RH camshaft chain timing mark

Both timing marks should face upward in reassemby.

5. Install the timing chain tensioner.

(1) Insert the set pin by pressing the timing chain tensioner.

(2) Install the chain tensioner(A) in the cylinder head assembly.

Page 46 of 1575

7.Using the SST(09214- 21000), install the camshaft oil seal.

a.Befor installing, apply engine oil.

b. The camshaft cap surface should adhere to the cylinder head assembly.

c. Do not press an eccentric load.

8. Install the CKP sensor connector bracket(A).

9.Install the bank 1 timing belt rear cover(A).

10. Install the bank 2 timing belt rear cover(A).