KIA CARNIVAL 2007 Repair Manual

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 Repair Manual

Page 295 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Camshaft Position Sensor (CMPS) is a hall sensor and detects the camshaft position by using a hall element. It is

related with Crankshaft Position Sensor (CKPS) and detects the piston position of each cylinder which the CKPS can't

detect. The two CMPS are installed on engine head cover of bank 1 and 2 and uses a target wheel installed on the

camshaft. This sensor has a hall - effect IC which output voltage changes when magnetic field is made on the IC with

current flow.

Page 299 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Based on information from various sensors, the PCM measures the fuel injection amount. The fuel injector is a

solenoid- operated valve and the fuel injection amount is controlled by length of time that the fuel injector is held open.

The PCM controls each injector by grounding the control circuit. When the PCM energizes the injector by grounding

the control circuit, the circuit voltage should be low (theoretically 0V) and the fuel is injected. When the PCM de-

energizes the injector by opening control circuit, the fuel injector is closed and circuit voltage should momentarily peak.

If an injector connector is disconnected for more than 46 seconds while the engine runs, the PCM will determine

that the cylinder is misfiring and cut fuel supply. So be careful not to exceed 46 seconds. But the engine runs

normally in 10 seconds after turning the ignition key off.

SPECIFICATION

Item Specification

Coil Resistance (Ω) 13.8 ~ 15.2Ω at 20°C (68°F)

CIRCUIT DIAGRAM

Page 306 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

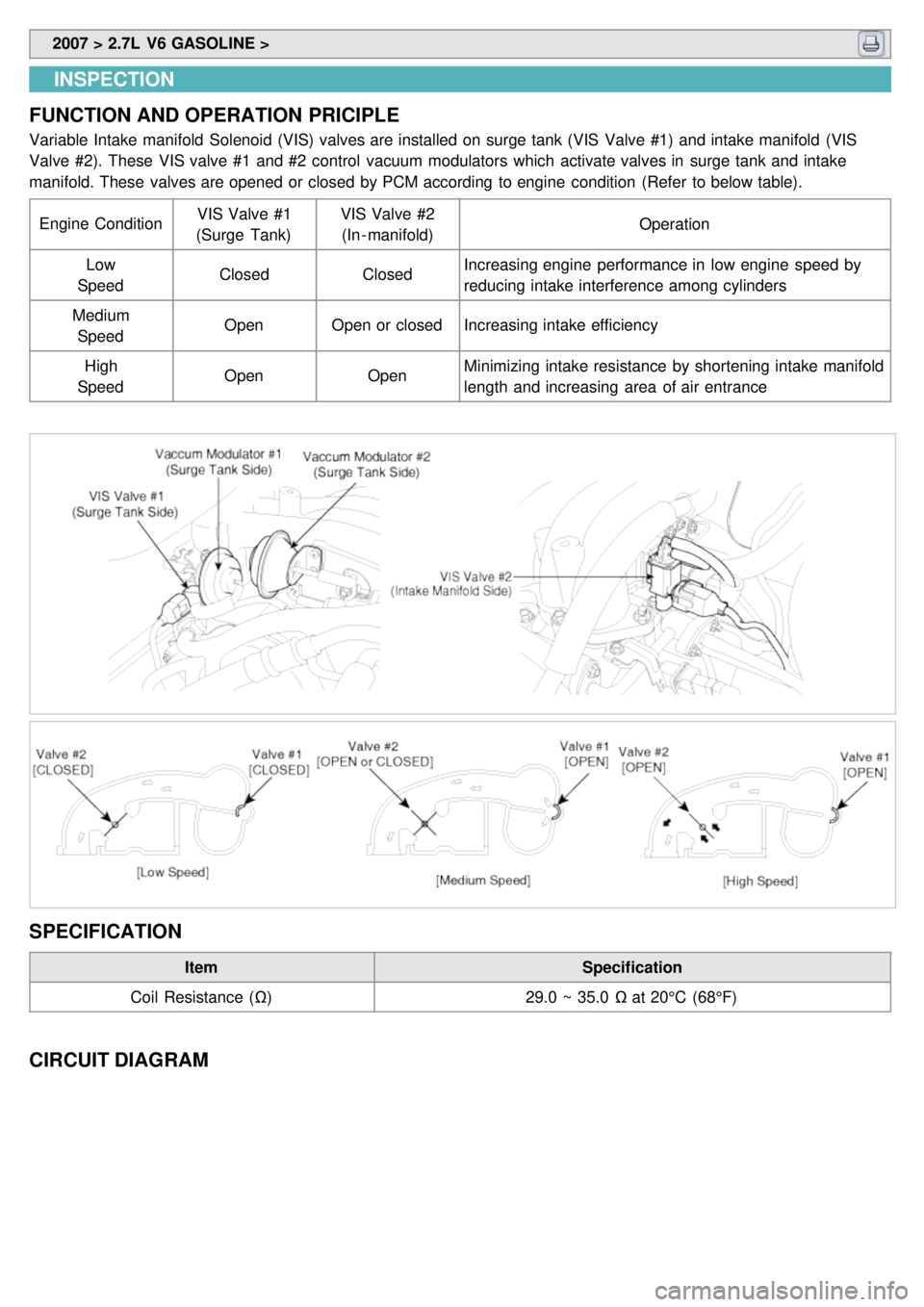

Variable Intake manifold Solenoid (VIS) valves are installed on surge tank (VIS Valve #1) and intake manifold (VIS

Valve #2). These VIS valve #1 and #2 control vacuum modulators which activate valves in surge tank and intake

manifold. These valves are opened or closed by PCM according to engine condition (Refer to below table).

Engine Condition VIS Valve #1

(Surge Tank) VIS Valve #2

(In - manifold) Operation

Low

Speed Closed

ClosedIncreasing engine performance in low engine speed by

reducing intake interference among cylinders

Medium Speed Open

Open or closed Increasing intake efficiency

High

Speed Open

OpenMinimizing intake resistance by shortening intake manifold

length and increasing area of air entrance

SPECIFICATION

Item

Specification

Coil Resistance (Ω) 29.0 ~ 35.0 Ω at 20°C (68°F)

CIRCUIT DIAGRAM

Page 422 of 1575

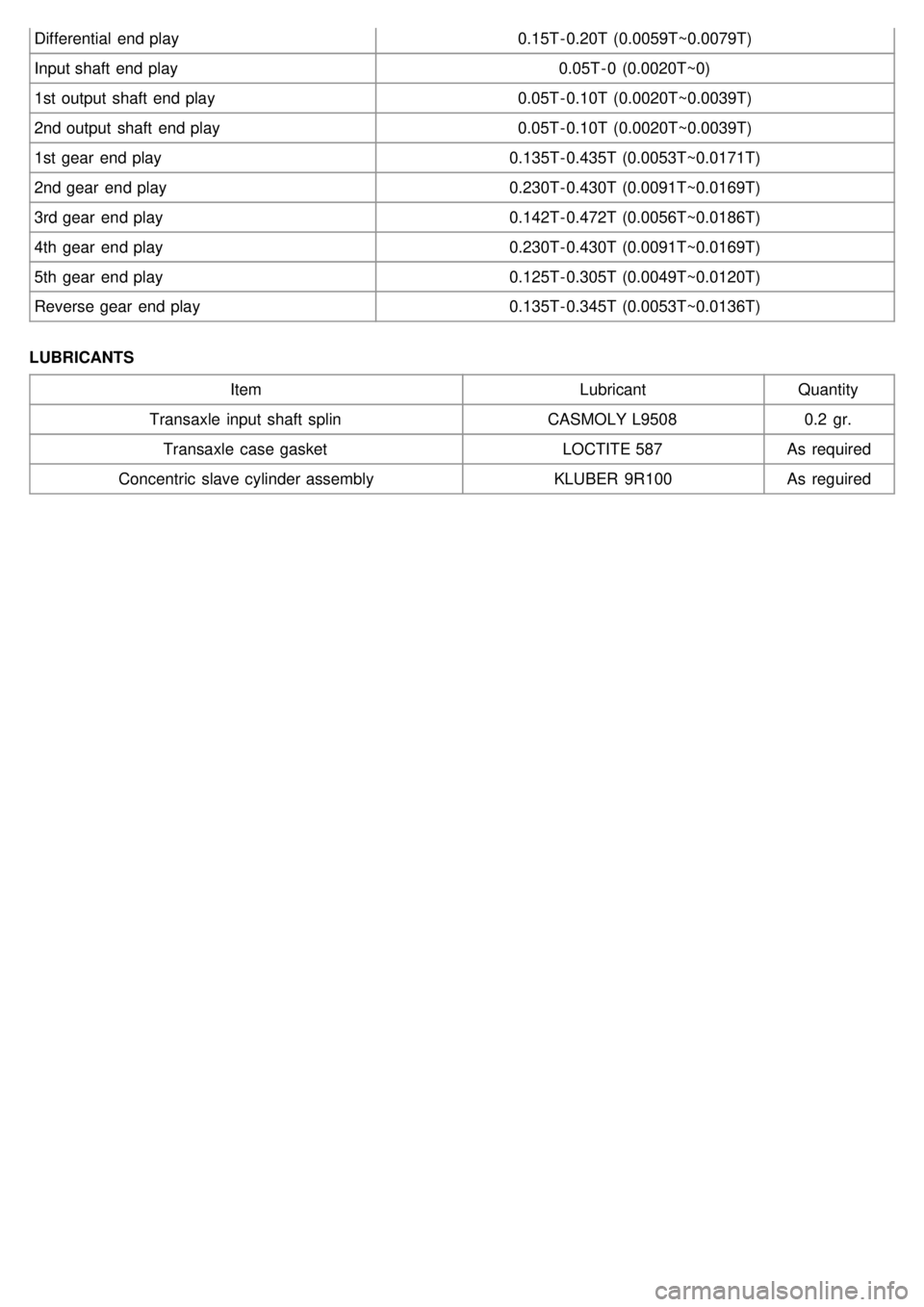

Differential end play0.15T - 0.20T (0.0059T~0.0079T)

Input shaft end play 0.05T - 0 (0.0020T~0)

1st output shaft end play 0.05T - 0.10T (0.0020T~0.0039T)

2nd output shaft end play 0.05T - 0.10T (0.0020T~0.0039T)

1st gear end play 0.135T- 0.435T (0.0053T~0.0171T)

2nd gear end play 0.230T- 0.430T (0.0091T~0.0169T)

3rd gear end play 0.142T- 0.472T (0.0056T~0.0186T)

4th gear end play 0.230T- 0.430T (0.0091T~0.0169T)

5th gear end play 0.125T- 0.305T (0.0049T~0.0120T)

Reverse gear end play 0.135T- 0.345T (0.0053T~0.0136T)

LUBRICANTS Item LubricantQuantity

Transaxle input shaft splin CASMOLY L95080.2 gr.

Transaxle case gasket LOCTITE 587As required

Concentric slave cylinder assembly KLUBER 9R100As reguired

Page 428 of 1575

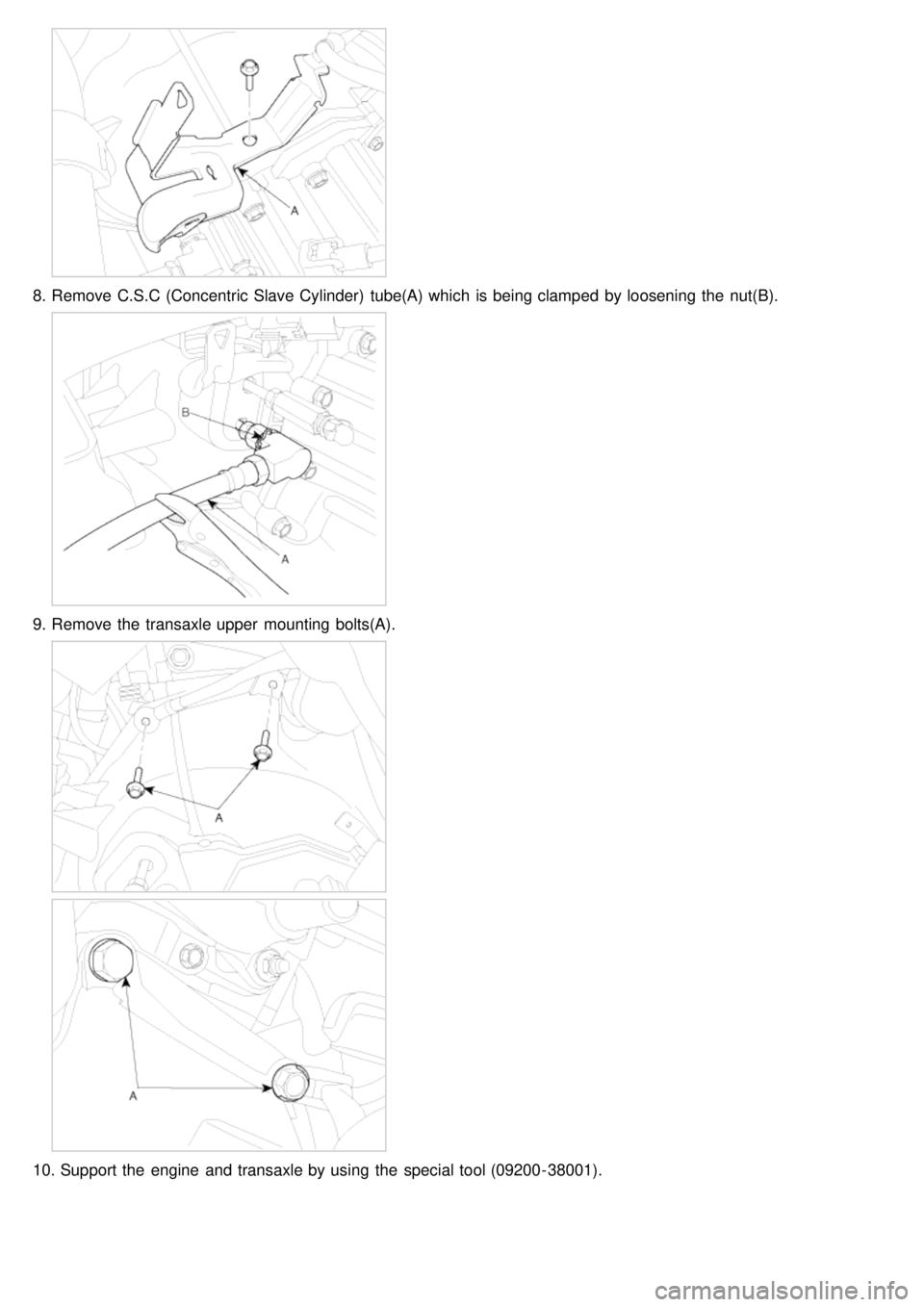

8.Remove C.S.C (Concentric Slave Cylinder) tube(A) which is being clamped by loosening the nut(B).

9.Remove the transaxle upper mounting bolts(A).

10. Support the engine and transaxle by using the special tool (09200- 38001).

Page 439 of 1575

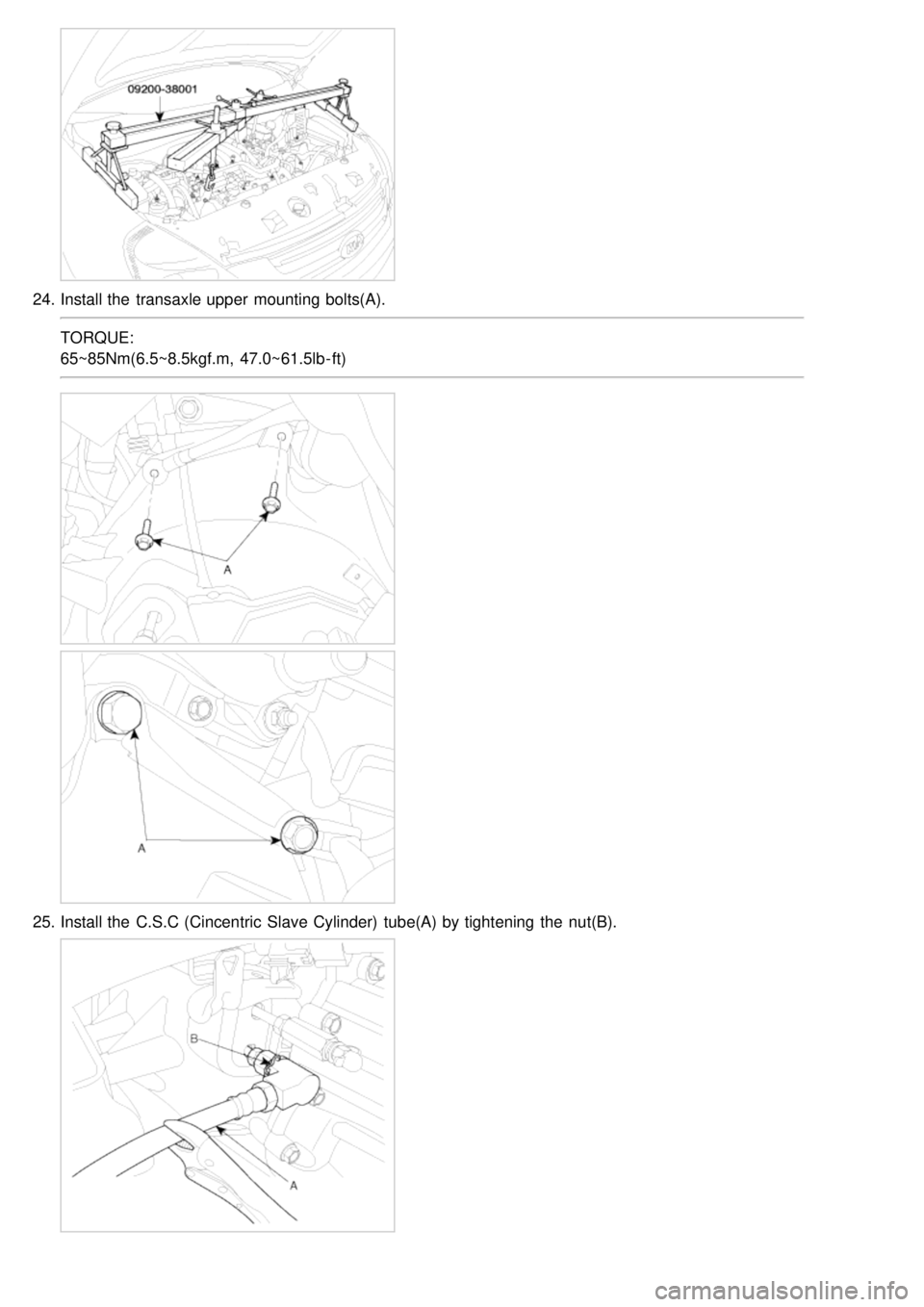

24.Install the transaxle upper mounting bolts(A).

TORQUE:

65~85Nm(6.5~8.5kgf.m, 47.0~61.5lb - ft)

25.Install the C.S.C (Cincentric Slave Cylinder) tube(A) by tightening the nut(B).

Page 606 of 1575

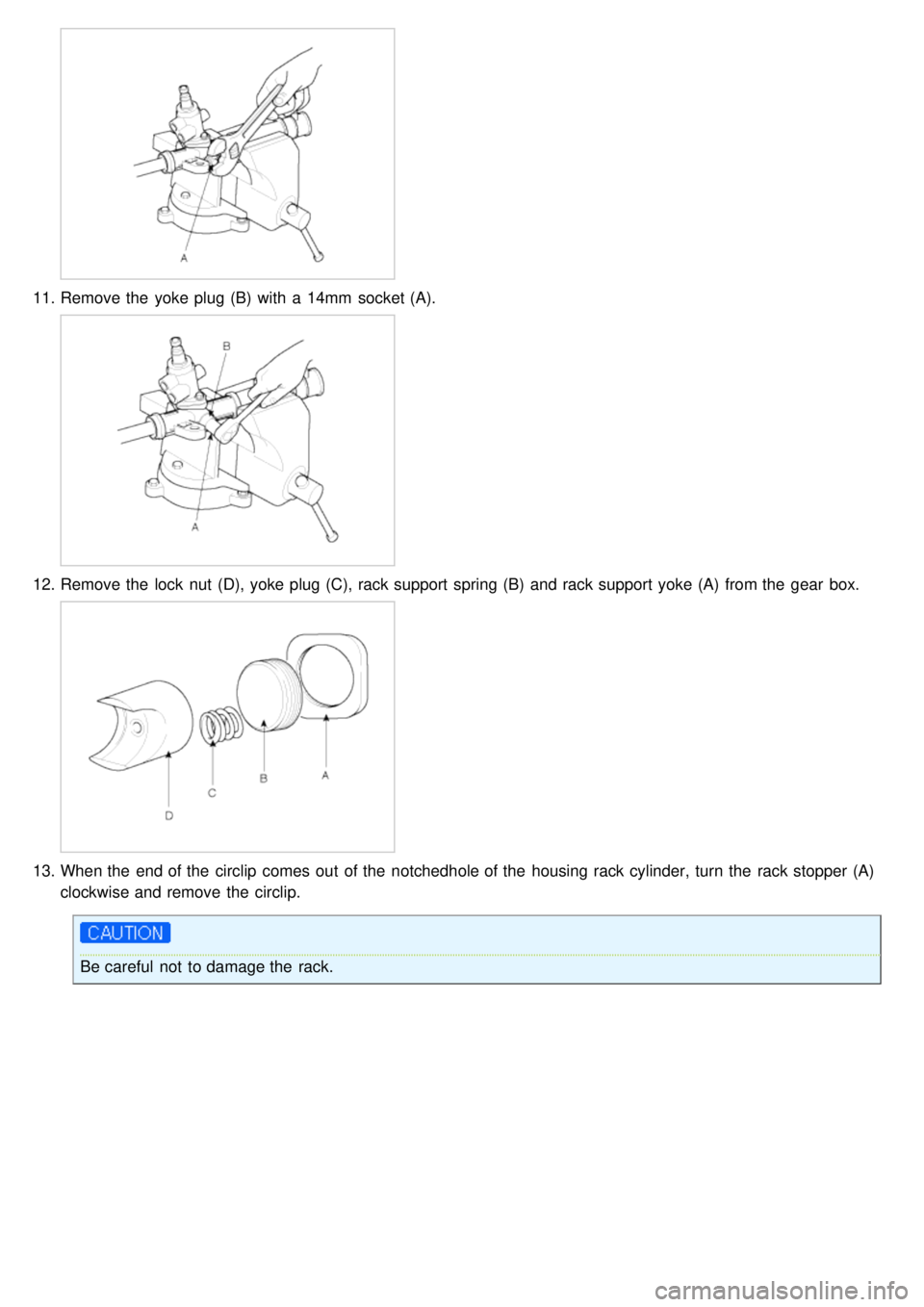

11.Remove the yoke plug (B) with a 14mm socket (A).

12.Remove the lock nut (D), yoke plug (C), rack support spring (B) and rack support yoke (A) from the gear box.

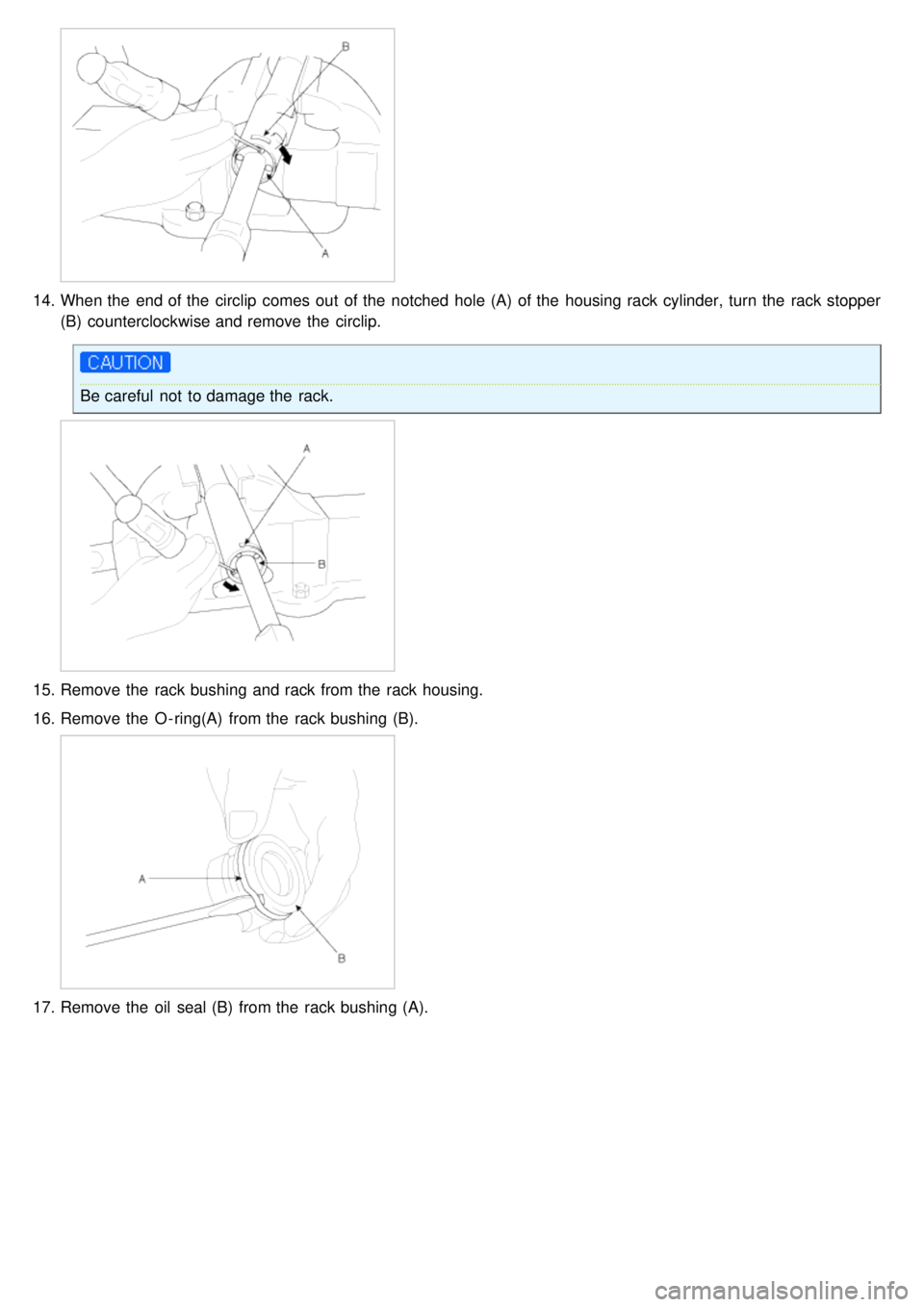

13.When the end of the circlip comes out of the notchedhole of the housing rack cylinder, turn the rack stopper (A)

clockwise and remove the circlip.

Be careful not to damage the rack.

Page 607 of 1575

14.When the end of the circlip comes out of the notched hole (A) of the housing rack cylinder, turn the rack stopper

(B) counterclockwise and remove the circlip.

Be careful not to damage the rack.

15.Remove the rack bushing and rack from the rack housing.

16. Remove the O - ring(A) from the rack bushing (B).

17.Remove the oil seal (B) from the rack bushing (A).

Page 608 of 1575

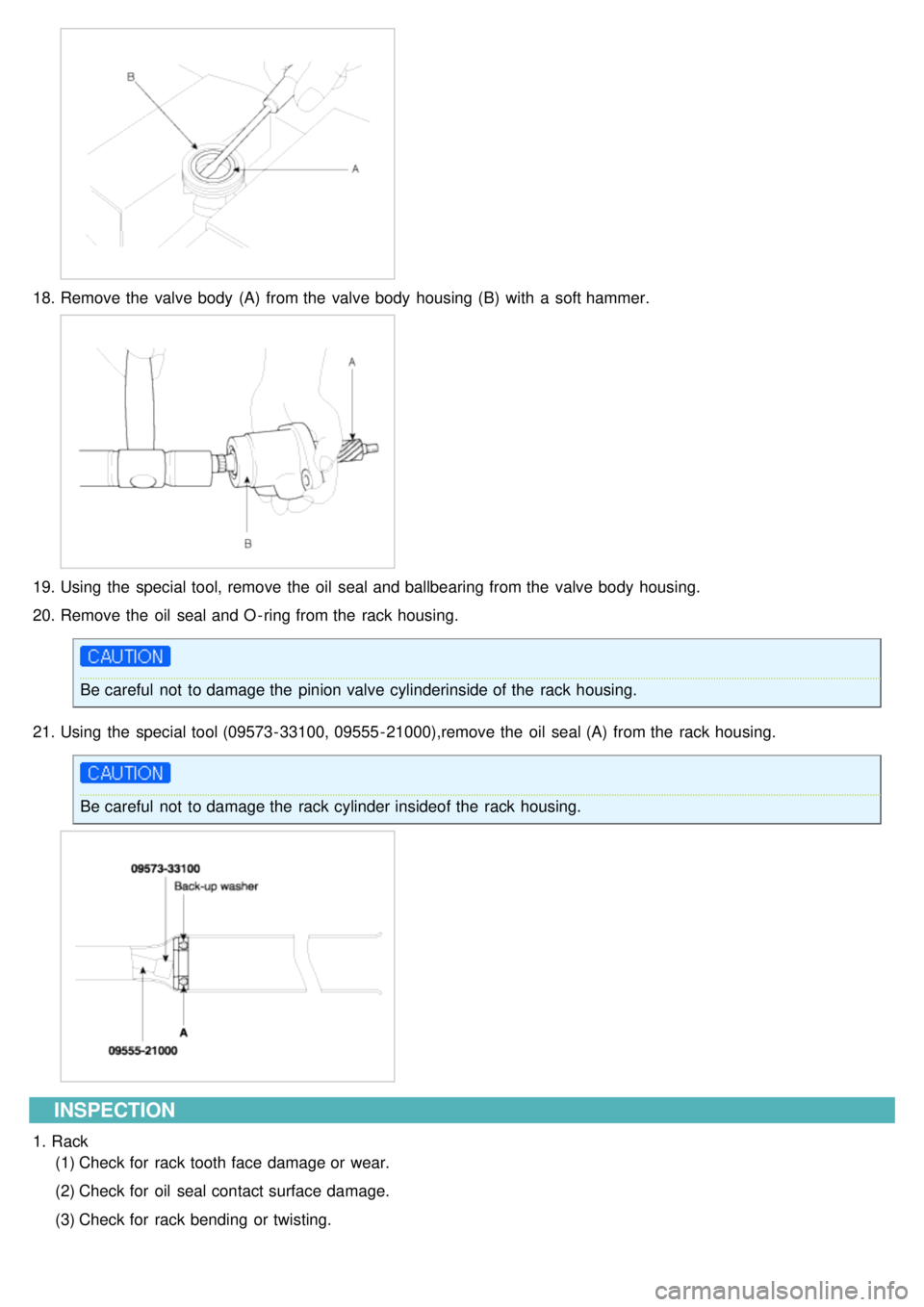

18.Remove the valve body (A) from the valve body housing (B) with a soft hammer.

19.Using the special tool, remove the oil seal and ballbearing from the valve body housing.

20. Remove the oil seal and O - ring from the rack housing.

Be careful not to damage the pinion valve cylinderinside of the rack housing.

21. Using the special tool (09573- 33100, 09555 - 21000),remove the oil seal (A) from the rack housing.

Be careful not to damage the rack cylinder insideof the rack housing.

INSPECTION

1.Rack

(1) Check for rack tooth face damage or wear.

(2) Check for oil seal contact surface damage.

(3) Check for rack bending or twisting.

Page 609 of 1575

(4)Check for oil seal ring damage or wear.

(5) Check for oil seal damage or wear.

2.Pinion valve

(1) Check for pinion gear tooth face damage or wear.

(2) Check for oil seal contact surface damage.

(3) Check for seal ring damage or wear.

(4) Check for oil seal damage or wear.

3.Bearing

(1) Check for seizure or abnormal noise during abearing rotation.

(2) Check for excessive play.

(3) Check for missing needle bearing rollers.

4. Others

(1) Check for damage of the rack housing cylinder bore.

(2) Check for boot damage, cracking or aging.

REASSEMBLY

1.Apply the specified fluid to the entire surface of the rack oil seal.

Recommended fluid : PSF - 3

2. Install the backup washer and oil seal (A) to the specified position in the rack housing.