air condition KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 37 of 1575

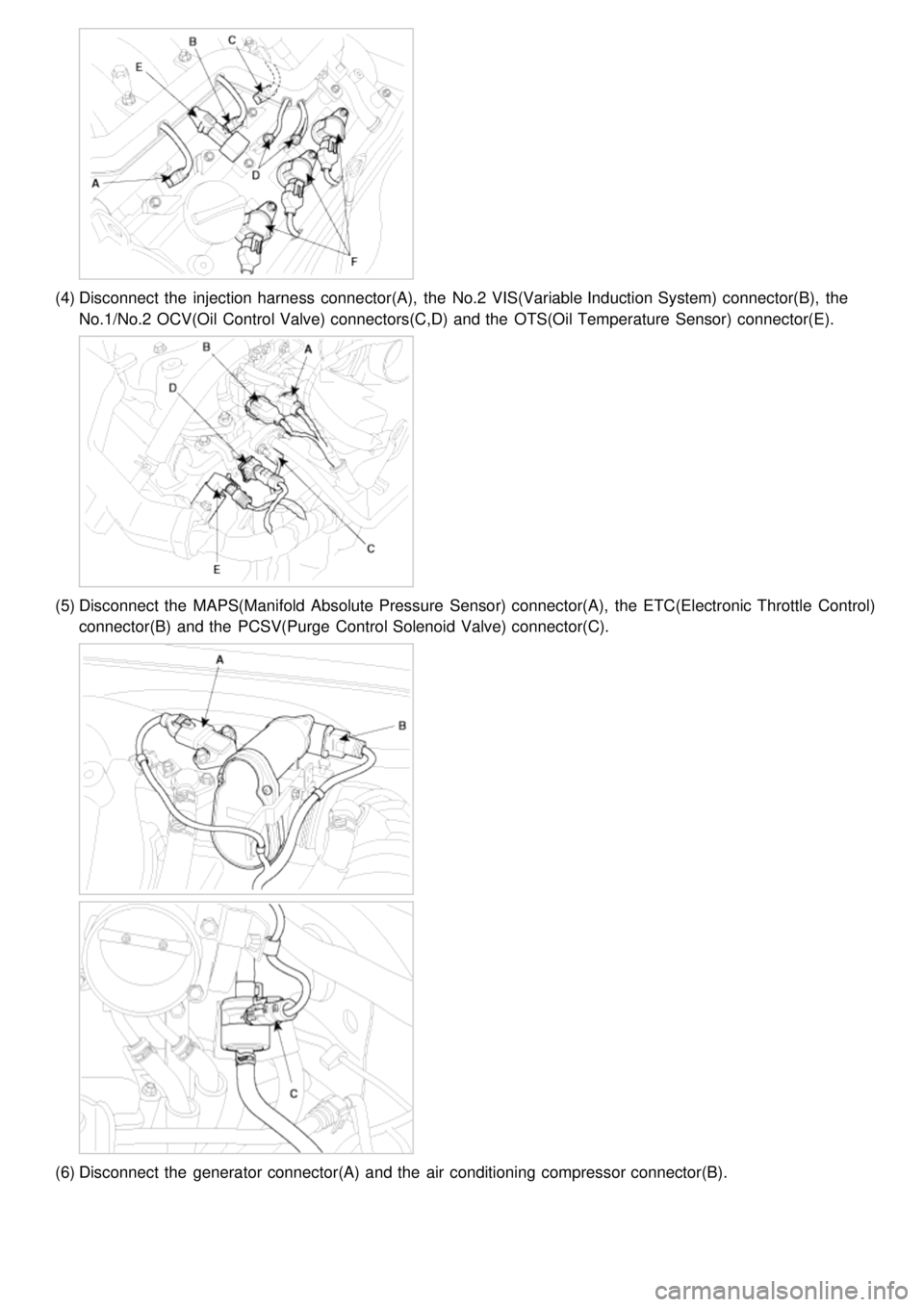

(4)Disconnect the injection harness connector(A), the No.2 VIS(Variable Induction System) connector(B), the

No.1/No.2 OCV(Oil Control Valve) connectors(C,D) and the OTS(Oil Temperature Sensor) connector(E).

(5)Disconnect the MAPS(Manifold Absolute Pressure Sensor) connector(A), the ETC(Electronic Throttle Control)

connector(B) and the PCSV(Purge Control Solenoid Valve) connector(C).

(6)Disconnect the generator connector(A) and the air conditioning compressor connector(B).

Page 49 of 1575

(2)Connect the bank 2 front/rear O2 sensor connectors(A,B) and the CKP sensor connector(C).

(3)Connect the bank 2 CMP sensor connector(A) and the WTS(Water Temperature Sensor) connector(B).

(4)Connect the generator connector(A) and the air conditioning compressor connector(B).

(5)Connect the MAPS(Manifold Absolute Pressure Sensor) connector(A), the ETC(Electronic Throttle Control)

connector(B) and the PCSV(Purge Control Solenoid Valve) connector(C).

Page 66 of 1575

(5)Disconnect the MAPS(Manifold Absolute Pressure Sensor) connector(A), the ETC(Electronic Throttle Control)

connector(B) and the PCSV(Purge Control Solenoid Valve) connector(C).

(6)Remove the cooling fan relay cable(A).

(7)Disconnect the generator connector(A) and the air conditioning compressor connector(B).

(8)Disconnect the bank 2 CMP sensor connector(A) and the WTS(Water Temperature Sensor) connector(B).

(9)Disconnect the bank 2 front/rear O2 sensor connectors(A,B) and the CKP sensor connector(C).

Page 69 of 1575

The bottom side bolt(A) which can be seen after removing the under cover should be loosened for removal of

the radiator support upper member assembly.

18.Drain engine oil.

19. Remove the brake caliper.(Refer to DS group).

20. Disconnect the air conditioning compressor hoses.(Refer to HA group).

21. Remove the front wheels and tires.(Refer to DS group).

22. Remove the brake caliper hub nut.(Refer to DS group).

23. Remove the tie rod end ball joint from the knuckle.(Refer to DS group)

24. Remove the driver shaft and the stabilizer bar link(Refer to SS group).

25. Remove the front muffler(A).

26.Using a floor jack, support the engine and transaxle assembly.

After removing the sub frame mounting bolt , the engine and transaxle assembly may fall downward, and so

support them securely with floor jack.

Page 75 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Remove the drive plate(A).

2.Remove the rear plate(A).

3.Remove timing belt.

4. Remove intake manifold.

5. Remove exhaust manifold.

6. Remove generator from engine.(Refer to 'ST' group).

7. Remove power steering pump from engine.(Refer to 'HA' group).

8. Remove cylinder head.

9. Remove A/C compressor from engine.(Refer to 'EE' group).

10. Remove water pump assembly.

INSTALLATION

1.Install the water pump.

2. Install the air conditioning compressor.(Refer to 'HA' group).

3. Install the cylinder head.

4. Install the power steering pump.(Refer to 'ST' group).

5. Install the generator.

6. Install the intake manifold.

7. Install the exhaust manifold.

8. Install the timing belt.

9. Install the rear plate(A).

Tightening torque

Page 76 of 1575

9.8 ~ 11.8Nm(1.0 ~ 1.2kgf.m, 7.2 ~ 8.7lb - ft)

10.Install the drive plate(A).

Tightening torque

71.6 ~ 75.5Nm(7.3 ~ 7.7kgf.m, 52.8 ~ 55.7lb- ft)

DISASSEMBLY

1.Remove the power steering pump bracket(A) and the knock sensor(B).

2.Remove the air conditioning compressor bracket(A).

Page 99 of 1575

Uniformly tighten the bolts in several passes.

Tightening torque

9.8 ~ 11.8Nm (1.0 ~ 1.2kgf.m, 7.2 ~ 8.7lb - ft)

18. Install the air conditioning compressor bracket(A). (Refer to 'HA' group)

19.Install the power steering pump bracket(A) and the knock sensor(B).

Tightening torque

18.6 ~ 23.5Nm (1.9 ~ 2.4kgf.m, 13.7 ~ 17.4lb- ft)

a.On Bank 1, the black knock sensor connector should be installed and on Bank 2, the gray one should.

Page 132 of 1575

(4)Disconnect the injection harness connector(A), the No.2 VIS(Variable Induction System) connector(B), the

No.1/No.2 OCV(Oil Control Valve) connectors(C,D) and the OTS(Oil Temperature Sensor) connector(E).

(5)Disconnect the MAPS(Manifold Absolute Pressure Sensor) connector(A), the ETC(Electronic Throttle Control)

connector(B) and the PCSV(Purge Control Solenoid Valve) connector(C).

(6)Disconnect the generator connector(A) and the air conditioning compressor connector(B).

Page 144 of 1575

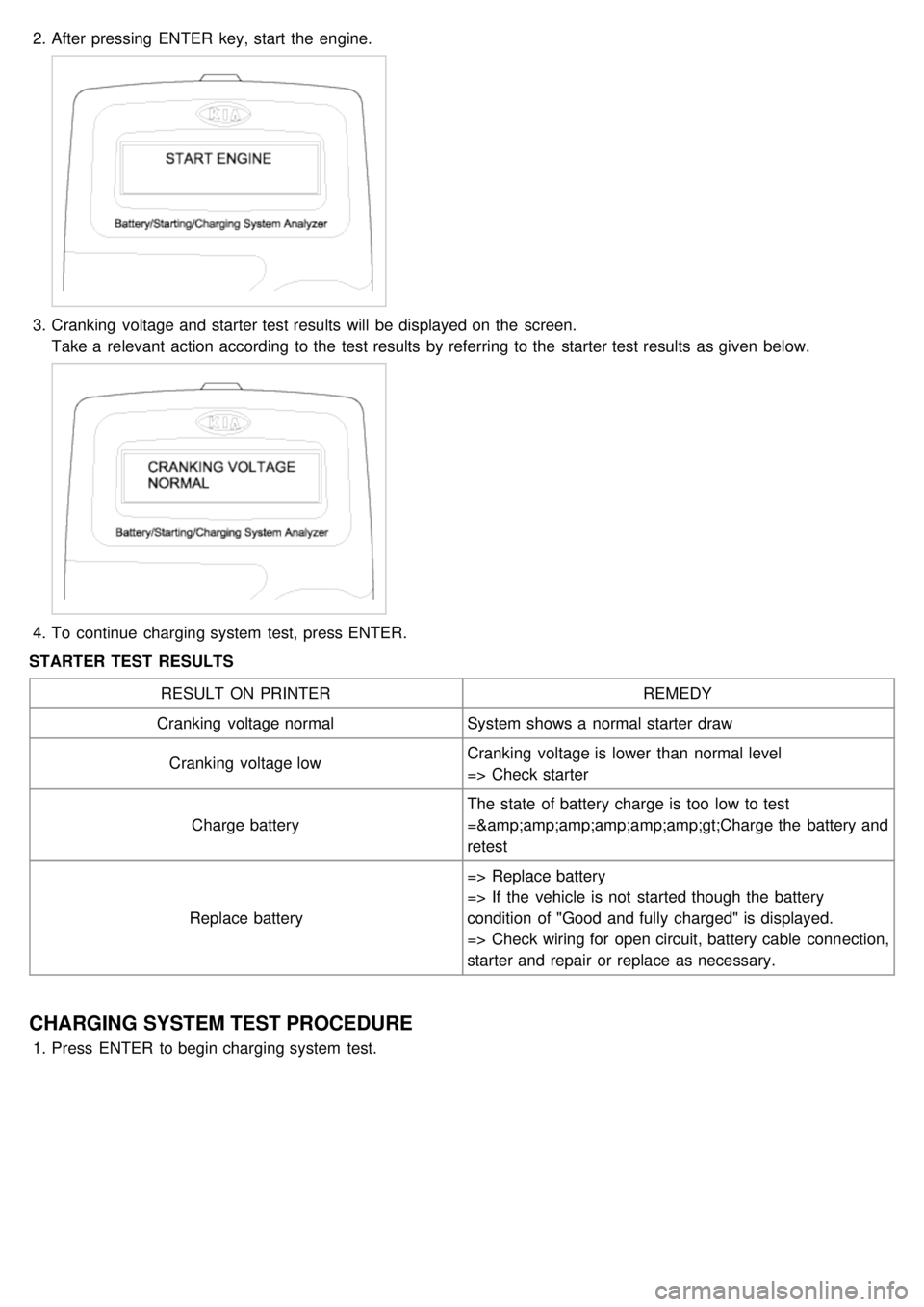

2.After pressing ENTER key, start the engine.

3.Cranking voltage and starter test results will be displayed on the screen.

Take a relevant action according to the test results by referring to the starter test results as given below.

4.To continue charging system test, press ENTER.

STARTER TEST RESULTS

RESULT ON PRINTER REMEDY

Cranking voltage normal System shows a normal starter draw

Cranking voltage low Cranking voltage is lower than normal level

=> Check starter

Charge battery The state of battery charge is too low to test

=>Charge the battery and

retest

Replace battery => Replace battery

=> If the vehicle is not started though the battery

condition of "Good and fully charged" is displayed.

=> Check wiring for open circuit, battery cable connection,

starter and repair or replace as necessary.

CHARGING SYSTEM TEST PROCEDURE

1.

Press ENTER to begin charging system test.

Page 146 of 1575

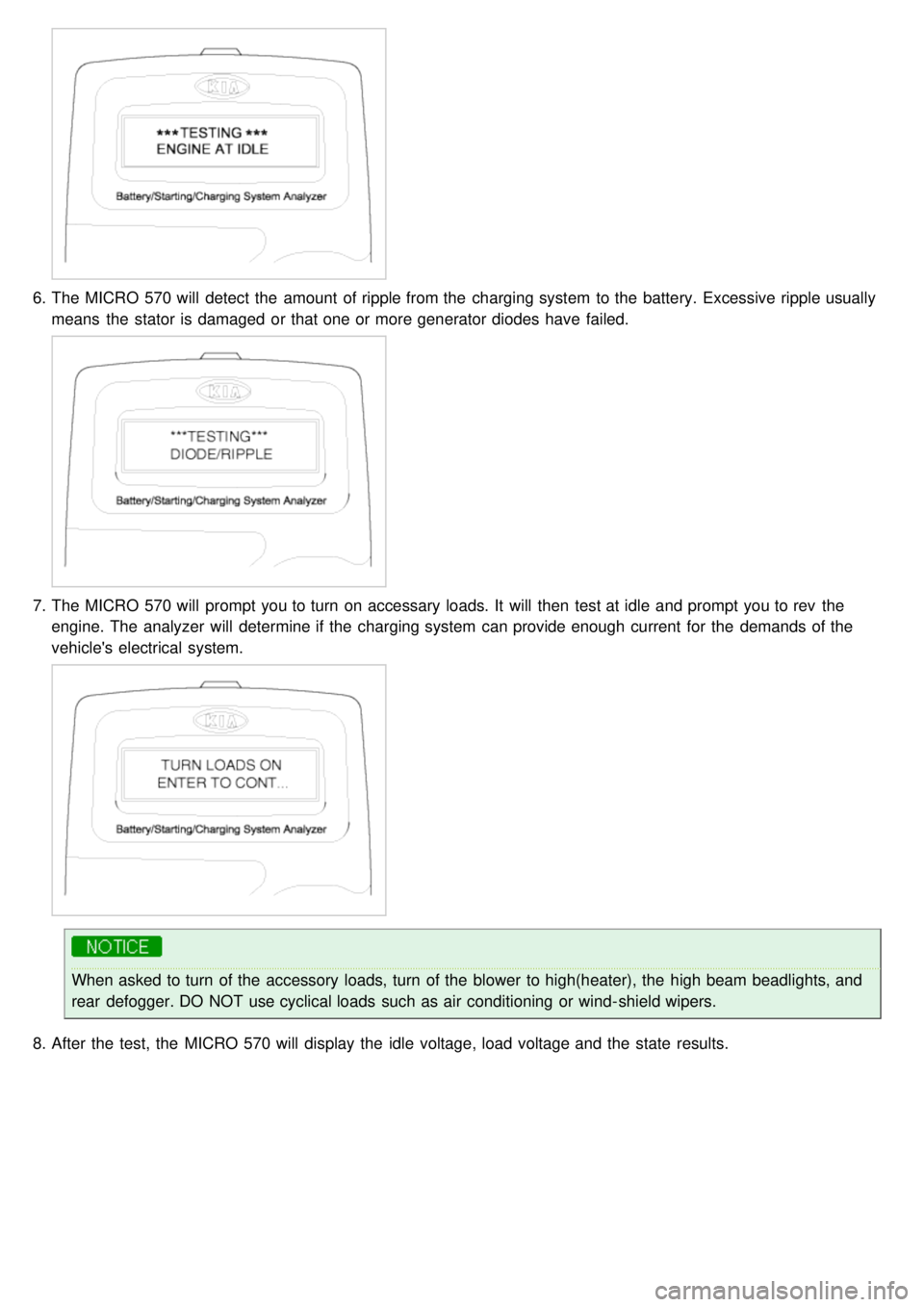

6.The MICRO 570 will detect the amount of ripple from the charging system to the battery. Excessive ripple usually

means the stator is damaged or that one or more generator diodes have failed.

7.The MICRO 570 will prompt you to turn on accessary loads. It will then test at idle and prompt you to rev the

engine. The analyzer will determine if the charging system can provide enough current for the demands of the

vehicle's electrical system.

When asked to turn of the accessory loads, turn of the blower to high(heater), the high beam beadlights, and

rear defogger. DO NOT use cyclical loads such as air conditioning or wind- shield wipers.

8. After the test, the MICRO 570 will display the idle voltage, load voltage and the state results.