KIA CARNIVAL 2007 User Guide

CARNIVAL 2007

KIA

KIA

https://www.carmanualsonline.info/img/2/57045/w960_57045-0.png

KIA CARNIVAL 2007 User Guide

Page 290 of 1575

Page 292 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Crankshaft Position Sensor (CKPS) detects the crankshaft position and is one of the most important sensors of the

engine control system. If there is no CKPS signal input, fuel is not supplied and the main relay does not operate. That

is, vehicle can't run without CKPS signal. This sensor is installed on transaxle housing and generates alternating

current by magnetic flux field which is made by the sensor and the target wheel when engine runs. The target wheel

consists of 58 slots and 2 missing slots on 360 CA (Crank Angle).

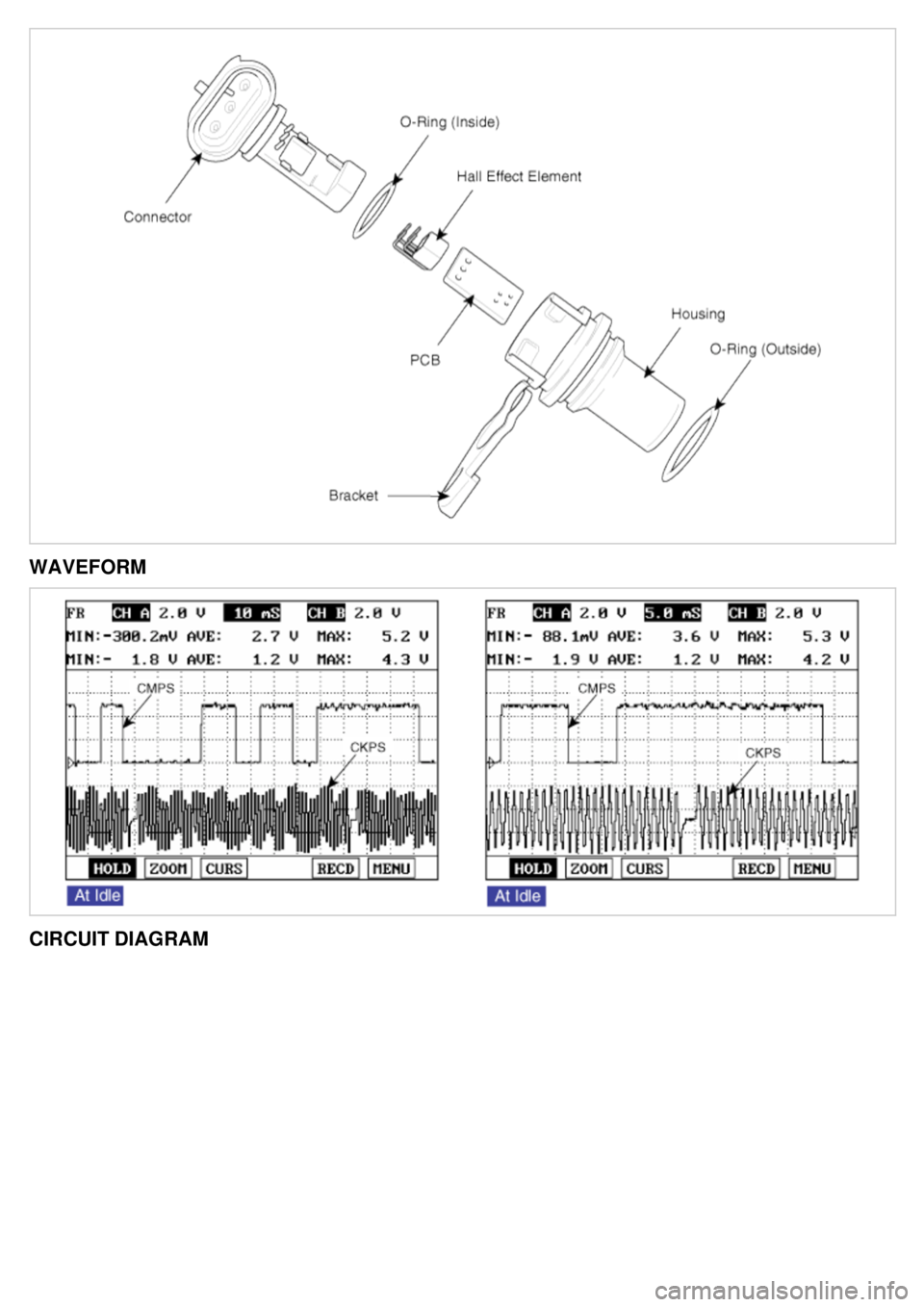

WAVEFORM

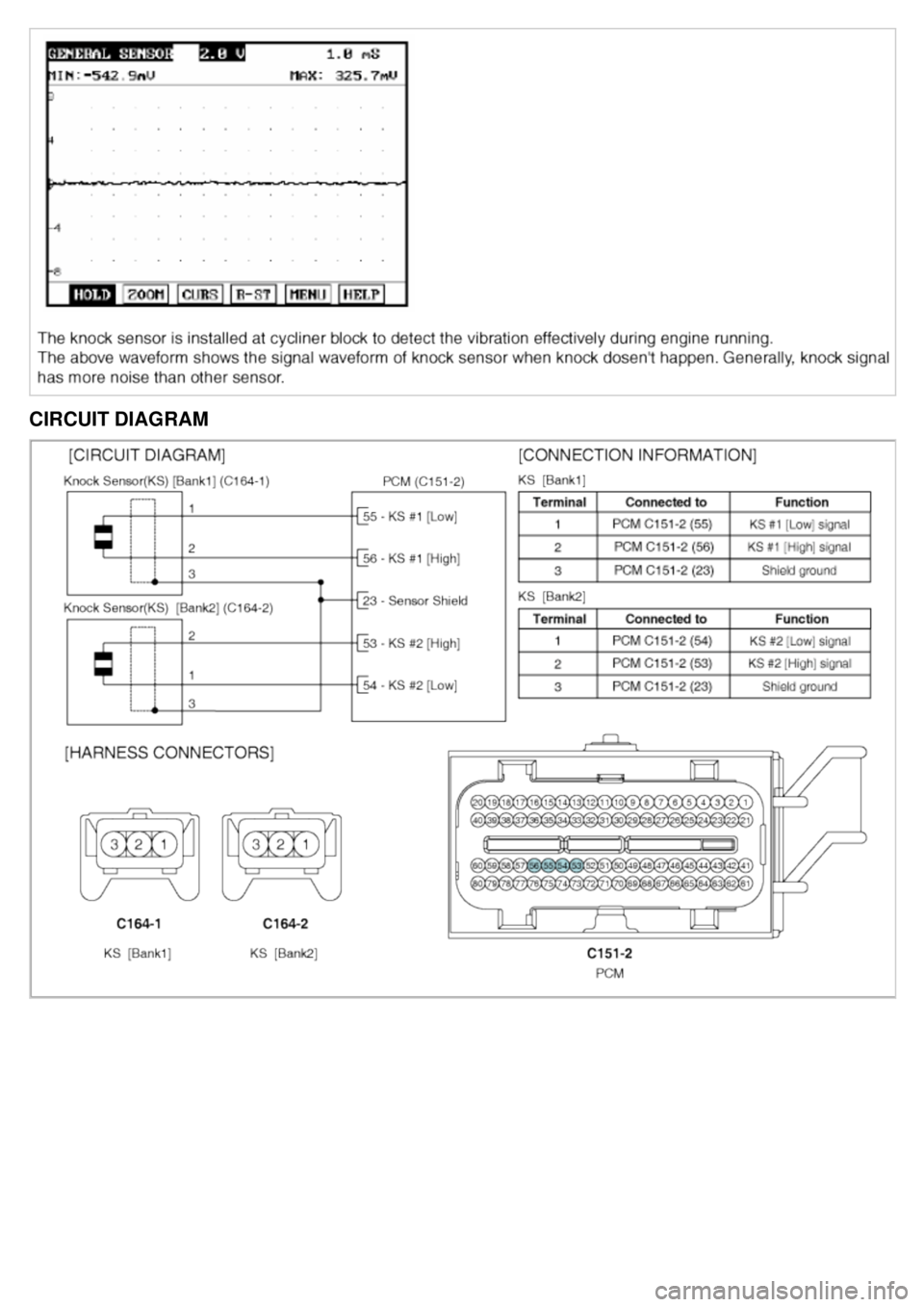

CIRCUIT DIAGRAM

Page 296 of 1575

Page 299 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

Based on information from various sensors, the PCM measures the fuel injection amount. The fuel injector is a

solenoid- operated valve and the fuel injection amount is controlled by length of time that the fuel injector is held open.

The PCM controls each injector by grounding the control circuit. When the PCM energizes the injector by grounding

the control circuit, the circuit voltage should be low (theoretically 0V) and the fuel is injected. When the PCM de-

energizes the injector by opening control circuit, the fuel injector is closed and circuit voltage should momentarily peak.

If an injector connector is disconnected for more than 46 seconds while the engine runs, the PCM will determine

that the cylinder is misfiring and cut fuel supply. So be careful not to exceed 46 seconds. But the engine runs

normally in 10 seconds after turning the ignition key off.

SPECIFICATION

Item Specification

Coil Resistance (Ω) 13.8 ~ 15.2Ω at 20°C (68°F)

CIRCUIT DIAGRAM

Page 303 of 1575

2007 > 2.7L V6 GASOLINE >

INSTALLATION

If the OCVs are installed incorrectly, the vehicle may be damaged.

So when installing them, ensure the OCV and harness connector colors match(Components and harness side).

[Bank and its color] Bank Component side Harness side

Bank 1 (RH) GreyGrey

Bank 2 (LH) BlackBlack

INSPECTION

FUNCTION AND OPERATION PRICIPLE

The Continuously Variable Valve Timing (CVVT) system controls the amount of valve overlap by varying the amount of

oil flow into an assembly mounted on each intake camshaft through PCM control of an oil control valve. This system

uses two oil control valves, one on each bank. An Oil Temperature Sensor (OTS) is used to allow PCM monitoring of

engine oil temperature. As oil is directed into the chambers of the CVVT assembly, the cam phase is changed to suit

various performance and emissions requirements.. 1. When camshaft rotates engine rotation- wise: Intake- Advance / Exhaust- Retard

2. When camshaft rotates counter engine rotation- wise: Intake- Retard / Exhaust- Advance

SPECIFICATION

Item Specification

Coil Resistance (Ω) 6.7 ~ 7.7Ω at 20°C (68°F)

CIRCUIT DIAGRAM

Page 306 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

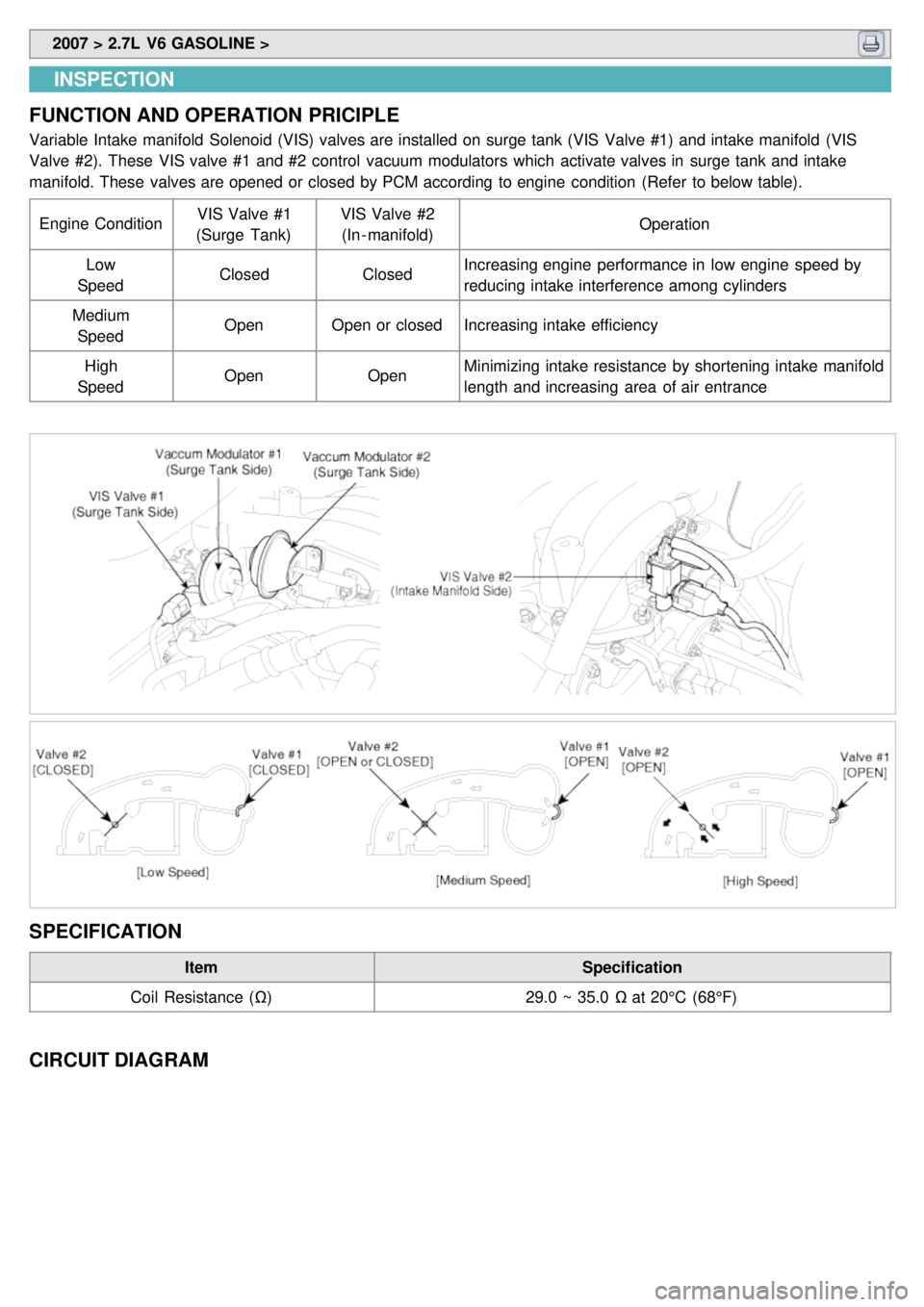

Variable Intake manifold Solenoid (VIS) valves are installed on surge tank (VIS Valve #1) and intake manifold (VIS

Valve #2). These VIS valve #1 and #2 control vacuum modulators which activate valves in surge tank and intake

manifold. These valves are opened or closed by PCM according to engine condition (Refer to below table).

Engine Condition VIS Valve #1

(Surge Tank) VIS Valve #2

(In - manifold) Operation

Low

Speed Closed

ClosedIncreasing engine performance in low engine speed by

reducing intake interference among cylinders

Medium Speed Open

Open or closed Increasing intake efficiency

High

Speed Open

OpenMinimizing intake resistance by shortening intake manifold

length and increasing area of air entrance

SPECIFICATION

Item

Specification

Coil Resistance (Ω) 29.0 ~ 35.0 Ω at 20°C (68°F)

CIRCUIT DIAGRAM

Page 309 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUNCTION AND OPERATION PRICIPLE

ETC (Electronic Throttle Control) system is electronically controlled throttle device which controls the throttle valve. It

consists of ETC motor, throttle body and throttle position sensor (TPS). A mechanical throttle control system receives a

driver's intention via a wire cable between the accelerator and the throttle valve, while this ETC system uses the signal

from the Accelerator Position Sensor (APS) installed on the accelerator pedal. After the PCM receives the APS signal

and calculates the throttle opening angle, it activates the throttle valve by using the ETC motor. Additionally, it can

handle cruise control function without any special devices.

SHEMATIC DIAGRAM

Page 311 of 1575

[ETC MOTOR]Item Sensor Resistance

Coil Resistance (Ω) 1.275 ~ 1.725Ω at 20°C (68°F)

CIRCUIT DIAGRAM

FAIL-SAFE MODE

ModeDescription Symptom Possible Cause

a. ETC system can't proceed reliable

algorithm procedure

Page 331 of 1575

2007 > 2.7L V6 GASOLINE >

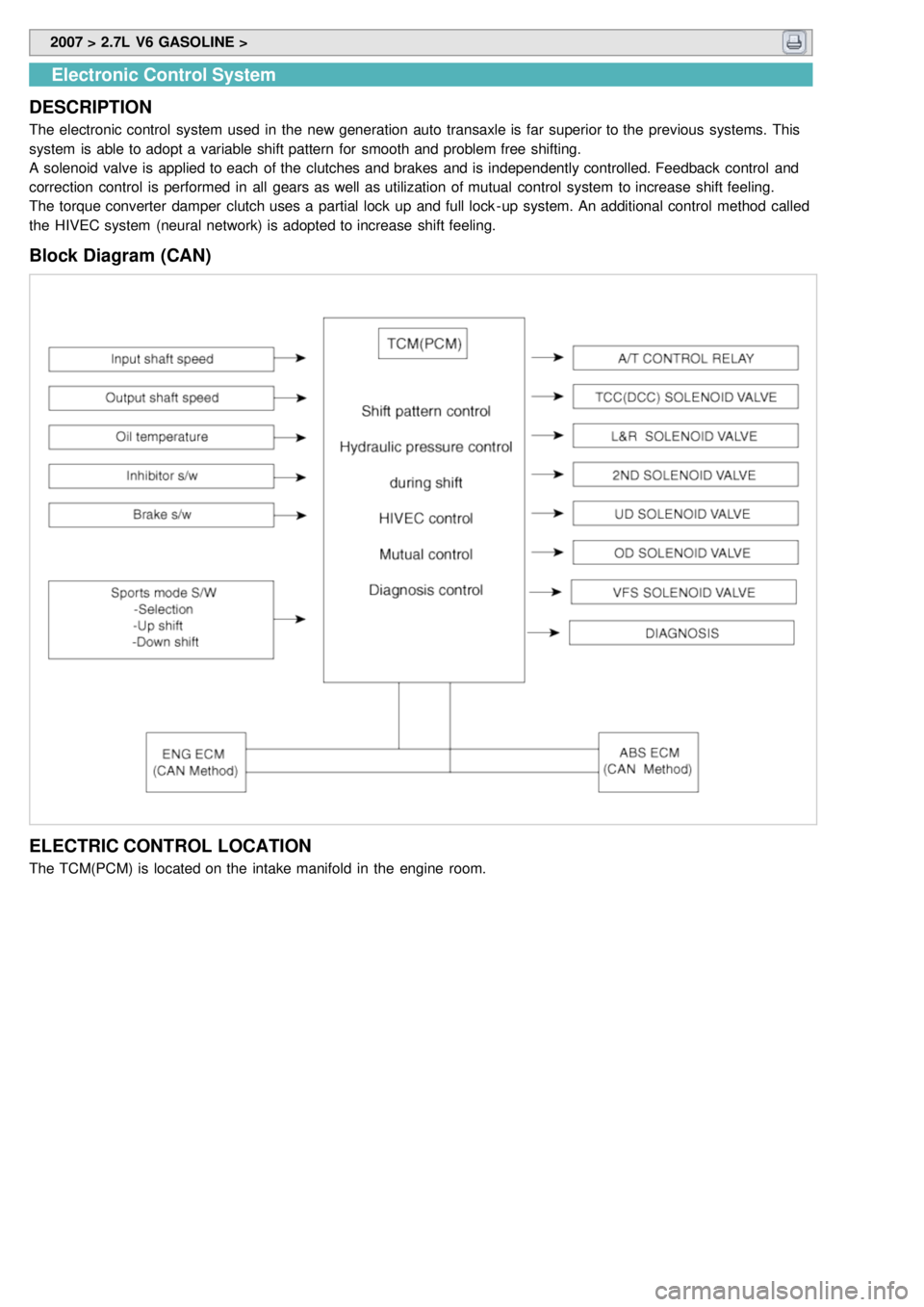

Electronic Control System

DESCRIPTION

The electronic control system used in the new generation auto transaxle is far superior to the previous systems. This

system is able to adopt a variable shift pattern for smooth and problem free shifting.

A solenoid valve is applied to each of the clutches and brakes and is independently controlled. Feedback control and

correction control is performed in all gears as well as utilization of mutual control system to increase shift feeling.

The torque converter damper clutch uses a partial lock up and full lock - up system. An additional control method called

the HIVEC system (neural network) is adopted to increase shift feeling.

Block Diagram (CAN)

ELECTRIC CONTROL LOCATION

The TCM(PCM) is located on the intake manifold in the engine room.

Page 807 of 1575

2007 > 2.7L V6 GASOLINE >

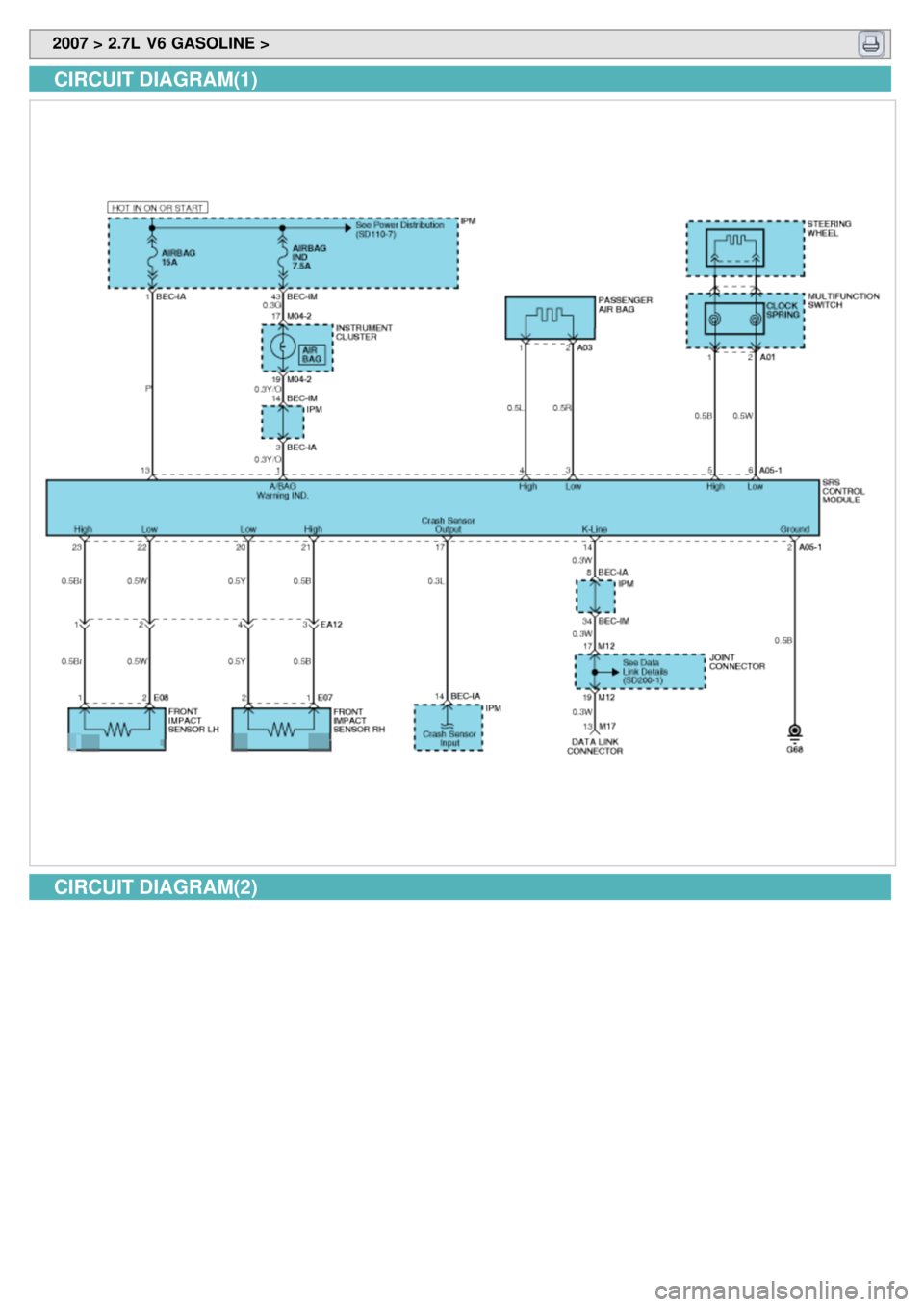

CIRCUIT DIAGRAM(1)

CIRCUIT DIAGRAM(2)

![KIA CARNIVAL 2007 User Guide [ETC MOTOR]Item Sensor Resistance

Coil Resistance (Ω) 1.275 ~ 1.725Ω at 20°C (68°F)

CIRCUIT DIAGRAM

FAIL-SAFE MODE

ModeDescription Symptom Possible Cause

a. ETC system cant proceed reliab KIA CARNIVAL 2007 User Guide [ETC MOTOR]Item Sensor Resistance

Coil Resistance (Ω) 1.275 ~ 1.725Ω at 20°C (68°F)

CIRCUIT DIAGRAM

FAIL-SAFE MODE

ModeDescription Symptom Possible Cause

a. ETC system cant proceed reliab](/img/2/57045/w960_57045-310.png)