battery replacement KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 762 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the crush pad.(Refer to BD group)

3. Disconnect the connectors from the intake actuator, the blower motor and power mosfet.

4. Remove the cowl cross bar assembly.(Refer to BD group)

5. Remove the blower unit (A) from the heater unit after loosening a mounting bolt and 2 screws.

Make sure that there is no air leaking out of the blower and duct joints.

6. Installation is the reverse order of removal.

Page 765 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

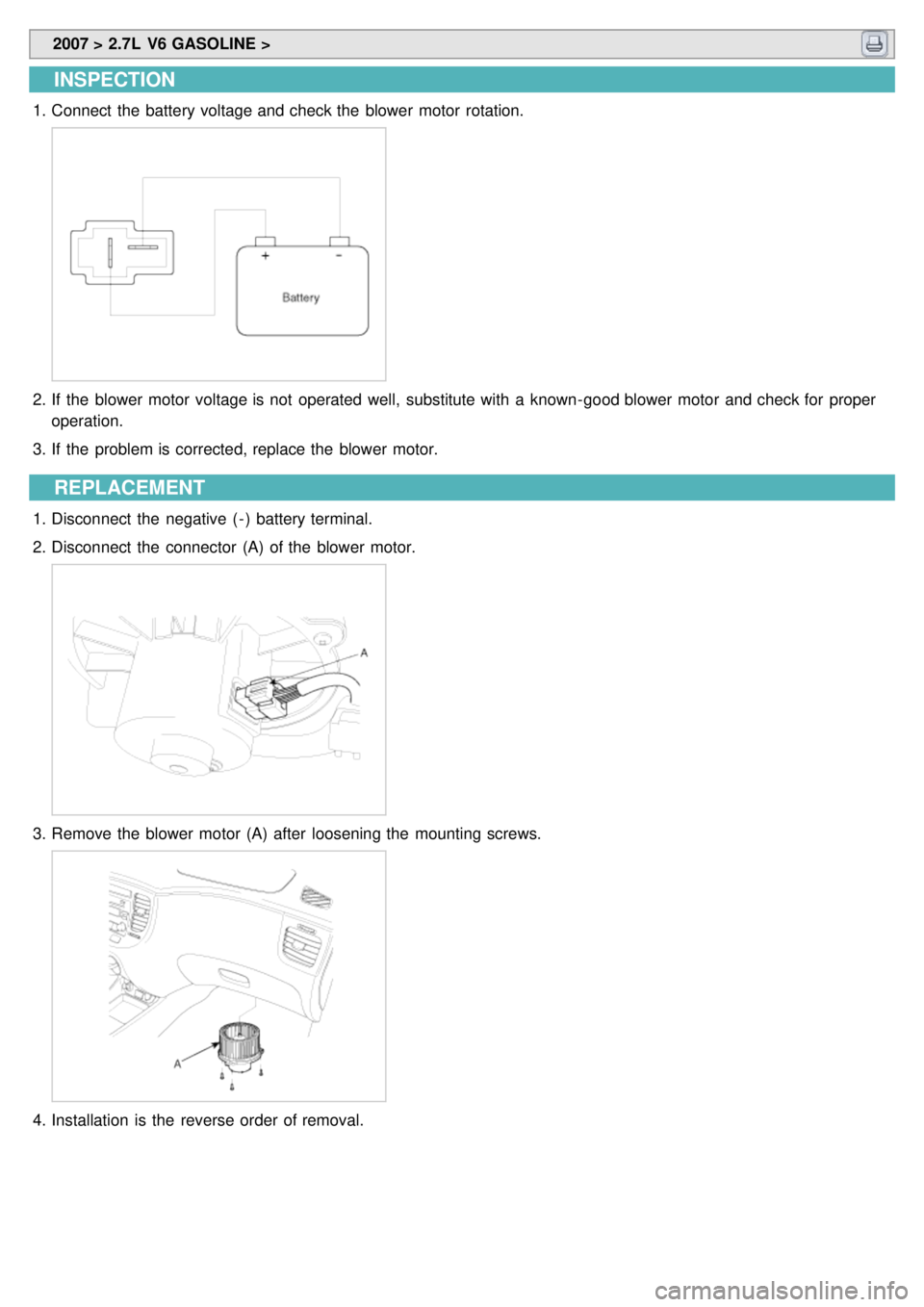

1.Connect the battery voltage and check the blower motor rotation.

2.If the blower motor voltage is not operated well, substitute with a known- good blower motor and check for proper

operation.

3. If the problem is corrected, replace the blower motor.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Disconnect the connector (A) of the blower motor.

3.Remove the blower motor (A) after loosening the mounting screws.

4.Installation is the reverse order of removal.

Page 768 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.There should be continuity between the NO.1 in the A and NO.10 in the B terminals when power and ground are

connected to the NO.7 and NO.13 in the A terminals. (Passenger compartment relay box)

2. There should be to no continuity btween the NO.1 in the A and NO.10 in the B terminals when power is

disconnected.

REAR BLOWER

1.There should be continuity between the NO.4in the A and NO.12n the B terminals when power and ground are

connected to the NO.2and NO.14in the A terminals. (Passenger compartment relay box)

2. There should be to no continuity btween the NO.4in the A and NO.12in the B terminals when power is

disconnected.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the crash pad center lower side cover. (Refer to BD group)

3. Loosen the relat box mounting nut, and then remove the relay box(A).

4.Install in the reverse order of removal.

Page 771 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

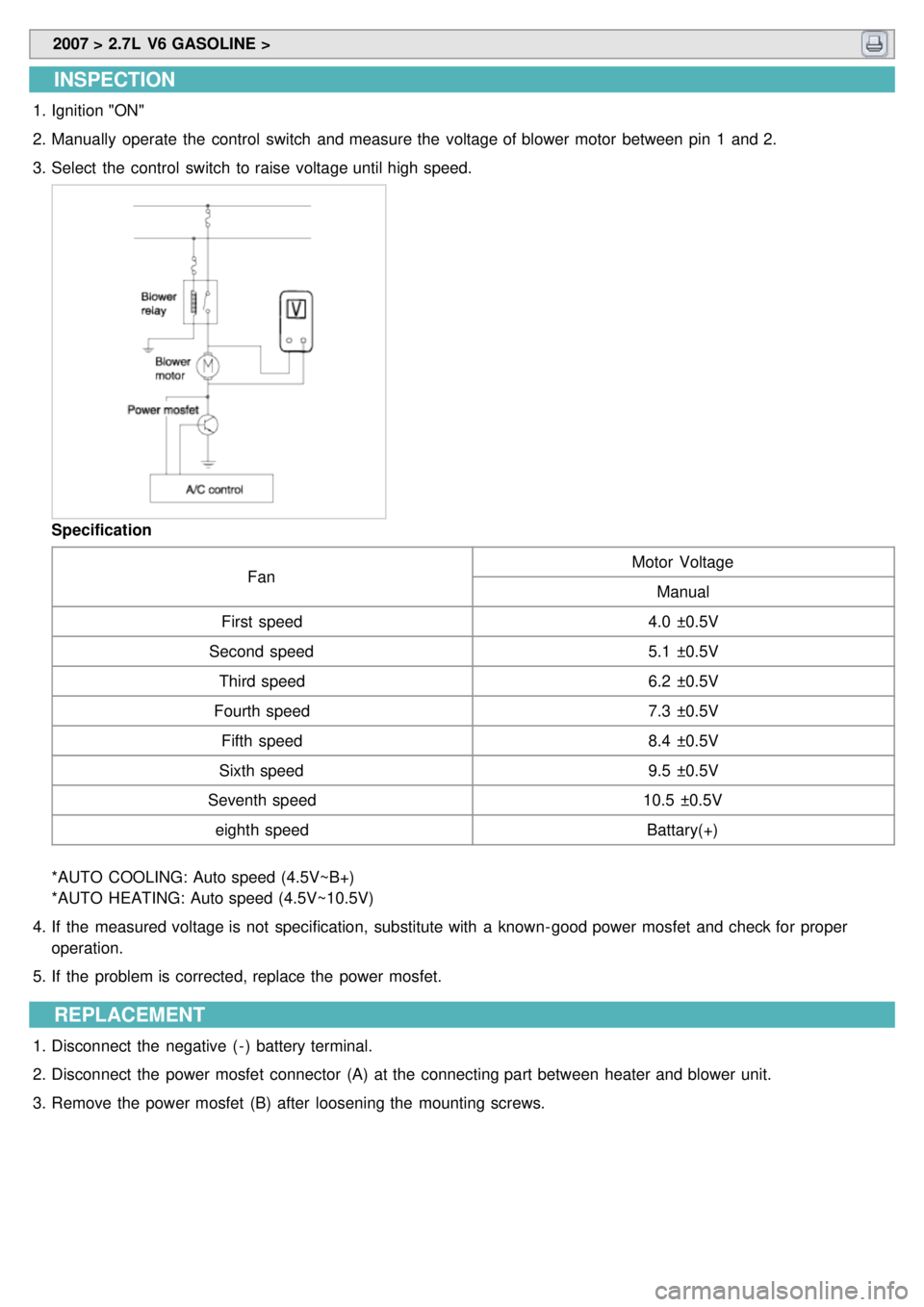

1.Ignition "ON"

2. Manually operate the control switch and measure the voltage of blower motor between pin 1 and 2.

3. Select the control switch to raise voltage until high speed.

Specification

Fan Motor Voltage

Manual

First speed 4.0 ±0.5V

Second speed 5.1 ±0.5V

Third speed 6.2 ±0.5V

Fourth speed 7.3 ±0.5V

Fifth speed 8.4 ±0.5V

Sixth speed 9.5 ±0.5V

Seventh speed 10.5 ±0.5V

eighth speed Battary(+)

*AUTO COOLING: Auto speed (4.5V~B+)

*AUTO HEATING: Auto speed (4.5V~10.5V)

4. If the measured voltage is not specification, substitute with a known- good power mosfet and check for proper

operation.

5. If the problem is corrected, replace the power mosfet.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Disconnect the power mosfet connector (A) at the connecting part between heater and blower unit.

3. Remove the power mosfet (B) after loosening the mounting screws.

Page 779 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF"

2. Disconnect the intake actuator connector.

3. Verify that the actuator operates to the recirculation position when connecting 12V to the terminal 3 and grounding

terminal 4.

4. Verify that the intake actuator operates to the fresh position when connecting in the reverse.

5.If the intake actuator is not operated well, substitute with a known- good intake actuator and check for proper

operation.

6. If the problem is corrected, replace the intake actuator.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the glove box (Refer to BD group).

3. Disconnect the intake actuator connector.

4. Loosen the mounting screw and then remove the intake actuator (A) from the blower unit.

5.Installation is the reverse order of removal.

Page 784 of 1575

2007 > 2.7L V6 GASOLINE >

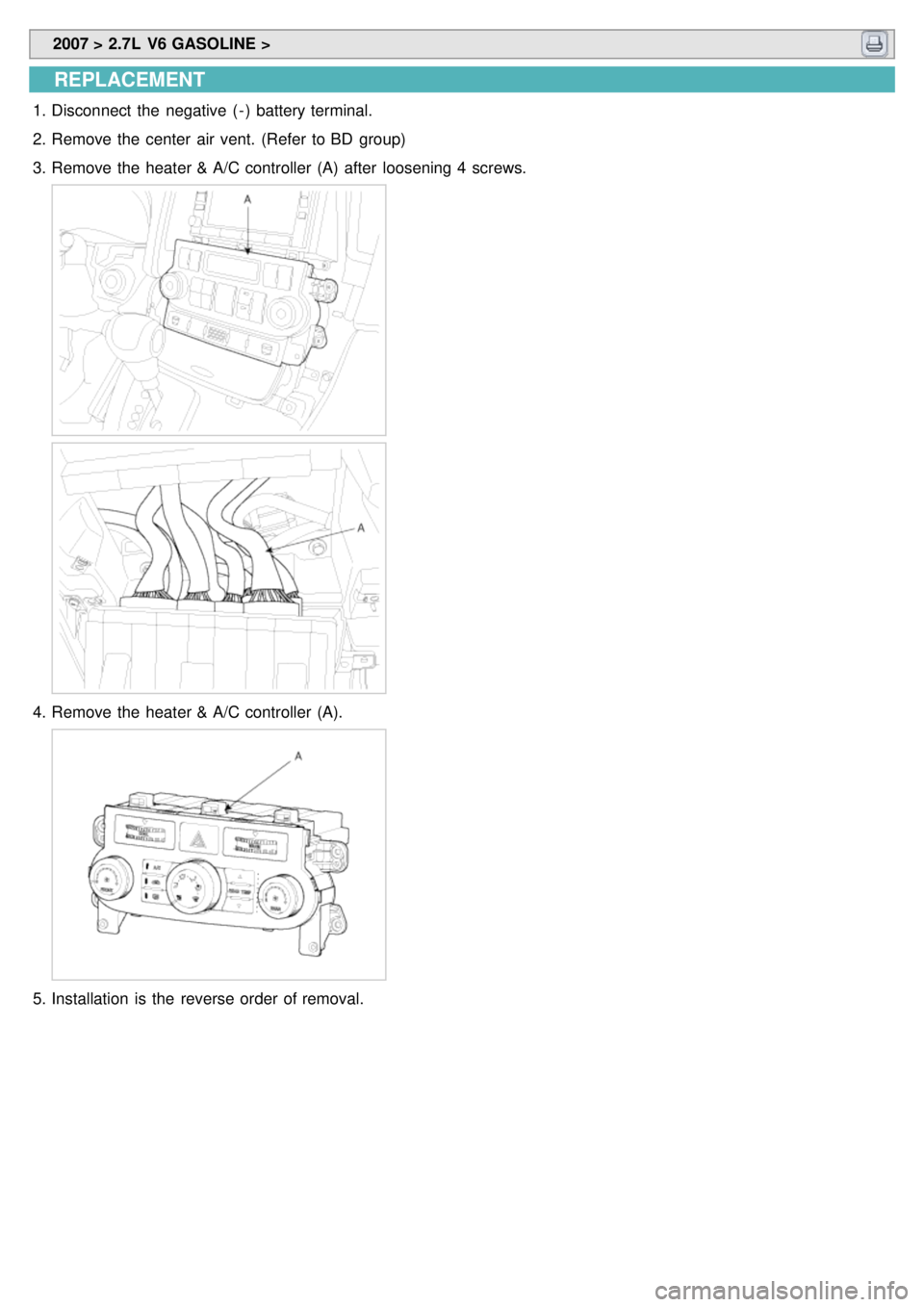

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center air vent. (Refer to BD group)

3. Remove the heater & A/C controller (A) after loosening 4 screws.

4.Remove the heater & A/C controller (A).

5.Installation is the reverse order of removal.

Page 788 of 1575

2007 > 2.7L V6 GASOLINE >

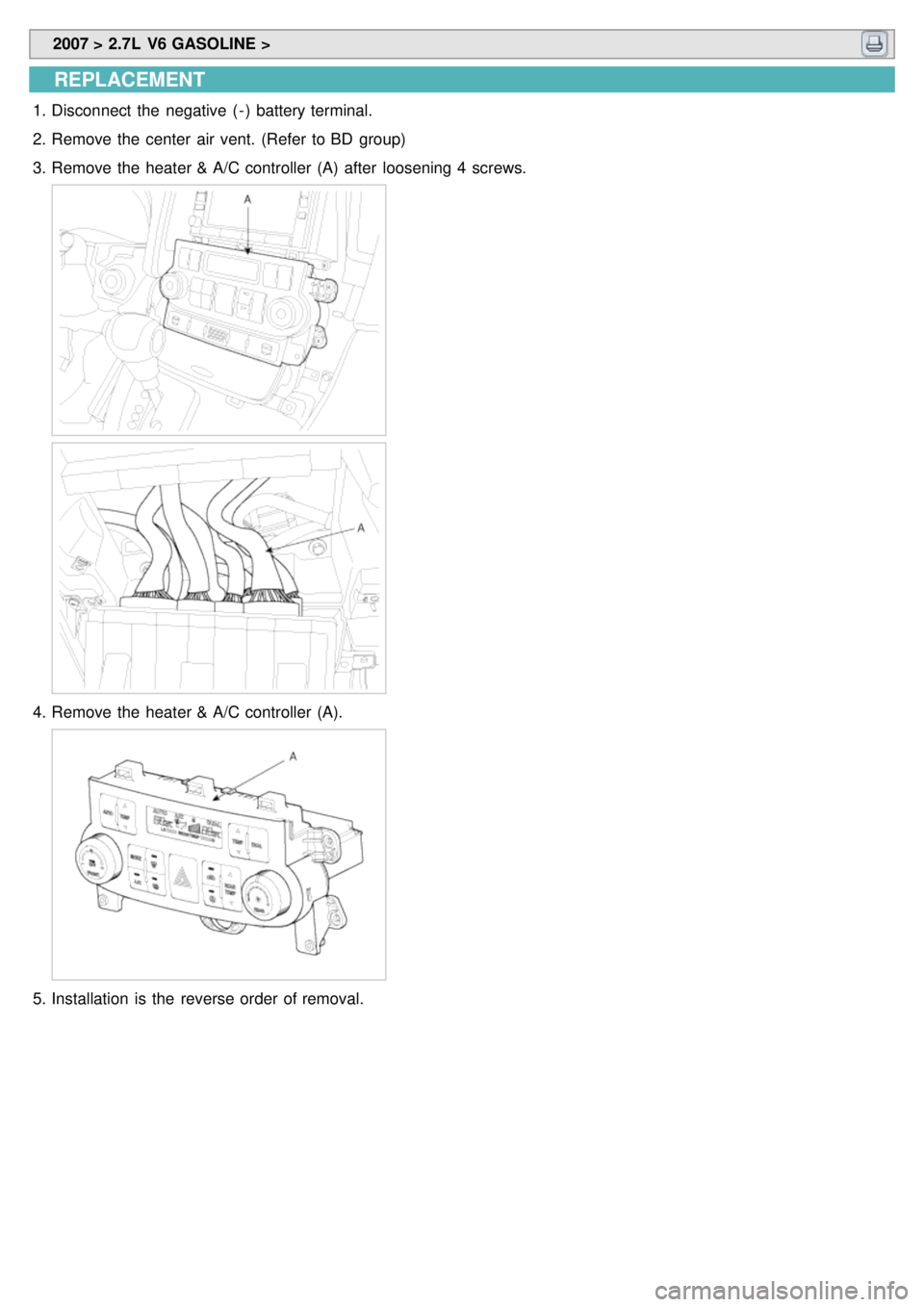

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center air vent. (Refer to BD group)

3. Remove the heater & A/C controller (A) after loosening 4 screws.

4.Remove the heater & A/C controller (A).

5.Installation is the reverse order of removal.

Page 791 of 1575

2007 > 2.7L V6 GASOLINE >

Precautions

General Precautions

Please read the following precautions carefully before performing the airbag system service. Observe the instructions

described in this manual, or the airbags could accidentally deploy and cause damage or injuries. a. Except when performing electrical inspections, always turn the ignition switch OFF and disconnect the negative

cable from the battery, and wait at least three minutes before beginning work.

The contents in the memory are not erased even if the ignition switch is turned OFF or the battery cables are

disconnected from the battery.

b. Use the replacement parts which are manufactured to the same standards as the original parts and quality.

Do not install used SRS parts from another vehicle.

Use only new parts when making SRS repairs.

c. Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being dropped or improperly handled, such as dents, cracks or

deformation.

d.Before removing any of the SRS parts (including the disconnection of the connectors), always disconnect the SRS

connector.

Airbag Handling and Storage

Do not disassemble the airbags; it has no serviceable parts. Once an airbag has been deployed, it cannot be repaired

or reused.

For temporary storage of the air bag during service, please observe the following precautions.

a. Store the removed airbag with the pad surface up.

b. Keep free from any oil, grease, detergent, or water to prevent damage to the airbag assembly.

Page 792 of 1575

c.Store the removed airbag on secure, flat surface away from any high heat source (exceeding 85°C/185°F).

d. Never perform electrical inspections to the airbags, such as measuring resistance.

e. Do not position yourself in front of the airbag assembly during removal, inspection, or replacement.

f. Refer to the scrapping procedures for disposal of the damaged airbag.

g. Be careful not to bump or impact the SRS unit or the side impact sensors whenever the ignition switch is ON, wait

at least three minutes after the ignition switch is turned OFF before begin work.

h. During installation or replacement, be careful not to bump (by impact wrench, hammer, etc.) the area around the

SRS unit and the side impact sensor. The airbags could accidentally deploy and cause damage or injury.

i. After a collision in which the airbags were deployed, replace the front airbags and the SRS unit. After a collision in

which the side airbag was deployed, replace the side airbag, the front impact sensor and side impact sensor on

the side where the side airbag deployed and the SRS unit. After a collision in which the airbags or the side air

bags did not deploy, inspect for any damage or any deformation on the SRS unit and the side impact sensors. If

there is any damage, replace the SRS unit, the front impact sensor and/or the side impact sensors.

j. Do not disassemble the SRS unit, the front impact sensor or the side impact sensors

k. Turn the ignition switch OFF, disconnect the battery negative cable and wait at least three minutes before

beginning installation or replacement of the SRS unit.

l. Be sure the SRS unit, the front impact sensor and side impact sensors are installed securely with the mounting

bolts.

m. Do not spill water or oil on the SRS unit,or the front impact sensor or the side impact sensors and keep them

away from dust.

n. Store the SRS unit, the front impact sensor and the side impact sensors in a cool (less than 40°C/104°F) and dry

(less than 80% relative humidity, no moisture) area.

Wiring Precautions

SRS wiring can be identified by special yellow outer covering (except the SRS circuits under the front seats).

Observe the instructions described in this section.

a. Never attempt to modify, splice, or repair SRS wiring.

If there is an open or damage in SRS wiring, replace the harness.

Page 1175 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

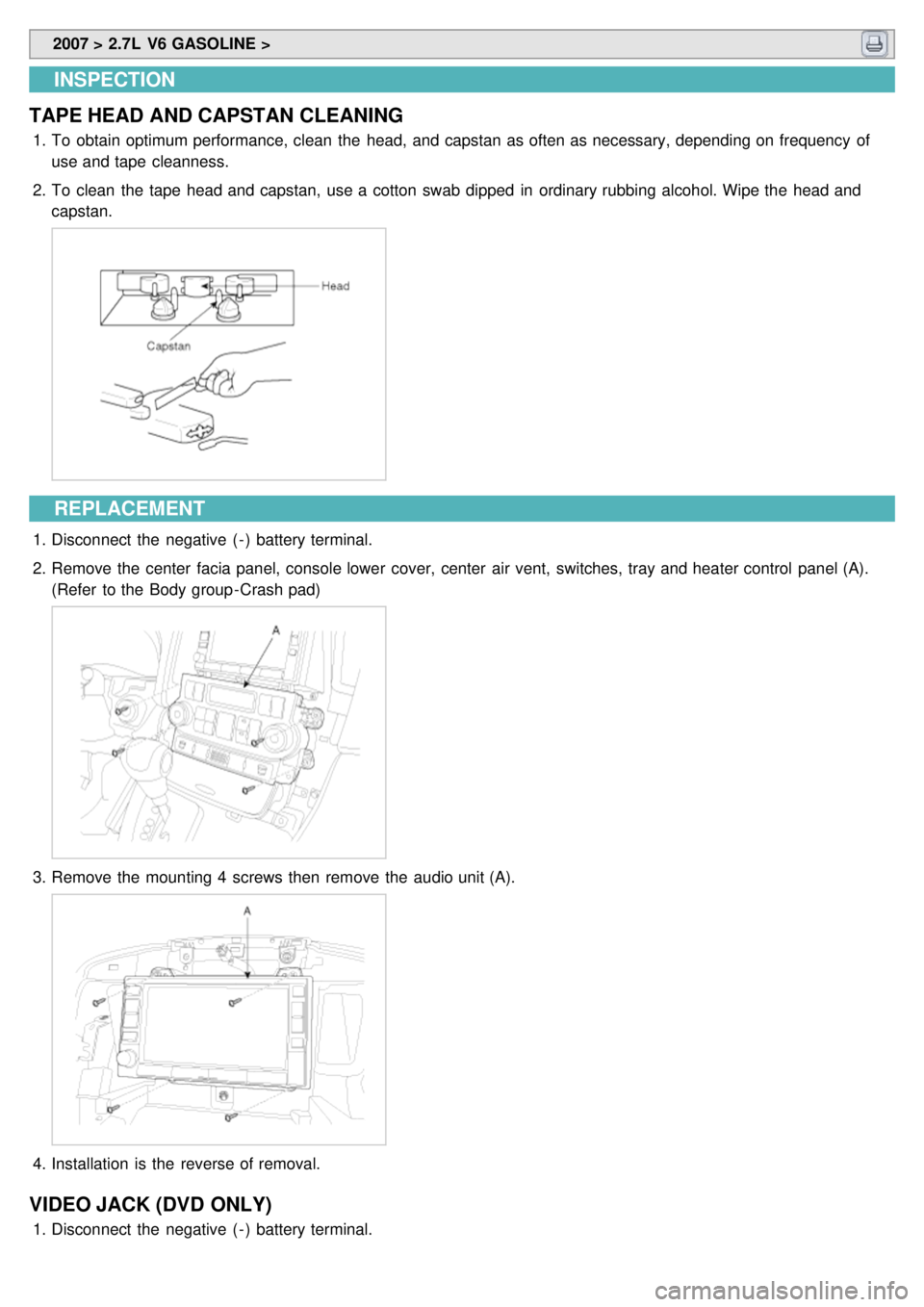

TAPE HEAD AND CAPSTAN CLEANING

1. To obtain optimum performance, clean the head, and capstan as often as necessary, depending on frequency of

use and tape cleanness.

2. To clean the tape head and capstan, use a cotton swab dipped in ordinary rubbing alcohol. Wipe the head and

capstan.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center facia panel, console lower cover, center air vent, switches, tray and heater control panel (A).

(Refer to the Body group - Crash pad)

3.Remove the mounting 4 screws then remove the audio unit (A).

4.Installation is the reverse of removal.

VIDEO JACK (DVD ONLY)

1.Disconnect the negative ( - ) battery terminal.