battery replacement KIA CARNIVAL 2007 Service Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1292 of 1575

3.If system of some relay is not operate accurately, replace with a new one and check the system.

REPLACEMENT

FAM (FRONT AREA MODULE)

1. Disconnect the negative ( - ) battery terminal.

2. Remove the FAM cover of engine room.

3. Remove the FAM connectors (2EA) (A) and battery terminal nut (1EA) (B).

4.Remove FAM mounting bolts (3EA) (A) and remove the FAM (B) from splash shield (C).

5.Disconnect the connector from splash shield.

6. Installation is the reverse of removal.

Page 1298 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

FUSE

1. Be sure there is no play in the fuse holders, and that the fuses are held securely.

2. Are the fuse capacities for each circuit correct?

3. Are there any blown fuses ?

If a fuse is to be replaced, be sure to use a new fuse of the same capacity. Always determine why the fuse blew

first and completely eliminate the problem before installing a new fuse.

RELAY

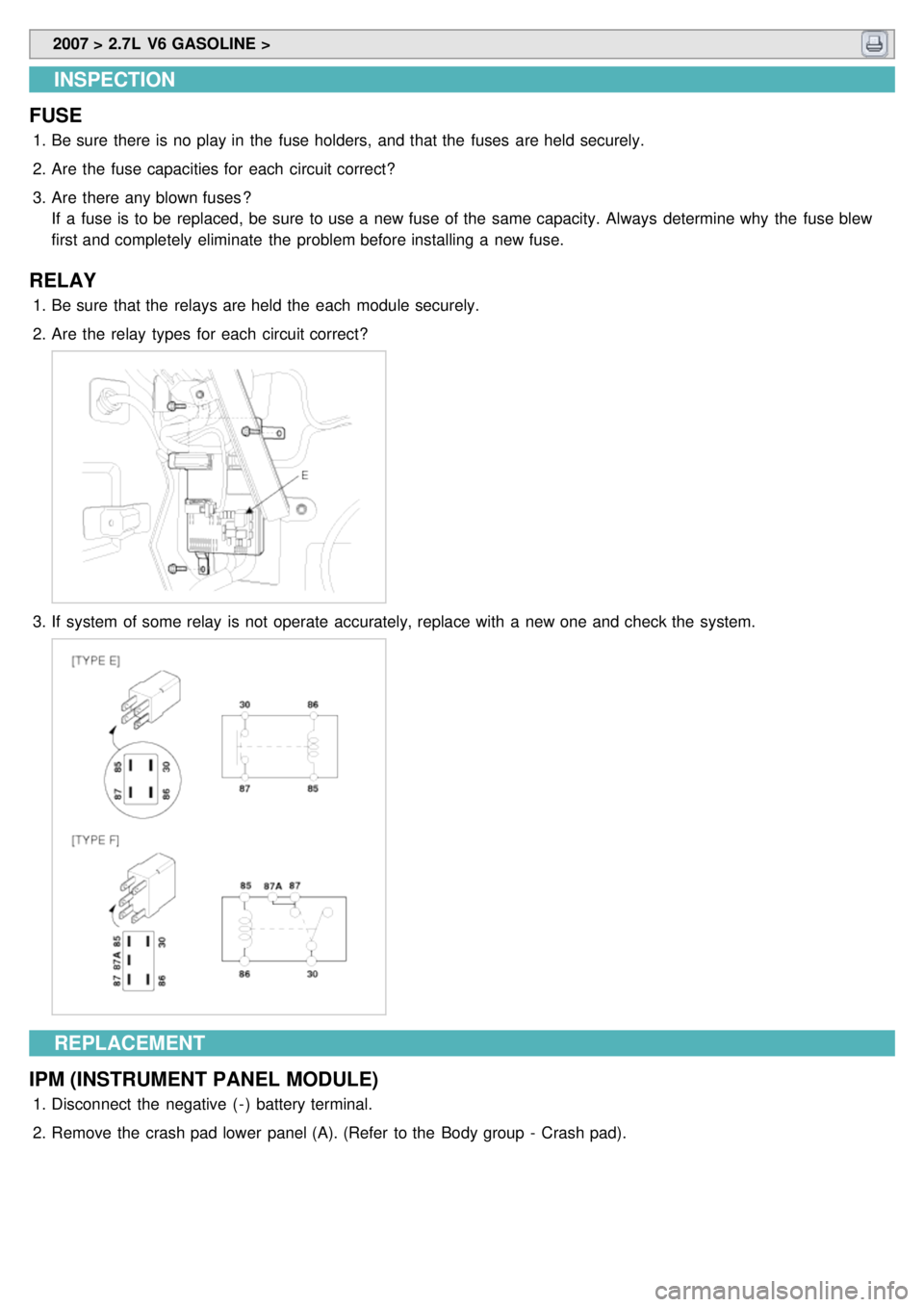

1.Be sure that the relays are held the each module securely.

2. Are the relay types for each circuit correct?

3.If system of some relay is not operate accurately, replace with a new one and check the system.

REPLACEMENT

IPM (INSTRUMENT PANEL MODULE)

1. Disconnect the negative ( - ) battery terminal.

2. Remove the crash pad lower panel (A). (Refer to the Body group - Crash pad).

Page 1307 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

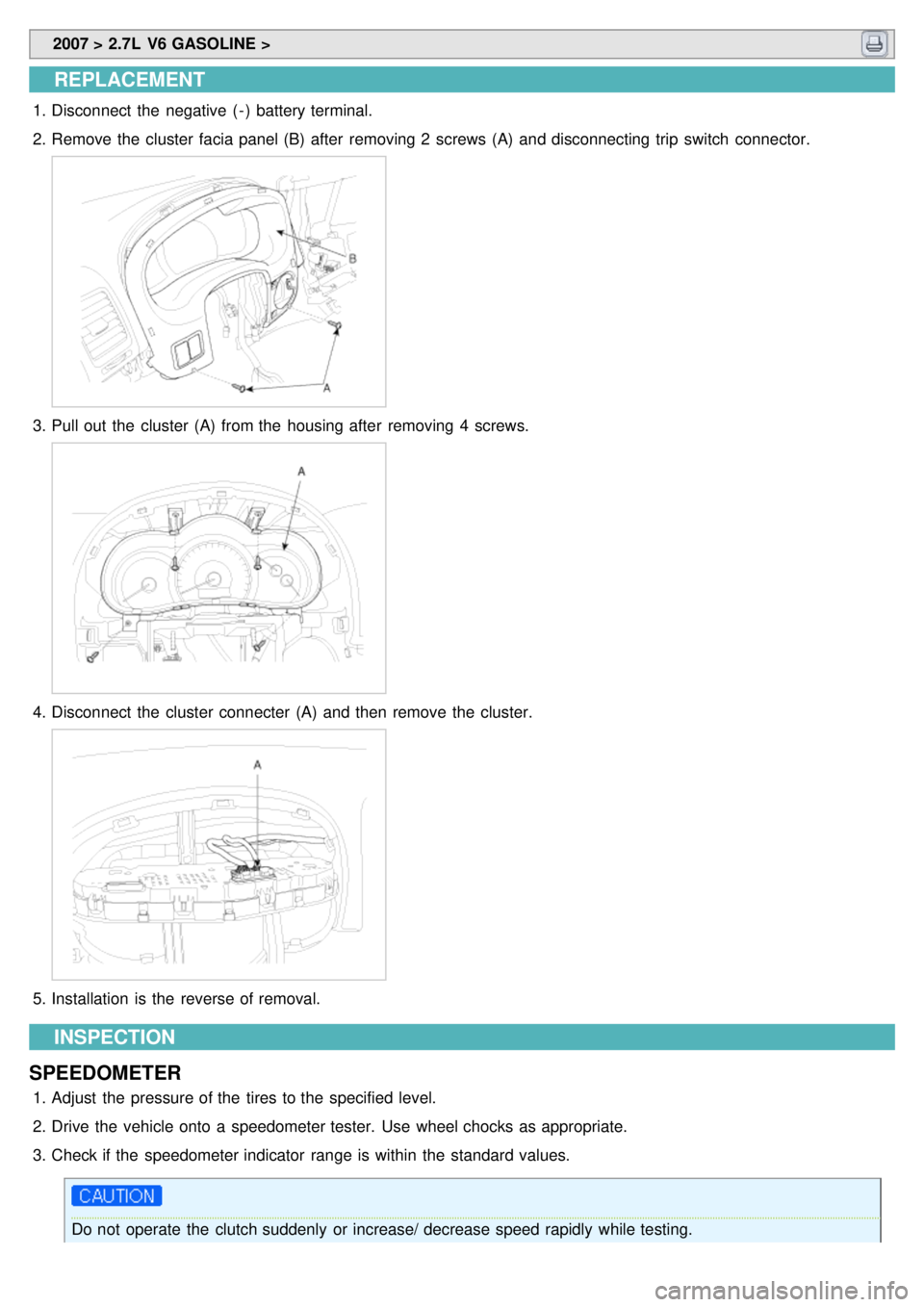

1.Disconnect the negative ( - ) battery terminal.

2. Remove the cluster facia panel (B) after removing 2 screws (A) and disconnecting trip switch connector.

3.Pull out the cluster (A) from the housing after removing 4 screws.

4.Disconnect the cluster connecter (A) and then remove the cluster.

5.Installation is the reverse of removal.

INSPECTION

SPEEDOMETER

1. Adjust the pressure of the tires to the specified level.

2. Drive the vehicle onto a speedometer tester. Use wheel chocks as appropriate.

3. Check if the speedometer indicator range is within the standard values.

Do not operate the clutch suddenly or increase/ decrease speed rapidly while testing.

Page 1319 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

DDM/ADM

1. Disconnect the negative battery terminal.

2. Remove the front door trim panel. (Refer to the Body group - Front door)

3. Remove the door module (A) mounting screws (5EA) after disconnecting the connector (3EA) from the actuator.

4.Remove the front door modules (DDMDM) from the front door trim panel.

INSPECTION

1.The DDM inputs can be checked using the scan tool..

2. To check the Input Value of door lock switch, select option "09. BODY CONTROL MODULE".

3.Select option "04. DRIVER DOOR MODULE".

Page 1340 of 1575

3.Select the "POWER SLIDING DOOR" to check.

4.Select the sensor output. And then check the optical sensor volt while operating power sliding door in power mode.

※ Above voltage and numerical value may be different from the real value.

5. Change the drive unit, if there is no change during operation.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the rear trim panel (Refer to the Body group - interior trim)

3. Disconnect the connectors (6EA) from the power sliding door drive unit.

4. Remove the rear combination lamp (Refer to the Body group - rear bumper)

5. Remove the mounting bolts (4EA) and rail cover (A).

Page 1344 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal..

2. Remove the rear trim panel (Refer to the Body group - interior trim)

3. Remove the connectors and mounting bolts (2EA) from the power sliding door unit(A). And then remove the power

sliding door control module (B).

TORQUE 0.25 - 0.35N.m(0.025- 0.035Kg.m)

4.Installation is the reverse of removal.

a.A learn cycle must be performed whenever the power is removed.

b. Check the normal operation whenever a power sliding door component is removed or replaced. If the

chime sound is heard, check the DTC, wiring harness and cable connections.

Page 1356 of 1575

3.Select a rear area module (RAM) and sensor output.

4.Check the value of RSD/LSD, left/right door switch.

5.Confirm that the door switch output is changed by the controlling ON/OFF switch on center pillar trim.

REPLACEMENT

OVERHEAD CONSOLE SWITCH

1. Disconnect the negative ( - ) battery terminal.

2. Open the sunglass case cover from the overhead console then remove the 2 screws holding the overhead console

(A). And then disconnect the connector (B).

Page 1364 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the front door trim panel. (Refer to the Body group - front door)

3. Remove the power window main switch mounting screws (3EA) (A) after disconnecting the switch connector

(12pin) from the switch.

4.Remove the switch from the front door trim panel.

5. Installation is the reverse of removal.

INSPECTION

1.Disconnect the 12P connector from the switch.

2.Check for continuity between the terminals in each switch position according to the table.

Page 1380 of 1575

4.Select the sensor output. And then check the clutch feedback sensor output while operating power tailgate in

power mode.

※ Above voltage and numerical value may be different from the real value.

5. Change the drive unit, if there is no change during operation.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the third, fourth seat (Refer to the Body group - seat)

3. Remove the D pillar and luggage side trim (Refer to the Body group - Interior trim).

4. Use a small screw driver to loosen clip (A). But do not remove power tailgate push rod (B).

5.Remove the power tail gate motor mounting bolts (3EA) and connectors (4EA). And then remove the power tail

gate drive unit(A).

TORQUE : 22- 27N.m(2.2- 2.7Kg.m)

Page 1382 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

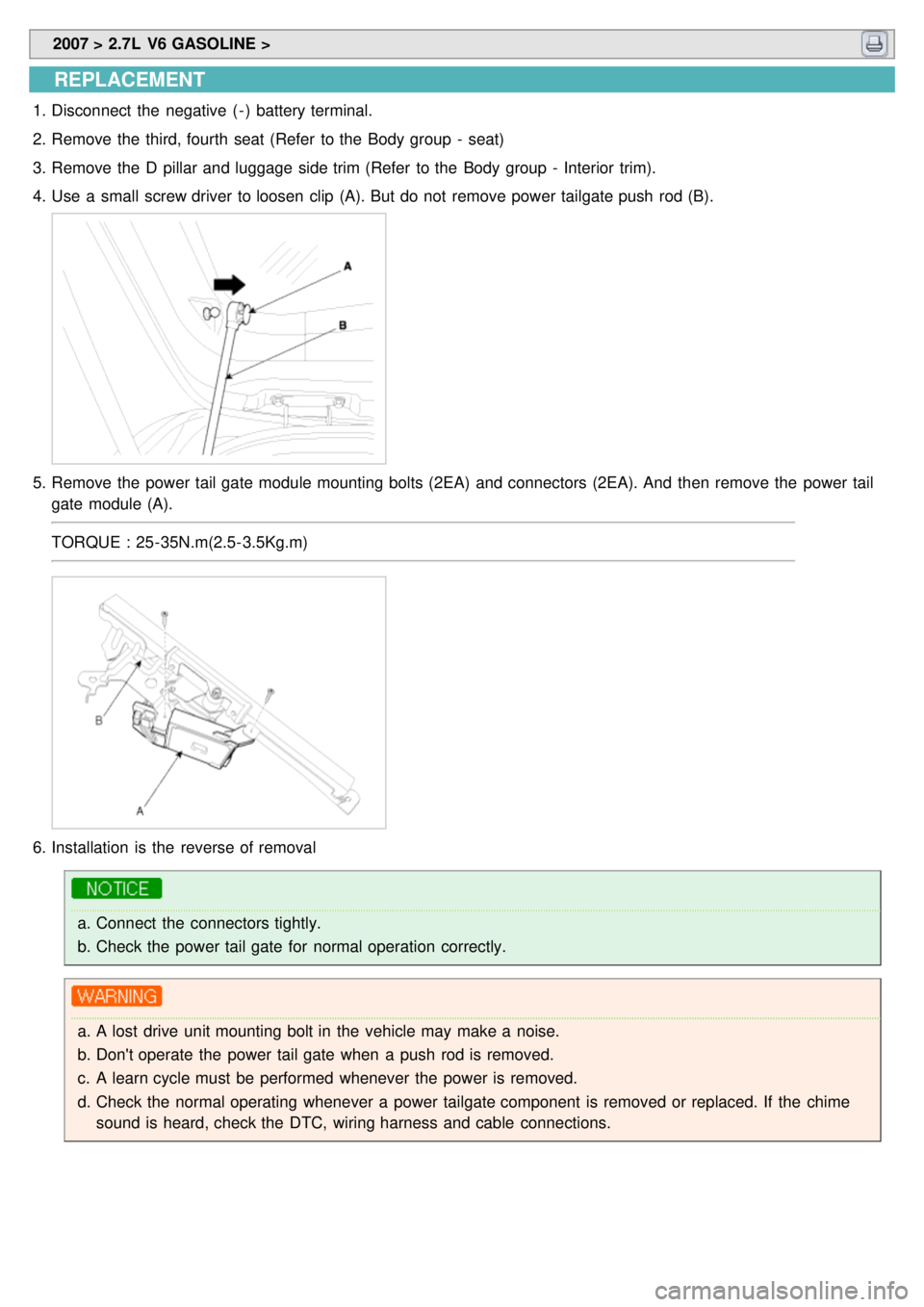

1.Disconnect the negative ( - ) battery terminal.

2. Remove the third, fourth seat (Refer to the Body group - seat)

3. Remove the D pillar and luggage side trim (Refer to the Body group - Interior trim).

4. Use a small screw driver to loosen clip (A). But do not remove power tailgate push rod (B).

5.Remove the power tail gate module mounting bolts (2EA) and connectors (2EA). And then remove the power tail

gate module (A).

TORQUE : 25- 35N.m(2.5- 3.5Kg.m)

6.Installation is the reverse of removal

a.Connect the connectors tightly.

b. Check the power tail gate for normal operation correctly.

a.A lost drive unit mounting bolt in the vehicle may make a noise.

b. Don't operate the power tail gate when a push rod is removed.

c. A learn cycle must be performed whenever the power is removed.

d. Check the normal operating whenever a power tailgate component is removed or replaced. If the chime

sound is heard, check the DTC, wiring harness and cable connections.