fuel KIA CARNIVAL 2007 Workshop Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 2 of 1575

2007 > 2.7L V6 GASOLINE >

IDENTIFICATION NUMBER DESCRIPTION

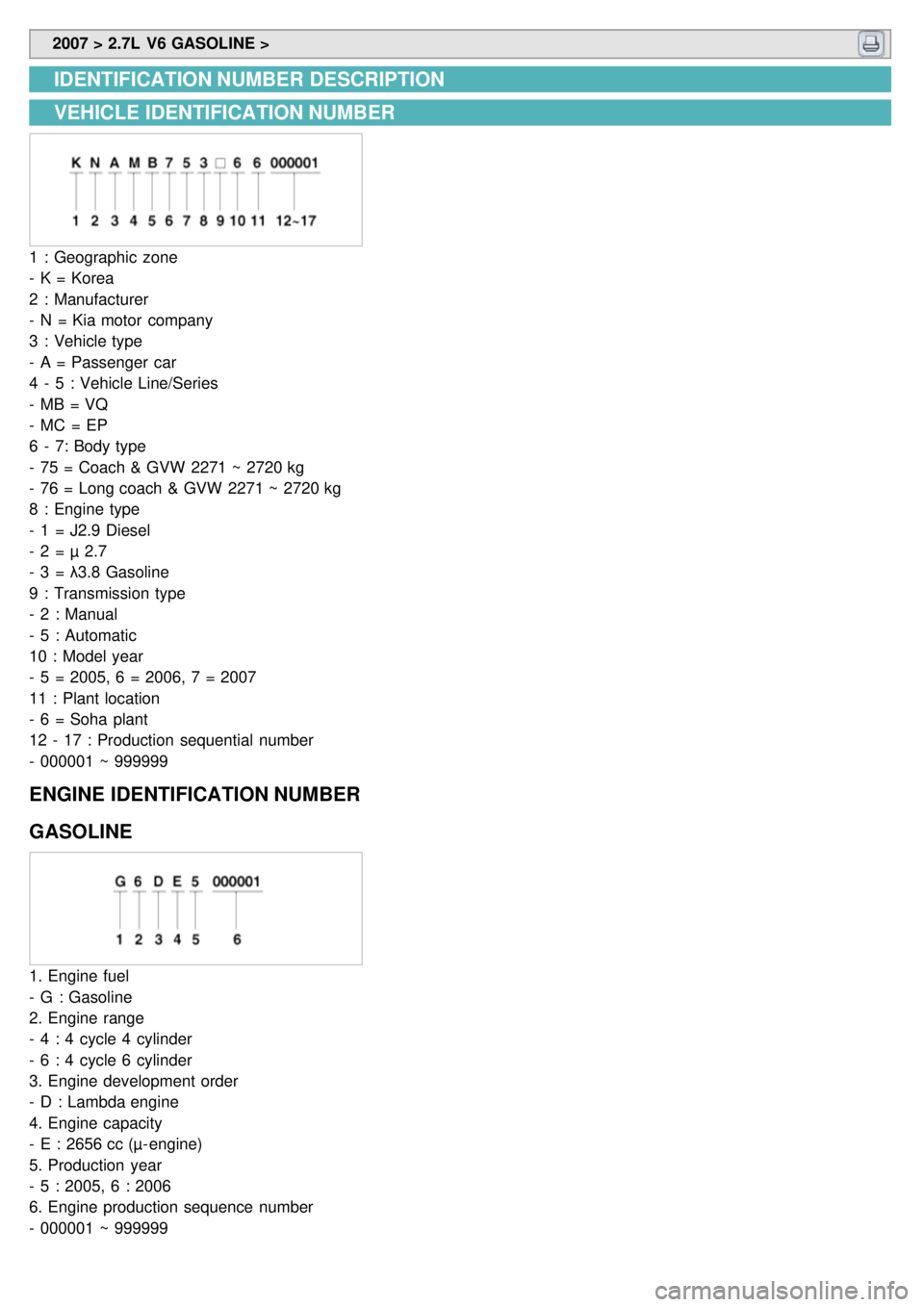

VEHICLE IDENTIFICATION NUMBER

1 : Geographic zone

- K = Korea

2 : Manufacturer

- N = Kia motor company

3 : Vehicle type

- A = Passenger car

4 - 5 : Vehicle Line/Series

- MB = VQ

- MC = EP

6 - 7: Body type

- 75 = Coach & GVW 2271 ~ 2720 kg

- 76 = Long coach & GVW 2271 ~ 2720 kg

8 : Engine type

- 1 = J2.9 Diesel

- 2 = µ 2.7

- 3 = λ3.8 Gasoline

9 : Transmission type

- 2 : Manual

- 5 : Automatic

10 : Model year

- 5 = 2005, 6 = 2006, 7 = 2007

11 : Plant location

- 6 = Soha plant

12 - 17 : Production sequential number

- 000001 ~ 999999

ENGINE IDENTIFICATION NUMBER

GASOLINE

1. Engine fuel

- G : Gasoline

2. Engine range

- 4 : 4 cycle 4 cylinder

- 6 : 4 cycle 6 cylinder

3. Engine development order

- D : Lambda engine

4. Engine capacity

- E : 2656 cc (µ- engine)

5. Production year

- 5 : 2005, 6 : 2006

6. Engine production sequence number

- 000001 ~ 999999

Page 10 of 1575

noise,regardless of

engine speed.Loose or damaged drive plate.

Repair or replace the drive plate.

Damaged oil pan, contacting the oil pump

screen. a.

Inspect the oil pan.

b. Inspect the oil pump screen.

c. Repair or replace as required.

Oil pump screen loose, damaged or

restricted. a.

Inspect the oil pump screen.

b. Repair or replace as required.

Excessive piston- to- cylinder bore clearance. a.Inspect the piston, piston pin and cylinder

bore.

b. Repair as required.

Excessive piston pin- to- piston clearance. a.Inspect the piston, piston pin and the

connecting rod.

b. Repair or replace as required.

Excessive connecting rod bearing clearance Inspect the following components and repair

as required.

a. The connecting rod bearings.

b. The connecting rods.

c. The crankshaft pin journals.

Excessive crankshaft bearing clearance. Inspect the following components, and repair

as required.

a. The crankshaft bearings.

b. The crankshaft main journals.

c. The cylinder block.

Incorrect piston, piston pin and connecting rod

installation a.

Verify the piston pins and connecting rods

are installed correctly.

b. Repair as required.

Engine noise under

load. Low oil pressure

Repair or replace as required.

Excessive connecting rod bearing clearance . Inspect the following components and repair

as required :

a. The connecting rod bearings.

b. The connecting rods.

c. The crankshaft.

Excessive crankshaft bearing clearance. Inspect the following components, and repair

as required.

a. The crankshaft bearings.

b. The crankshaft main journals.

c. The cylinder block.

Engine will not crank-

crankshaft will not

rotate. Hydraulically locked cylinder.

a. Coolant/antifreeze in cylinder.

b. Oil in cylinder.

c. Fuel in cylinder. a.

Remove spark plugs and check for fluid.

b. Inspect for broken head gasket.

c. Inspect for cracked engine block or

cylinder head.

d. Inspect for a sticking fuel injector and/or

leaking fuel regulator.

Broken timing chain and/or timing chain

and/or timing chain gears. a.

Inspect timing chain and gears.

b. Repair as required.

Material in cylinder. a. Broken valve

b. Piston material

c. Foreign material a.

Inspect cylinder for damaged components

and/or foreign materials.

b. Repair or replace as required.

Page 12 of 1575

2007 > 2.7L V6 GASOLINE >

Compression pressure inspection

If the there is lack of power, excessive oil consumption or poor fuel economy, measure the compression

pressure.

1. Warm up the engine until the normal operating temperature becoming 80~95°C(176~203°F).

2. Remove the surge tank.

3. Remove the ignition coil connectors(B) and ignition coils.

4.Using a 16mm plug wrench, remove the 6 spark plugs.

5. Check cylinder compression pressure.

(1) Insert a compression gauge into the spark plug hole.

(2) Open the throttle fully.

(3) With the fully - open throttle in cranking, measure the compression pressure.

Always use a fully charged battery to get the engine speed of 250 rpm or more.

Repeat steps 1) through 3) for each cylinder.

This measurement must be done in as short a time as possible.

Compression pressure: 1,176.79kPa (12.0kgf/cm², 170.68psi) - 200 ~ 250rpm

Minimum pressure: 1,029.69kPa (10.5kgf/cm², 149.34psi)

Difference between cylinders: 98.07kPa (1.0kgf/cm², 14.22psi)

(4) If the compression pressure in 1 or more cylinders is lower than the specification above, pour a small amount

of engine oil into the cylinder through the spark plug hole, repeat the steps (1) through (3) for the cylinder and

measure the pressure again.

a. If adding oil increases the pressure up, the piston rings or cylinder bores might be worn or damaged.

b. If the pressure doesn't increase, a valve may be sticking or seating may be improper, or there may be

leakage from the gasket.

6. Reinstall the spark plugs.

7. Install the ignition coils and connect ignition coil connectors.

8. Install the surge tank.

VALVE CLEARANCE INSPECTION AND ADJUSTMENT

Inspect and adjust the valve clearance when the engine is cold (Engine coolant temperature : 20°C

±5°C(59~77°F)) and cylinder head is installed on the cylinder block.

Page 36 of 1575

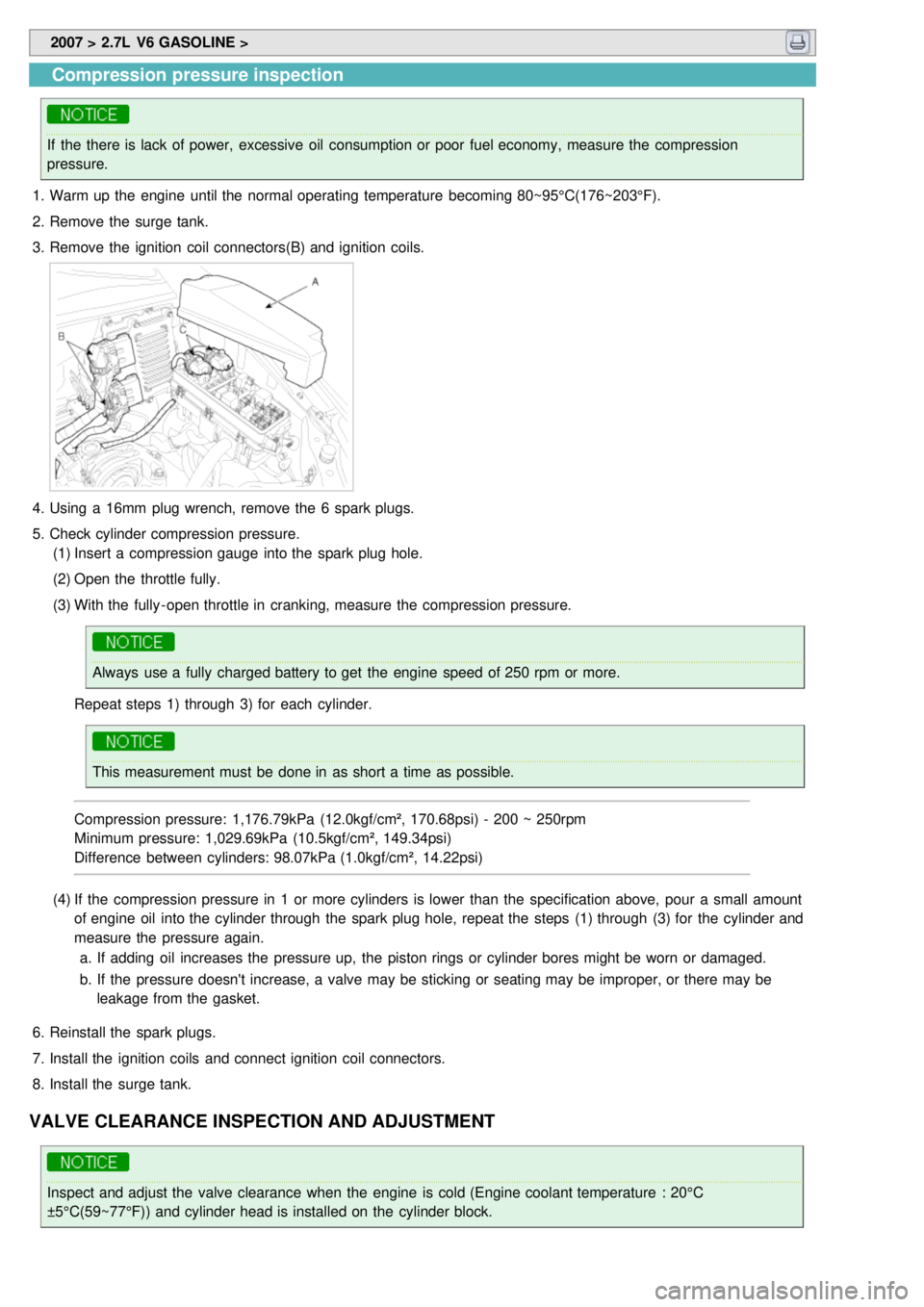

5.Remove the fuel inlet hose(A) from the delivery pipe.

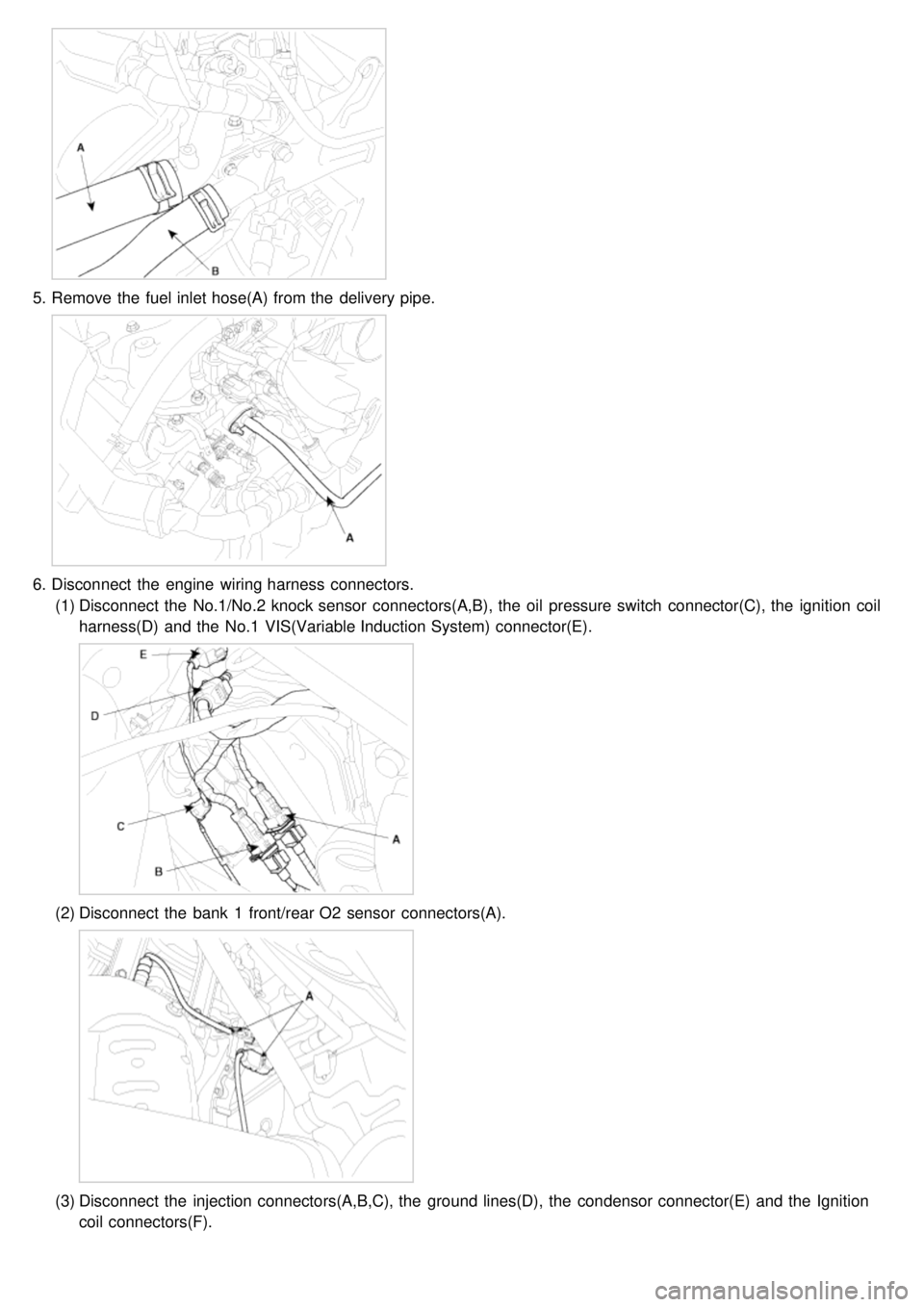

6.Disconnect the engine wiring harness connectors.

(1) Disconnect the No.1/No.2 knock sensor connectors(A,B), the oil pressure switch connector(C), the ignition coil

harness(D) and the No.1 VIS(Variable Induction System) connector(E).

(2)Disconnect the bank 1 front/rear O2 sensor connectors(A).

(3)Disconnect the injection connectors(A,B,C), the ground lines(D), the condensor connector(E) and the Ignition

coil connectors(F).

Page 51 of 1575

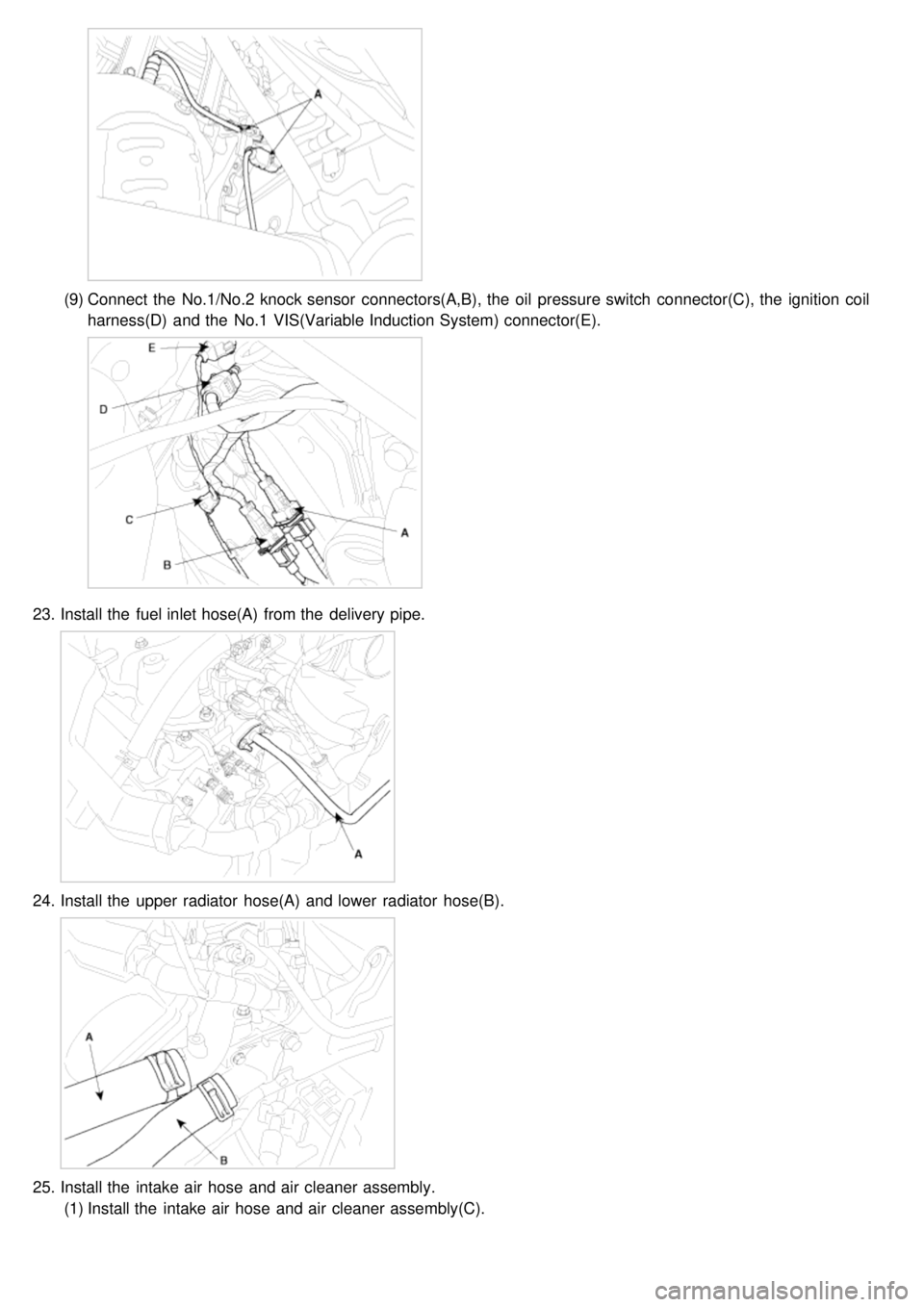

(9)Connect the No.1/No.2 knock sensor connectors(A,B), the oil pressure switch connector(C), the ignition coil

harness(D) and the No.1 VIS(Variable Induction System) connector(E).

23. Install the fuel inlet hose(A) from the delivery pipe.

24.Install the upper radiator hose(A) and lower radiator hose(B).

25.Install the intake air hose and air cleaner assembly.

(1) Install the intake air hose and air cleaner assembly(C).

Page 64 of 1575

5.Remove the under cover.

6.Drain the engine coolant.

7. Remove the upper radiator hose(A) and lower radiator hose(B).

8.Remove the transaxle oil cooler hoses(A/T vehicles only).

9. Remove the fuel inlet hose(A) from the delivery pipe.

10. Disconnect the engine wiring harness connectors.

Page 71 of 1575

INSTALLATION

Installation is in the reverse order of removal.

Perform the following :a. Adjust the shift cable.

b. Refill the engine with engine oil.

c. Refill the transaxle with fluid.

d. Refill the radiator with engine coolant.

e. Bleed air from the cooling system with the heater valve open.

f. Clean the battery posts and cable terminals with sandpaper assemble them, then apply grease to prevent

corrosion.

g. Inspect for fuel leakage.

After assembling the fuel line, turn on the ignition switch (do not operate the starter) so that the fuel pump runs for

approximately two seconds and fuel line pressurizes.

Repeat this operation two or three times, then check for fuel leakage at any point in the fuel line.

Page 155 of 1575

![KIA CARNIVAL 2007 Workshop Manual a.[U2.7]

L nleaded : ILFR5B11

Leaded : LFR5A

ON-VEHICLE INSPECTION

SPARK TEST

1. Remove the ignition coil connector(A).

Disconnect the iguition coil connector while pulling up tre connector KIA CARNIVAL 2007 Workshop Manual a.[U2.7]

L nleaded : ILFR5B11

Leaded : LFR5A

ON-VEHICLE INSPECTION

SPARK TEST

1. Remove the ignition coil connector(A).

Disconnect the iguition coil connector while pulling up tre connector](/img/2/57045/w960_57045-154.png)

a.[U2.7]

L nleaded : ILFR5B11

Leaded : LFR5A

ON-VEHICLE INSPECTION

SPARK TEST

1. Remove the ignition coil connector(A).

Disconnect the iguition coil connector while pulling up tre connector lock.

2. Remove the ignition coil.

3. Using a spark plug socket, remove the spark plug.

4. Install the spark plug to the ignition coil.

5. Ground the spark plug to the engine.

6.Check is spark occurs while engine is being cranked.

To prevent fuel being injected from injectors while the engine is being cranked, remove the fuel pump(A) relay

from the fuse box.

Crank the engine for no more than 5 ~ 10 seconds.

7. Inspect all the spark plugs.

8. Using a spark plug socket, install the spark plug.

9. Install the ignition coil.

10. Reconnect the ignition coil connector.

Page 156 of 1575

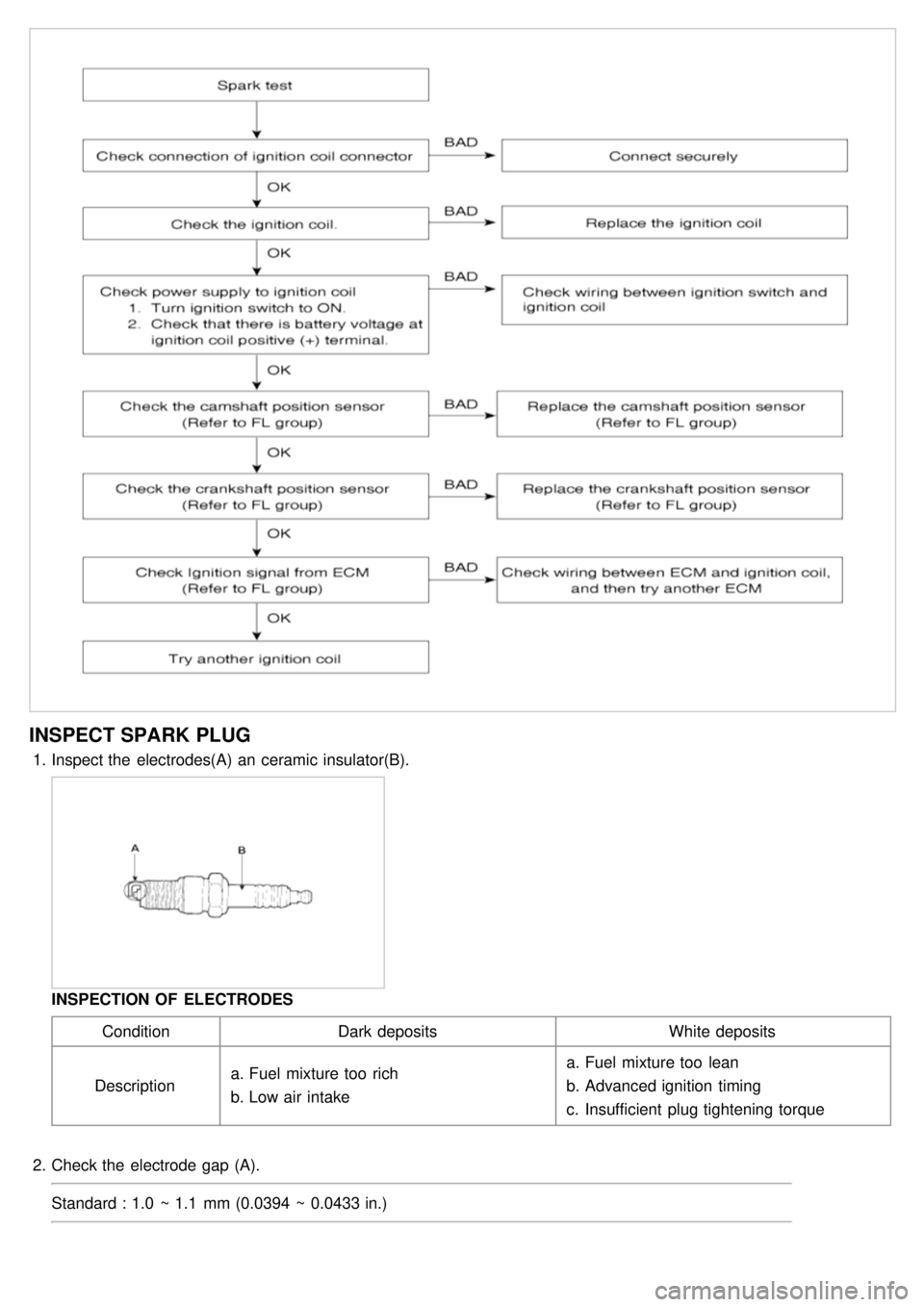

INSPECT SPARK PLUG

1.Inspect the electrodes(A) an ceramic insulator(B).

INSPECTION OF ELECTRODES

Condition Dark deposits White deposits

Description a.

Fuel mixture too rich

b. Low air intake a.

Fuel mixture too lean

b. Advanced ignition timing

c. Insufficient plug tightening torque

2. Check the electrode gap (A).

Standard : 1.0 ~ 1.1 mm (0.0394 ~ 0.0433 in.)

Page 176 of 1575

2007 > 2.7L V6 GASOLINE >

STARTER CIRCUIT TROUBLESHOOTING

The battery must be in good condition and fully charged.

1. Remove the fuel pump relay(A) from the fuse box.

2. With the shift lever in N or P (A/T) or clutch pedal pressed (M/T), turn the ignition switch to "START"

If the starter normally cranks the engine, starting system is OK. If the starter will not crank the engine at all, go to

next step.

If it won't disengage from the ring gear when you release key, check for the following until you find the cause.

a. Solenoid plunger and switch malfunction.

b. Dirty pinion gear or damaged overrunning clutch.

3. Check the battery condition. Check electrical connections at the battery, battery negative cable connected to the

body, engine ground cables, and the starter for looseness and corrosion. Then try starting the engine again.

If the starter cranks normally the engine, repairing the loose connection repaired the problem. The starting system

is now OK.

If the starter still does not crank the engine, go to next step.

4. Disconnect the connector from the S- terminal of solenoid. Connect a jumper wire from the B- terminal of solenoid to

the S- terminal of solenoid.

If the starter cranks the engine, go to next step.

If the starter still does not crank the engine, remove the starter, and repair or replace as necessary.

5. Check the following items in the order listed until you find the open circuit.

a. Check the wire and connectors between the driver's under - dash fuse/relay box and the ignition switch, and

between the driver's under - dash fuse/relay box and the starter.

b. Check the ignition switch (Refer to BE group - ignition system)

c. Check the transaxle range switch connector or ignition lock switch connector.

d. Inspect the starter relay.

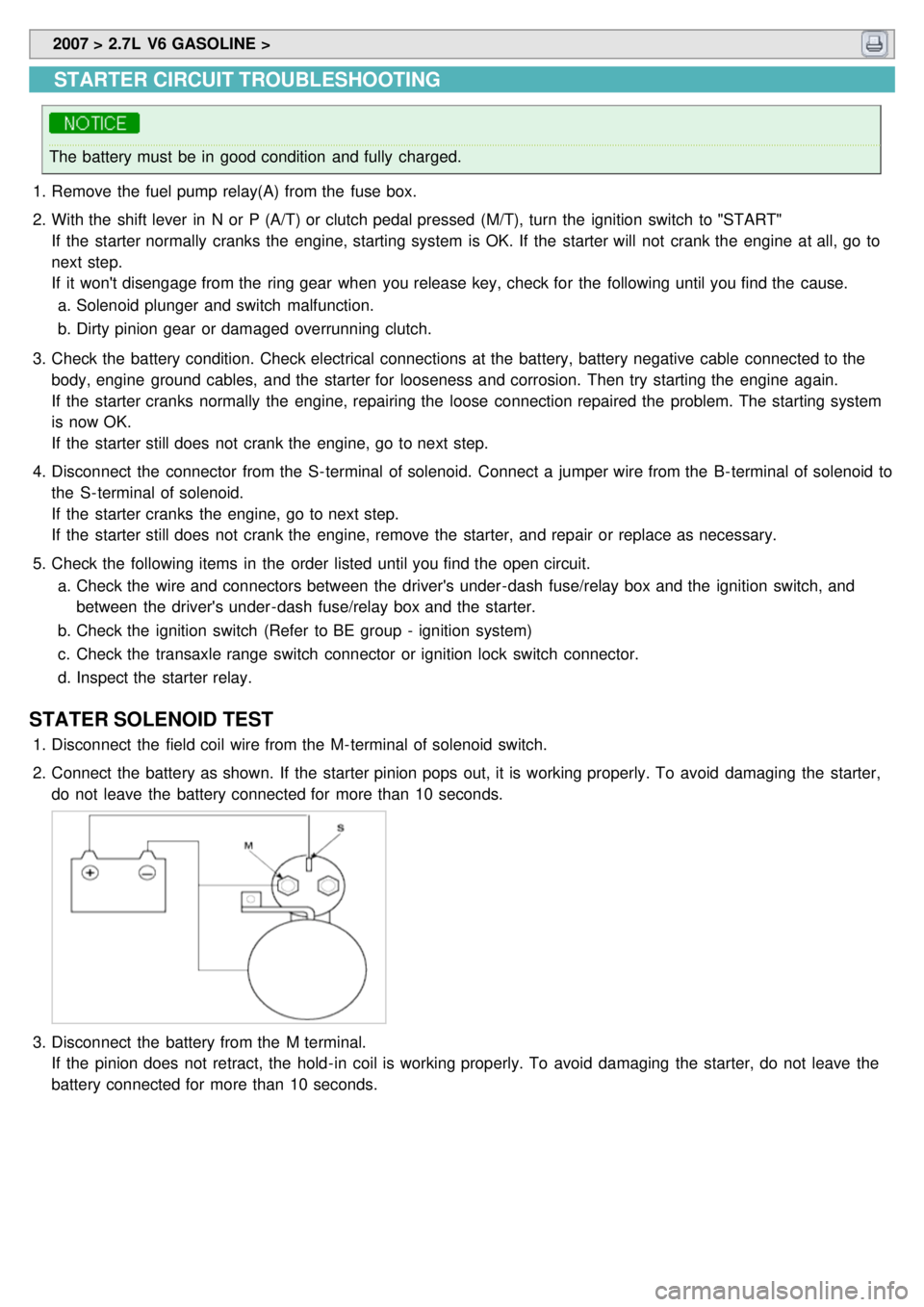

STATER SOLENOID TEST

1.Disconnect the field coil wire from the M- terminal of solenoid switch.

2. Connect the battery as shown. If the starter pinion pops out, it is working properly. To avoid damaging the starter,

do not leave the battery connected for more than 10 seconds.

3.Disconnect the battery from the M terminal.

If the pinion does not retract, the hold- in coil is working properly. To avoid damaging the starter, do not leave the

battery connected for more than 10 seconds.