relay KIA CARNIVAL 2007 Owner's Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 366 of 1575

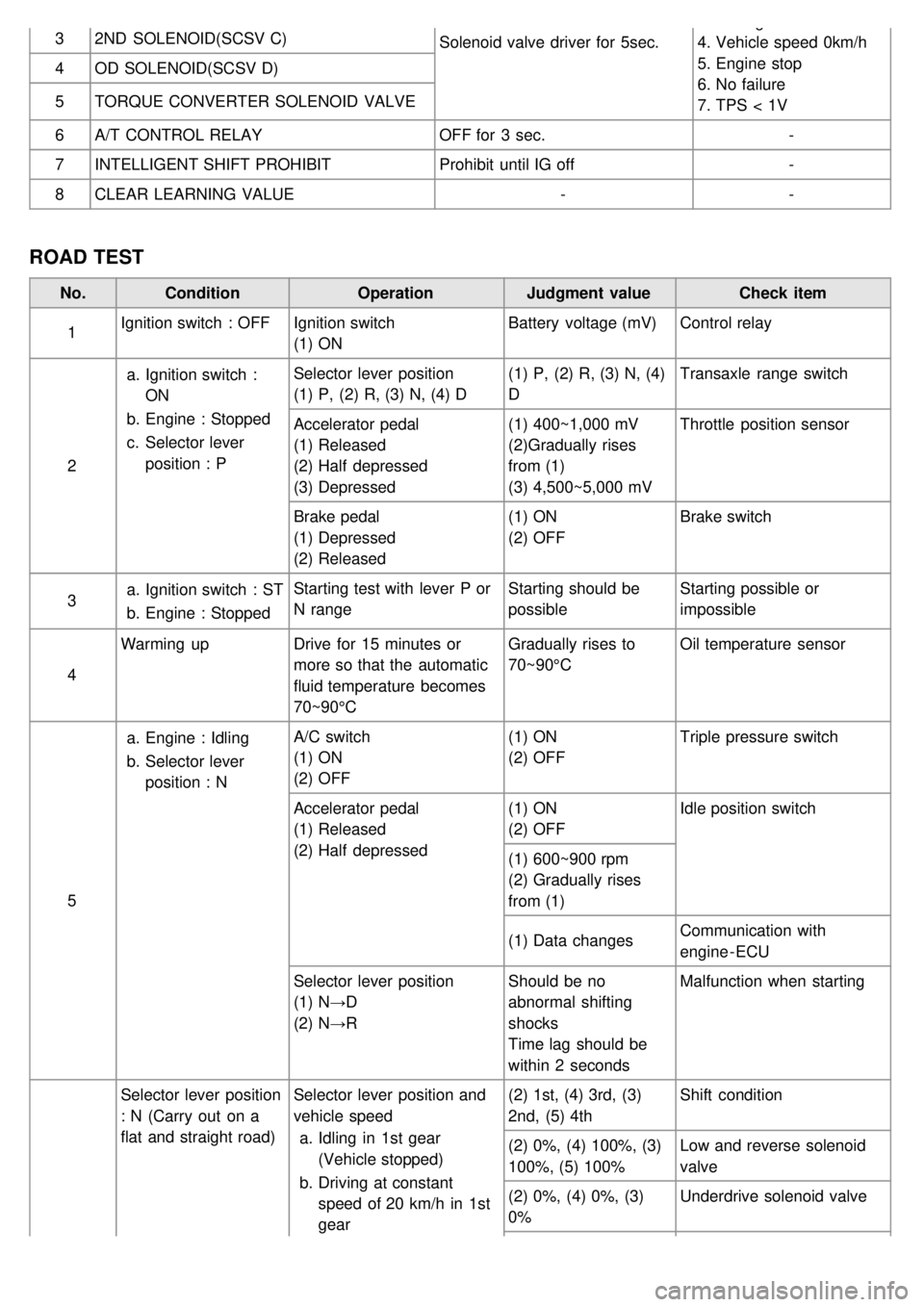

32ND SOLENOID(SCSV C)

Solenoid valve driver for 5sec.3. P range

4. Vehicle speed 0km/h

5. Engine stop

6. No failure

7. TPS < 1V

4

OD SOLENOID(SCSV D)

5 TORQUE CONVERTER SOLENOID VALVE

6 A/T CONTROL RELAY OFF for 3 sec. -

7 INTELLIGENT SHIFT PROHIBIT Prohibit until IG off -

8 CLEAR LEARNING VALUE --

ROAD TEST

No.Condition OperationJudgment value Check item

1 Ignition switch : OFF

Ignition switch

(1) ON Battery voltage (mV)

Control relay

2 a.

Ignition switch :

ON

b. Engine : Stopped

c. Selector lever

position : P Selector lever position

(1) P, (2) R, (3) N, (4) D

(1) P, (2) R, (3) N, (4)

DTransaxle range switch

Accelerator pedal

(1) Released

(2) Half depressed

(3) Depressed (1) 400~1,000 mV

(2)Gradually rises

from (1)

(3) 4,500~5,000 mVThrottle position sensor

Brake pedal

(1) Depressed

(2) Released (1) ON

(2) OFF

Brake switch

3 a.

Ignition switch : ST

b. Engine : Stopped Starting test with lever P or

N range

Starting should be

possibleStarting possible or

impossible

4 Warming up

Drive for 15 minutes or

more so that the automatic

fluid temperature becomes

70~90°C Gradually rises to

70~90°C

Oil temperature sensor

5 a.

Engine : Idling

b. Selector lever

position : N A/C switch

(1) ON

(2) OFF

(1) ON

(2) OFF

Triple pressure switch

Accelerator pedal

(1) Released

(2) Half depressed (1) ON

(2) OFF

Idle position switch

(1) 600~900 rpm

(2) Gradually rises

from (1)

(1) Data changes Communication with

engine - ECU

Selector lever position

(1) N→D

(2) N→R Should be no

abnormal shifting

shocks

Time lag should be

within 2 secondsMalfunction when starting

Selector lever position

: N (Carry out on a

flat and straight road) Selector lever position and

vehicle speed

a. Idling in 1st gear

(Vehicle stopped)

b. Driving at constant

speed of 20 km/h in 1st

gear (2) 1st, (4) 3rd, (3)

2nd, (5) 4th

Shift condition

(2) 0%, (4) 100%, (3)

100%, (5) 100% Low and reverse solenoid

valve

(2) 0%, (4) 0%, (3)

0% Underdrive solenoid valve

Page 646 of 1575

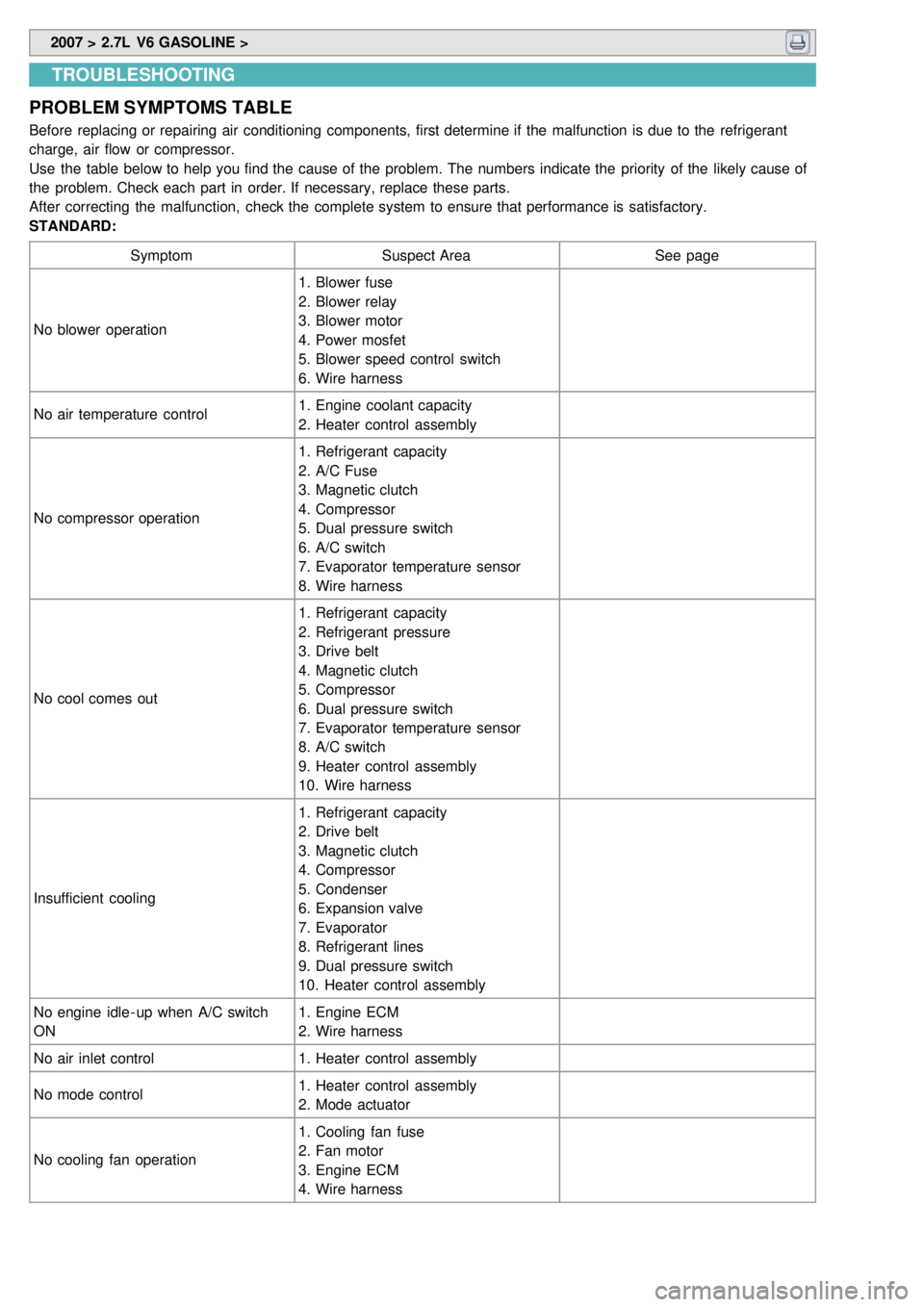

2007 > 2.7L V6 GASOLINE >

TROUBLESHOOTING

PROBLEM SYMPTOMS TABLE

Before replacing or repairing air conditioning components, first determine if the malfunction is due to the refrigerant

charge, air flow or compressor.

Use the table below to help you find the cause of the problem. The numbers indicate the priority of the likely cause of

the problem. Check each part in order. If necessary, replace these parts.

After correcting the malfunction, check the complete system to ensure that performance is satisfactory.

STANDARD:

Symptom Suspect Area See page

No blower operation 1. Blower fuse

2. Blower relay

3. Blower motor

4. Power mosfet

5. Blower speed control switch

6. Wire harness

No air temperature control 1. Engine coolant capacity

2. Heater control assembly

No compressor operation 1. Refrigerant capacity

2. A/C Fuse

3. Magnetic clutch

4. Compressor

5. Dual pressure switch

6. A/C switch

7. Evaporator temperature sensor

8. Wire harness

No cool comes out 1. Refrigerant capacity

2. Refrigerant pressure

3. Drive belt

4. Magnetic clutch

5. Compressor

6. Dual pressure switch

7. Evaporator temperature sensor

8. A/C switch

9. Heater control assembly

10. Wire harness

Insufficient cooling 1. Refrigerant capacity

2. Drive belt

3. Magnetic clutch

4. Compressor

5. Condenser

6. Expansion valve

7. Evaporator

8. Refrigerant lines

9. Dual pressure switch

10. Heater control assembly

No engine idle - up when A/C switch

ON 1. Engine ECM

2. Wire harness

No air inlet control 1. Heater control assembly

No mode control 1. Heater control assembly

2. Mode actuator

No cooling fan operation 1. Cooling fan fuse

2. Fan motor

3. Engine ECM

4. Wire harness

Page 679 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

The evaporator temperature sensor will detect the evaporator core temperature and interrupt compressor relay power

in order to prevent evaporator freezing by excessive cooling.

Page 737 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

Inspect the PTC operation by confirmation logic as below.

1. Entering method

(1) Set the floor mode, maximum heating

(2) Turn off the blower switch

(3) Press the intake button more than 5 times.

(4) Indicator of entire button is flashed with an interval of 0.5 seconds continuously (Manual).

Graphics of the entire LCD display switch on and off with an interval of 0.5 seconds continuously (Automatic)

(5) Confirm the PTC operation by operating the blower switch

Manual : 1~4 step, Automatic: 1~8step.

(6) Each PTC relay is operated with an interval of 3 seconds.

(7) Execute the PTC operation by confirmation logic for 30 seconds.

2. Cancellation method

(1) Select the A/C button or intake button.

(2) IG "OFF".

(3) Cancel the logic after 30 seconds automatically.

3. If the PTC operation is not operated, substitute with a known- good PTC and check for proper operation.

If the problem is corrected, replace the PTC.

Page 766 of 1575

Blower Relay

Page 768 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.There should be continuity between the NO.1 in the A and NO.10 in the B terminals when power and ground are

connected to the NO.7 and NO.13 in the A terminals. (Passenger compartment relay box)

2. There should be to no continuity btween the NO.1 in the A and NO.10 in the B terminals when power is

disconnected.

REAR BLOWER

1.There should be continuity between the NO.4in the A and NO.12n the B terminals when power and ground are

connected to the NO.2and NO.14in the A terminals. (Passenger compartment relay box)

2. There should be to no continuity btween the NO.4in the A and NO.12in the B terminals when power is

disconnected.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the crash pad center lower side cover. (Refer to BD group)

3. Loosen the relat box mounting nut, and then remove the relay box(A).

4.Install in the reverse order of removal.

Page 783 of 1575

Connector AConnector B

6 REAR TEMP ACTUATOR

(F/B) 12

SENSOR POWER (+5V)

7 REAR TEMP SWITCH 13-

8 REAR MODE ACTUATOR

(VENT) 14

HAZARD SEIECT

9 REAR MODE ACTUATOR

(FLOOR) 15

-

10 REAR MODE ACTUATOR

(F/B) 16

-

11 BLOWER MOTOR (+)

Connector C1

DRIVE'S TEMP ACTUATOR

(COOL)

12 GROUND 2DRIVE'S TEMP ACTUATOR

(WARM)

13 RHEOSTAT (ILL- ) 3DRIVE'S TEMP ACTUATOR (F/B)

14 A/C SELECT SIGNAL 4DRIVE'S MODE ACTUATOR

(COOL)

15 A/C OUTPUT 5DRIVE'S MODE ACTUATOR

(WARM)

16 REAR DEFOGGER 6DRIVE'S MODE ACTUATOR (F/B)

17 REAR DEFOGGER

SWITCH 7

INTAKE ACTUATOR (FRESH)

18 - 8INTAKE ACTUATOR

(RECIRCULATION)

19 REAR BLOWER SWITCH 9INTAKE ACTUATOR (F/B)

20 REAR MODE SWITCH

(VENT) 10

PASSENGER'S TEMP ACTUATOR

(COOL)

21 REAR MODE SWITCH (B/L) 11EVAPORATOR SENSOR (+)

22 REAR MODE SWITCH

(FLOOR) 12

SENSOR POWER (+5V)

23 REAR MODE GND (VENT) 13PASSENGER'S TEMP ACTUATOR

(WARM)

24 REAR MODE GND (B/L) 14PASSENGER'S TEMP ACTUATOR

(F/B)

25 REAR MODE GND

(FLOOR) 15

-

26 - 16DATA PORT

Connector B 1

- 17RESET PIN

2 A/C OUTPUT 18-

3 PTC RELAY2 19POWER MOSFET (GATE) -

FRONT

4 PTC RELAY3 20POWER MOSFET (DRAIN) -

FRONT

5 BLOWER SELECT SIGNAL 21SENSOR GND

6 PTC ON SIGNAL 22-

Page 787 of 1575

Connector AConnector B

6 REAR TEMP ACTUATOR

(F/B) 12

SENSOR POWER (+5V)

7 REAR TEMP SWITCH 13-

8 REAR MODE ACTUATOR

(VENT) 14

HAZARD SEIECT

9 REAR MODE ACTUATOR

(FLOOR) 15

-

10 REAR MODE ACTUATOR

(F/B) 16

-

11 BLOWER MOTOR (+)

Connector C1

DRIVE'S TEMP ACTUATOR

(COOL)

12 GROUND 2DRIVE'S TEMP ACTUATOR

(WARM)

13 RHEOSTAT (ILL- ) 3DRIVE'S TEMP ACTUATOR (F/B)

14 A/C SELECT SIGNAL 4DRIVE'S MODE ACTUATOR

(COOL)

15 A/C OUTPUT 5DRIVE'S MODE ACTUATOR

(WARM)

16 REAR DEFOGGER 6DRIVE'S MODE ACTUATOR (F/B)

17 REAR DEFOGGER

SWITCH 7

INTAKE ACTUATOR (FRESH)

18 - 8INTAKE ACTUATOR

(RECIRCULATION)

19 REAR BLOWER SWITCH 9INTAKE ACTUATOR (F/B)

20 REAR MODE SWITCH

(VENT) 10

PASSENGER'S TEMP ACTUATOR

(COOL)

21 REAR MODE SWITCH (B/L) 11EVAPORATOR SENSOR (+)

22 REAR MODE SWITCH

(FLOOR) 12

SENSOR POWER (+5V)

23 REAR MODE GND (VENT) 13PASSENGER'S TEMP ACTUATOR

(WARM)

24 REAR MODE GND (B/L) 14PASSENGER'S TEMP ACTUATOR

(F/B)

25 REAR MODE GND

(FLOOR) 15

-

26 - 16DATA PORT

Connector B 1

- 17RESET PIN

2 A/C OUTPUT 18-

3 PTC RELAY2 19POWER MOSFET (GATE) -

FRONT

4 PTC RELAY3 20POWER MOSFET (DRAIN) -

FRONT

5 BLOWER SELECT SIGNAL 21SENSOR GND

6 PTC ON SIGNAL 22-

Page 866 of 1575

TIGHTENING TORQUE

ItemsNmkgf.m lb - ft

Master cylinder to booster mounting nut 8 ~ 120.8 ~ 1.2 5.8 ~ 8.7

Brake booster mounting nut 13 ~ 161.3 ~ 1.6 9.4 ~ 11.6

Bleeder screw 7 ~ 130.7 ~ 1.3 5.06 ~ 9.4

Brake tube nut, brake hose 13 ~ 171.3 ~ 1.7 9.4 ~ 12.3

Caliper guide rod bolt (Front) 22 ~ 322.2 ~ 3.215.9 ~ 23.1

Caliper guide rod bolt (Rear) 22 ~ 322.2 ~ 3.215.9 ~ 23.1

Caliper assembly to knuckle (Front) 85 ~ 1008.5 ~ 1061.5 ~ 72.3

Caliper assembly to knuckle (Rear) 50 ~ 605.0 ~ 6.036.2 ~ 43.4

Brake hose to front caliper 25 ~ 302.5 ~ 3.018.1 ~ 21.7

Brake pedal assembly bracket mounting nut 10 ~ 151.0 ~ 1.5 7.2 ~ 10.8

Brake pedal mounting nut 13 ~ 161.3 ~ 1.6 9.4 ~ 11.6

Stop lamp switch mounting nut 8 ~ 100.8 ~ 1.0 5.8 ~ 7.23

Active wheel speed sensor mounting bolt on

the brake plate 7 ~ 10

0.7 ~ 1.0 5.1 ~ 7.2

HECU mounting bracket bolt 17 ~ 261.7 ~ 2.612.3 ~ 18.8

HECU mounting nut 6 ~ 100.6 ~ 1.0 4.3 ~ 7.2

Yaw rate & lateral acceleration sensor bolt 5 ~ 80.5 ~ 0.8 3.62 ~ 5.8

SPECIFICATION (ABS)

Part ItemStandard valueRemark

HECU(Hydraulic and

Electronic Control

Unit) System

4 channel 4 sensor

(Solenoid)

·ABS system:ABS &

EBD control

Type

Motor, valve relay

intergrated type

Operating voltage 8 V ~ 16 V(DC)

Operating temperature - 40 ~ 120 °C

( - 40 ~ 248 °F)

Warning lamp Operating voltage

12 V·ABS W/L:ABS failure

·Brake W/L:Parking,

brake oil, EBD failure

Current consumption 80 mA

Acitve wheel speed

sensor Supply voltage

DC 4.5 ~ 2.0 V

Operating temperature - 40 ~ 150 °C

Output current low 5.9 ~ 8.4 mATyp.7 mA

Output current High 11.8 ~ 16.8 mATyp.14 mA

Frequency range 1 ~ 2500 HZ

Air gap Front

0.15 ~ 1.5 mm Typ.0.7 mm

Rear 0.2 ~ 1.2 mm Typ.0.7 mm

Tone wheel 48 teeth

Output duty 30~70 %

SPECIFICATION(ESP)

Page 867 of 1575

PartItemStandard ValueRemark

HECU(Hydraulic and

Electronic Control

Unit) System

4 channel 4

sensor(Solenoid)

·Total control(ABS,

EBD, TCS, ESP)

Type

Motor, valve relay

intergrated type

Operating voltage 8 V ~ 16 V(DC)

Operating temperature - 40 ~ 120 °C(- 40 ~

248 °F)

Warning lamp Operating voltage

12 V

·ESP Operating Lamp

·ESP Warning Lamp

Current consumption 80 mA

Active wheel speed

sensor Supply voltage

DC 4.5 ~ 20V

Operating temperature - 40 ~ 150 °C

Output current low 5.9 ~ 8.4 mA

Output current high 11.8 ~ 16.8 mA

Tone wheel 48 teeth

Frequency range 1 ~ 2500 HZ

Airgap Front

0.15 ~ 1.5 mm Typ. 0.7 mm

Rear 0.2 ~ 1.2 mm Typ. 0.7 mm

Steering Wheel Angle

Sensor Operating Voltage

8V ~ 16 V

Current Consumption Max 150 mA

Operating Angular velocity Max ± 780 °/sec

Yaw - rate & Lateral G

sensor Operating Voltage

8 V ~ 16 V

Current Consumption Max. 120 mA

Output Voltage high 4.35 V~ 4.65 VTyp. 4.5 V

Output Voltage low 0.35 ~ 0.65 VTyp. 0.5 V

Yaw Sensor Operating Range ±100 ° /s

G Sensor Operating Range ±1.8 G

Reference voltage output 2.464 ~ 2.536 VTyp. 2.5 V

LUBRICANT

Item Recommended lubricantQuantity

Brake fluid DOT 3 or DOT 4As required

Brake pedal bushing and brake pedal bolt Chassis greaseAs required

Parking brake shoe and backing plate contact surfaces Bearing greaseAs required

Caliper guide rod and boot RX - 2 grease0.8 ~ 1.3 g

Rear caliper guide rod and boot Rubber grease0.8 ~ 1.3g