relay KIA CARNIVAL 2007 Owner's Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 927 of 1575

4FR Wheel speed sensor FR WHEELKm/h

5 RL Wheel speed sensor RL WHEELKm/h

6 RR Wheel speed sensor RR WHEELKm/h

7 ABS Warning lamp ABS LAMP-

8 EBD Warning lamp EBD LAMP-

9 Brake Lamp B/LAMP-

10 Pump relay state PUMP RLY-

11 Valve relay state VALVE RLY-

12 Motor MOTOR-

13 Front Left valve(IN) FL INLET-

14 Front Right valve (IN) FR INLET-

15 Rear Left valve (IN) RL INLET-

16 Rear Right valve (IN) RR INLET-

17 Front Left valve (OUT) FL OUTLET-

18 Front Right valve (OUT) FR OUTLET-

19 Rear Left valve(OUT) RL OUTLET-

20 Rear Right valve (OUT) RR OUTLET-

Page 928 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

This specification applies to HCU(Hydraulic Control Unit) and ECU(Electronic Control Unit) of the HECU.(Hydraulic and

Electronic Control Unit)

This specification is for the wiring design and installation of ABS/TCS/ESC ECU.

This unit has the functions as follows.

a. Input of signal from Pressure sensor, Steering angle sensor, Yaw & Lateral G sensor, the wheel speed sensors

attached to each wheel.

b. Control of braking force / traction force/ yaw moment.

c. Failsafe function.

d. Self diagnosis function.

e. Interface with the external diagnosis tester.

Installation position : engine compartment a. Brake tube length from Master cylinder port to HECU inlet port should be max. 1m

b. The position should not be close to the engine block and not lower than the wheel.

OPERATION

The ECU shall be put into operation by switching on the operating voltage (IGN).

On completion of the initialization phase, the ECU shall be ready for operation.

In the operating condition, the ECU shall be ready, within the specified limits (voltage and temperature), to process the

signals offered by the various sensors and switches in accordance with the control algorithm defined by the software

and to control the hydraulic and electrical actuators.

Wheel Sensor signal processing

The ECU shall receive wheel speed signal from the four active wheel sensors.

The wheel signals are converted to voltage signal by the signal conditioning circuit after receiving current signal from

active wheel sensors and given as input to the MCU.

Solenoid Valve Control

When one side of the valve coil is connected to the positive voltage that is provided through the valve relay and the

other side is connected to the ground by the semiconductor circuit, the solenoid valve goes into operation.

The electrical function of the coils are always monitored by the valve test pulse under normal operation conditions.

Voltage limits

a.Overvoltage

When overvoltage is detected(above 16.8 V), the ECU switches off the valve relay and shuts down the system.

When voltage is returned to operating range, the system goes back to the normal condition after the initialization

phase.

b. Undervoltage

In the event of undervoltage(below 9.3 V), ABS control shall be inhibited and the warning lamp shall be turned on.

When voltage is returned to operating range, the warning lamp is switched off and ECU returns to normal operating

mode.

Pump Motor Checking

The ECU performs a pump motor test at a speed of 15km/h once after IGN is switched on.

Diagnostic Interface

Failures detected by the ECU are encoded on the ECU, stored in a EEPROM and read out by diagnostic equipment

when the ignition switch is turned on.

The diagnosis interface can also be used for testing the ECU during production of the ECU and for actuating the HCU

(Air - bleeding line or Roll and Brake Test line).

Warning Lamp module

Page 946 of 1575

DTCDESCRIPTION WARNING LAMP

REMARK

ABS EBDESC

C1101 BATTERY VOLTAGE HIGH ООО

C1102 BATTERY VOLTAGE LOW ОО

C1200 FL WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1201 FL WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1202 FL WHEEL WHEEL SPEED SENSOR- NO SIGNAL ОО

C1203 FR WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1204 FR WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1205 FR WHEEL SPEED SENSOR- NO SIGNAL ОО

C1206 RL WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1207 RL WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1208 RL WHEEL SPEED SENSOR- NO SIGNAL ОО

C1209 RR WHEEL SPEED SENSOR- OPEN/SHORT ОО

C1210 RR WHEEL SENSOR- RANGE/ PERFORMANCE ОО

C1211 RR WHEEL SPEED SENSOR- NO SIGNAL ОО

C1213 WHEEL SPEED FREQUENCY ERROR ОО

C1235 PRESSURE SENSOR- ELECTRICAL ОESP

C1237 PRESSURE SENSOR- SIGNAL FAULT ОESP

C1260 STEERING ANGLE SENSOR- SIGNAL ОESP

C1261 STEERING ANGLE SENSOR NOT CALIBRATED ОESP

C1282 YAW RATE & LATERAL G SENSOR- ELECTRICAL ОESP

C1283 YAW RATE & LATERAL G SENSOR- SIGNAL ОESP

C1503 ESP SWITCH ERROR ОESP

C1513 BRAKE LIGHT SWITCH MALFUNCTION О

C1604 ECU HARDWARE ERROR ООО

C1605 CAN CONTROL HARDWARE ERROR ОESP

C1611 CAN TIME OUT- PCM(ECM) ОESP

C1612 CAN TIME OUT- PCM(TCM) ОESP

C1616 CAN BUS OFF ОESP

C1623 CAN TIMEOUT STEERING ANGLE SENSOR ОESP

C1625 CAN TIME OUT- ESP ОESP

C1626 IMPLAUSIBLE CONTROL ООESP

C1702 VARIANT CODING ООО ESP

C2112 VALVE RELAY MALFUNCTION ООО

C2308 FL INLET VALVE MALFUNCTION ООО

C2312 FL OUTLET VALVE MALFUNCTION ООО

C2316 FR INLET VALVE MALFUNCTION ООО

C2320 FR OUTLET VALVE MALFUNCTION ООО

C2324 RL INLET VALVE MALFUNCTION ООО

C2328 RL OUTLET VALVE MALFUNCTION ООО

Page 977 of 1575

2007 > 2.7L V6 GASOLINE >

FAILURE DIAGNOSIS

1.In principle, ESP and TCS controls are prohibited in case of ABS failure.

2. When ESP or TCS fails, only the failed system control is prohibited.

3. However, when the solenoid valve relay should be turned off in case of ESP failure, refer to the ABS fail- safe.

4. Information on ABS fail- safe is identical to the fail- safe in systems where ESP is not installed.

MEMORY OF FAIL CODE

1.It keeps the code as far as the backup lamp power is connected. (O)

2. It keeps the code as long as the HCU power is on. (X)

FAILURE CHECKUP

1.Initial checkup is performed immediately after the HECU power on.

2. Valve relay checkup is performed immediately after the IG2 ON.

3. It executes the checkup all the time while the IG2 power is on.

4. Initial checkup is made in the following cases.

(1) When no failure is detected

(2) When ABS and ESP are not in control.

(3) Initial checkup is not made after ECU power on.

(4) If the vehicle speed is over 5 mph(8 km/h) when the brake lamp switch is off.

(5) When the vehicle speed is over 24.8 mph(40 km/h).

5. Though, it keeps on checkup even if the brake lamp switch is on.

6. When performing ABS or ESP control before the initial checkup, stop the initial checkup and wait for the HECU

power input again.

7. Judge failure in the following cases.

(1) When the power is normal.

(2) From the point in which the vehicle speed reaches 4.9 mph(8 km/h) after HECU power on.

COUNTERMEASURES IN FAIL

1.Shut the system down and perform the following actions and wait for HECU power OFF.

2. Turn the valve relay off.

3. Do not perform any ABS/TCS/ESC functions until normal operating condition is restored.

WARNING LAMP ON

1.ABS warning lamp turns on when ABS is malfunctioning.

2. ESP operation lamp turns on when ESP is malfunctioning.

When power voltage and valve relay voltage are abnormal, input/output related failure judgment is not made.

Page 1152 of 1575

2007 > 2.7L V6 GASOLINE >

GENERAL TROUBLESHOOTING INFORMATION

BEFORE TROUBLESHOOTING

1. Check applicable fuses in the appropriate fuse/relay box.

2. Check the battery for damage, state of charge, and clean and tight connections.

a.Do not quick- charge a battery unless the battery ground cable has been disconnected, otherwise you will

damage the generator diodes.

b. Do not attempt to crank the engine with the battery ground cable loosely connected or you will severely

damage the wiring.

3. Check the generator belt tension.

HANDLING CONNECTORS

1.Make sure the connectors are clean and have no loose wire terminals.

2. Make sure multiple cavity connectors are packed with grease (except watertight connectors).

3. All connectors have push - down release type locks (A).

4.Some connectors have a clip on their side used to attach them to a mount bracket on the body or on another

component. This clip has a pull type lock.

5. Some mounted connectors cannot be disconnected unless you first release the lock and remove the connector from

its mount bracket (A).

6.Never try to disconnect connectors by pulling on their wires; pull on the connector halves instead.

7. Always reinstall plastic covers.

Page 1225 of 1575

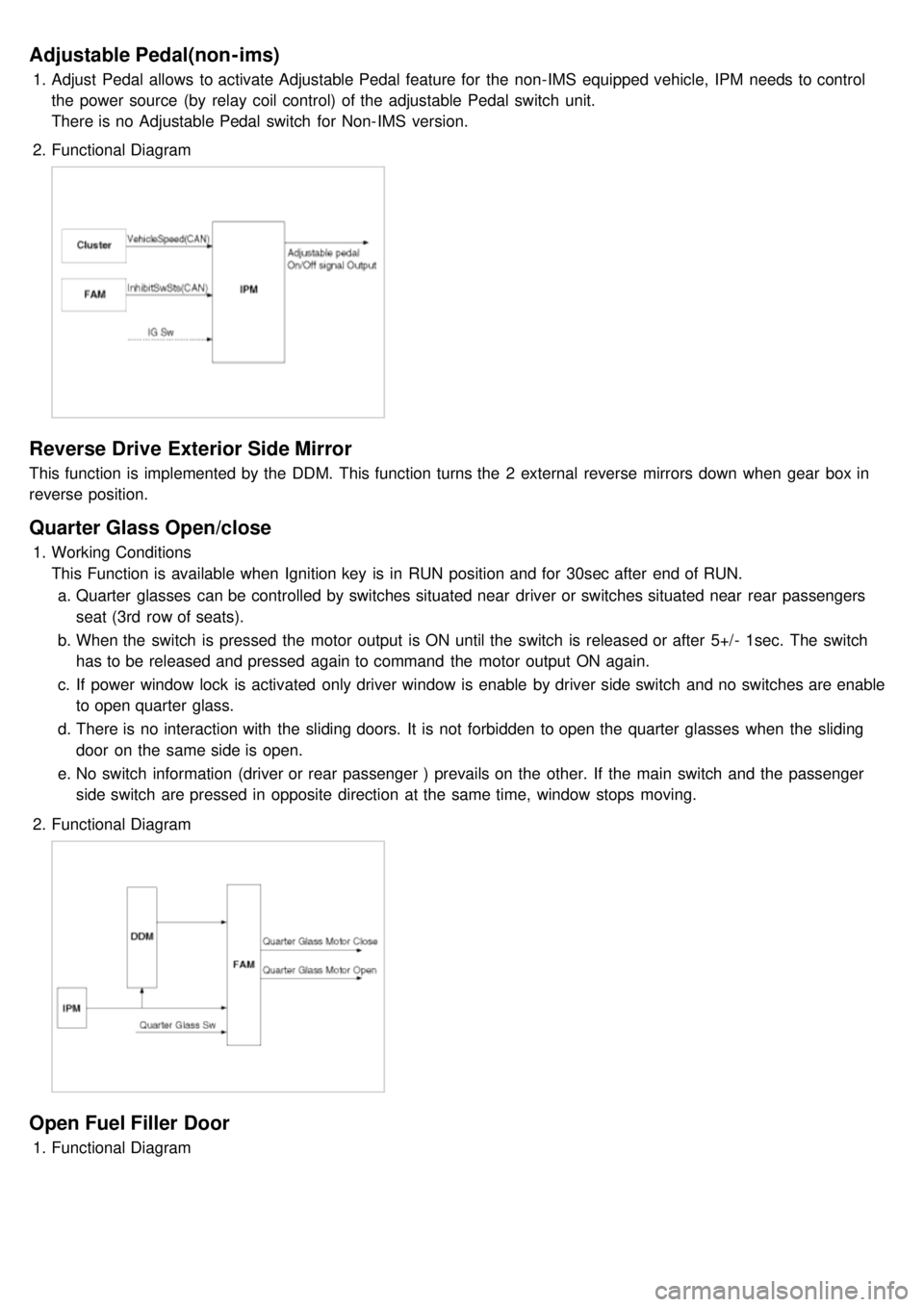

Adjustable Pedal(non-ims)

1.Adjust Pedal allows to activate Adjustable Pedal feature for the non- IMS equipped vehicle, IPM needs to control

the power source (by relay coil control) of the adjustable Pedal switch unit.

There is no Adjustable Pedal switch for Non- IMS version.

2. Functional Diagram

Reverse Drive Exterior Side Mirror

This function is implemented by the DDM. This function turns the 2 external reverse mirrors down when gear box in

reverse position.

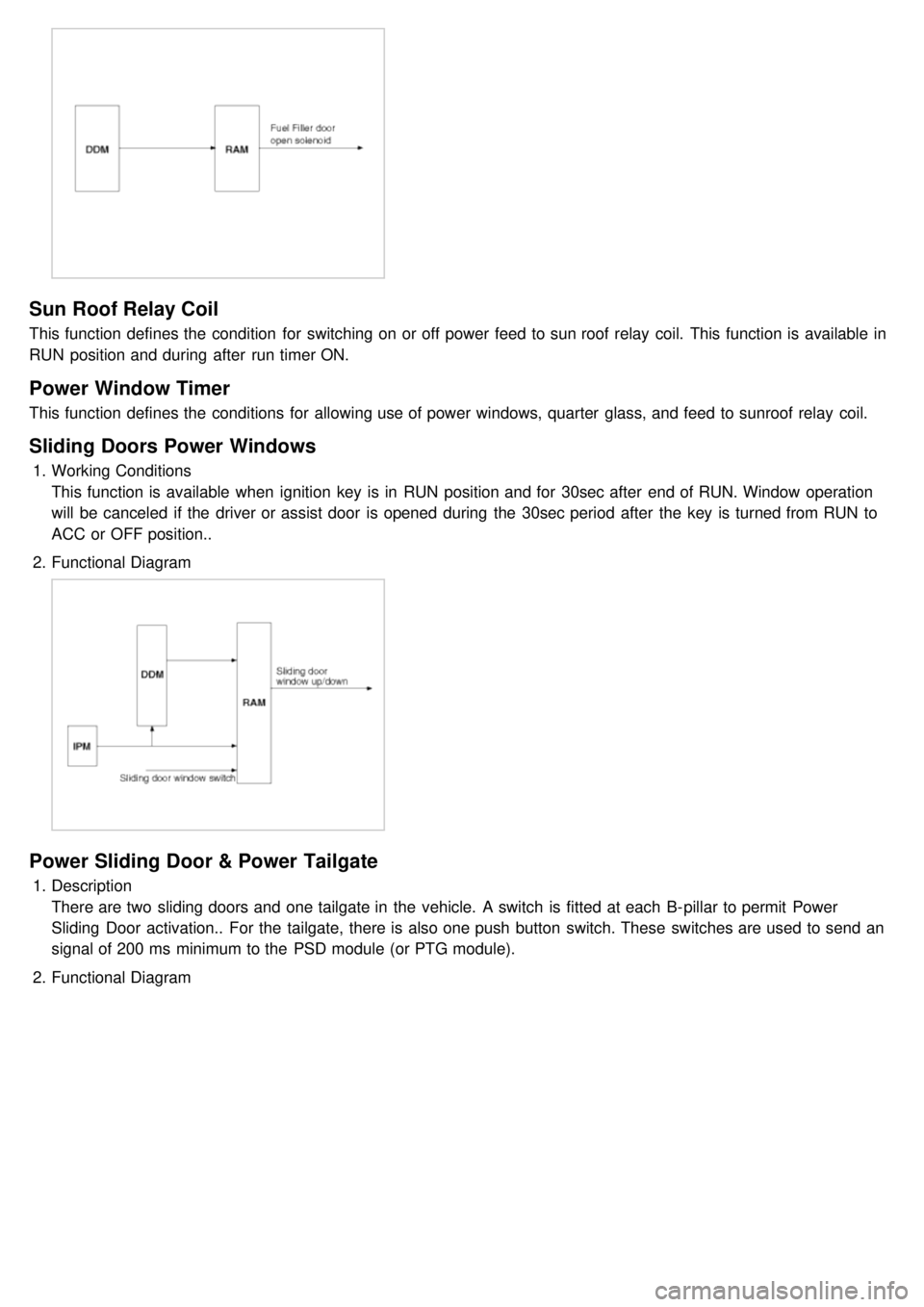

Quarter Glass Open/close

1.Working Conditions

This Function is available when Ignition key is in RUN position and for 30sec after end of RUN.

a. Quarter glasses can be controlled by switches situated near driver or switches situated near rear passengers

seat (3rd row of seats).

b. When the switch is pressed the motor output is ON until the switch is released or after 5+/- 1sec. The switch

has to be released and pressed again to command the motor output ON again.

c. If power window lock is activated only driver window is enable by driver side switch and no switches are enable

to open quarter glass.

d. There is no interaction with the sliding doors. It is not forbidden to open the quarter glasses when the sliding

door on the same side is open.

e. No switch information (driver or rear passenger ) prevails on the other. If the main switch and the passenger

side switch are pressed in opposite direction at the same time, window stops moving.

2. Functional Diagram

Open Fuel Filler Door

1.Functional Diagram

Page 1226 of 1575

Sun Roof Relay Coil

This function defines the condition for switching on or off power feed to sun roof relay coil. This function is available in

RUN position and during after run timer ON.

Power Window Timer

This function defines the conditions for allowing use of power windows, quarter glass, and feed to sunroof relay coil.

Sliding Doors Power Windows

1.Working Conditions

This function is available when ignition key is in RUN position and for 30sec after end of RUN. Window operation

will be canceled if the driver or assist door is opened during the 30sec period after the key is turned from RUN to

ACC or OFF position..

2. Functional Diagram

Power Sliding Door & Power Tailgate

1.Description

There are two sliding doors and one tailgate in the vehicle. A switch is fitted at each B- pillar to permit Power

Sliding Door activation.. For the tailgate, there is also one push button switch. These switches are used to send an

signal of 200 ms minimum to the PSD module (or PTG module).

2. Functional Diagram

Page 1235 of 1575

T1 : 0.5 sec

T2 : 1.0 ± 0.1 sec

Disarm Mode

a.If RKE unlock signal is received, then UNLOCK output is issued together with the flashing of hazard lamp (two

times) and the system enters into the DISARM condition.

b. When entering into DISARM from ALARM state, current alarm will be cancelled and burglar alarm relay drive

output is turned off.

c. When RKE unlock signal is received again in the DISARM state, UNLOCK output is issued again and hazard lamp

is flashed also (two times).

Alarm Mode

a.If one or more of entrances are opened in the ARM or REARM state, then Burglar alarm relay drive output is

turned ON in order to inhibit the start condition, and hazard lamp and siren are activated for once of 27 seconds

duration.

b. Siren output and hazard lamp should be synchronized to get the same output period.

c. Even though all the doors are closed during alarm, alarm continues to operate it for the remaining time.

d. When there is a new attack (with one of the entrance is still open) in the vehicle after completing the alarm output,

alarm should not be started again.

T1 : 27 sec ( - 0, +3sec)

T2 : 0.5 ± 0.1 sec

After Alarm State

a.If ALARM cycle is elapsed, the system goes into AFTER ALARM state.

b. During this state,

a. Burglar alarm relay drive output maintains ON.

b. Siren and hazard lamp output are stopped.

c. If another entry is opened during the AFTER ALARM state, the burglar alarm relay drive output remains ON, but

the siren will not be re- activated.

Rearm State

a.If all entrances are is closed during AFTER ALARM state, the system goes into REARM state.

Page 1245 of 1575

16B1646 S/W RESCUE MODE Module enters rescue mode

17 B1647 VAS ERROR No VAS chip transition from busy to not busy for more than 5 s after

a VAS message command has been issued

FAM DTC List No. DTC

Code DTC

Passiblecause

1 B1624 EEPROM FAILURE Failed attempt to read or write EEPROM

2 B1627 EEPROM CORRUPTION Data in EEPROM is not coherent

3 B1646 S/W RESCUE MODE As soon as the module enters rescue mode

4 B2119 WINDSHIELD DEFOG

RELAY FAIL Windshield defog relay failure

5 B2521 BRAKE CIRCUIT OPEN OR

FUSE FAIL Stop lamp fuse failure

6 B2535 RIGHT T/SIGNAL LAMP

SHORT TO GND Right turn signal lamp circuit short to ground error

7 B2537 RIGHT T/SIGNAL LAMP

OPEN Right turn signal lamp circuit open error

8 B2539 LEFT T/SIGNAL LAMP

SHORT TO GND Left turn signal lamp circuit short to ground error

9 B2541 LEFT T/SIGNAL LAMP

OPEN Left turn signal lamp circuit open error

10 B2543 RIGHT H/LAMP HIGH

SHORT TO GND Right headlamp high circuit short to ground error

11 B2545 RIGHT H/LAMP HIGH

OPEN Right headlamp high circuit open error

12 B2547 LEFT H/LAMP HIGH

SHORT TO GND Left headlamp high circuit short to ground error

13 B2549 LEFT H/LAMP HIGH OPEN Left headlamp high circuit open error

14 B2551 RIGHT H/LAMP LOW

SHORT TO GND Right headlamp low circuit short to ground error

15 B2553 RIGHT H/LAMP LOW

OPEN Right headlamp low circuit open error

16 B2555 LEFT H/LAMP LOW

SHORT TO GND Left headlamp low circuit short to ground error

17 B2557 LEFT H/LAMP LOW OPEN Left headlamp low circuit open error

18 B2559 FR FOG LAMP SHORT TO

GND Right front fog lamp circuit short to ground error

19 B2561 FR FOG LAMP OPEN Right front fog lamp circuit open error

20 B2563 FL FOG LAMP SHORT TO

GND Left front fog lamp circuit short to ground error

21 B2565 FL FOG LAMP OPEN Left front fog lamp circuit open error

22 B2571 RIGHT P/LAMP SHORT TO

GND Right parking lamp circuit short to ground error

23 B2573 RIGHT P/LAMP OPEN Right parking lamp circuit open error

24 B2575 LEFT P/LAMP SHORT TO

GND Left parking lamp circuit short to ground error

Page 1246 of 1575

24B2575

GND Left parking lamp circuit short to ground error

25 B2577 LEFT P/LAMP OPEN Left parking lamp circuit open error

RAM DTC List No. DTC

Code DTC

Passiblecause

1 B1624 EEPROM FAILURE Failed attempt to read or write EEPROM

2 B1627 EEPROM CORRUPTION Data in EEPROM is not coherent

3 B1646 S/W RESCUE MODE As soon as the module enters rescue mode

4 B2115 REAR DEFOG RELAY FAIL Command active and check entry not active

5 B2441 RR WIPER P. POS.

DETECT FAIL Command active and park position does not change during 5s

6 B2524 BRAKE LAMP OPEN Stop lamps open circuit error

7 B2535 RIGHT T/SIGNAL LAMP

SHORT TO GND Right turn signal lamp circuit short to ground error

8 B2537 RIGHT T/SIGNAL LAMP

OPEN Right turn signal lamp circuit open error

9 B2539 LEFT T/SIGNAL LAMP

SHORT TO GND Left turn signal lamp circuit short to ground error

10 B2541 LEFT T/SIGNAL LAMP

OPEN Left turn signal lamp circuit open error

11 B2579 RR TAIL MARKER LAMP

SHORT TO GND Right tail license side marker lamp circuit short to ground error

12 B2581 RR TAIL MARKER LAMP

OPEN Right tail license side marker lamp circuit open error

13 B2583 RL TAIL MARKER LAMP

SHORT TO GND Left tail license side marker lamp circuit short to ground error

14 B2585 RL TAIL MARKER LAMP

OPEN Left tail license side marker lamp circuit open error

15 B2587 BACK UP LAMP SHORT

TO GND Back up lamps for Back Up Warning System unit circuit short to

ground error

16 B2589 BACK UP LAMP OPEN Back up lamps for Back Up Warning System unit circuit open error

17 B2598 RR BLOWER SW ILLU.

CIR. OPEN Rear blower switch illumination circuit open

18 B2599 RR BLOWER SW ILLU.

SHORT TO GND Rear blower switch illumination short to ground

DDM DTC List No. DTC Code DTC Passiblecause

1 B1910 Left OSM horizontal motor

or sensor error Right OSM horizontal motor circuit open error

2 B1911 Left OSM vertical motor or

sensor error Right OSM horizontal motor circuit open error

3 B1952 OSRVM defogger error Left OSM deicer circuit open error

4 B2330 Driver door lock actuator

error Assist door lock actuator circuit open error