battery KIA CARNIVAL 2007 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 415 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Pull up the parking brake.

2. Position the shift lever in 'N' range.

3. Remove the air cleaner assembly.

4. Remove the battery.

5. Remove the battery tray.

6. Remove the inhibiter switch connector.

7. Remove the shift cable mounting nut(A).

8.Remove the inhibiter switch loosening the mounting bolts.

9. Refering to 'INSPECTION', check for continuity. If there is an error, replace the inhibiter switch.

10. After tightening the shift cable mounting nut, connect the inhibiter switch.

11. Install the battery, battery tray and the air cleaner assembly.

INSPECTION

1.Check for the starter motor when the ignition switch is at 'START' position and the shift lever at 'P' or 'N' range.

2. Check for the rear lamp when the ignition switch if it does not work properly.

3. Check for the inhibiter switch if it does not work properly.

4. If the inhibiter switch is not fixed in a proper position, reassemble it in the right position.

5. Re- check 1 and 2 procedures.

6. Using a scan tool, confirm the DTCs.

7. Disconnect the battery ( - ) terminal and the inhibiter switch.

8. Check for continuity between terminals at the switch connector.

Page 426 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

a.Use a cover not to damage the vehicle surface.

b. Disconnect connectors carefully not to be damaged.

a.Mark wires or hoses for identification not to be confused.

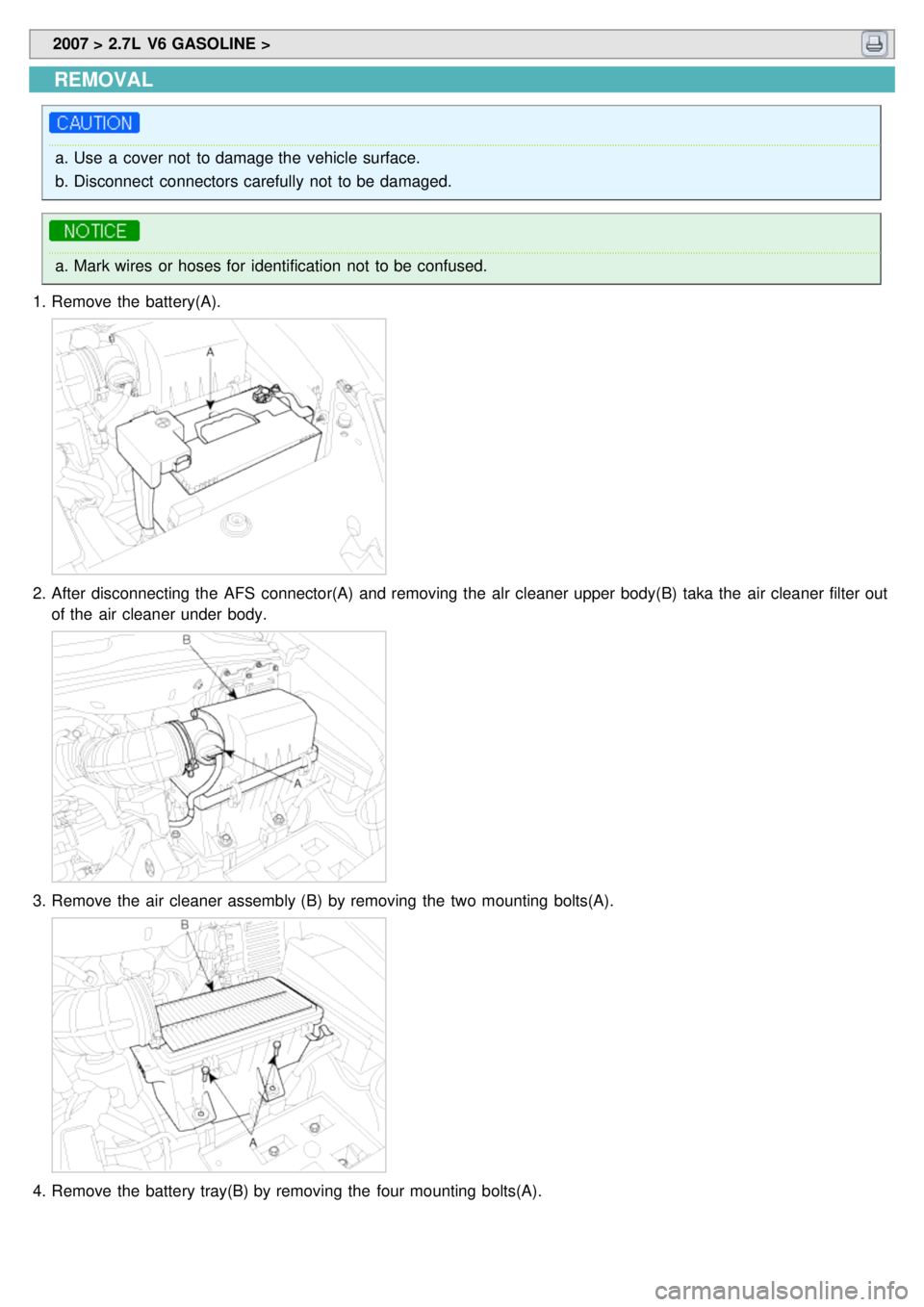

1. Remove the battery(A).

2.After disconnecting the AFS connector(A) and removing the alr cleaner upper body(B) taka the air cleaner filter out

of the air cleaner under body.

3.Remove the air cleaner assembly (B) by removing the two mounting bolts(A).

4.Remove the battery tray(B) by removing the four mounting bolts(A).

Page 440 of 1575

26.Install the wire harness bracket(b).

27.Install the shift cable assembly (A) with the clips(B) and pins(C).

28.Install the vehicle speed sensor connector (A) and the back up lamp switch(B).

29.Install the battery tray(B) by removing the four mounting bolts(A).

Page 441 of 1575

30.Install the air cleaner assembly(B) by tightening the two mounting bolts(A).

31.Reassemble the air cleaner filter, install the air cleaner upper body(B) and connect the air flow sensor

connector(A).

32.Install the battery(A).

Page 590 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

1.Disconnect the negative terminal (A) from the battery and then wait for 30 seconds.

2.Loosen the bolts in the illustration and then remove the horn pad (A).

3.Disconnect the connectors and remove the steering wheel lock nut.

Page 660 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

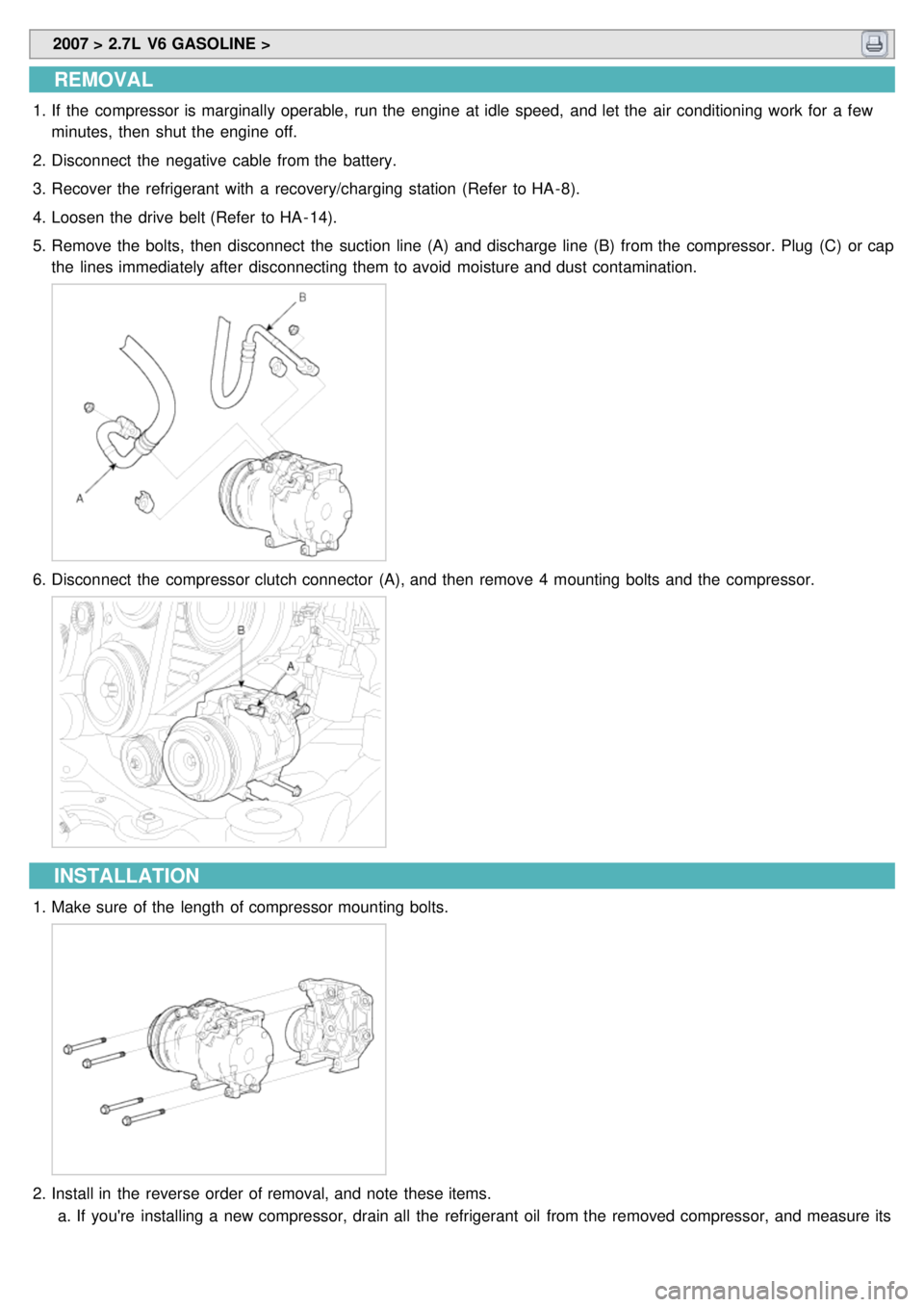

1.If the compressor is marginally operable, run the engine at idle speed, and let the air conditioning work for a few

minutes, then shut the engine off.

2. Disconnect the negative cable from the battery.

3. Recover the refrigerant with a recovery/charging station (Refer to HA - 8).

4. Loosen the drive belt (Refer to HA - 14).

5. Remove the bolts, then disconnect the suction line (A) and discharge line (B) from the compressor. Plug (C) or cap

the lines immediately after disconnecting them to avoid moisture and dust contamination.

6.Disconnect the compressor clutch connector (A), and then remove 4 mounting bolts and the compressor.

INSTALLATION

1.Make sure of the length of compressor mounting bolts.

2.Install in the reverse order of removal, and note these items.

a. If you're installing a new compressor, drain all the refrigerant oil from the removed compressor, and measure its

volume, Subtract the volume of drained oil from 120cc(4.20 oz.) the result is the amount of oil you should drain

Page 662 of 1575

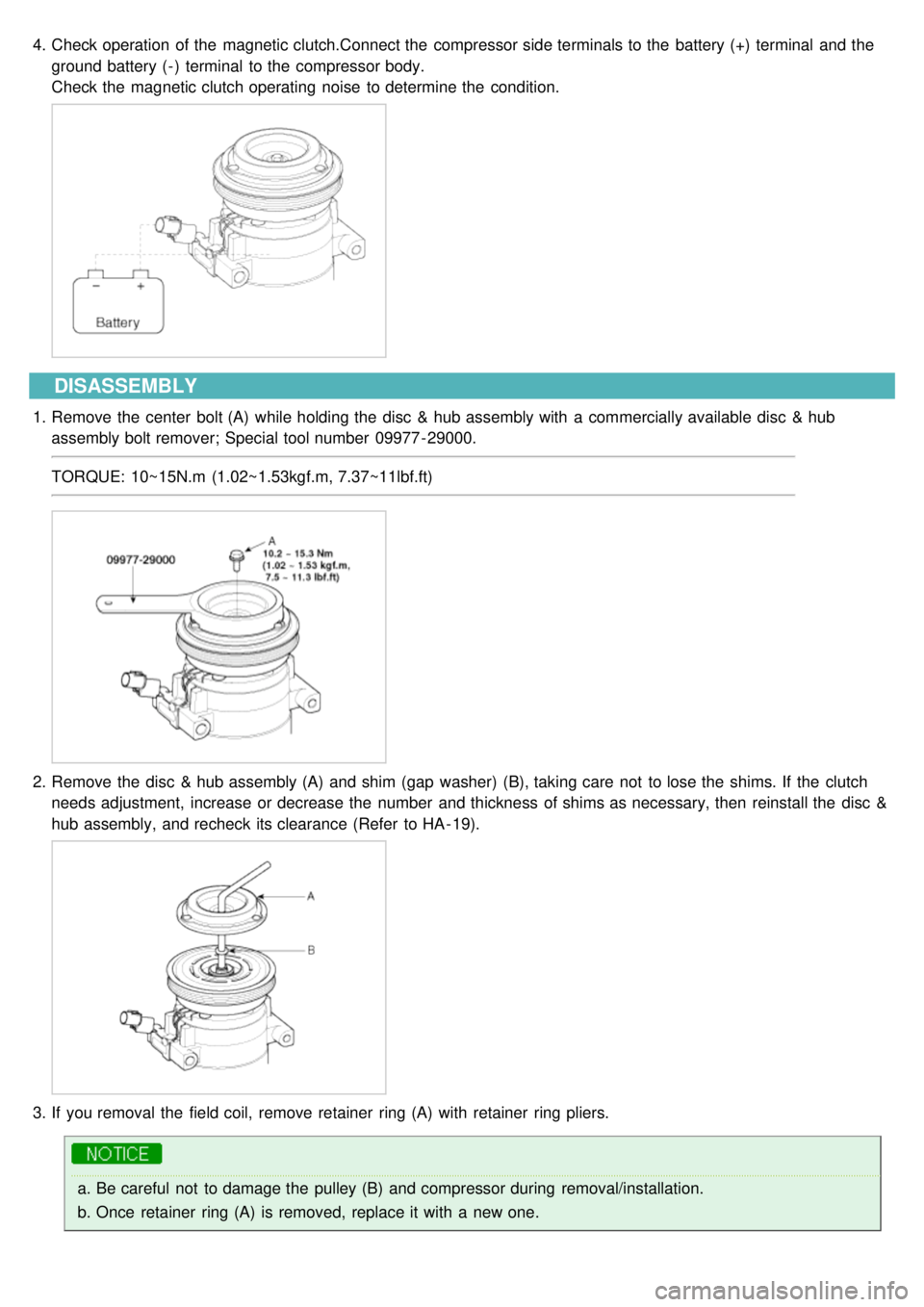

4.Check operation of the magnetic clutch.Connect the compressor side terminals to the battery (+) terminal and the

ground battery ( - ) terminal to the compressor body.

Check the magnetic clutch operating noise to determine the condition.

DISASSEMBLY

1.Remove the center bolt (A) while holding the disc & hub assembly with a commercially available disc & hub

assembly bolt remover; Special tool number 09977 - 29000.

TORQUE: 10~15N.m (1.02~1.53kgf.m, 7.37~11lbf.ft)

2.Remove the disc & hub assembly (A) and shim (gap washer) (B), taking care not to lose the shims. If the clutch

needs adjustment, increase or decrease the number and thickness of shims as necessary, then reinstall the disc &

hub assembly, and recheck its clearance (Refer to HA - 19).

3.If you removal the field coil, remove retainer ring (A) with retainer ring pliers.

a.Be careful not to damage the pulley (B) and compressor during removal/installation.

b. Once retainer ring (A) is removed, replace it with a new one.

Page 668 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Check the condenser fins for clogging and damage. If clogged, clean them with water, and blow them with

compressed air. If bent, gently bend them using a screwdriver or pliers.

2. Check the condenser connections for leakage, and repair or replace it, if required.

REPLACEMENT

CONDENSER ASSEMBLY

1. Recover the refrigerant with a recovery/ recycling/ charging station (Refer to HA - 8).

2. Disconnect the negative ( - ) battery terminal.

3. Remove the radiator. (Refer to EM group)

4. Remove 2 bolts, and then remove the condenser (A) by lifting it up. Be careful not to damage the radiator and

condenser fins when removing the condenser.

5.Install in the reverse order of removal, and note these items :

a. If you're installing a new condenser, add refrigerant oil ND- OIL8.

b. Replace the O - rings with new ones at each fitting, and apply a thin coat of refrigerant oil before installing them.

Be sure to use the right O - rings for R- 134a to avoid leakage.

c. Be careful not to damage the radiator and condenser fins when installing the condenser.

d. Be sure to install the lower mount cushions of condenser securely into the holes.

e. Charge the system, and test its performance. (Refer to HA - 9)

DESICCANT

1.Remove the condenser, and then remove the bottom cap (B) with L wrench (A) from the condenser.

TORQUE: 20~25N.m (2.0~2.5kgf•m, 14.5~18.2lb - ft)

Page 676 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Measure the pressure of high pressure line by measuring voltage output between NO.1 and NO.2 terminals.

2.Inspect the voltage value whether it is sufficient to be regular value or not.

Vout = Vdd(0.025 * P + 0.1) [kgf/cm²G]

Vout = Vdd(0.001758 * P + 0.074162) [PSIA]

3. If the measured voltage value is not specification, replace the A/C pressure transducer.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Recover the refrigerant with a recovery/charging station.

3. Disconnect A/C pressure transducer connector (3P) (A).

Page 680 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF"

2. Disconnect evaporator temperature sensor.

3. Using the multi- tester, Measure resistance between terminal "1" and "2" of evaporator temperature sensor.

Specification

Evaporator core temperature [°C(°F)] Resistance [kΩ]

- 10(14) 13.6

0(32) 8

10(50) 4.9

15(59) 3.9

30(86) 2

40(104) 1.3

50(122) 0.9

4. If the measured resistance is not specification, substitute with a known- good evaporator temperature sensor and

check for proper operation.

5. If the problem is corrected, replace the evaporator temperature sensor.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center lower side cover(B).