battery KIA CARNIVAL 2007 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 685 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "ON"

2. Blow air with changing temperature to the in car sensor air inlet. Measure sensor resistance between 2 and 4

terminals.

Specification

Temperature [°C(°F)] Resistance between terminals 2and 4 (kΩ)

0 (32) 97.83 ± 2.61%

15 (59) 47.12 ± 1.45%

25 (77) 30.00 ± 1.20%

35 (95) 19.60 ± 1.44%

50 (122) 10.82 ± 2.26%

In car sensor is negative type thermistor that resistance will rise with lower temperature, and reduce with

higher temperature.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the A/C control pannel. (Refer to BD group).

3. Disconnect the connector of in - car sensor (A).Loosen the mounting 2 screws and then remove the in - car sensor

(B).

4.Installation is the reverse order of removal.

Page 689 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

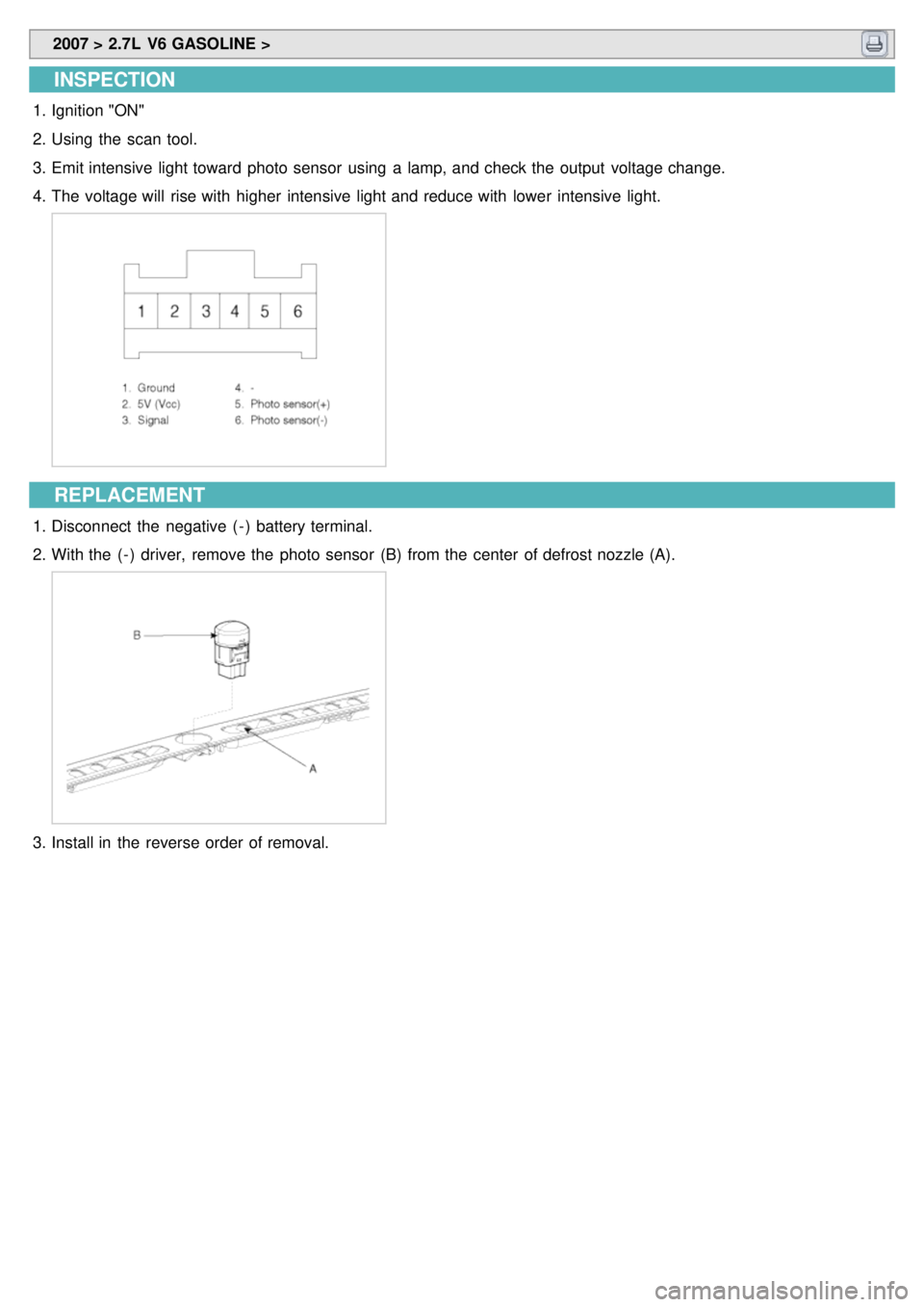

1.Ignition "ON"

2. Using the scan tool.

3. Emit intensive light toward photo sensor using a lamp, and check the output voltage change.

4. The voltage will rise with higher intensive light and reduce with lower intensive light.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. With the ( - ) driver, remove the photo sensor (B) from the center of defrost nozzle (A).

3.Install in the reverse order of removal.

Page 693 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "ON"

2. Using the multi- tester, Measure resistance between terminal "1" and "2" of water temperature sensor.

Specification

Coolant temperature [°C(°F)] Resistance (kΩ)Voltage (V)

- 10(14) 55.85 ± 3% 4.24 ± 3%

0(32) 32.91 ± 3% 3.83 ± 3%

10(50) 19.99 ± 3% 3.33 ± 3%

20(68) 12.51 ± 3% 2.78 ± 3%

30(86) 8.047 ± 3% 2.23 ± 3%

40(104) 5.311 ± 3% 1.73 ± 3%

50(122) 3.588 ± 3% 1.32 ± 3%

60(140) 2.476 ± 3% 0.99 ± 3%

70(158) 1.742 ±3% 0.74 ± 3%

80(176) 1.246 ± 3% 0.55 ± 3%

3. If the measured resistance is not specification, substitute with a known- good water temperature sensor and check

for proper operation.

4. If the problem is corrected, replace the water temperature sensor.

Negative type thermistor that resistance will rise with lower temperature, and reduce with higher temperature.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the grove box. (Refer to BD group)

3. Disconnect the connector (B) of water temperature sensor and then remove the water temperature sensor(A) by

pulling out.

Page 698 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF"

2. Disconnect ambient temperature sensor.

3. Check the resistance of ambient temperature sensor between terminals 1 and 2 whether it is changed by changing

of the ambient temperature.

Specification

Ambient temperature [°C(°F)] Resistance between terminals 1and 2 (kΩ)

- 10(14) 164 ± 3%

0 (32) 97.5 ± 3%

10 (50) 59.6 ± 3%

20 (68) 37.5 ± 3%

4.If the measured resistance is not specification, substitute with a known- good ambient temperature sensor and

check for proper operation.

5. If the problem is corrected, replace the ambient temperature sensor.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the front bumper. (Refer to BD group)

3. Remove the ambient temperature sensor (A).

4.Installation is the reverse order of removal.

Page 702 of 1575

2007 > 2.7L V6 GASOLINE >

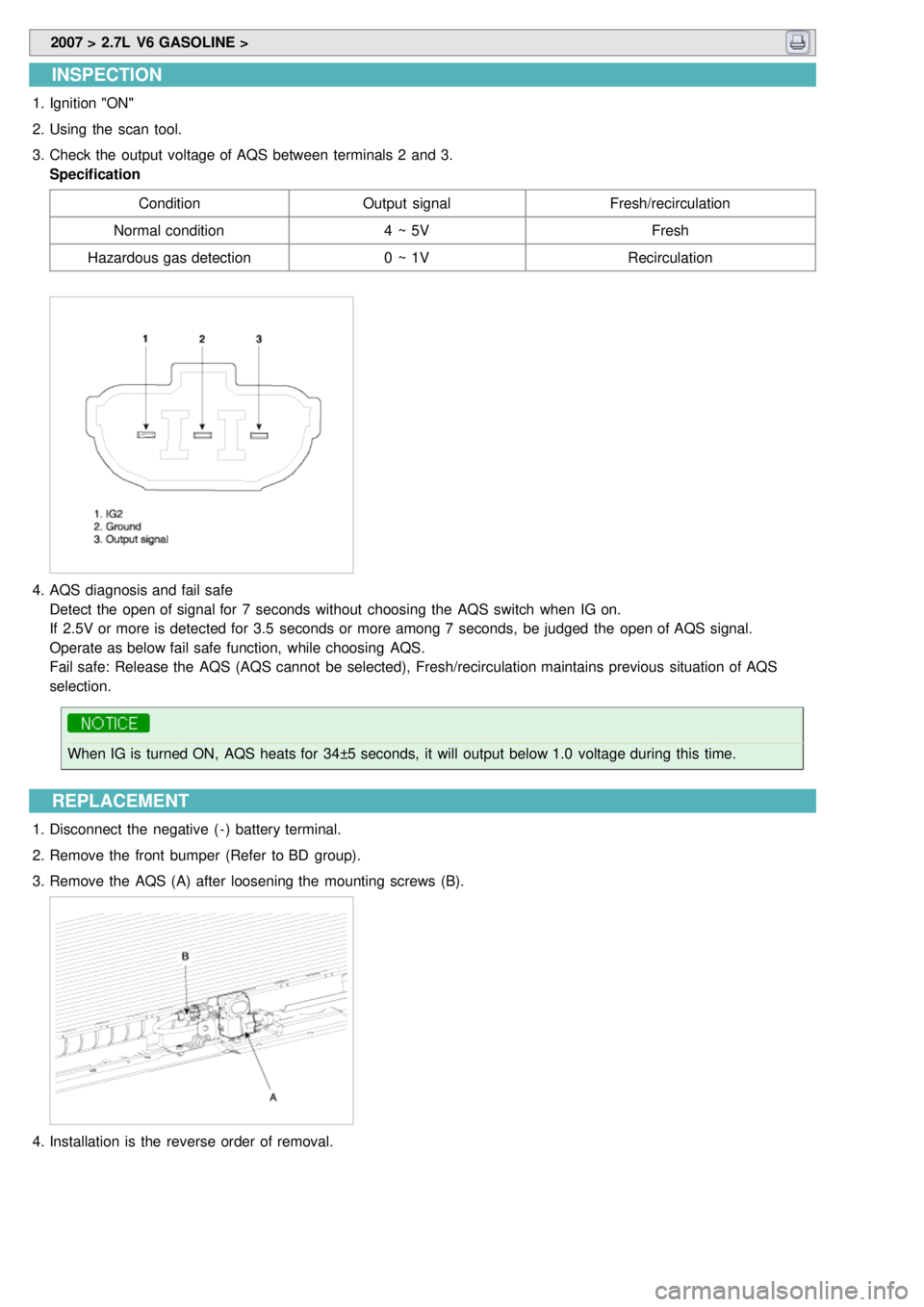

INSPECTION

1.Ignition "ON"

2. Using the scan tool.

3. Check the output voltage of AQS between terminals 2 and 3.

Specification

Condition Output signal Fresh/recirculation

Normal condition 4 ~ 5VFresh

Hazardous gas detection 0 ~ 1VRecirculation

4.AQS diagnosis and fail safe

Detect the open of signal for 7 seconds without choosing the AQS switch when IG on.

If 2.5V or more is detected for 3.5 seconds or more among 7 seconds, be judged the open of AQS signal.

Operate as below fail safe function, while choosing AQS.

Fail safe: Release the AQS (AQS cannot be selected), Fresh/recirculation maintains previous situation of AQS

selection.

When IG is turned ON, AQS heats for 34±5 seconds, it will output below 1.0 voltage during this time.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the front bumper (Refer to BD group).

3. Remove the AQS (A) after loosening the mounting screws (B).

4.Installation is the reverse order of removal.

Page 706 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "ON"

2. Using the scan tool.

3. Check the frequency of humidity sensor between terminals 2 and 3.

Humidity (%) Frequency between terminals 2and 3 (Hz)

30 6976 ± 5%

50 6728 ± 5%

60 6600 ± 5%

70 6468 ± 5%

80 6330 ± 5%

90 6186 ± 5%

4. If the measured resistance is not specification, substitute with a known- good humidity sensor and check for proper

operation.

5. If the problem is corrected, replace the Humidity sensor.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the center facia lower panel (A). (Refer to BD group)

3. Disconnect the humidity sensor connector (A).

4. Loosen 2 screws and then remove the humidity sensor (B).

5.Installation is the reverse order of removal.

Page 713 of 1575

2007 > 2.7L V6 GASOLINE >

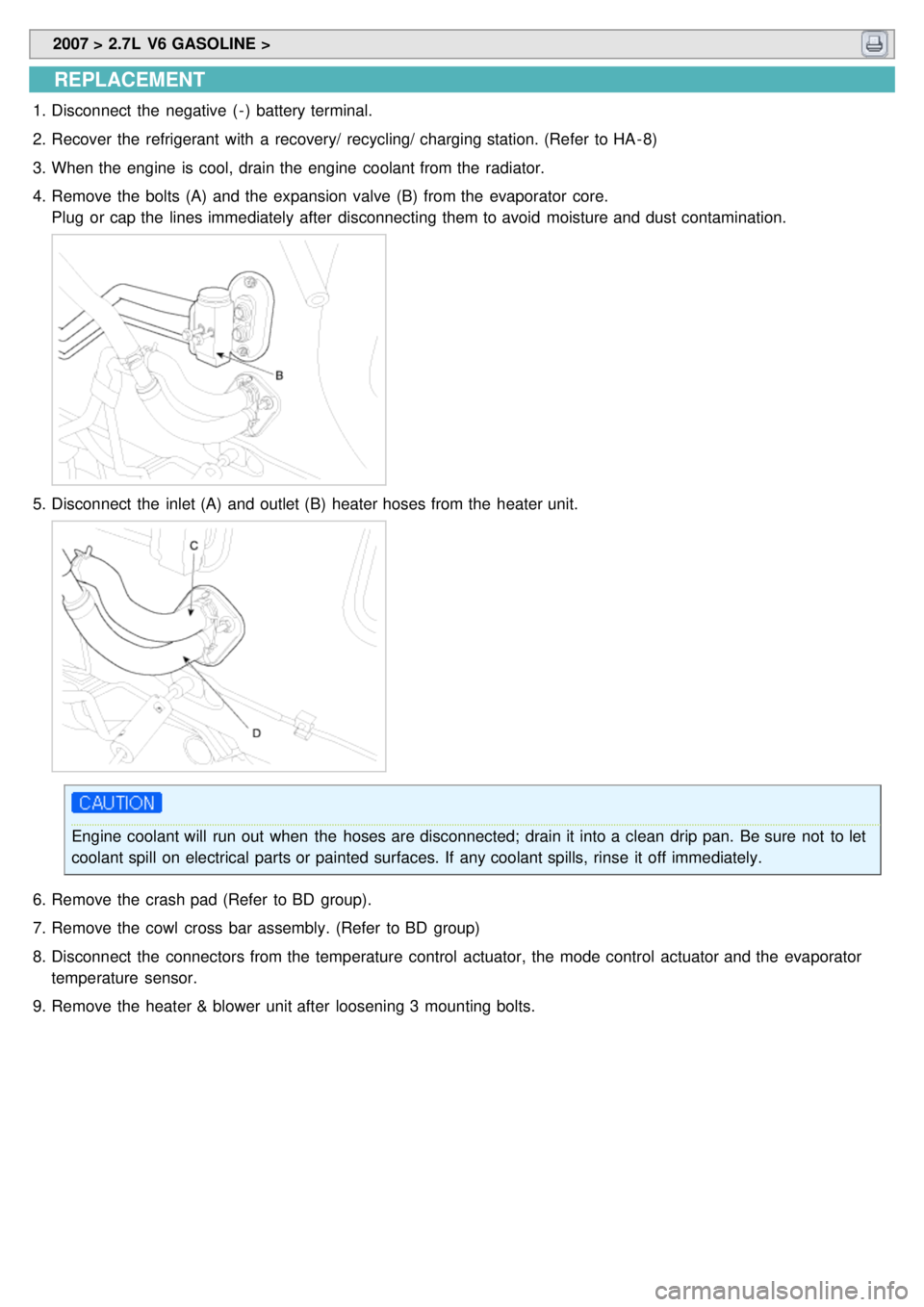

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Recover the refrigerant with a recovery/ recycling/ charging station. (Refer to HA - 8)

3. When the engine is cool, drain the engine coolant from the radiator.

4. Remove the bolts (A) and the expansion valve (B) from the evaporator core.

Plug or cap the lines immediately after disconnecting them to avoid moisture and dust contamination.

5.Disconnect the inlet (A) and outlet (B) heater hoses from the heater unit.

Engine coolant will run out when the hoses are disconnected; drain it into a clean drip pan. Be sure not to let

coolant spill on electrical parts or painted surfaces. If any coolant spills, rinse it off immediately.

6. Remove the crash pad (Refer to BD group).

7. Remove the cowl cross bar assembly. (Refer to BD group)

8. Disconnect the connectors from the temperature control actuator, the mode control actuator and the evaporator

temperature sensor.

9. Remove the heater & blower unit after loosening 3 mounting bolts.

Page 720 of 1575

1.Disconnect the negative ( - ) battery terminal.

2. Remove the driver’s crush pad lower panel (Refer to BD group).

3. Disconnect the temperature control actuator connector (A) after removing the air duct.

4. Loosen the mounting screw and then remove the temperature control actuator (B).

[Passenger's]

[Driver's]

5.Installation is the reverse order of removal.

Page 724 of 1575

2007 > 2.7L V6 GASOLINE >

INSPECTION

1.Ignition "OFF"

2. Disconnect the connector of mode control actuator.

3. Verify that the mode control actuator operates to the defrost mode when connecting 12V to the terminal 1 and

grounding terminal 2.

4. Verify that the mode control actuator operates to the vent mode when connecting in the reverse.

[DRIVER]

[PASSENGER]

5.Check the voltage between terminals 3 and 4.

Door position Voltage (3- 4)Error detecting

Vent 0.4 ± 0.15VLow voltage :0.1V or less

Defrost 4.6 ± 0.15VHigh voltage :4.9V or more

It will feedback current position of actuator to controls.

6. If the measured voltage is not specification, substitute with a known- good mode control actuator and check for

proper operation.

7. If the problem is corrected, replace the mode control actuator.

REPLACEMENT

1.Disconnect the negative ( - ) battery terminal.

2. Remove the driver’s crush pad lower panel (Refer to BD group).

3. Disconnect the temperature control actuator connector (A) after removing the air duct.

4. Loosen the mounting screw and then remove the temperature control actuator (B).

Page 736 of 1575

2007 > 2.7L V6 GASOLINE >

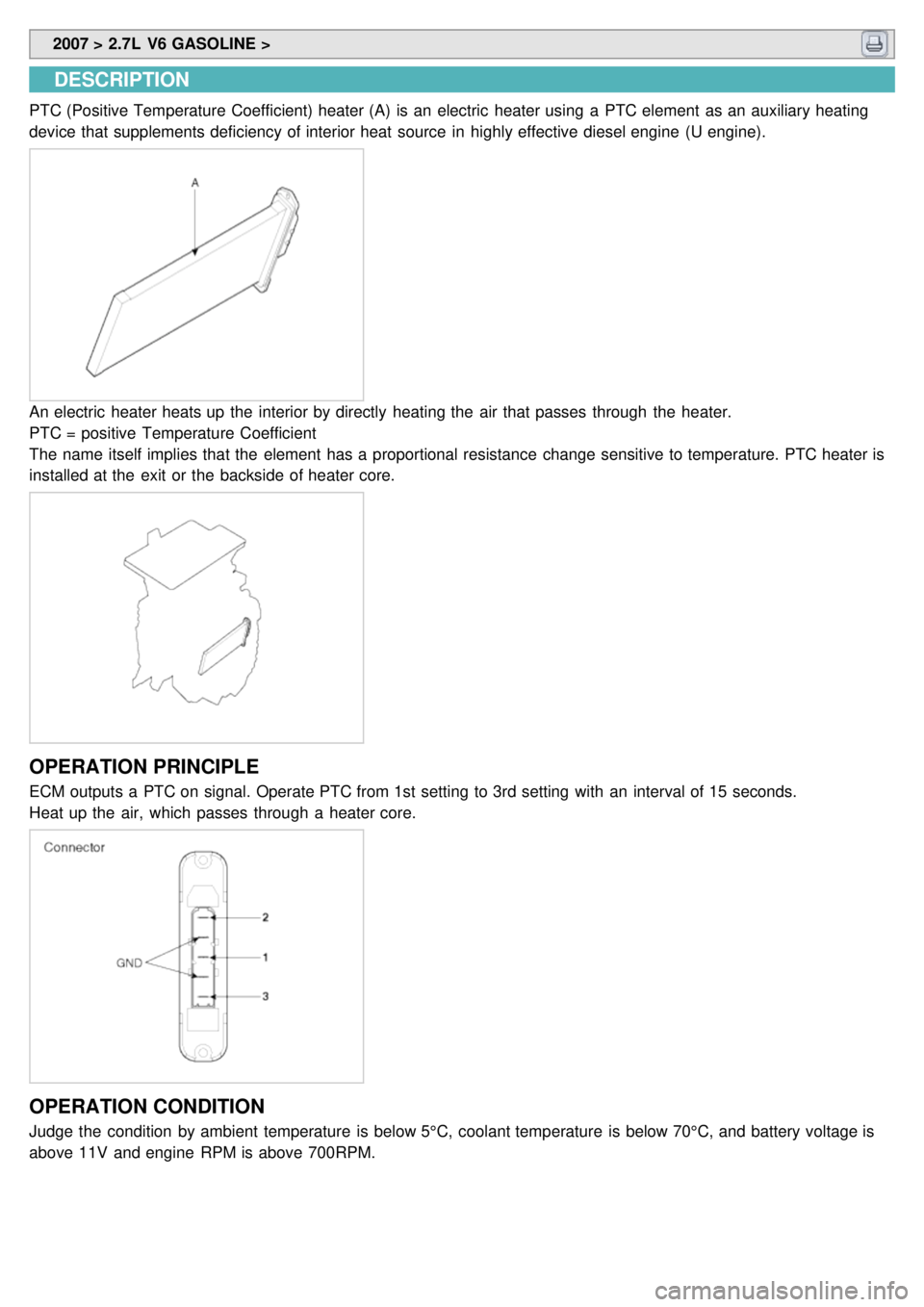

DESCRIPTION

PTC (Positive Temperature Coefficient) heater (A) is an electric heater using a PTC element as an auxiliary heating

device that supplements deficiency of interior heat source in highly effective diesel engine (U engine).

An electric heater heats up the interior by directly heating the air that passes through the heater.

PTC = positive Temperature Coefficient

The name itself implies that the element has a proportional resistance change sensitive to temperature. PTC heater is

installed at the exit or the backside of heater core.

OPERATION PRINCIPLE

ECM outputs a PTC on signal. Operate PTC from 1st setting to 3rd setting with an interval of 15 seconds.

Heat up the air, which passes through a heater core.

OPERATION CONDITION

Judge the condition by ambient temperature is below 5°C, coolant temperature is below 70°C, and battery voltage is

above 11V and engine RPM is above 700RPM.