clutch KIA CARNIVAL 2007 Repair Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2007, Model line: CARNIVAL, Model: KIA CARNIVAL 2007Pages: 1575, PDF Size: 44.86 MB

Page 1459 of 1575

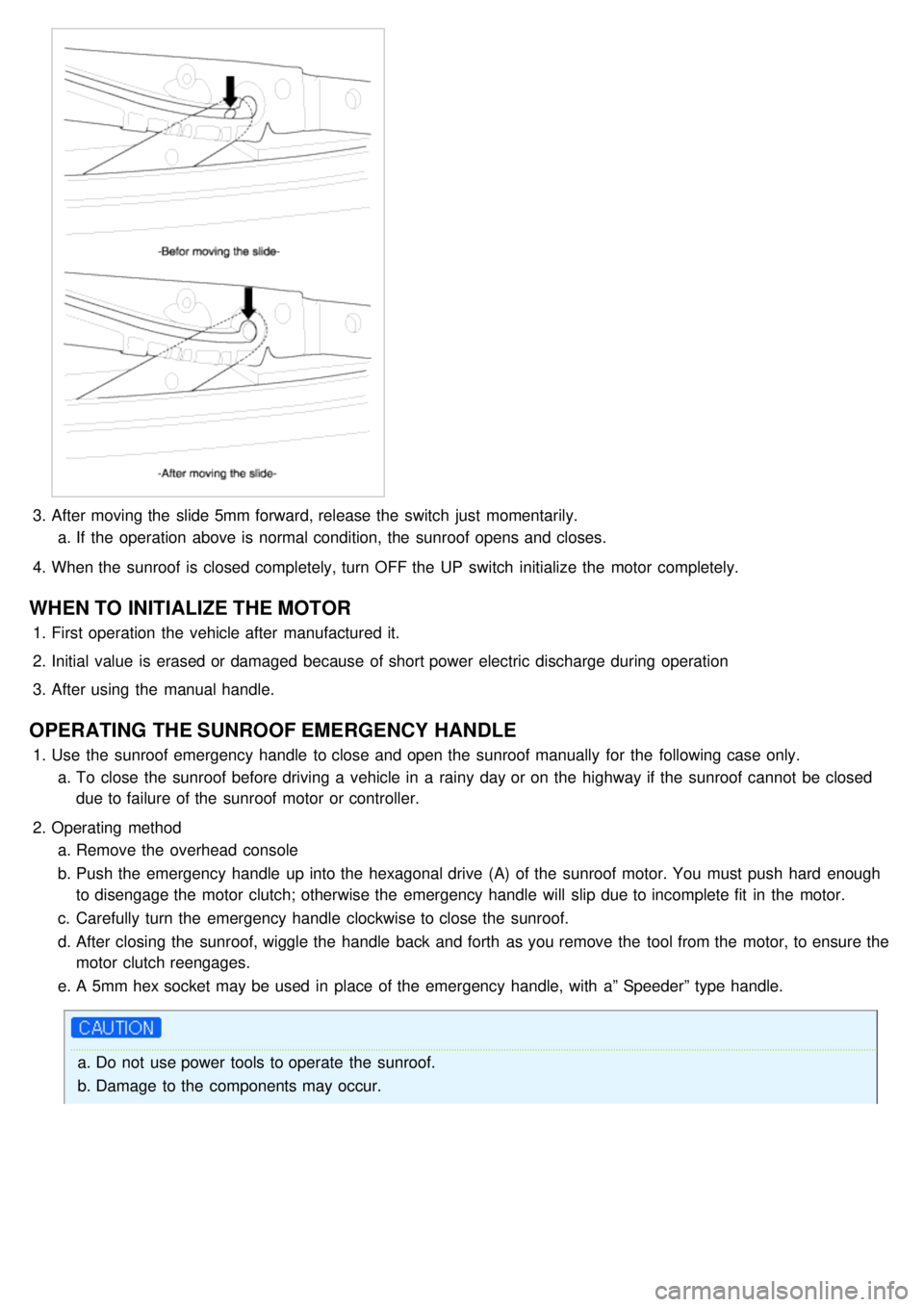

3.After moving the slide 5mm forward, release the switch just momentarily.

a. If the operation above is normal condition, the sunroof opens and closes.

4. When the sunroof is closed completely, turn OFF the UP switch initialize the motor completely.

WHEN TO INITIALIZE THE MOTOR

1.First operation the vehicle after manufactured it.

2. Initial value is erased or damaged because of short power electric discharge during operation

3. After using the manual handle.

OPERATING THE SUNROOF EMERGENCY HANDLE

1.Use the sunroof emergency handle to close and open the sunroof manually for the following case only.

a. To close the sunroof before driving a vehicle in a rainy day or on the highway if the sunroof cannot be closed

due to failure of the sunroof motor or controller.

2. Operating method

a. Remove the overhead console

b. Push the emergency handle up into the hexagonal drive (A) of the sunroof motor. You must push hard enough

to disengage the motor clutch; otherwise the emergency handle will slip due to incomplete fit in the motor.

c. Carefully turn the emergency handle clockwise to close the sunroof.

d. After closing the sunroof, wiggle the handle back and forth as you remove the tool from the motor, to ensure the

motor clutch reengages.

e. A 5mm hex socket may be used in place of the emergency handle, with a” Speeder” type handle.

a.Do not use power tools to operate the sunroof.

b. Damage to the components may occur.

Page 1561 of 1575

CHAPTER 16:

Clutch System

Page 1562 of 1575

2007 > 2.7L V6 GASOLINE >

DESCRIPTION

SELF ADJUSTING CLUTCH(S.A.C.) COVER

a. As a clutch disc facing is worn away according to its durability, a cover weight is increasing and a clutch pedal

pressure can be more needed.

b. To make up for this defect, the self adjusting clutch system makes the requsted pedal pressure minimized so that

makes the maintenance cycle longer.

CONCENTRIC SLAVE CYLINDER-C.S.C.

It improves working efficiency and lowers the number and the weight of part by unifing clutch release control

parts(clutch release bearing ~ clutch release cylinder) in a manual transaxle.

OPERATION

CONCENTRIC SLAVE CYLINDER-C.S.C

When the clutch pedal is pressed, oil pressure is transmitted along the arrow directions shown below and that moves

the clutch slave cylinder and the diaphragm spring of the clutch cover.

Page 1564 of 1575

Clutch Cover And Disc

Page 1566 of 1575

2007 > 2.7L V6 GASOLINE >

REPLACEMENT

1.Remove a transaxle assembly (refer to 'MT'- group).

2. Remove the clutch cover bolts. Not to be bent or twisted, loosen them in diagonal directions.

3.Remove the clutch cover and disc.

4. Using the SST(09411- 43000), install a clutch disc and cover.

a. Replace a clutch cover and disc as a set.

* Possible problems when not following the caution

a. When replacing only a disc, slip problem can occur because of the initial clamp load loss by the adjusting

ring's unusual work.

b. When replacing only a disc, it can be difficult to cut power because the thickness of the disc cannot be

permitted.

b. Apply grease on a disc spline part and transmission input shaft spline part as required.

* Possible problems when not following

a. When not applying: Excessively wear of splines and bad clutch operation

b. When excessively applying: Scattered grease by centrifugal force conteminates the clutch disc. Loss of friction

force can cause a slip

c. The 'T/M SIDE' marked surface should face the transaxle.

→ If the surface face the opposite side, there can be an interference between a disc and a flywheel surface.

Page 1567 of 1575

5.Tighten the clutch cover.

TORQUE:

24.5~35.3Nm (250~360kgf.cm, 18.1~26.0lb - ft) (6EA)

When installing the clutch cover, tighten the bolts in diagonal directions not to be bent or twisted.

* Possible problems when not following

a. When tightening the bolt completely at a time: the clutch cover can be twisted and vibration can occur.

b. On vehicles with self adjusting clutches, it is necessary to follow this caution.

c. Not following tightening torque: There can be bad torque transmission in clutch and relaxation possibility of

bolts.

INSPECTION

1.Inspect diaphragm spring wear which is in contact with a concentric slave cylinder bearing.

Page 1568 of 1575

2.Check the clutch cover and disc surface for wear or crack.

3. Check the clutch disc lining for slipping or oil mark.

4. Measure the depth from a clutch lining surface to a rivet. If the measured value is less than the specification below,

replace it.

Specification: 0.3mm(0.0118inch)

Page 1569 of 1575

Clutch Master Cylinder

Page 1570 of 1575

2007 > 2.7L V6 GASOLINE >

REMOVAL

Do not spill brake fluid on the vehicle; it may damage the paint if brake fluid does contact the paint, wash it off

immediately with water.

1. Remove the brake fluid fron the clutch master cylinder reservoir with a syringe.

2. Clamp the clutch master cylinder hose(A). If there is no enough room for clamping, you can also clamp the hose

from the brake master cylinder side.

3.Disconnect the hose(A) from the cylinder by releasing the clutch master cylinder clamp.

4.Remove the clutch master cylinder mounting bolts(A,B).

One is the engine room, the other near the clutch pedal assembly.

Page 1571 of 1575

5.Remove the pin and washer which connect the clutch pedal with the clutch master cylinder.

6. Remove the clutch master cylinder. It can be helpful to do this step after removing the clutch pedal mounting

bracket.

INSTALLATION

Installation is in the reverse order of removal.

After installation, bleed the clutch hydaulic system.

CONCENTRIC SLAVE CYLINDER AIR BLEEDING PROCEDURE

1.After disconnecting a cap from the concentric slave cylinder air bleeder, insert a vinyl hose in the plug.

2. Loosening the plug screw, press and release the clutch pedal about 10 times.

Hold the air bleeder body not to rotate with a spanner(A). The holding is needed when the plug loosened or

tightened.

3. Tighten the plug during the clutch pedal pressed. Afterwards, raise the pedal with a hand.

TORQUE :

25~29Nm (250~290Kgf.cm, 18.2~21.1lb - ft)

4. After pressing the clutch pedal 3 times more, loosen the plug and retighten it with the pedal pressed. Raise it

again, then.

5. Repeat the step 4 two or three times. (until there is no bubble in the fluid)

a.Do not clamp the pipe of a concentric slave cylinder.

b. Be careful not to damage O - rings.