KIA SEDONA 2019 Owners Manual

Manufacturer: KIA, Model Year: 2019, Model line: SEDONA, Model: KIA SEDONA 2019Pages: 593, PDF Size: 15.93 MB

Page 551 of 593

Maintenance

84

7

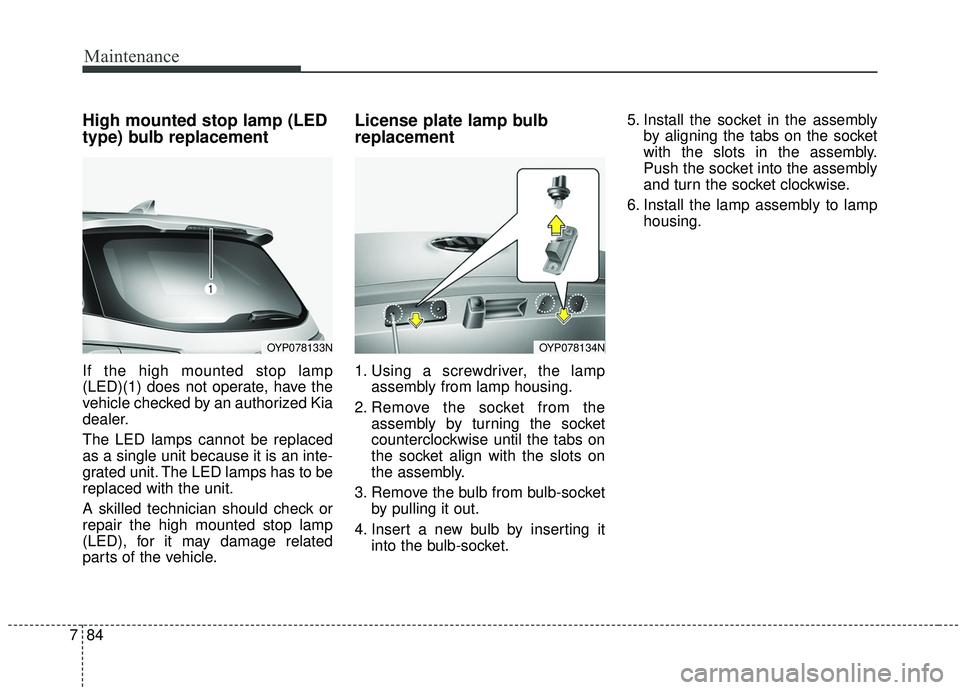

High mounted stop lamp (LED

type) bulb replacement

If the high mounted stop lamp

(LED)(1) does not operate, have the

vehicle checked by an authorized Kia

dealer.

The LED lamps cannot be replaced

as a single unit because it is an inte-

grated unit. The LED lamps has to be

replaced with the unit.

A skilled technician should check or

repair the high mounted stop lamp

(LED), for it may damage related

parts of the vehicle.

License plate lamp bulb

replacement

1. Using a screwdriver, the lamp

assembly from lamp housing.

2. Remove the socket from the assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

3. Remove the bulb from bulb-socket by pulling it out.

4. Insert a new bulb by inserting it into the bulb-socket. 5. Install the socket in the assembly

by aligning the tabs on the socket

with the slots in the assembly.

Push the socket into the assembly

and turn the socket clockwise.

6. Install the lamp assembly to lamp housing.

OYP078133NOYP078134N

Page 552 of 593

785

Maintenance

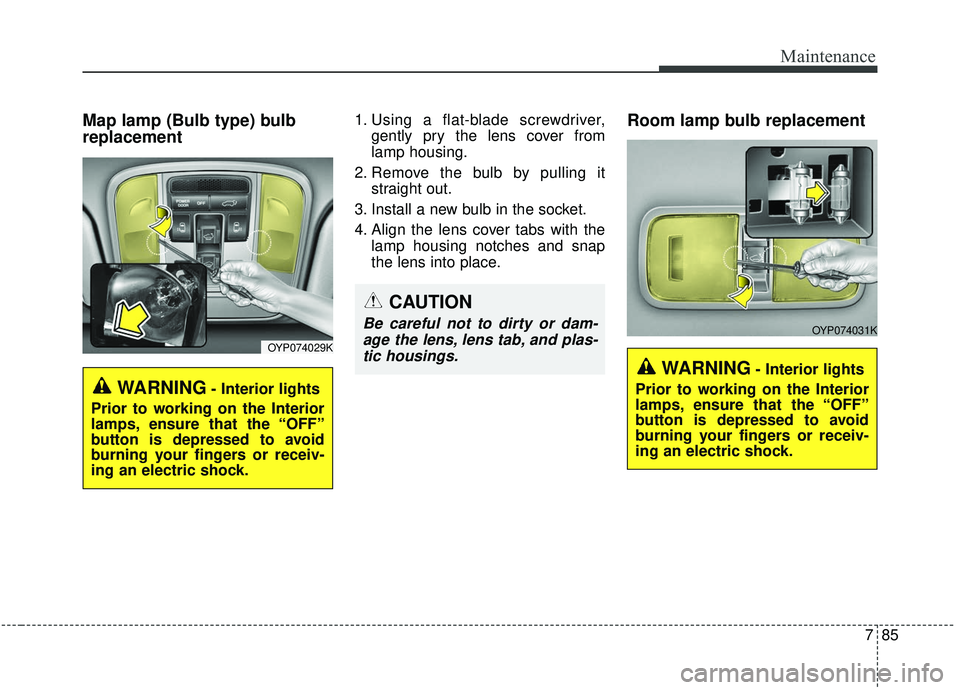

Map lamp (Bulb type) bulb

replacement1. Using a flat-blade screwdriver,gently pry the lens cover from

lamp housing.

2. Remove the bulb by pulling it straight out.

3. Install a new bulb in the socket.

4. Align the lens cover tabs with the lamp housing notches and snap

the lens into place.Room lamp bulb replacement

OYP074029K

WARNING- Interior lights

Prior to working on the Interior

lamps, ensure that the “OFF”

button is depressed to avoid

burning your fingers or receiv-

ing an electric shock.

CAUTION

Be careful not to dirty or dam- age the lens, lens tab, and plas-tic housings.OYP074031K

WARNING- Interior lights

Prior to working on the Interior

lamps, ensure that the “OFF”

button is depressed to avoid

burning your fingers or receiv-

ing an electric shock.

Page 553 of 593

Maintenance

86

7

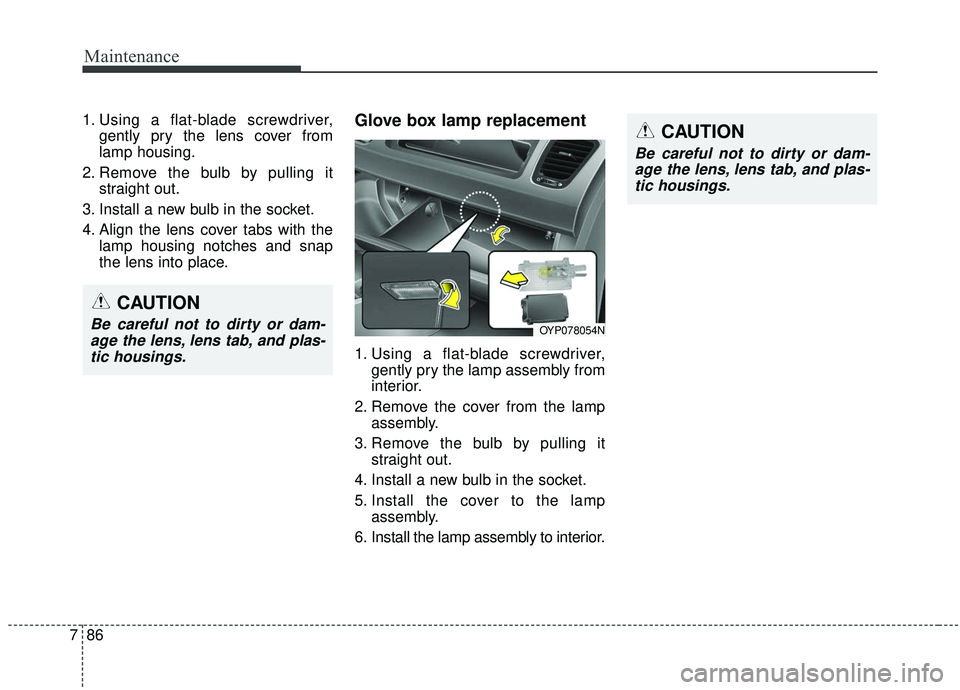

1. Using a flat-blade screwdriver,

gently pry the lens cover from

lamp housing.

2. Remove the bulb by pulling it straight out.

3. Install a new bulb in the socket.

4. Align the lens cover tabs with the lamp housing notches and snap

the lens into place.Glove box lamp replacement

1. Using a flat-blade screwdriver,gently pry the lamp assembly from

interior.

2. Remove the cover from the lamp assembly.

3. Remove the bulb by pulling it straight out.

4. Install a new bulb in the socket.

5. Install the cover to the lamp assembly.

6. Install the lamp assembly to interior.

CAUTION

Be careful not to dirty or dam- age the lens, lens tab, and plas-tic housings.OYP078054N

CAUTION

Be careful not to dirty or dam-age the lens, lens tab, and plas-tic housings.

Page 554 of 593

787

Maintenance

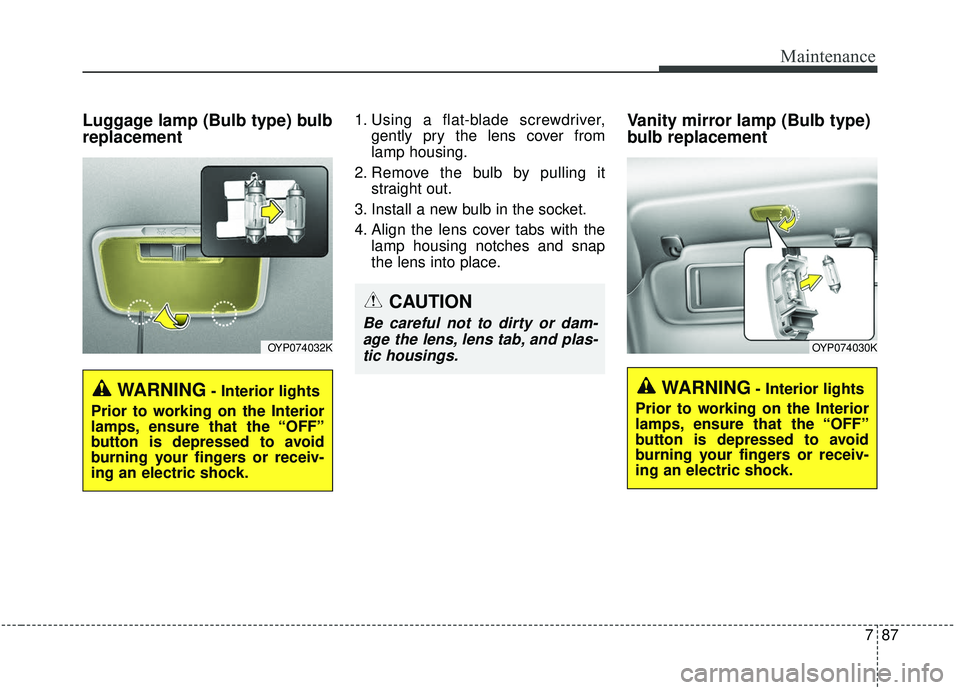

Luggage lamp (Bulb type) bulb

replacement1. Using a flat-blade screwdriver,gently pry the lens cover from

lamp housing.

2. Remove the bulb by pulling it straight out.

3. Install a new bulb in the socket.

4. Align the lens cover tabs with the lamp housing notches and snap

the lens into place.Vanity mirror lamp (Bulb type)

bulb replacement

WARNING- Interior lights

Prior to working on the Interior

lamps, ensure that the “OFF”

button is depressed to avoid

burning your fingers or receiv-

ing an electric shock.

OYP074032K

CAUTION

Be careful not to dirty or dam- age the lens, lens tab, and plas-tic housings.

OYP074030K

WARNING- Interior lights

Prior to working on the Interior

lamps, ensure that the “OFF”

button is depressed to avoid

burning your fingers or receiv-

ing an electric shock.

Page 555 of 593

Maintenance

88

7

1. Using a flat-blade screwdriver,

gently pry the lamp assembly from

interior.

2. Remove the bulb by pulling it straight out.

3. Install a new bulb in the socket.

4. Install the lamp assembly to interior.

CAUTION

Be careful not to dirty or dam- age the lens, lens tab, and plas-tic housings.

Page 556 of 593

789

Maintenance

APPEARANCE CARE

Exterior care

Exterior general caution

It is very important to follow the label

directions when using any chemical

cleaner or polish. Read all warning

and caution statements that appear

on the label.

Finish maintenance

Washing

To help protect your vehicle’s finish

from rust and deterioration, wash it

thoroughly and frequently at least

once a month with lukewarm or cold

water.

If you use your vehicle for off-road

driving, you should wash it after each

off-road trip. Pay special attention to

the removal of any accumulation of

salt, dirt, mud, and other foreign

materials. Make sure the drain holes

in the lower edges of the doors and

rocker panels are kept clear and

clean.

Insects, tar, tree sap, bird droppings,

industrial pollution and similar

deposits can damage your vehicle’s

finish if not removed immediately.

Even prompt washing with plain

water may not completely remove all

these deposits. A mild soap, safe for

use on painted surfaces, may be

used.After washing, rinse the vehicle thor-

oughly with lukewarm or cold water.

Do not allow soap to dry on the fin-

ish.

After washing the vehicle, test the

brakes while driving slowly to see if

they have been affected by water. If

braking performance is impaired, dry

the brakes by applying them lightly

while maintaining a slow forward

speed.

CAUTION - Headlight Lens

To prevent damage, do not

clean headlight lens with chem-ical solvents or strong deter-gents.

Page 557 of 593

Maintenance

90

7

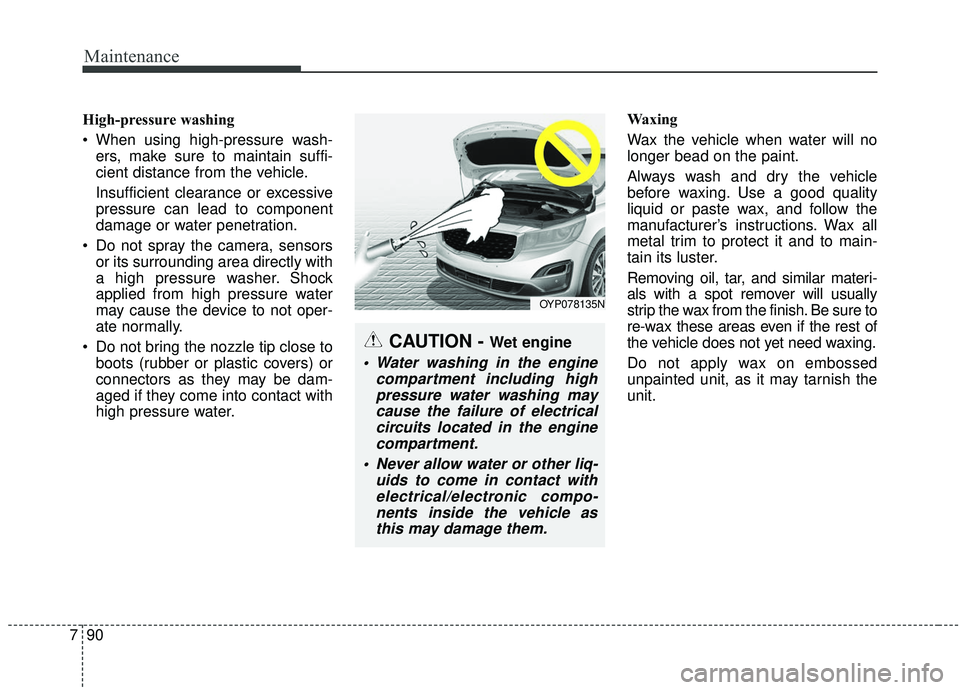

High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water. Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure to

re-wax these areas even if the rest of

the vehicle does not yet need waxing.

Do not apply wax on embossed

unpainted unit, as it may tarnish the

unit.

CAUTION - Wet engine

Water washing in the engine

compartment including highpressure water washing maycause the failure of electricalcircuits located in the enginecompartment.

Never allow water or other liq- uids to come in contact withelectrical/electronic compo-nents inside the vehicle asthis may damage them.

OYP078135N

Page 558 of 593

791

Maintenance

Finish damage repair

Deep scratches or stone chips in the

painted surface must be repaired

promptly. Exposed metal will quickly

rust and may develop into a major

repair expense.

If your vehicle is damaged and

requires any metal repair or replace-

ment, be sure the body shop applies

anti-corrosion materials to the parts

repaired or replaced.

Bright-metal maintenance

To remove road tar and insects,use a tar remover, not a scraper or

other sharp object.

To protect the surfaces of bright- metal parts from corrosion, apply a

coating of wax or chrome preser-

vative and rub to a high luster.

During winter weather or in coastal areas, cover the bright metal parts

with a heavier coating of wax or

preservative. If necessary, coat the

parts with non-corrosive petroleum

jelly or other protective compound.CAUTION - Drying vehicle

Wiping dust or dirt off the body with a dry cloth willscratch the finish.

Do not use steel wool, abra- sive cleaners, acid detergentsor strong detergents contain-ing high alkaline or causticagents on chrome-plated oranodized aluminum parts.This may result in damage tothe protective coating andcause discoloration or paintdeterioration.

Page 559 of 593

Maintenance

92

7

Underbody maintenance

Road salt and other corrosive chem-

icals are used in cold weather states

to melt snow and prevent ice accu-

mulation. If these chemicals are not

regularly removed, they will corrode

the vehicle underbody and over time

damage fuel lines, the fuel tank

retention system, the vehicle sus-

pension, the exhaust system, and

even the body frame. The National

Highway Traffic Safety Administration

has warned all vehicle owners of all

brands of the need to take the follow-

ing steps: Wash the undercarriage of your

vehicle regularly during the winter

and whenever your vehicle has

been exposed to such salts or

chemicals.

Do a thorough washing of the undercarriage at the end of the

winter.

Use professional service techni- cians or governmental inspection

stations to annually inspect for cor-

rosion.

Immediately seek an inspection of your vehicle if you become visually

aware of corrosion flaking or scal-

ing or if you become aware of a

change in vehicle performance,

such as soft or spongy brakes, flu-

ids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.

Aluminum wheel maintenance

The aluminum wheels are coated

with a clear protective finish.

Do not use any abrasive cleaner,polishing compound, solvent, or

wire brushes on aluminum wheels.

They may scratch the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral detergent, and rinse thoroughly

with water. Also, be sure to clean

the wheels after driving on salted

roads. This helps prevent corrosion.

Avoid washing the wheels with highspeed vehicle wash brushes.

Do not use any alkaline or acid detergents It may damage and cor-

rode the aluminum wheels coated

with a clear protective finish.

Page 560 of 593

793

Maintenance

Corrosion protection

Protecting your vehicle from corro-

sion

By using the most advanced design

and construction practices to combat

corrosion, we produce vehicles of

the highest quality. However, this is

only part of the job. To achieve the

long-term corrosion resistance your

vehicle can deliver, the owner's

cooperation and assistance is also

required.

Common causes of corrosion

The most common causes of corro-

sion on your vehicle are:

Road salt, dirt and moisture that isallowed to accumulate underneath

the vehicle.

Removal of paint or protective coatings by stones, gravel, abra-

sion or minor scrapes and dents

which leave unprotected metal

exposed to corrosion. High-corrosion areas

If you live in an area where your vehi-

cle is regularly exposed to corrosive

materials, corrosion protection is

particularly important. Some of the

common causes of accelerated cor-

rosion are road salts, dust control

chemicals, ocean air and industrial

pollution.

Moisture breeds corrosion

Moisture creates the conditions in

which corrosion is most likely to

occur. For example, corrosion is

accelerated by high humidity, partic-

ularly when temperatures are just

above freezing. In such conditions,

the corrosive material is kept in con-

tact with the vehicle’s surface by

moisture that evaporates slowly.

Mud is particularly corrosive

because it dries slowly and holds

moisture in contact with the vehicle.

Although the mud appears to be dry,

it can still retain the moisture and

promote corrosion. High temperatures can also acceler-

ate corrosion of parts that are not

properly ventilated so the moisture

can be dispersed. For all these rea-

sons, it is particularly important to

keep your vehicle clean and free of

mud or accumulations of other mate-

rials. This applies not only to the vis-

ible surfaces but particularly to the

underside of the vehicle.

To help prevent corrosion

You can help prevent corrosion from

beginning by observing the following: