cooling KIA Soul EV 2016 2.G User Guide

[x] Cancel search | Manufacturer: KIA, Model Year: 2016, Model line: Soul EV, Model: KIA Soul EV 2016 2.GPages: 524, PDF Size: 25.82 MB

Page 383 of 524

79

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace. ❈

Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

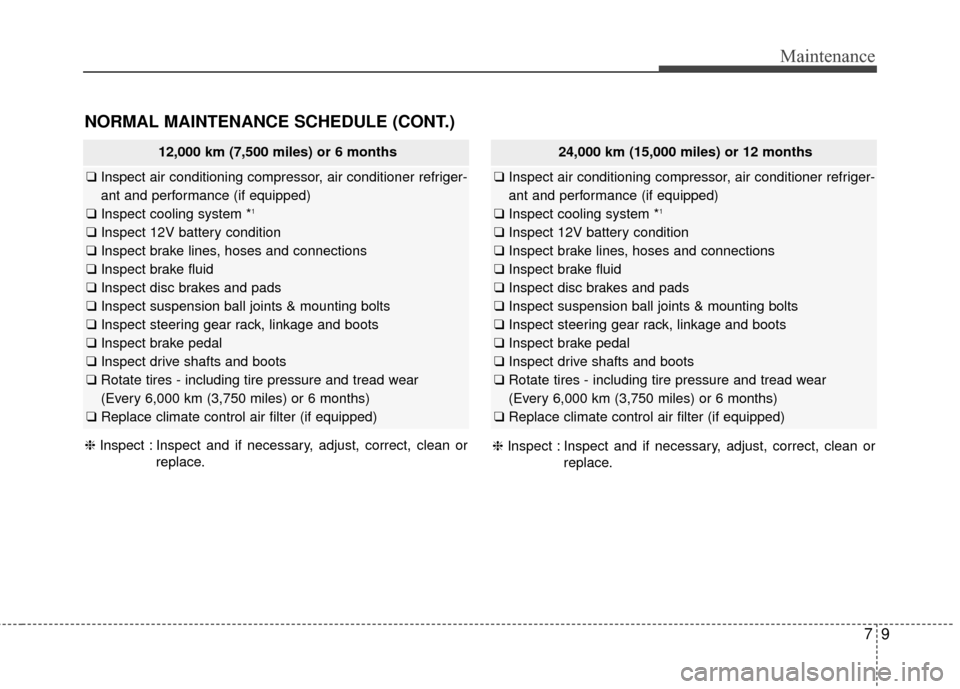

12,000 km (7,500 miles) or 6 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

24,000 km (15,000 miles) or 12 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

Page 384 of 524

Maintenance

10

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

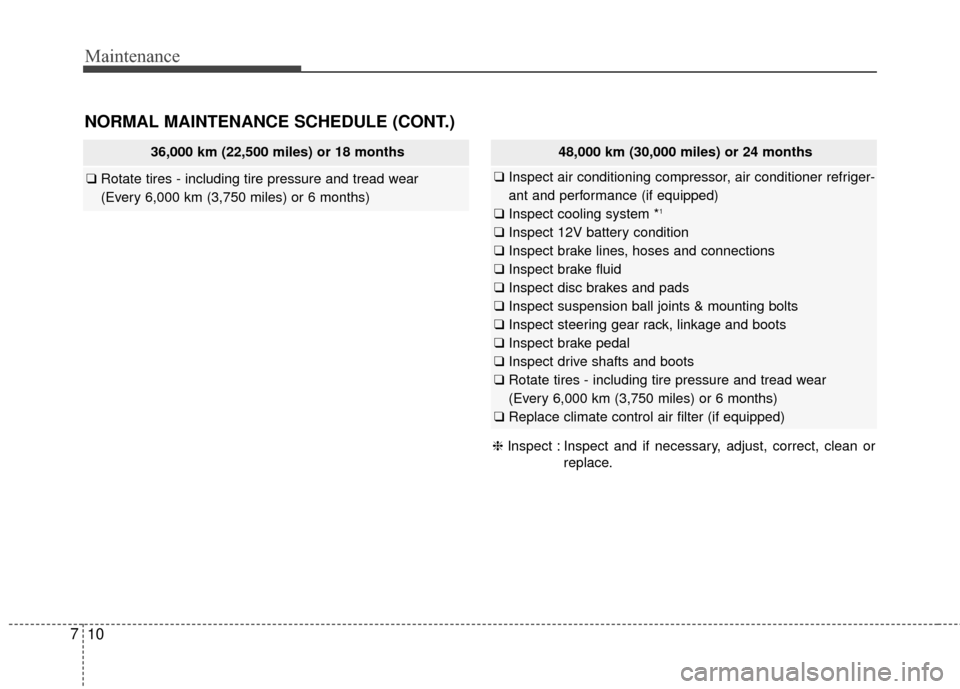

36,000 km (22,500 miles) or 18 months

❑Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

48,000 km (30,000 miles) or 24 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

Page 385 of 524

711

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

❈Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

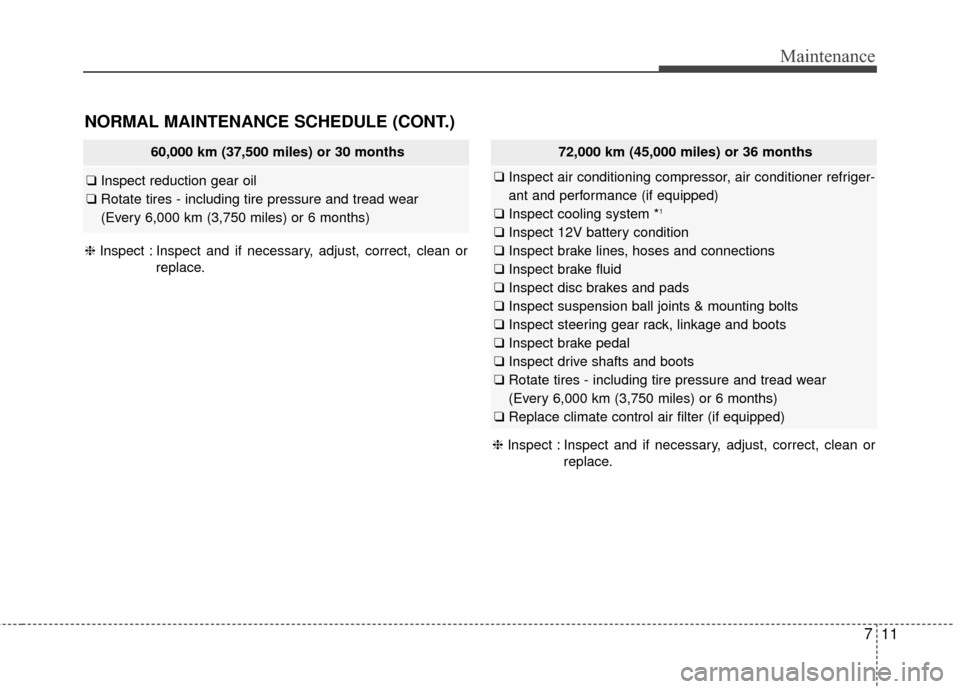

60,000 km (37,500 miles) or 30 months

❑Inspect reduction gear oil

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

72,000 km (45,000 miles) or 36 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 386 of 524

Maintenance

12

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

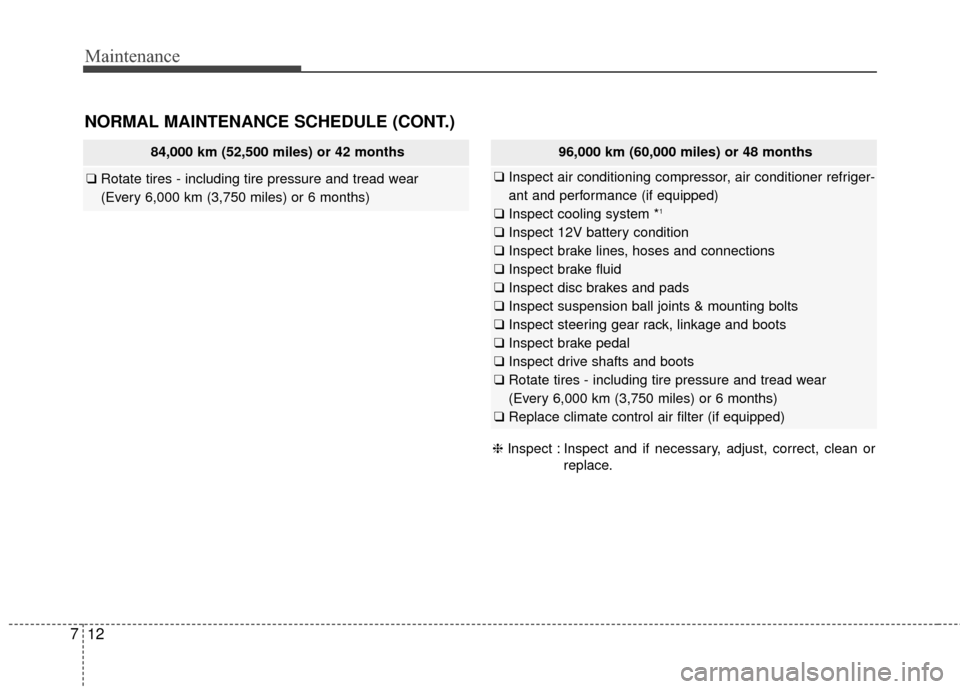

84,000 km (52,500 miles) or 42 months

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

96,000 km (60,000 miles) or 48 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 387 of 524

713

Maintenance

NORMAL MAINTENANCE SCHEDULE (CONT.)

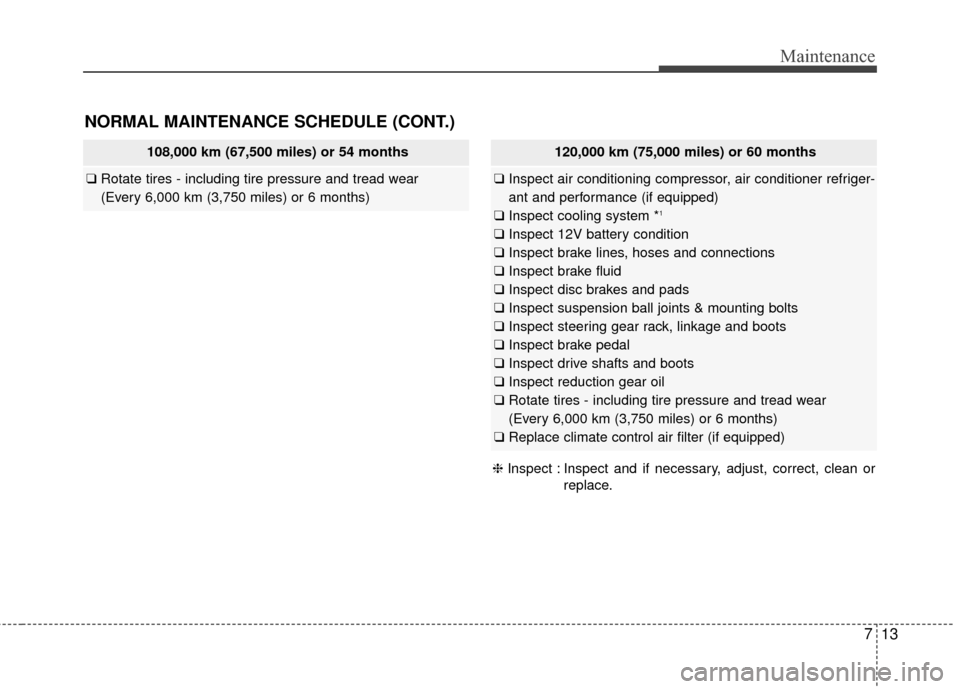

108,000 km (67,500 miles) or 54 months

❑Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

120,000 km (75,000 miles) or 60 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Inspect reduction gear oil

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 388 of 524

Maintenance

14

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

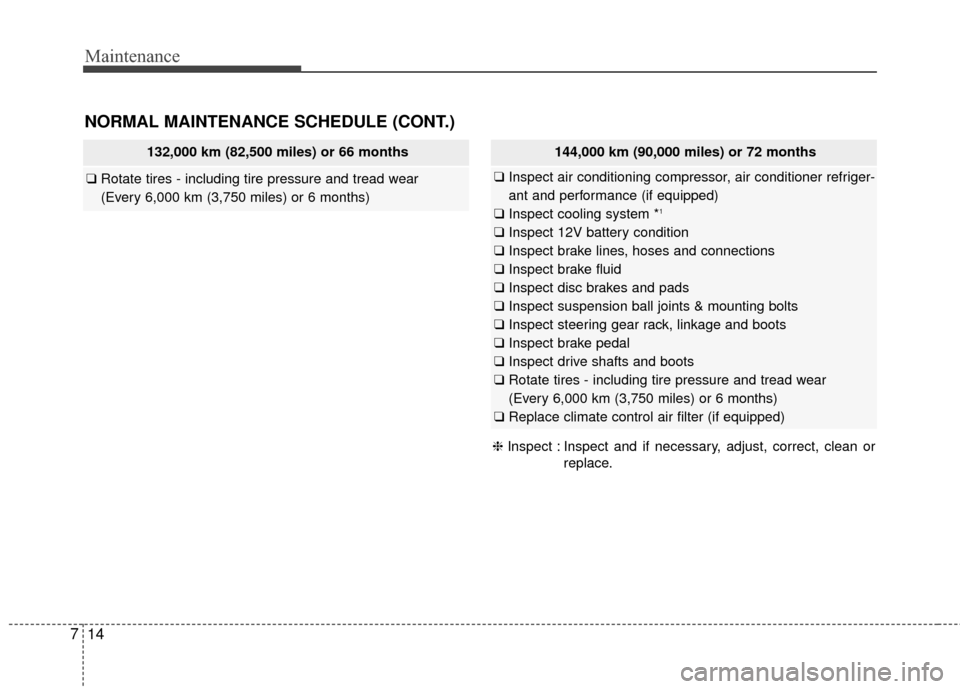

132,000 km (82,500 miles) or 66 months

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

144,000 km (90,000 miles) or 72 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 389 of 524

715

Maintenance

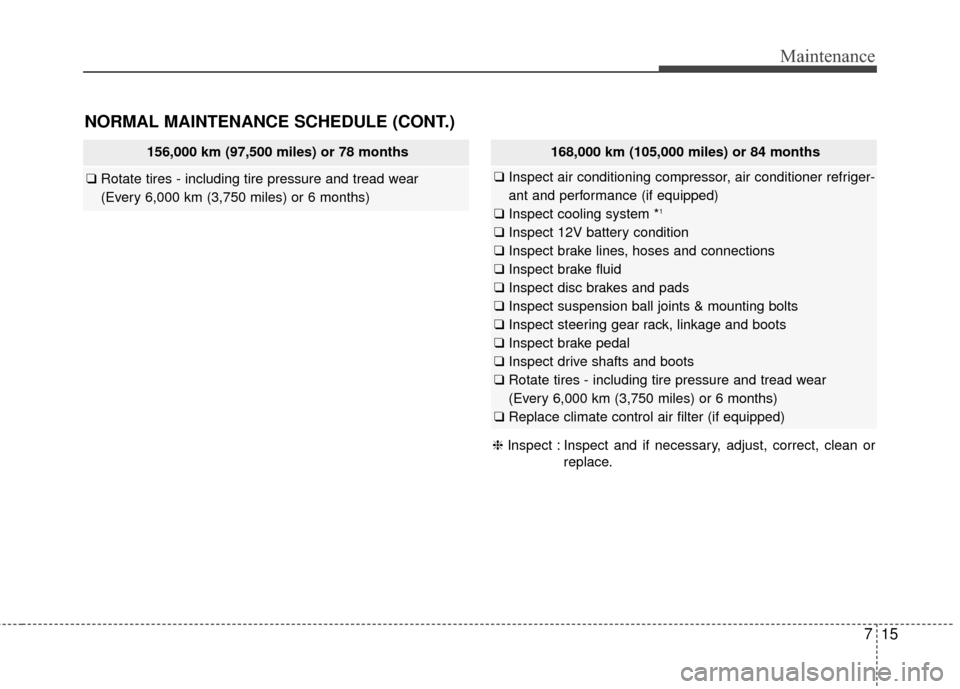

156,000 km (97,500 miles) or 78 months

❑Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

NORMAL MAINTENANCE SCHEDULE (CONT.)

168,000 km (105,000 miles) or 84 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 390 of 524

Maintenance

16

7

NORMAL MAINTENANCE SCHEDULE (CONT.)

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

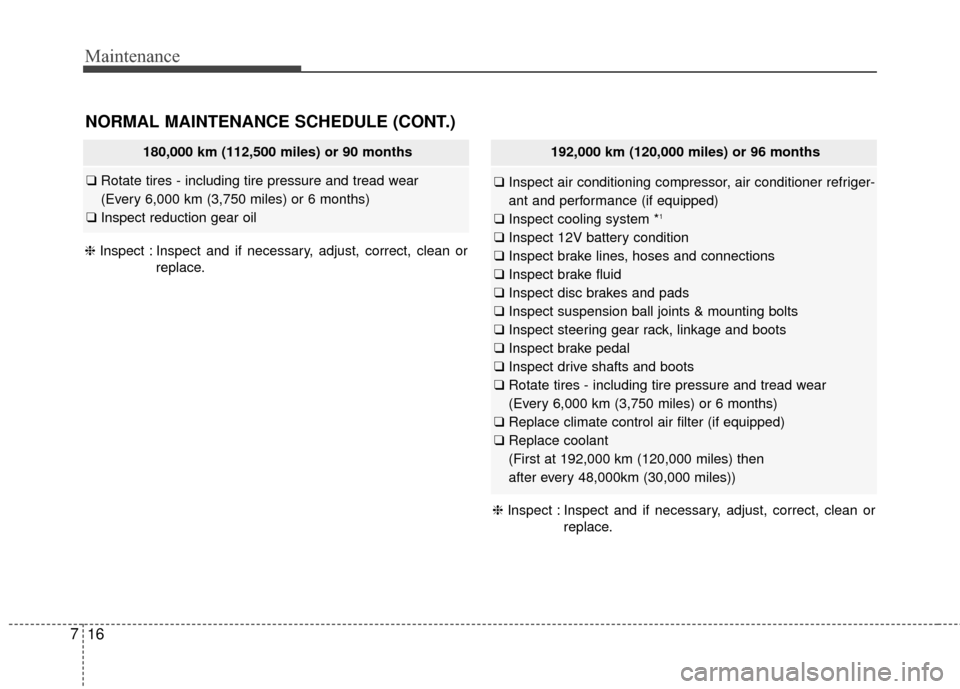

180,000 km (112,500 miles) or 90 months

❑Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Inspect reduction gear oil

192,000 km (120,000 miles) or 96 months

❑Inspect air conditioning compressor, air conditioner refriger-

ant and performance (if equipped)

❑ Inspect cooling system *

1

❑Inspect 12V battery condition

❑ Inspect brake lines, hoses and connections

❑ Inspect brake fluid

❑ Inspect disc brakes and pads

❑ Inspect suspension ball joints & mounting bolts

❑ Inspect steering gear rack, linkage and boots

❑ Inspect brake pedal

❑ Inspect drive shafts and boots

❑ Rotate tires - including tire pressure and tread wear

(Every 6,000 km (3,750 miles) or 6 months)

❑ Replace climate control air filter (if equipped)

❑ Replace coolant

(First at 192,000 km (120,000 miles) then

after every 48,000km (30,000 miles))

❈ Inspect : Inspect and if necessary, adjust, correct, clean or

replace.

Page 393 of 524

719

Maintenance

EXPLANATION OF SCHEDULED MAINTENANCE ITEMS

Cooling system

Check the cooling system compo-

nents, such as the radiator, coolant

reservoir, hoses and connections ,

coolant 3way valve, chiller for leak-

age and damage. Replace any dam-

aged parts.

Coolant

The coolant should be changed at

the intervals specified in the mainte-

nance schedule.

Brake hoses and lines

Visually check for proper installation,

chafing, cracks, deterioration and

any leakage. Replace any deteriorat-

ed or damaged parts immediately.

Brake fluid

Check the brake fluid level in the

brake fluid reservoir. The level should

be between “MIN” and “MAX” marks

on the side of the reservoir. Use only

hydraulic brake fluid conforming to

DOT 3 or DOT 4 specification.

Brake discs, pads, calipers

and rotors

Check the pads for excessive wear,

discs for run out and wear, and

calipers for fluid leakage.

For more information on checking the

pads or lining wear limit, we recom-

mend you to refer to the Kia website.

(http://www

.kia-hotline.com)

Suspension mounting bolts

Check the suspension connections

for looseness or damage. Retighten

to the specified torque.

Steering gear box, linkage &

boots/lower arm ball joint

With the vehicle stopped and off,

check for excessive free-play in the

steering wheel.

Check the linkage for bends or dam-

age. Check the dust boots and ball

joints for deterioration, cracks, or dam-

age. Replace any damaged parts.

Drive shafts and boots

Check the drive shafts, boots and

clamps for cracks, deterioration, or

damage. Replace any damaged

parts and, if necessary, repack the

grease.

Air conditioning refrigerant

Check the air conditioning lines and

connections for leakage and dam-

age.

Page 394 of 524

Maintenance

20

7

COOLANT

The high-pressure cooling system

has a reservoir filled with year round

antifreeze coolant. The reservoir is

filled at the factory.

Check the antifreeze protection and

coolant level at least once a year, at

the beginning of the winter season,

and before traveling to a colder cli-

mate.Checking the coolant levelTurn the vehicle off and wait until it

cools down. Use extreme care when

removing the radiator cap. Wrap a

thick towel around it, and turn it

counterclockwise slowly to the first

stop. Step back while the pressure is

released from the cooling system.

When you are sure all the pressure

has been released, press down on

the cap, using a thick towel, and con-

tinue turning counterclockwise to

remove it.

WARNING

Removing radiator

cap

Never attempt to remove the

radiator cap while the motor

compartment is operating or

hot. Doing so might lead to

cooling system damage and

could result in serious personal

injury from escaping hot

coolant or steam.