ECO KIA SPORTAGE 2018 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: SPORTAGE, Model: KIA SPORTAGE 2018Pages: 605, PDF Size: 13.79 MB

Page 517 of 605

847

Maintenance

Remove the valve cap from the tire

valve stem. Press the tire gauge firm-

ly onto the valve to get a pressure

measurement. If the cold tire inflation

pressure matches the recommended

pressure on the tire and loading

information label, no further adjust-

ment is necessary. If the pressure is

low, add air until you reach the rec-

ommended amount.

If you overfill the tire, release air by

pushing on the metal stem in the

center of the tire valve. Recheck the

tire pressure with the tire gauge. Be

sure to put the valve caps back on

the valve stems. They help prevent

leaks by keeping out dirt and mois-

ture. Inspect your tires frequently for

proper inflation as well as wear and

damage. Always use a tire pres-

sure gauge.

Tires with too much or too little pressure wear unevenly causing

poor handling, loss of vehicle con-

trol, and sudden tire failure leading

to accidents, injuries, and even

death. The recommended cold tire

pressure for your vehicle can be

found in this manual and on the tire

label located on the driver's side

center pillar.

Remember to check the pressure of your spare tire. Kia recommends

that you check the spare every

time you check the pressure of the

other tires on your vehicle.Tire rotation

To equalize tread wear, it is recom-

mended that the tires be rotated

every 7,500 miles (12,000 km) or

sooner if irregular wear develops.

During rotation, check the tires for

correct balance.

When rotating tires, check for uneven

wear and damage. Abnormal wear is

usually caused by incorrect tire pres-

sure, improper wheel alignment, out-

of-balance wheels, severe braking or

severe cornering. Look for bumps or

bulges in the tread or side of tire.

Replace the tire if you find either of

these conditions. Replace the tire if

fabric or cord is visible. After rotation,

be sure to bring the front and rear tire

pressures to specification and check

lug nut tightness.

Refer to “Tire and wheels” in chapter

9.

Page 519 of 605

849

Maintenance

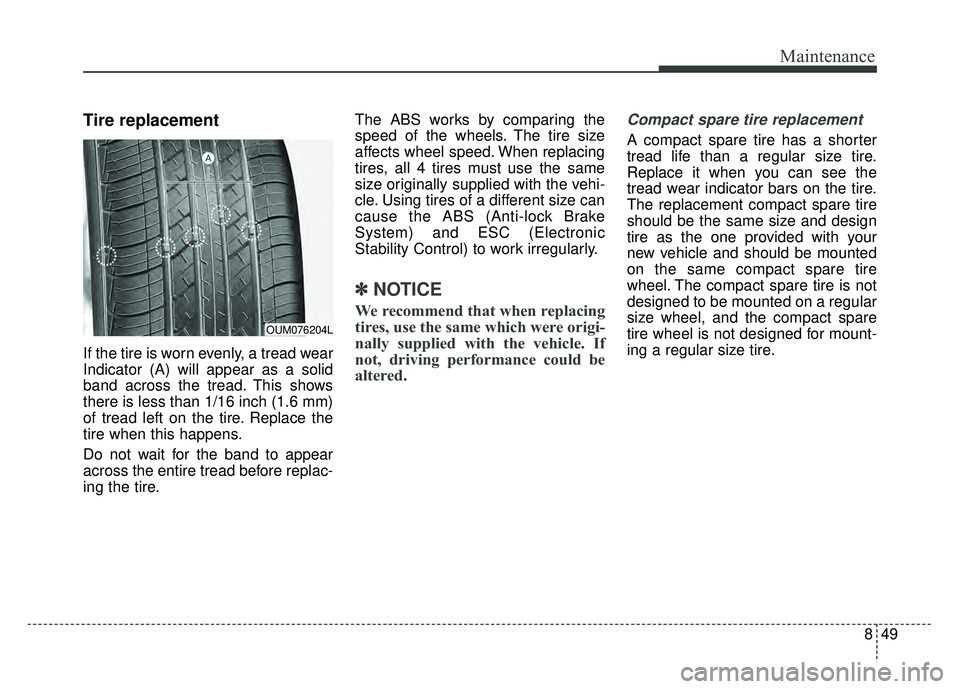

Tire replacement

If the tire is worn evenly, a tread wear

Indicator (A) will appear as a solid

band across the tread. This shows

there is less than 1/16 inch (1.6 mm)

of tread left on the tire. Replace the

tire when this happens.

Do not wait for the band to appear

across the entire tread before replac-

ing the tire.The ABS works by comparing the

speed of the wheels. The tire size

affects wheel speed. When replacing

tires, all 4 tires must use the same

size originally supplied with the vehi-

cle. Using tires of a different size can

cause the ABS (Anti-lock Brake

System) and ESC (Electronic

Stability Control) to work irregularly.

✽ ✽

NOTICE

We recommend that when replacing

tires, use the same which were origi-

nally supplied with the vehicle. If

not, driving performance could be

altered.

Compact spare tire replacement

A compact spare tire has a shorter

tread life than a regular size tire.

Replace it when you can see the

tread wear indicator bars on the tire.

The replacement compact spare tire

should be the same size and design

tire as the one provided with your

new vehicle and should be mounted

on the same compact spare tire

wheel. The compact spare tire is not

designed to be mounted on a regular

size wheel, and the compact spare

tire wheel is not designed for mount-

ing a regular size tire.

OUM076204L

Page 522 of 605

Maintenance

52

8

3. Checking tire life (TIN : Tire

Identification Number)

Any tires that are over 6 years old,

based on the manufacturing date,

(including the spare tire) should be

replaced by new ones. You can find

the manufacturing date on the tire

sidewall (possibly on the inside of the

wheel), displaying the DOT Code.

The DOT Code is a series of num-

bers on a tire consisting of numbers

and English letters. The manufactur-

ing date is designated by the last four

digits (characters) of the DOT code.

DOT : XXXX XXXX OOOO

The front part of the DOT means a

plant code number, tire size and

tread pattern and the last four num-

bers indicate week and year manu-

factured.

For example:

DOT XXXX XXXX 1617 represents

that the tire was produced in the 16th

week of 2017.

4. Tire ply composition and mate-rial

The number of layers or plies of rub-

ber-coated fabric in the tire. Tire

manufacturers also must indicate the

materials in the tire, which include

steel, nylon, polyester, and others.

The letter "R" means radial ply con-

struction; the letter "D" means diago-

nal or bias ply construction; and the

letter "B" means belted-bias ply con-

struction.

5. Maximum permissible inflationpressure

This number is the greatest amount of

air pressure that should be put in the

tire. Do not exceed the maximum per-

missible inflation pressure. Refer to

the Tire and Loading Information label

for recommended inflation pressure.

6. Maximum load rating

This number indicates the maximum

load in kilograms and pounds that can

be carried by the tire. When replacing

the tires on the vehicle, always use a

tire that has the same load rating as

the factory installed tire.

7. Uniform tire quality grading

Quality grades can be found where

applicable on the tire sidewall

between tread shoulder and maxi-

mum section width.

For example:

TREADWEAR 440

TRACTION A

TEMPERATURE A

WARNING - Tire age

Replace tires within the recom-

mended time frame. Failure to

replace tires as recommended

can result in sudden tire failure,

which could lead to a loss of

control and an accident.

Page 523 of 605

853

Maintenance

Tread wear

The tread wear grade is a compara-

tive rating based on the wear rate of

the tire when tested under controlled

conditions on a specified govern-

ment test course. For example, a tire

graded 150 would wear one-and-a-

half times (1½) as well on the gov-

ernment course as a tire graded 100.

The relative performance of tires

depends upon the actual conditions

of their use, however, and may

depart significantly from the norm

due to variations in driving habits,

service practices and differences in

road characteristics and climate.Tires degrade over time, even when

they are not being used. Regardless

of the remaining tread, we recom-

mend that tires be replaced after

approximately six (6) years of normal

service. Heat caused by hot climates

or frequent high loading conditions

can accelerate the aging process.

These grades are molded on the

side-walls of passenger vehicle tires.

The tires available as standard or

optional equipment on your vehicles

may vary with respect to grade.

Traction - AA, A, B & C

The traction grades, from highest to

lowest, are AA, A, B and C. Those

grades represent the tires ability to

stop on wet pavement as measured

under controlled conditions on spec-

ified government test surfaces of

asphalt and concrete. A tire marked

C may have poor traction perform-

ance.

The traction grade assigned to this

tire is based on straight-ahead brak-

ing traction tests, and does not

include acceleration, cornering,

hydroplaning, or peak traction char-

acteristics.

Page 526 of 605

Maintenance

56

8

Production options weight: The

combined weight of installed regular

production options weighing over 5

lb.(2.3 kg) in excess of the standard

items which they replace, not previ-

ously considered in curb weight or

accessory weight, including heavy

duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure:

Vehicle manufacturer's recommend-

ed tire inflation pressure and shown

on the tire placard.

Radial Ply Tire: A pneumatic tire in

which the ply cords that extend to the

beads are laid at 90 degrees to the

centerline of the tread.

Rim: A metal support for a tire and

upon which the tire beads are seat-

ed.

Sidewall: The portion of a tire

between the tread and the bead. Speed Rating:

An alphanumeric

code assigned to a tire indicating the

maximum speed at which a tire can

operate.

Traction: The friction between the

tire and the road surface. The

amount of grip provided.

Tread: The portion of a tire that

comes into contact with the road.

Treadwear Indicators: Narrow

bands, sometimes called "wear

bars," that show across the tread of a

tire when only 1/16 inch of tread

remains.

UTQGS: Uniform Tire Quality

Grading Standards, a tire information

system that provides consumers with

ratings for a tire's traction, tempera-

ture and treadwear. Ratings are

determined by tire manufacturers

using government testing proce-

dures. The ratings are molded into

the sidewall of the tire.

Vehicle Capacity Weight: The num-

ber of designated seating positions

multiplied by 150 lbs. (68kg) plus the

rated cargo and luggage load. Vehicle Maximum Load on the

Tire:

Load on an individual tire due

to curb and accessory weight plus

maximum occupant and cargo

weight.

Vehicle Normal Load on the Tire:

Load on an individual tire that is

determined by distributing to each

axle its share of the curb weight,

accessory weight, and normal occu-

pant weight and driving by 2.

Vehicle Placard: A label permanent-

ly attached to a vehicle showing the

original equipment tire size and rec-

ommended inflation pressure.

Page 527 of 605

857

Maintenance

All season tires

Kia specifies all season tires on

some models to provide good per-

formance for use all year round,

including snowy and icy road condi-

tions. All season tires are identified

by ALL SEASON and/or M+S (Mud

and Snow) on the tire sidewall. Snow

tires have better snow traction than

all season tires and may be more

appropriate in some areas.

Summer tires

Kia specifies summer tires on some

models to provide superior perform-

ance on dry roads. Summer tire per-

formance is substantially reduced in

snow and ice. Summer tires do not

have the tire traction rating M+S

(Mud and Snow) on the tire side wall.

If you plan to operate your vehicle in

snowy or icy conditions, Kia recom-

mends the use of snow tires or all

season tires on all four wheels.

Snow tires

If you equip your car with snow tires,

they should be the same size and

have the same load capacity as the

original tires. Snow tires should be

installed on all four wheels; other-

wise, poor handling may result.

Snow tires should carry 4 psi (28

kPa) more air pressure than the

pressure recommended for the stan-

dard tires on the tire label on the dri-

ver's side of the center pillar, or up to

the maximum pressure shown on the

tire sidewall, whichever is less.

Do not drive faster than 75 mph (120

km/h) when your vehicle is equipped

with snow tires.

Tire chains

Tire chains, if necessary, should be

installed on the front wheels.

Be sure that the chains are installed

in accordance with the manufactur-

er's instructions.

To minimize tire and chain wear, do

not continue to use tire chains when

they are no longer needed.

When driving on roads coveredwith snow or ice, drive at less than

20 mph (30 km/h).

Use the SAE “S” class or wire chains.

If you hear noise caused by chains contacting the body, retighten the

chain to avoid contact with the

vehicle body.

To prevent body damage, retighten the chains after driving 0.3~0.6

miles (0.5~1.0 km).

Do not use tire chains on vehicles equipped with aluminum wheels.

In unavoidable circumstances, use

a wire type chain.

Use wire chains less than 0.47 inches (12 mm) to prevent damage

to the chain’s connection.

Page 528 of 605

Maintenance

58

8

Radial-ply tires

Radial-ply tires provide improved

tread life, road hazard resistance and

smoother high speed ride. The radi-

al-ply tires used on this vehicle are

of belted construction and are select-

ed to complement the ride and han-

dling characteristics of your vehicle.

Radial-ply tires have the same load

carrying capacity as bias-ply or bias

belted tires of the same size and use

the same recommended inflation

pressure. Mixing of radial-ply tires

with bias-ply or bias belted tires is

not recommended. Any combina-

tions of radial-ply and bias-ply or bias

belted tires when used on the same

vehicle will seriously deteriorate

vehicle handling. The best rule to fol-

low is: identical radial-ply tires should

always be used as a set of four. Longer wearing tires can be more

susceptible to irregular tread wear. It

is very important to follow the tire

rotation interval shown in this section

to achieve the tread life potential of

these tires. Cuts and punctures in

radial-ply tires are repairable only in

the tread area, because of sidewall

flexing. Consult your tire dealer for

radial-ply tire repairs.

Low aspect ratio tire

(if equipped)

Low aspect ratio tires, whose aspect

ratio is lower than 50, are provided

for sporty looks.

Because the low aspect ratio tires

are optimized for handling and brak-

ing, it may be more uncomfortable to

ride in and there is more noise com-

pare with normal tires.

Page 529 of 605

859

Maintenance

It is not easy to recognize the tiredamage with your own eyes. But if

there is the slightest hint of tire

damage, even though you cannot

see it, have the tire checked or

replaced because the tire damage

may cause air leakage from the tire.

If the tire is damaged by driving on a rough road, off road, pothole,

manhole, or curb stone, it will not

be covered by the warranty.

You can find out the tire information on the tire sidewall.CAUTION

Because the sidewall of the lowaspect ratio tire is shorter thanthe normal, the wheel and tire ofthe low aspect ratio tire is easi-er to be damaged. So, follow theinstructions below.

- When driving on a rough road or off road, drive cautiouslybecause tires and wheels maybe damaged. And after driv-ing, inspect tires and wheels.

- When passing over a pothole, speed bump, manhole, or curbstone, drive slowly so that thetires and wheels are not dam-aged.

- If the tire is impacted, we rec- ommend that you inspect thetire condition or contact anauthorized Kia dealer.

- To prevent damage to the tire, inspect the tire condition andpressure every 1,900 miles(3,000 km).

Page 548 of 605

Maintenance

78

8

LIGHT BULBS

Bulb replacement precaution

Please keep extra bulbs on hand

with appropriate wattage ratings in

case of emergencies.

Refer to “Bulb Wattage” in chapter 9.

When changing lamps, first turn off

the engine at a safe place, firmly

apply the parking brake and detach

the battery’s negative (-) terminal.

Use only bulbs of the specified

wattage.✽ ✽ NOTICE

• If the light bulb or lamp connector

is removed while the lamp is still

on, the fuse box's electronic sys-

tem may log it as a malfunction.

Therefore, a lamp malfunction

incident may be recorded as a

Diagnostic Trouble Code (DTC) in

the fuse box.

• It is normal for an operating lamp to flicker momentarily. This is due

to a stabilization function of the

vehicle’s electronic control device.

If the lamp lights up normally

after momentarily blinking, then

it is functioning as normal.

However, if the lamp continues to

flicker several times or turns off

completely, there may be an error

in the vehicle’s electronic control

device. Please have the vehicle

checked by an authorized Kia

dealer immediately.

WARNING- Working on

the lights

Prior to working on the light,

firmly apply the parking brake,

ensure that the ignition switch

is turned to the LOCK position

and turn off the lights to avoid

sudden movement of the vehi-

cle and burning your fingers or

receiving an electric shock.

CAUTION -Light replace-

ment

Be sure to replace the burned- out bulb with one of the samewattage rating. Otherwise, itmay cause damage to the fuseor electric wiring system.

CAUTION -Headlamp

Lens

To prevent damage, do notclean the headlamp lens withchemical solvents or strongdetergents.

Page 553 of 605

883

Maintenance

Always handle them carefully, andavoid scratches and abrasions. If

the bulbs are lit, avoid contact with

liquids. Never touch the glass with

bare hands. Residual oil may

cause the bulb to overheat and

burst when lit. A bulb should be

operated only when installed in a

headlamp.

If a bulb becomes damaged or cracked, replace it immediately

and carefully dispose of it.

Wear eye protection when chang- ing a bulb. Allow the bulb to cool

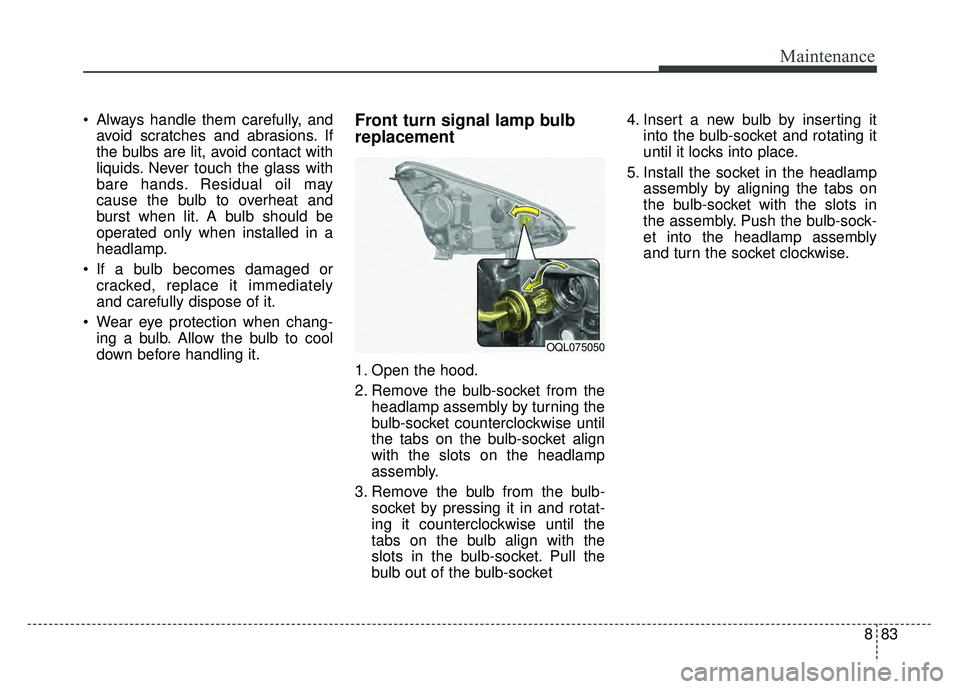

down before handling it.Front turn signal lamp bulb

replacement

1. Open the hood.

2. Remove the bulb-socket from the headlamp assembly by turning the

bulb-socket counterclockwise until

the tabs on the bulb-socket align

with the slots on the headlamp

assembly.

3. Remove the bulb from the bulb- socket by pressing it in and rotat-

ing it counterclockwise until the

tabs on the bulb align with the

slots in the bulb-socket. Pull the

bulb out of the bulb-socket 4. Insert a new bulb by inserting it

into the bulb-socket and rotating it

until it locks into place.

5. Install the socket in the headlamp assembly by aligning the tabs on

the bulb-socket with the slots in

the assembly. Push the bulb-sock-

et into the headlamp assembly

and turn the socket clockwise.

OQL075050