ECO KIA SPORTAGE 2018 Owners Manual

[x] Cancel search | Manufacturer: KIA, Model Year: 2018, Model line: SPORTAGE, Model: KIA SPORTAGE 2018Pages: 605, PDF Size: 13.79 MB

Page 554 of 605

Maintenance

84

8

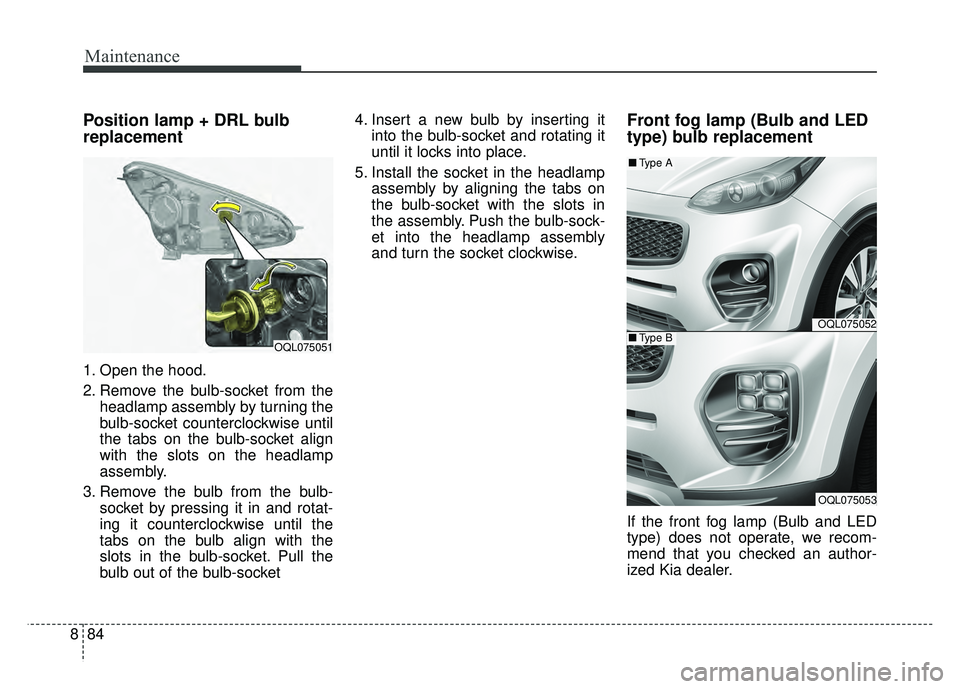

Position lamp + DRL bulb

replacement

1. Open the hood.

2. Remove the bulb-socket from the

headlamp assembly by turning the

bulb-socket counterclockwise until

the tabs on the bulb-socket align

with the slots on the headlamp

assembly.

3. Remove the bulb from the bulb- socket by pressing it in and rotat-

ing it counterclockwise until the

tabs on the bulb align with the

slots in the bulb-socket. Pull the

bulb out of the bulb-socket 4. Insert a new bulb by inserting it

into the bulb-socket and rotating it

until it locks into place.

5. Install the socket in the headlamp assembly by aligning the tabs on

the bulb-socket with the slots in

the assembly. Push the bulb-sock-

et into the headlamp assembly

and turn the socket clockwise.

Front fog lamp (Bulb and LED

type) bulb replacement

If the front fog lamp (Bulb and LED

type) does not operate, we recom-

mend that you checked an author-

ized Kia dealer.

OQL075051

OQL075052

OQL075053

■Type A

■Type B

Page 557 of 605

887

Maintenance

6. Install the socket in the assemblyby aligning the tabs on the socket

with the slots in the assembly.

Push the socket into the assembly

and turn the socket clockwise.

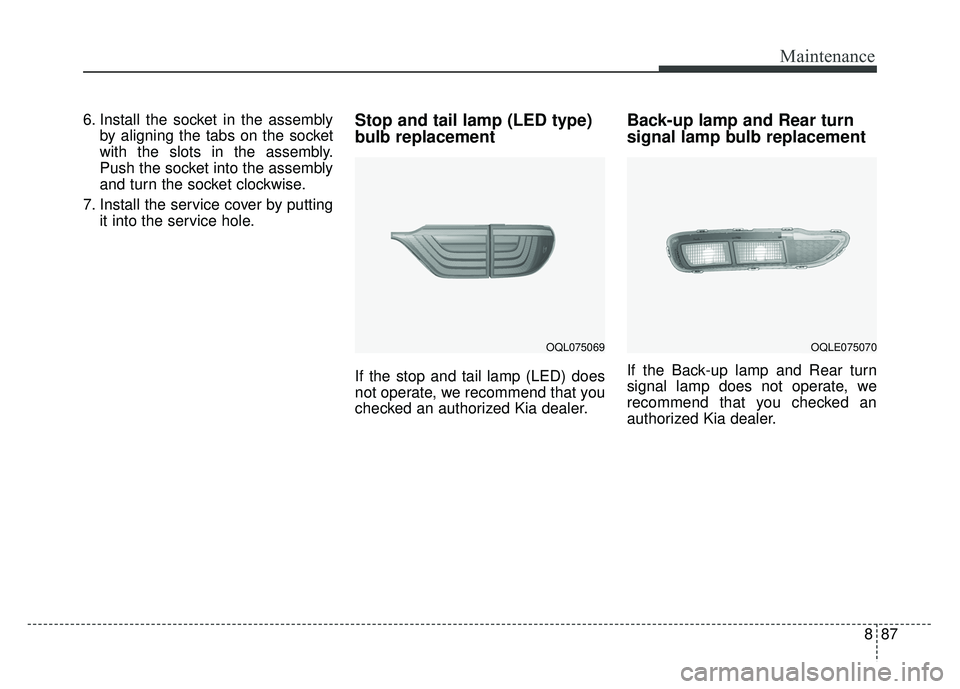

7. Install the service cover by putting it into the service hole.Stop and tail lamp (LED type)

bulb replacement

If the stop and tail lamp (LED) does

not operate, we recommend that you

checked an authorized Kia dealer.

Back-up lamp and Rear turn

signal lamp bulb replacement

If the Back-up lamp and Rear turn

signal lamp does not operate, we

recommend that you checked an

authorized Kia dealer.

OQL075069OQLE075070

Page 558 of 605

Maintenance

88

8

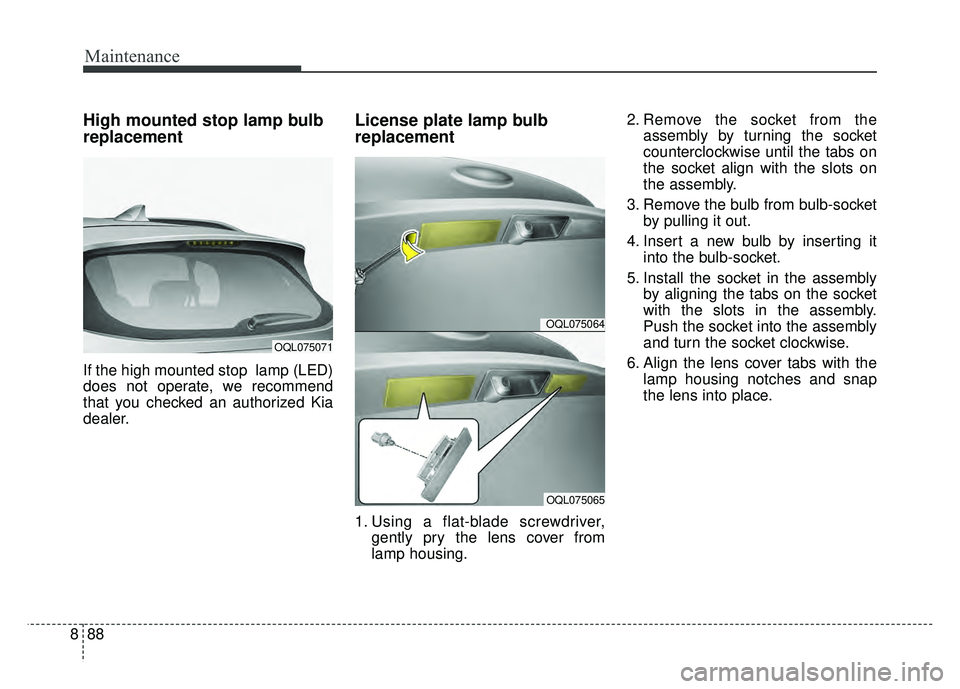

High mounted stop lamp bulb

replacement

If the high mounted stop lamp (LED)

does not operate, we recommend

that you checked an authorized Kia

dealer.

License plate lamp bulb

replacement

1. Using a flat-blade screwdriver,

gently pry the lens cover from

lamp housing. 2. Remove the socket from the

assembly by turning the socket

counterclockwise until the tabs on

the socket align with the slots on

the assembly.

3. Remove the bulb from bulb-socket by pulling it out.

4. Insert a new bulb by inserting it into the bulb-socket.

5. Install the socket in the assembly by aligning the tabs on the socket

with the slots in the assembly.

Push the socket into the assembly

and turn the socket clockwise.

6. Align the lens cover tabs with the lamp housing notches and snap

the lens into place.

OQL075071

OQL075064

OQL075065

Page 559 of 605

889

Maintenance

Side repeater lamp (LED type)

bulb replacement

If the side repeater lamp (LED type)

does not operate, we recommend

that you checked an authorized Kia

dealer.

Map lamp bulb replacement

If the map lamp (bulb and LED type)

does not operate, we recommend

that you checked an authorized Kia

dealer.

Vanity mirror lamp bulb

replacement

OQL075047L

WARNING

Prior to working on the Interior

lamps, ensure that the “OFF”

button is depressed to avoid

burning your fingers or receiv-

ing an electric shock.

OQL075066

OQL075067

Page 561 of 605

891

Maintenance

Personal lamp bulb replacement

If the personal lamp (LED) does not

operate, we recommend that you

checked an authorized Kia dealer.

Glove box lamp bulb

replacement

1. Using a flat-blade screwdriver,gently pry the lamp assembly from

interior.

2. Remove the bulb by pulling it straight out.

3. Install a new bulb in the socket.

4. Install the lamp assembly to interior.

✽ ✽ NOTICE

Be careful not to dirty or damage the

lens, lens tab, and plastic housings.

OQL075054

OQL075055

Page 564 of 605

Maintenance

94

8

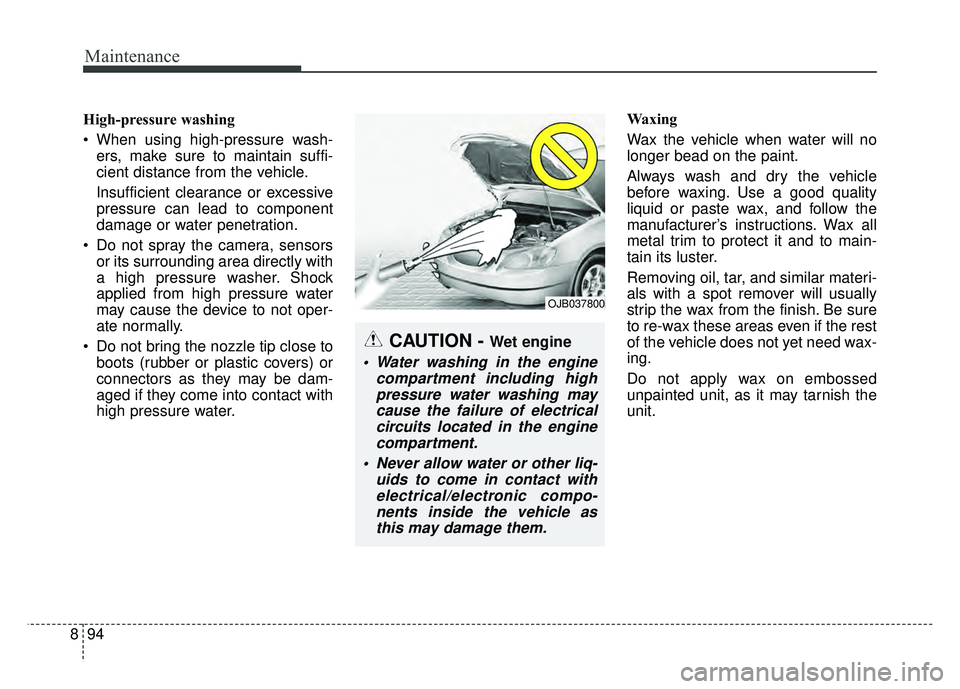

High-pressure washing

When using high-pressure wash-

ers, make sure to maintain suffi-

cient distance from the vehicle.

Insufficient clearance or excessive

pressure can lead to component

damage or water penetration.

Do not spray the camera, sensors or its surrounding area directly with

a high pressure washer. Shock

applied from high pressure water

may cause the device to not oper-

ate normally.

Do not bring the nozzle tip close to boots (rubber or plastic covers) or

connectors as they may be dam-

aged if they come into contact with

high pressure water. Waxing

Wax the vehicle when water will no

longer bead on the paint.

Always wash and dry the vehicle

before waxing. Use a good quality

liquid or paste wax, and follow the

manufacturer’s instructions. Wax all

metal trim to protect it and to main-

tain its luster.

Removing oil, tar, and similar materi-

als with a spot remover will usually

strip the wax from the finish. Be sure

to re-wax these areas even if the rest

of the vehicle does not yet need wax-

ing.

Do not apply wax on embossed

unpainted unit, as it may tarnish the

unit.

OJB037800

CAUTION - Wet engine

Water washing in the engine

compartment including highpressure water washing maycause the failure of electricalcircuits located in the enginecompartment.

Never allow water or other liq- uids to come in contact withelectrical/electronic compo-nents inside the vehicle asthis may damage them.

Page 566 of 605

Maintenance

96

8

Do a thorough washing of the

undercarriage at the end of the

winter.

Use professional service techni- cians or governmental inspection

stations to annually inspect for cor-

rosion.

Immediately seek an inspection of your vehicle if you become visually

aware of corrosion flaking or scal-

ing or if you become aware of a

change in vehicle performance,

such as soft or spongey brakes,

fluids leaking, impairment of direc-

tional control, suspension noises

or rattling metal straps.Aluminum wheel maintenance

The aluminum wheels are coated

with a clear protective finish.

Do not use any abrasive cleaner,polishing compound, solvent, or

wire brushes on aluminum wheels.

They may scratch the finish.

Clean the wheel when it has cooled.

Use only a mild soap or neutral detergent, and rinse thoroughly

with water. Also, be sure to clean

the wheels after driving on salted

roads. This helps prevent corro-

sion.

Avoid washing the wheels with highspeed vehicle wash brushes.

Do not use any alkaline or acid detergents It may damage and cor-

rode the aluminum wheels coated

with a clear protective finish.

Corrosion protection

Protecting your vehicle from corrosion

By using the most advanced design

and construction practices to combat

corrosion, we produce vehicles of

the highest quality. However, this is

only part of the job. To achieve the

long-term corrosion resistance your

vehicle can deliver, the owner's

cooperation and assistance is also

required.

Common causes of corrosion

The most common causes of corro-

sion on your vehicle are:

Road salt, dirt and moisture that isallowed to accumulate underneath

the vehicle.

Removal of paint or protective coatings by stones, gravel, abra-

sion or minor scrapes and dents

which leave unprotected metal

exposed to corrosion.

Page 568 of 605

Maintenance

98

8

When cleaning lower door panels,

rocker panels and frame members,

be sure that drain holes are kept

open so that moisture can escape

and not be trapped inside to accel-

erate corrosion.

Keep your garage dry

Don't park your vehicle in a damp,

poorly ventilated garage. This cre-

ates a favorable environment for cor-

rosion. This is particularly true if you

wash your vehicle in the garage or

drive it into the garage when it is still

wet or covered with snow, ice or

mud. Even a heated garage can con-

tribute to corrosion unless it is well

ventilated so moisture is dispersed. Keep paint and trim in good con-

dition

Scratches or chips in the finish

should be covered with "touch-up"

paint as soon as possible to reduce

the possibility of corrosion. If bare

metal is showing through, the atten-

tion of a qualified body and paint

shop is recommended.

Bird droppings : Bird droppings are

highly corrosive and may damage

painted surfaces in just a few hours.

Always remove bird droppings as

soon as possible.

Don't neglect the interior

Moisture can collect under the floor

mats and carpeting and cause corro-

sion. Check under the mats periodi-

cally to be sure the carpeting is dry.

Use particular care if you carry fertil-

izers, cleaning materials or chemi-

cals in the vehicle.

These should be carried only in prop-

er containers and any spills or leaks

should be cleaned up, flushed with

clean water and thoroughly dried.Interior care

Interior general precautions

Prevent chemicals such as perfume,

cosmetic oil, sun cream, hand clean-

er, and air freshener from contacting

the interior parts because they may

cause damage or discoloration. If

they do contact the interior parts,

wipe them off immediately. If neces-

sary, use a vinyl cleaner, see product

instructions for correct usage.

CAUTION - Electrical

components

Never allow water or other liq-

uids to come in contact withelectrical/electronic compo-nents inside the vehicle as thismay damage them.

Page 570 of 605

Maintenance

100

8

Cleaning the upholstery and inte-

rior trim

Vinyl

Remove dust and loose dirt from

vinyl with a whisk broom or vacuum

cleaner. Clean vinyl surfaces with a

vinyl cleaner.

Fabric

Remove dust and loose dirt from fab-

ric with a whisk broom or vacuum

cleaner. Clean with a mild soap solu-

tion recommended for upholstery or

carpets. Remove fresh spots imme-

diately with a fabric spot cleaner. If

fresh spots do not receive immediate

attention, the fabric can be stained

and its color can be affected. Also, its

fire-resistant properties can be

reduced if the material is not proper-

ly maintained.

Using anything but recommended

cleaners and procedures may affect

the fabric’s appearance and fire-

resistant properties.

Cleaning the lap/shoulder beltwebbing

Clean the belt webbing with any mild

soap solution recommended for

cleaning upholstery or carpet. Follow

the instructions provided with the

soap. Do not bleach or re-dye the

webbing because this may weaken it.

Cleaning the interior windowglass

If the interior glass surfaces of the

vehicle become fogged (that is, cov-

ered with an oily, greasy or waxy

film), they should be cleaned with a

glass cleaner. Follow the directions

on the glass cleaner container.

CAUTION- Rear window

Do not scrape or scratch theinside of the rear window. Thismay result in damage of the rearwindow defroster grid.

CAUTION - Leather

When cleaning leather products(steering wheel, seats etc.), useneutral detergents or low alco-hol content solutions. If you usehigh alcohol content solutionsor acid/alkaline detergents, thecolor of the leather may fade orthe surface may get stripped off.

Page 571 of 605

8101

Maintenance

EMISSION CONTROL SYSTEM

The emission control system of your

vehicle is covered by a written limited

warranty. Please see the warranty

information contained in the

Warranty & Consumer Information

manual in your vehicle.

Your vehicle is equipped with an

emission control system to meet all

applicable emission regulations.

There are three emission control

systems, as follows.

(1) Crankcase emission control sys-tem

(2) Evaporative emission control sys- tem

(3) Exhaust emission control system

In order to assure the proper function

of the emission control systems, it is

recommended that you have your

vehicle inspected and maintained by

an authorized Kia dealer in accor-

dance with the maintenance sched-

ule in this manual. Caution for the Inspection and

Maintenance Test (With Electronic

Stability Control (ESC) system)

To prevent the vehicle from mis-

firing during dynamometer test-

ing, turn the Electronic Stability

Control (ESC) system off by

pressing the ESC switch.

After dynamometer testing is completed, turn the ESC system

back on by pressing the ESC

switch again.1. Crankcase emission control system

The positive crankcase ventilation

system is employed to prevent air

pollution caused by blow-by gases

being emitted from the crankcase.

This system supplies fresh filtered air

to the crankcase through the air

intake hose. Inside the crankcase,

the fresh air mixes with blow-by

gases, which then pass through the

PCV valve into the induction system.

2. Evaporative emission con-trol (including ORVR:

Onboard Refueling Vapor

Recovery)

system

The Evaporative Emission Control

System is designed to prevent fuel

vapors from escaping into the atmos-

phere.

(The ORVR system is designed to

allow the vapors from the fuel tank to

be loaded into a canister while refu-

eling at the gas station, preventing

the escape of fuel vapors into the

atmosphere.)