engine Lancia Flavia 2012 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2012, Model line: Flavia, Model: Lancia Flavia 2012Pages: 233, PDF Size: 2.61 MB

Page 156 of 233

ELECTRONIC STABILITY

CONTROL (ESC)

This system enhances directional con-

trol and stability of the vehicle under

various driving conditions. ESC cor-

rects for over/under steering of the

vehicle by applying the brake of the

appropriate wheel to assist in counter-

acting the over/under steer condition.

Engine power may also be reduced to

help the vehicle maintain the desired

path. ESC uses sensors in the vehicle

to determine the vehicle path in-

tended by the driver and compares it

to the actual path of the vehicle. When

the actual path does not match the

intended path, ESC applies the brake

of the appropriate wheel to assist in

counteracting the oversteer or under-

steer condition.

Over-steer - when the vehicle isturning more than appropriate for

the steering wheel position.

Under-steer - when the vehicle is turning less than appropriate for

the steering wheel position.

WARNING!

The Electronic Stability Control

(ESC) cannot prevent the natural

laws of physics from acting on the

vehicle, nor can it increase the trac-

tion afforded by prevailing road

conditions. ESC cannot prevent ac-

cidents, including those resulting

from excessive speed in turns, driv-

ing on very slippery surfaces, or hy-

droplaning. ESC also cannot pre-

vent accidents resulting from loss of

vehicle control due to inappropriate

driver input for the conditions. Only

a safe, attentive, and skillful driver

can prevent accidents. The capabili-

ties of an ESC equipped vehicle

must never be exploited in a reckless

or dangerous manner which could

jeopardize the user’s safety or the

safety of others. ESC Operating Modes

All ESC equipped vehicles can choose

the following ESC operating modes:

ESC On

This is the normal operating mode for

ESC. Whenever the vehicle is started

the ESC system will be in this mode.

This mode should be used for almost

all driving situations. ESC should

only be turned to “Partial Off” for

specific reasons as noted below.

Partial ESC Mode

This mode is entered by momentarily

pressing the “ESC Off” switch (lo-

cated in the lower switch bank below

the heater/air conditioning controls).

When in “Partial Off” mode, the TCS

portion of ESC, except for the limited

slip feature described in the TCS sec-

tion, has been disabled and the “ESC

Activation/Malfunction Indicator

Light” will be illuminated. All other

stability features of ESC function nor-

mally, with the exception of engine

power reduction. This mode is in-

tended to be used if the vehicle is in

deep snow, sand, or gravel conditions

149

Page 157 of 233

and more wheel spin than ESC would

normally allow is required to gain

traction.

To turn ESC on again, momentarily

press the “ESC Off” switch. This will

restore the normal “ESC On” mode of

operation.WARNING!

In partial ESC mode, the engine

power reduction feature of ESC is

disabled. Therefore, enhanced ve-

hicle stability offered by the ESC

system is reduced.

NOTE:

To improve the vehicle's traction

when driving with snow chains, or

starting off in deep snow, sand or

gravel, it may be desirable to switch to the “Partial Off” mode by

pressing the “ESC Off” switch.

Once the situation requiring ESC

to be switched to the “Partial Off”

mode is overcome, turn ESC on

again by momentarily pressing the

“ESC Off” switch. This may be

done while the vehicle is in mo-

tion.

ESC ACTIVATION/

MALFUNCTION

INDICATOR LIGHT AND

ESC OFF INDICATOR

LIGHT

The “ESC Activation/Mal-

function Indicator Light” in

the instrument cluster will

come on when the ignition

switch is turned to the ON position. It

should go out with the engine running.

If the “ESC Activation/Malfunction In-

dicator Light” comes on continuously

with the engine running, a malfunction

has been detected in the ESC system. If

this light remains on after several igni-

tion cycles, and the vehicle has been

driven several miles (kilometers) at

speeds greater than 48 km/h, see your authorized dealer as soon as possible to

have the problem diagnosed and cor-

rected.

The “ESC Activation/Malfunction In-

dicator Light” (located in the instru-

ment cluster) starts to flash as soon as

the tires lose traction and the ESC

system becomes active. The “ESC

Activation/Malfunction Indicator

Light” also flashes when TCS is ac-

tive. If the “ESC Activation/

Malfunction Indicator Light” begins

to flash during acceleration, ease up

on the accelerator and apply as little

throttle as possible. Be sure to adapt

your speed and driving to the prevail-

ing road conditions.

NOTE:

The “ESC Activation/Malfunc-

tion Indicator Light” and the

“ESC OFF Indicator Light” come

on momentarily each time the ig-

nition switch is turned ON. Each time the ignition is turned

ON, the ESC system will be ON

even if it was turned off previ-

ously.

ESC Off Switch

150

Page 165 of 233

Check TPMS Warning

When a system fault is detected, a

chime will sound and the “Tire Pres-

sure Monitoring Telltale Light” will

flash on and off for 75 seconds and

then remain on solid. In addition, the

EVIC will display a "CHECK TPM

SYSTEM" message for a minimum of

five seconds and then display dashes

(- -) in place of the pressure value to

indicate which sensor is not being re-

ceived.

If the ignition key is cycled, this se-

quence will repeat, providing the sys-

tem fault still exists. If the system

fault no longer exists, the “Tire Pres-

sure Monitoring Telltale Light” will

no longer flash, and the "CHECK

TPM SYSTEM" message will no lon-

ger display, and a pressure value will

display in place of the dashes. A sys-

tem fault can occur due to any of the

following:

1. Jamming due to electronic devices

or driving next to facilities emitting

the same Radio Frequencies as the

TPM sensors.2. Installing some form of aftermar-

ket window tinting that affects radio

wave signals.

3. Lots of snow or ice around the

wheels or wheel housings.

4. Using tire chains on the vehicle.

5. Using wheels/tires not equipped

with TPM sensors.

The EVIC will also display a

"CHECK TPM SYSTEM" message

for a minimum of five seconds when a

system fault related to an incorrect

sensor location fault is detected. In

this case, the "CHECK TPM SYS-

TEM" message is then followed with a

graphic display with pressure values

still shown. This indicates that the

pressure values are still being received

from the TPM sensors but they may

not be located in the correct vehicle

position. The system still needs to be

serviced as long as the "CHECK TPM

SYSTEM" message is displayed.

FUEL REQUIREMENTS

All engines are designed to meet all

emissions regulations and provide ex-

cellent fuel economy and performance

when using high quality unleaded

gasoline with a minimum research oc-

tane rating of 91.

Light spark knock at low engine speeds

is not harmful to your engine. How-

ever, continued heavy spark knock at

high speeds can cause damage and im-

mediate service is required. Poor qual-

ity gasoline can cause problems such as

hard starting, stalling, and hesitations.

If you experience these symptoms, try

another brand of gasoline before con-

sidering service for the vehicle.Over 40 auto manufactur

er's world

wide have issued and endorsed con-

sistent gasoline specifications (the

Worldwide Fuel Charter, WWFC)

which define fuel properties necessary

to deliver enhanced emissions, perfor-

mance, and durability for your ve-

hicle. The manufacturer recommends

the use of gasoline that meets the

WWFC specifications if they are

available.

158

Page 167 of 233

MATERIALS ADDED TO

FUEL

Besides using unleaded gasoline with

the proper octane rating, gasolines

that contain detergents, corrosion and

stability additives are recommended.

Using gasolines that have these addi-

tives will help improve fuel economy,

reduce emissions, and maintain ve-

hicle performance.

Indiscriminate use of fuel system

cleaning agents should be avoided.

Many of these materials intended for

gum and varnish removal may con-

tain active solvents or similar ingredi-

ents. These can harm fuel system gas-

ket and diaphragm materials.WARNING!

Carbon monoxide (CO) in exhaust

gases is deadly. Follow the precau-

tions below to prevent carbon mon-

oxide poisoning:(Continued)

WARNING!(Continued)

Do not inhale exhaust gases. They

contain carbon monoxide, a color-

less and odorless gas, which can

kill. Never run the engine in a

closed area, such as a garage, and

never sit in a parked vehicle with

the engine running for an ex-

tended period. If the vehicle is

stopped in an open area with the

engine running for more than a

short period, adjust the ventila-

tion system to force fresh, outside

air into the vehicle.

Guard against carbon monoxide

with proper maintenance. Have the

exhaust system inspected every

time the vehicle is raised. Have any

abnormal conditions repaired

promptly. Until repaired, drive

with all side windows fully open.

ADDING FUEL

FUEL FILLER CAP (GAS

CAP)

The gas cap is behind the fuel filler

door, on the left rear quarter panel of

the vehicle. If the gas cap is lost or damaged, be sure the replacement cap

is for use with this vehicle.

After removing the gas cap, place the

gas cap tether cable over a hook on

the inside of the fuel door. This keeps

the gas cap suspended away from and

protects the

vehicle's surface.

Fuel Filler DoorTether Cable

160

Page 172 of 233

6

WHAT TO DO IN EMERGENCIES

HAZARD WARNING FLASHERS . . . . . . . . . . . . 166

IF YOUR ENGINE OVERHEATS . . . . . . . . . . . . . 166 ENGINE OIL OVERHEATING . . . . . . . . . . . . . 167

TIREFIT KIT . . . . . . . . . . . . . . . . . . . . . . . . . . . 167 TIREFIT STORAGE . . . . . . . . . . . . . . . . . . . . 167

TIREFIT KIT COMPONENTS ANDOPERATION . . . . . . . . . . . . . . . . . . . . . . . . . 167

TIREFIT USAGE PRECAUTIONS . . . . . . . . . . 168

SEALING A TIRE WITH TIREFIT . . . . . . . . . 169

JUMP-STARTING . . . . . . . . . . . . . . . . . . . . . . . . 172 PREPARATIONS FOR JUMP-START . . . . . . . 173

JUMP-STARTING PROCEDURE . . . . . . . . . . . 173

FREEING A STUCK VEHICLE . . . . . . . . . . . . . . 174

SHIFT LEVER OVERRIDE . . . . . . . . . . . . . . . . . 175

TOWING A DISABLED VEHICLE . . . . . . . . . . . 176 AUTOMATIC TRANSMISSION . . . . . . . . . . . . 176

WITHOUT THE IGNITION KEY . . . . . . . . . . . 177

165

Page 173 of 233

HAZARD WARNING

FLASHERS

The Hazard Warning flasher switch is

located on the instrument panel, be-

low the radio.Press the switch to turn on the

Hazard Warning flasher. When

the switch is activated, all di-

rectional turn signals will flash on and

off to warn oncoming traffic of an

emergency. Press the switch a second

time to turn off the Hazard Warning

flashers.

This is an emergency warning system

and it should not be used when the

vehicle is in motion. Use it when your

vehicle is disabled and it is creating a

safety hazard for other motorists.

When you must leave the vehicle to

seek assistance, the Hazard Warning

flashers will continue to operate even

though the ignition is placed in the

OFF position.

NOTE:

With extended use the Hazard

Warning flashers may wear down

your battery. IF YOUR ENGINE

OVERHEATS

In any of the following situations, you

can reduce the potential for overheat-

ing by taking the appropriate action.

On the highways — Slow down.

In city traffic — While stopped, put

transaxle in NEUTRAL, but do not

increase engine idle speed.

CAUTION!

Driving with a hot cooling system

could damage your vehicle. If tem-

perature gauge reads “H”, pull over

and stop the vehicle with the engine

at idle, when safe. Turn the air con-

ditioner off and wait until the

pointer drops back into the normal

range. After appropriate action has

been taken, if the pointer remains on

the “H”, turn the engine off imme-

diately, and call for service.

NOTE:

There are steps that you can take to

slow down an impending overheat

condition: If your air conditioner (A/C) is

on, turn it off. The A/C system

adds heat to the engine cooling

system and turning the A/C off

can help remove this heat.

You can also turn the tempera- ture control to maximum heat,

the mode control to floor and the

blower control to high. This al-

lows the heater core to act as a

supplement to the radiator and

aids in removing heat from the

engine cooling system.

WARNING!

You or others can be badly burned

by hot engine coolant (antifreeze) or

steam from your radiator. If you see

or hear steam coming from under

the hood, do not open the hood until

the radiator has had time to cool.

Never try to open a cooling system

pressure cap when the radiator or

coolant bottle is hot.

166

Page 174 of 233

ENGINE OIL

OVERHEATING

During sustained high-speed driving

or trailer tow up long grades on a hot

day, the engine oil temperature may

become too hot. If this happens, the

“HOTOIL” message flashes in the

odometer and the vehicle speed will

be reduced to 85 km/h until the en-

gine oil temperature is reduced.

NOTE:

The vehicle speed is reduced to a

maximum of 85 km/h. You may of

course, reduce your vehicle speed

further if needed.

TIREFIT KIT

Small punctures up to 6 mm in the tire

tread can be sealed with TIREFIT.

Foreign objects (e.g., screws or nails)

should not be removed from the tire.

TIREFIT can be used in outside tem-

peratures down to approximately

20°C.

This kit will provide a temporary tire

seal, allowing you to drive your ve-

hicle up to 160 km with a maximum

speed of 88 km/h.TIREFIT STORAGE

The TIREFIT kit is located in the

trunk.

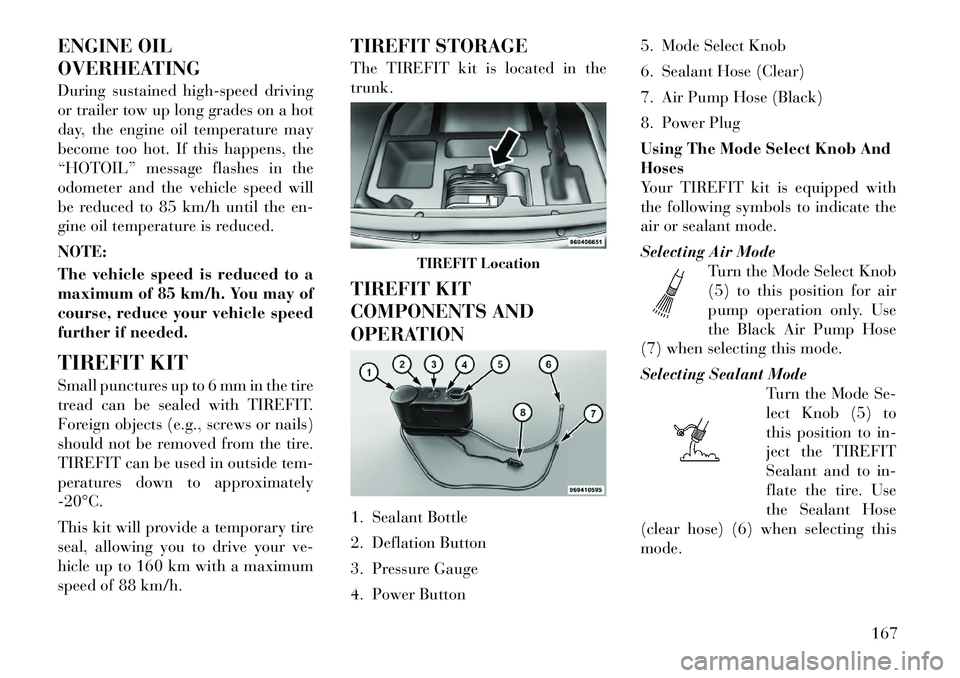

TIREFIT KIT

COMPONENTS AND

OPERATION

1. Sealant Bottle

2. Deflation Button

3. Pressure Gauge

4. Power Button5. Mode Select Knob

6. Sealant Hose (Clear)

7. Air Pump Hose (Black)

8. Power Plug

Using The Mode Select Knob And

Hoses

Your TIREFIT kit is equipped with

the following symbols to indicate the

air or sealant mode.

Selecting Air Mode

Turn the Mode Select Knob

(5) to this position for air

pump operation only. Use

the Black Air Pump Hose

(7) when selecting this mode.

Selecting Sealant Mode Turn the Mode Se-

lect Knob (5) to

this position to in-

ject the TIREFIT

Sealant and to in-

flate the tire. Use

the Sealant Hose

(clear hose) (6) when selecting this

mode.

TIREFIT Location

167

Page 177 of 233

(C) Injecting TIREFIT Sealant

Into The Deflated Tire:

Always start the engine beforeturning ON the TIREFIT kit.

NOTE:

Manual transmission vehicles

must have the parking brake en-

gaged and the shift lever in NEU-

TRAL.

After pressing the Power Button (4), the sealant (white fluid) will

flow from the Sealant Bottle (1)

through the Sealant Hose (6) and

into the tire.

NOTE:

Sealant may leak out through the

puncture in the tire.

If the sealant (white fluid) does not

flow within 0 – 10 seconds through

the Sealant Hose (6):

1. Press the Power Button (4) to turn

Off the TIREFIT kit. Disconnect the

Sealant Hose (6) from the valve stem.

Make sure the valve stem is free of

debris. Reconnect the Sealant Hose

(6) to the valve stem. Check that the

Mode Select Knob (5) is in the Sealant Mode position and not Air Mode.

Press the Power Button (4) to turn On

the TIREFIT kit.

2. Connect the Power Plug (8) to a

different 12 Volt power outlet in your

vehicle or another vehicle, if avail-

able. Make sure the engine is running

before turning ON the TIREFIT kit.

3. The Sealant Bottle (1) may be

empty due to previous use. Call for

assistance.

NOTE:

If the Mode Select Knob (5) is on

Air Mode and the pump is operat-

ing, air will dispense from the Air

Pump Hose (7) only, not the Seal-

ant Hose (6).

If the sealant (white fluid) does

flow

through the Sealant Hose (6):

1. Continue to operate the pump un-

til sealant is no longer flowing

through hose (typically takes 30 -

70 seconds). As the sealant flows

through the Sealant Hose (6), the

Pressure Gauge (3) can read as high

as 5 Bar. The Pressure Gauge (3) will

decrease quickly from approximately 70 psi (5 Bar) to the actual tire pres-

sure when the Sealant Bottle (1) is

empty.

2. The pump will start to inject air

into the tire immediately after the

Sealant Bottle (1) is empty. Continue

to operate the pump and inflate the

tire to the pressure indicated on the

tire pressure label on the driver-side

latch pillar (recommended pressure).

Check the tire pressure by looking at

the Pressure Gauge (3).

If the tire does not inflate to at least

1.8 Bar pressure within 15 min-

utes:

The tire is too badly damaged. Do

not attempt to drive the vehicle fur-

ther. Call for assistance.

NOTE:

If the tire becomes over-inflated,

press the Deflation Button to re-

duce the tire pressure to the rec-

ommended inflation pressure be-

fore continuing.

If the tire inflates to the recom-

mended pressure or is at least 1.8

Bar pressure within 15 minutes:

170

Page 180 of 233

PREPARATIONS FOR

JUMP-START

The battery in your vehicle is located

between the left front headlight as-

sembly and the left front wheel splash

shield. To allow jump-starting there

are remote battery posts located on

the left side of the engine compart-

ment.WARNING!

Take care to avoid the radiatorcooling fan whenever the hood is

raised. It can start anytime the

ignition switch is on. You can be

injured by moving fan blades.

(Continued)

WARNING!(Continued)

Remove any metal jewelry such as

watch bands or bracelets that

might make an inadvertent elec-

trical contact. You could be seri-

ously injured.

Batteries contain sulfuric acid

that can burn your skin or eyes

and generate hydrogen gas which

is flammable and explosive. Keep

open flames or sparks away from

the battery.

1. Set the parking brake, shift the

automatic transmission into PARK

and turn the ignition to LOCK.

2. Turn off the heater, radio, and all

unnecessary electrical accessories.

3. Remove the protective cover over

the remote positive (+)battery post.

To remove the cover, press the locking

tab and pull upward on the cover. 4. If using another vehicle to jump-

start the battery, park the vehicle

within the jumper cables reach, set

the parking brake and make sure the

ignition is OFF.

WARNING!

Do not allow vehicles to touch each

other as this could establish a

ground connection and personal in-

jury could result.

JUMP-STARTING

PROCEDUREWARNING!

Failure to follow this procedure

could result in personal injury or

property damage due to battery ex-

plosion.

Remote Battery Posts

1 — Remote Positive (+) Post (cov-

ered with protective cap)

2 — Remote Negative (-) Post

Locking Tab

173

Page 181 of 233

CAUTION!

Failure to follow these procedures

could result in damage to the charg-

ing system of the booster vehicle or

the discharged vehicle.

1. Connect the positive (+)end of the

jumper cable to the remote positive

(+) post of the discharged vehicle.

2. Connect the opposite end of the

positive (+)jumper cable to the posi-

tive (+)post of the booster battery.

3. Connect the negative end (-)of the

jumper cable to the negative (-)post

of the booster battery.

4. Connect the opposite end of the

negative (-)jumper cable to the re-

mote negative (-)post of the vehicle

with the discharged battery.WARNING!

Do not connect the cable to the nega-

tive post (-)of the discharged bat-

tery. The resulting electrical spark

could cause the battery to explode

and could result in personal injury.

5. Start the engine in the vehicle that

has the booster battery, let the engine idle a few minutes, and then start the

engine in the vehicle with the dis-

charged battery.

Once the engine is started, remove the

jumper cables in the reverse sequence:

6. Disconnect the negative

(-)jumper

cable from the remote negative (-)

post of the vehicle with the discharged

battery.

7. Disconnect the negative end (-)of

the jumper cable from the negative (-)

post of the booster battery.

8. Disconnect the opposite end of the

positive (+)jumper cable from the

positive (+)post of the booster bat-

tery.

9. Disconnect the positive (+)end of

the jumper cable from the remote

positive (+)post of the discharged ve-

hicle.

10. Reinstall the protective cover

over the remote positive (+)battery

post of the discharged vehicle.

If frequent jump-starting is required

to start your vehicle you should have

the battery and charging system in-

spected at your authorized dealer.

CAUTION!

Accessories that can be plugged into

the vehicle power outlets draw

power from the vehicle’s battery,

even when not in use (i.e., cellular

phones, etc.). Eventually, if plugged

in long enough, the vehicle’s battery

will discharge sufficiently to degrade

battery life and/or prevent the en-

gine from starting.

FREEING A STUCK

VEHICLE

If your vehicle becomes stuck in mud,

sand, or snow, it can often be moved

by a rocking motion. Turn your steer-

ing wheel right and left to clear the

area around the front wheels. Then

shift back and forth between DRIVE

and REVERSE. Using minimal accel-

erator pedal pressure to maintain the

rocking motion, without spinning the

wheels, is most effective.

174