dashboard Lancia Musa 2010 Owner handbook (in English)

[x] Cancel search | Manufacturer: LANCIA, Model Year: 2010, Model line: Musa, Model: Lancia Musa 2010Pages: 218, PDF Size: 3.71 MB

Page 138 of 218

137

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

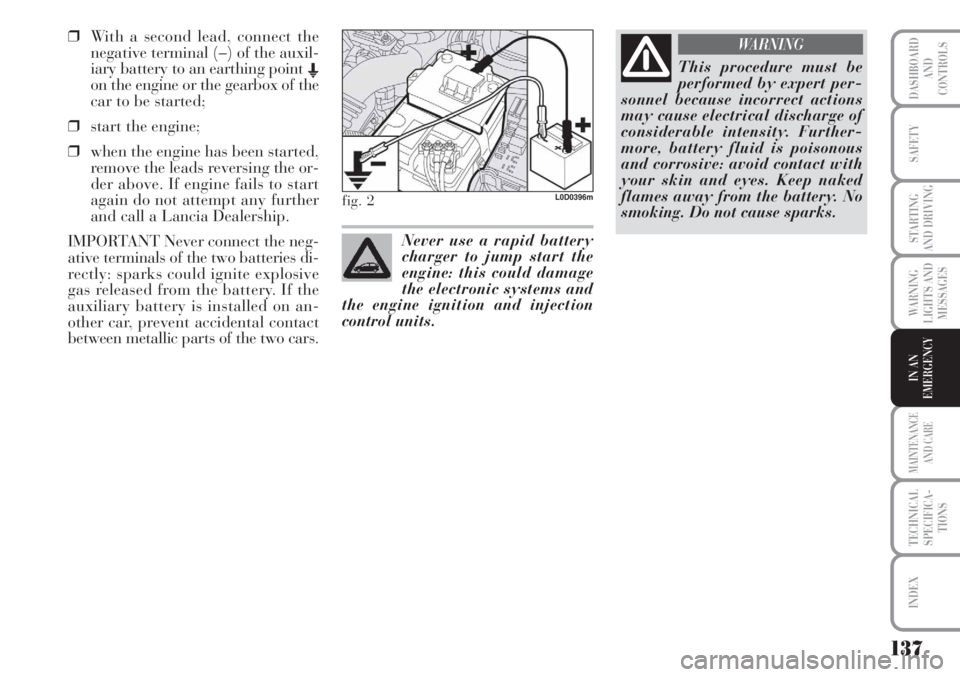

❒With a second lead, connect the

negative terminal (–) of the auxil-

iary battery to an earthing point E

on the engine or the gearbox of the

car to be started;

❒start the engine;

❒when the engine has been started,

remove the leads reversing the or-

der above. If engine fails to start

again do not attempt any further

and call a Lancia Dealership.

IMPORTANT Never connect the neg-

ative terminals of the two batteries di-

rectly: sparks could ignite explosive

gas released from the battery. If the

auxiliary battery is installed on an-

other car, prevent accidental contact

between metallic parts of the two cars.

fig. 2L0D0396m

This procedure must be

performed by expert per-

sonnel because incorrect actions

may cause electrical discharge of

considerable intensity. Further-

more, battery fluid is poisonous

and corrosive: avoid contact with

your skin and eyes. Keep naked

flames away from the battery. No

smoking. Do not cause sparks.

WARNING

Never use a rapid battery

charger to jump start the

engine: this could damage

the electronic systems and

the engine ignition and injection

control units.

Page 139 of 218

138

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

BUMP STARTING

Never bump start the engine by push-

ing, towing or driving downhill. This

could cause a flow of fuel into the cat-

alytic converter and damage it beyond

repair.

IMPORTANT Remember that the

brake servo and the electric power

steering system are not activated un-

til the engine is started, a greater ef-

fort will therefore be required to press

the brake pedal or turn the steering

wheel.

Indicate that the car is

standing according to the

laws in force: emergency lights, re-

fracting warning triangle, etc. Pas-

sengers should leave the car, partic-

ularly if it is very loaded, and wait

for the wheel to be changed away

from on-coming traffic. Arrange

wedges or other suitable material

under the wheels to block the car on

slopes or rough roads.

WARNINGAutomatic FIX & GO

QUICK TYRE

REPAIR KIT

(for versions/markets, where provided)

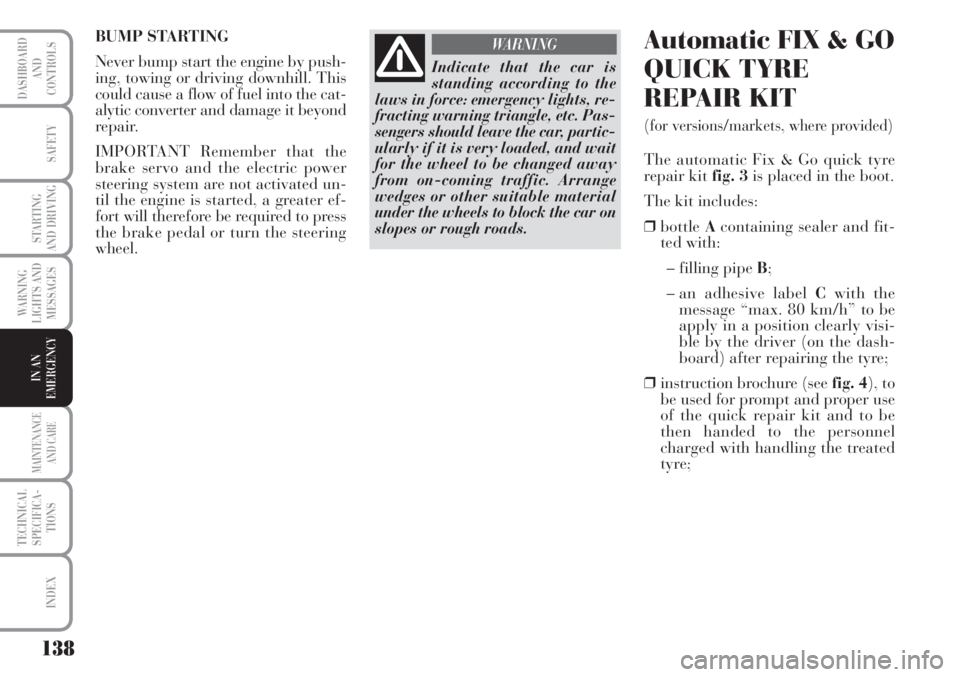

The automatic Fix & Go quick tyre

repair kit fig. 3is placed in the boot.

The kit includes:

❒bottleAcontaining sealer and fit-

ted with:

– filling pipe B;

– an adhesive label Cwith the

message “max. 80 km/h” to be

apply in a position clearly visi-

ble by the driver (on the dash-

board) after repairing the tyre;

❒instruction brochure (see fig. 4), to

be used for prompt and proper use

of the quick repair kit and to be

then handed to the personnel

charged with handling the treated

tyre;

Page 140 of 218

139

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

fig. 3L0D0361m

fig. 4L0D0362m

❒compressor Dincluding gauge and

connections;

❒a pair of protection gloves located

in the side space of the compressor;

❒adapters for inflating different ele-

ments.

The quick repair kit container in the

boot under the mat also contains the

screwdriver and tow rings.

Give the instruction book-

let to the tyre repair work-

shop personnel.

WARNING

IMPORTANT Do not use the quick

repair kit if the tyre was damaged by

running on a flat.

IMPORTANT INFORMATION:

The sealing fluid of the quick tyre re-

pair kit is effective with external tem-

peratures between 20 °C –and

+50 °C.

The sealing fluid will expire.

The kit cannot be used to

repair damage to the tyre

sidewall. Do not use the quick re-

pair kit if the tyre was damaged by

running on a flat.

The damage cannot be repaired

with the kit if the wheel rim is

damaged (deformation of the chan-

nel causing leakage of air). Do not

remove the foreign body (screw or

nail) from the tyre.

Do not operate the compressor for

longer than 20 consecutive min-

utes. Risk of overheating. The

quick repair kit is not suitable for

definitive repairs. The tyres may

only be repaired temporarily.

WARNING

In the event of a puncture

caused by foreign bodies,

the kit may be used to re-

pair tyres showing dam-

ages on the track or shoulder up to

max 4 mm diameter.

Replace the cylinder con-

taining the sealant after the

expiration date. Dispose of

the cylinder and the sealant

liquid properly. Dispose according to

the national and local laws in force.

Page 141 of 218

140

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

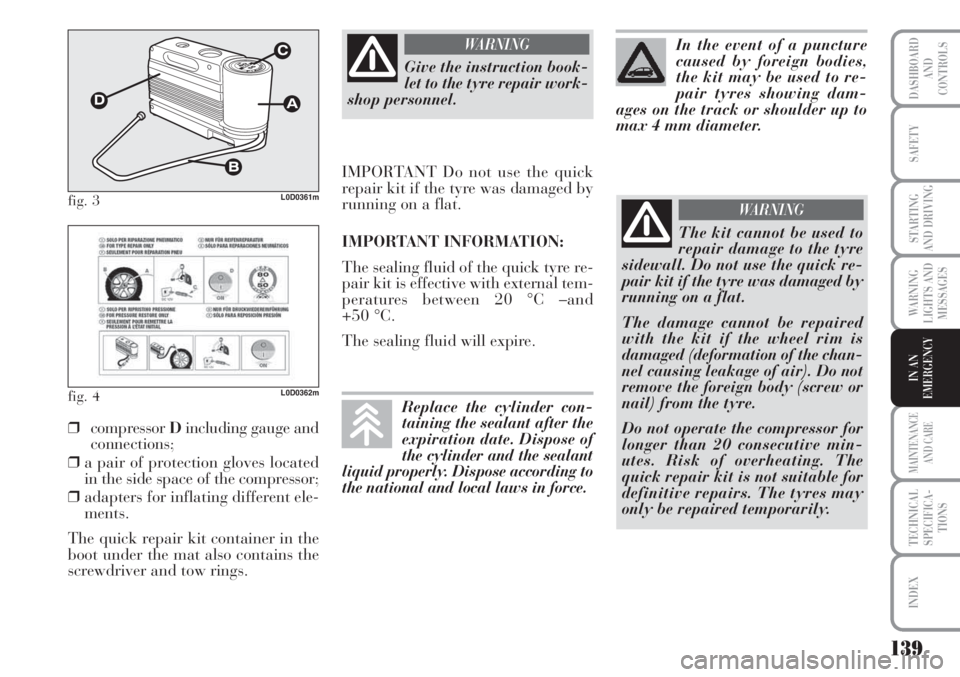

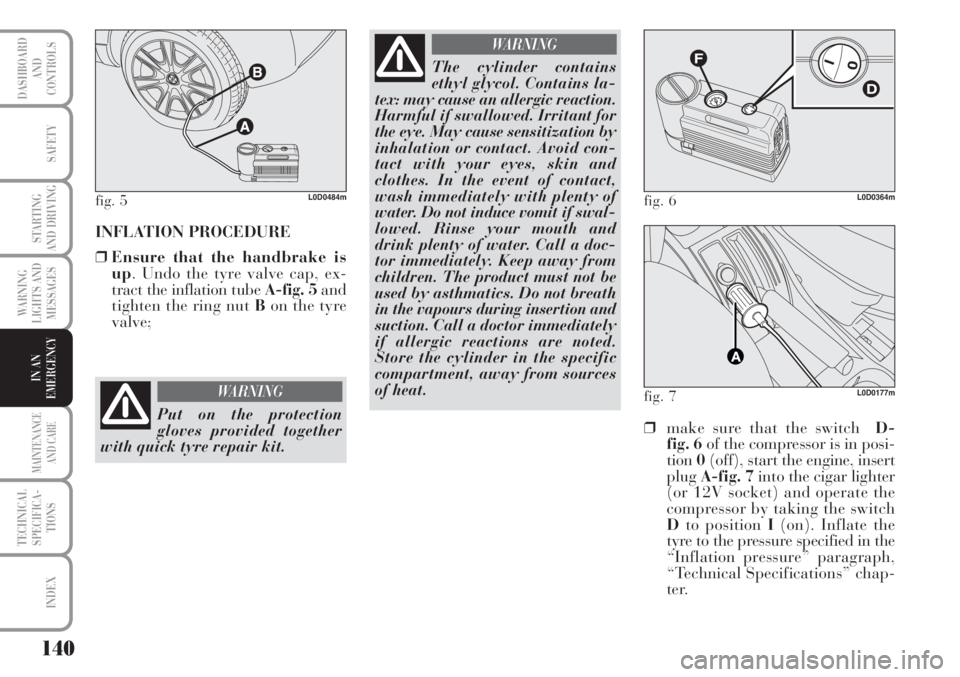

INFLATION PROCEDURE

❒Ensure that the handbrake is

up. Undo the tyre valve cap, ex-

tract the inflation tube A-fig. 5and

tighten the ring nut Bon the tyre

valve;

fig. 5L0D0484m

Put on the protection

gloves provided together

with quick tyre repair kit.

WARNING

The cylinder contains

ethyl glycol. Contains la-

tex: may cause an allergic reaction.

Harmful if swallowed. Irritant for

the eye. May cause sensitization by

inhalation or contact. Avoid con-

tact with your eyes, skin and

clothes. In the event of contact,

wash immediately with plenty of

water. Do not induce vomit if swal-

lowed. Rinse your mouth and

drink plenty of water. Call a doc-

tor immediately. Keep away from

children. The product must not be

used by asthmatics. Do not breath

in the vapours during insertion and

suction. Call a doctor immediately

if allergic reactions are noted.

Store the cylinder in the specific

compartment, away from sources

of heat.

WARNING

❒make sure that the switch D-

fig. 6of the compressor is in posi-

tion0(off), start the engine, insert

plugA-fig. 7into the cigar lighter

(or 12V socket) and operate the

compressor by taking the switch

Dto position I(on). Inflate the

tyre to the pressure specified in the

“Inflation pressure” paragraph,

“Technical Specifications” chap-

ter.

fig. 6L0D0364m

fig. 7L0D0177m

Page 142 of 218

141

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

For a more accurate reading,

check pressure gauge F-fig. 6with

the compressor off;

❒if after 5 minutes it is still impossi-

ble to reach at least 1.5 bar, disen-

gage compressor from valve and

current outlet, then move the car

forth for approx. ten metres in or-

der to distribute the sealing fluid

inside the tyre evenly, then repeat

the inflation operation;

❒If after this operation it is still im-

possible after 5 minutes to reach at

least 1.8 bar, do not start driving

since the tyre is excessively dam-

aged and the quick tyre repair kit

cannot guarantee suitable sealing,

contact Lancia Dealership.

fig. 8L0D0485m

Apply the adhesive label in

a position clearly visible

by the driver as a reminder that

the tyre has been treated with the

quick repair kit. Drive carefully,

particularly on bends. Do not ex-

ceed 80 km/h. Do not accelerate or

brake suddenly.

WARNING

Stop if the pressure has

dropped to less than 1.8

bars: the automatic Fix & Go quick

repair kit cannot work properly

because the tyre is excessively

damaged. Go to a Lancia Dealer-

ship.

WARNING

❒if reaching the tyre pressure speci-

fied in paragraph “Inflation pres-

sure” in section “Technical Specifi-

cations”, start driving immediately;

❒after driving for about 10 minutes

stop and check again the tyre pres-

sure; pull up the handbrake;

❒if at least 1.8 bar pressure is read,

restore proper pressure (with en-

gine running and handbrake on)

and restart;

❒drive with the utmost care to the

nearest Lancia Dealership.

FOR CHECKING AND

RESTORING PRESSURE ONLY

The compressor may also be used for

restoring pressure only. Release the

quick coupling and connect directly

to the tyre valve; in this way, the

cylinder will not be connected to the

compressor and no sealant will be in-

jected.

Page 143 of 218

142

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

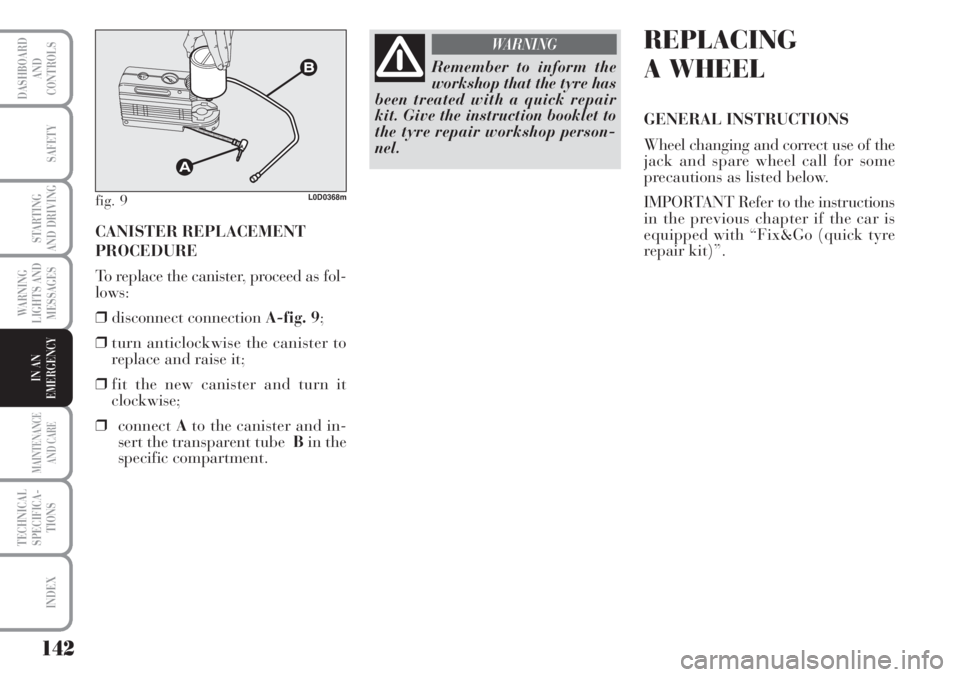

CANISTER REPLACEMENT

PROCEDURE

To replace the canister, proceed as fol-

lows:

❒disconnect connection A-fig. 9;

❒turn anticlockwise the canister to

replace and raise it;

❒fit the new canister and turn it

clockwise;

❒connectAto the canister and in-

sert the transparent tube Bin the

specific compartment.

fig. 9L0D0368m

Remember to inform the

workshop that the tyre has

been treated with a quick repair

kit. Give the instruction booklet to

the tyre repair workshop person-

nel.

WARNINGREPLACING

A WHEEL

GENERAL INSTRUCTIONS

Wheel changing and correct use of the

jack and spare wheel call for some

precautions as listed below.

IMPORTANT Refer to the instructions

in the previous chapter if the car is

equipped with “Fix&Go (quick tyre

repair kit)”.

Page 144 of 218

143

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

The spare wheel is specific

for your car. Do not use it

on cars of different models. Do not

use spare wheels of different mod-

els on your car. The space saver

spare wheel must only be used in

case of emergency. Use only for as

long as strictly necessary and drive

at a speed slower than

80 km/h. An orange label is affixed

on the spare wheel summarising

instructions and limitations for

use. Never remove or cover the la-

bel. Never apply a wheel cup on a

space saver spare. The following

information is provided in four

languages on the label: Warning!

Suitable for temporary use only!

80 km/h max! Replace with a

standard wheel as soon as possi-

ble. Do not cover this label.

WARNING

The driving features of the

car may change when a

space saver spare wheel is fitted.

Avoid sudden acceleration and

braking, sudden steering and fast

cornering. The total life of a space

saver spare wheel is approxi-

mately 3000 km, after which it

must be replaced by another wheel

of the same type. Never install a

traditional tyre on a space saver

spare wheel rim. Repair and refit

the standard wheel as soon as pos-

sible. Only one space saver spare

can be used at a time. Do not ap-

ply grease to the bolt threading be-

fore assembly: the bolts could come

loose unexpectedly.

WARNING

The jack may only be used

to replace wheels on the

car which it equips or other cars of

the same model. Never use the jack

for other purposes, such as lifting

other car models. Never use the

jack to carry out repairs under the

car. Incorrect positioning of the

jack may cause the car to fall. Do

not use the jack for loads higher

than those shown on the label.

Snow chains cannot be fitted on a

space saver spare wheel. There-

fore, if a front wheel (drive wheel)

is punctured and you need to use

snow chains, swap with a rear

wheel. In this way, you will have

two normal wheels on the front on

which you can fit snow chains and

solve the emergency.

WARNING

Page 145 of 218

144

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

Incorrect wheel cup as-

sembly may cause it to

come off when the car is travelling.

Never tamper with the inflation

valve. Never introduce tools of any

kind between rim and tyre. Check

tyre and space saver spare wheel

pressure regularly referring to the

values shown in the “Technical

Specifications” chapter.

WARNINGImportant notes:

❒the jack cannot be repaired: replace

with an original spare part if dam-

aged;

❒no tool other than its cranking de-

vice may be fitted on the jack.

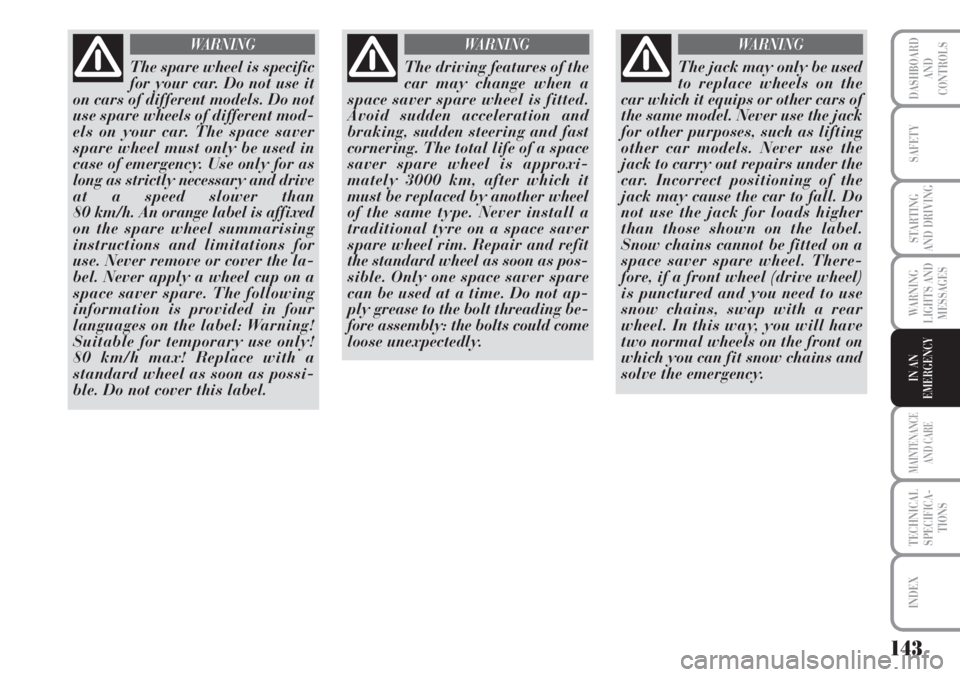

To change a wheel proceed as follows:

❒stop the car in a position so that it

is not a danger for on-coming traf-

fic and where you can replace the

wheel safely. The ground must be

flat and compact;

❒turn the engine off and pull up the

handbrake.

❒engage first gear or reverse;

❒lift the boot mat;

❒loosen the fastening device A-fig.

10;

❒take out the tool container Band

take it near to the wheel to be

changed;

❒take the space saver spare wheel

C;

L0D0161mfig. 10

Page 146 of 218

145

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

fig. 11L0D0397m

fig. 12L0D0163m

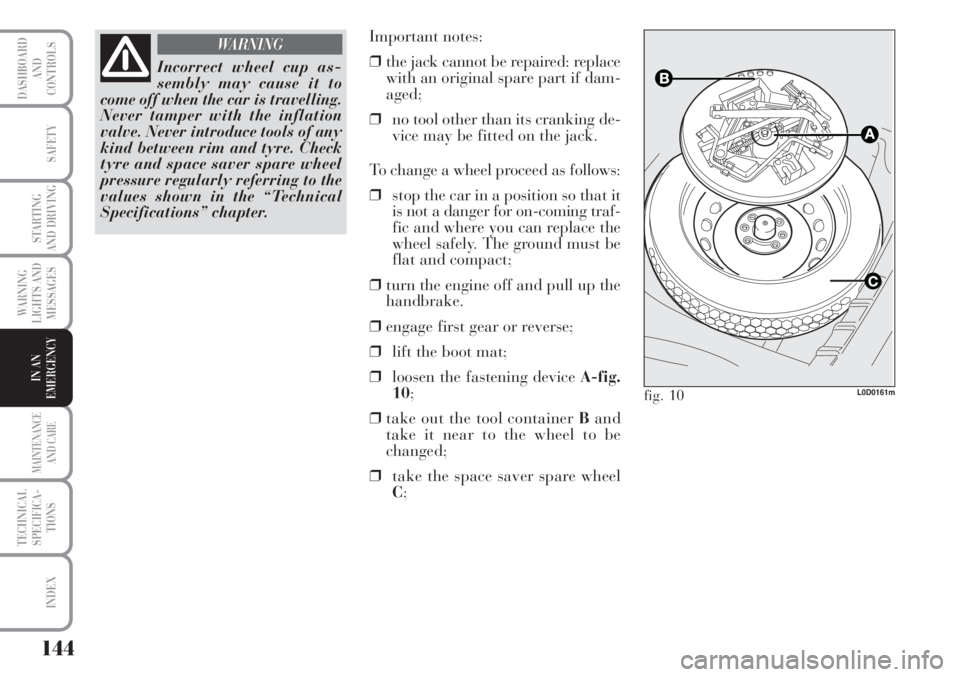

❒for cars fitting alloy rims, remove

the hub cap using the screwdriver

provided levering in groove E-

fig. 11, as shown in the figure;

❒loosen the bolts of the wheel to be

replaced by about one turn with the

wrench provided E-fig. 12; if the

car is fitted with alloy rims, shake

the car to facilitate removing the

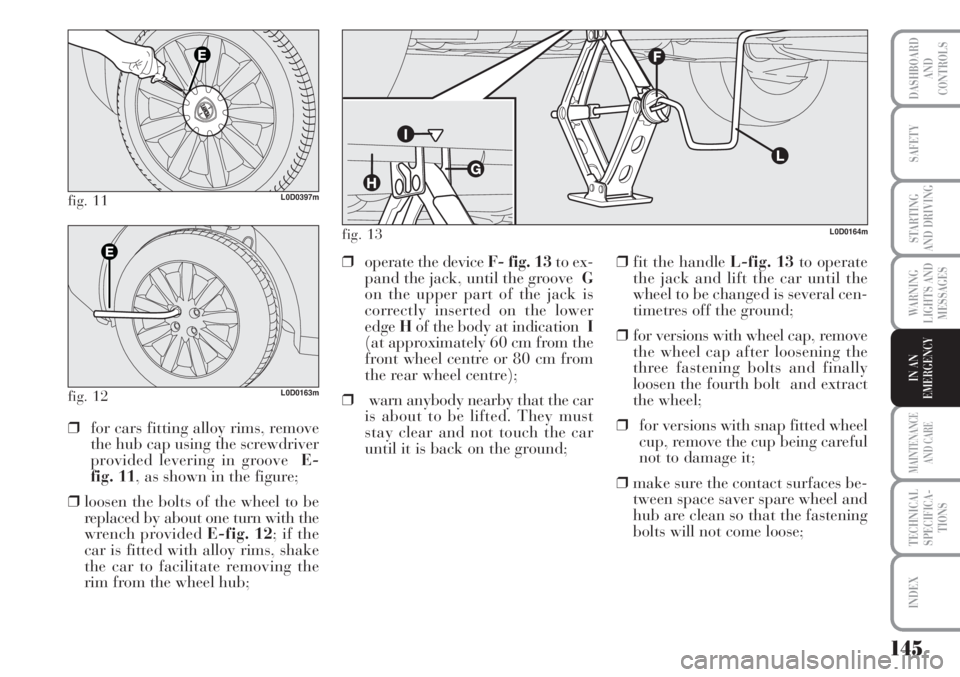

rim from the wheel hub;❒operate the device F- fig. 13to ex-

pand the jack, until the groove G

on the upper part of the jack is

correctly inserted on the lower

edgeHof the body at indication I

(at approximately 60 cm from the

front wheel centre or 80 cm from

the rear wheel centre);

❒warn anybody nearby that the car

is about to be lifted. They must

stay clear and not touch the car

until it is back on the ground;❒fit the handle L-fig. 13to operate

the jack and lift the car until the

wheel to be changed is several cen-

timetres off the ground;

❒for versions with wheel cap, remove

the wheel cap after loosening the

three fastening bolts and finally

loosen the fourth bolt and extract

the wheel;

❒for versions with snap fitted wheel

cup, remove the cup being careful

not to damage it;

❒make sure the contact surfaces be-

tween space saver spare wheel and

hub are clean so that the fastening

bolts will not come loose;

L0D0164mfig. 13

Page 147 of 218

146

WARNING

LIGHTS AND

MESSAGES

MAINTENANCE

AND CARE

TECHNICAL

SPECIFICA-

TIONS

INDEX

DASHBOARD

AND

CONTROLS

SAFETY

STARTING

AND DRIVING

IN AN

EMERGENCY

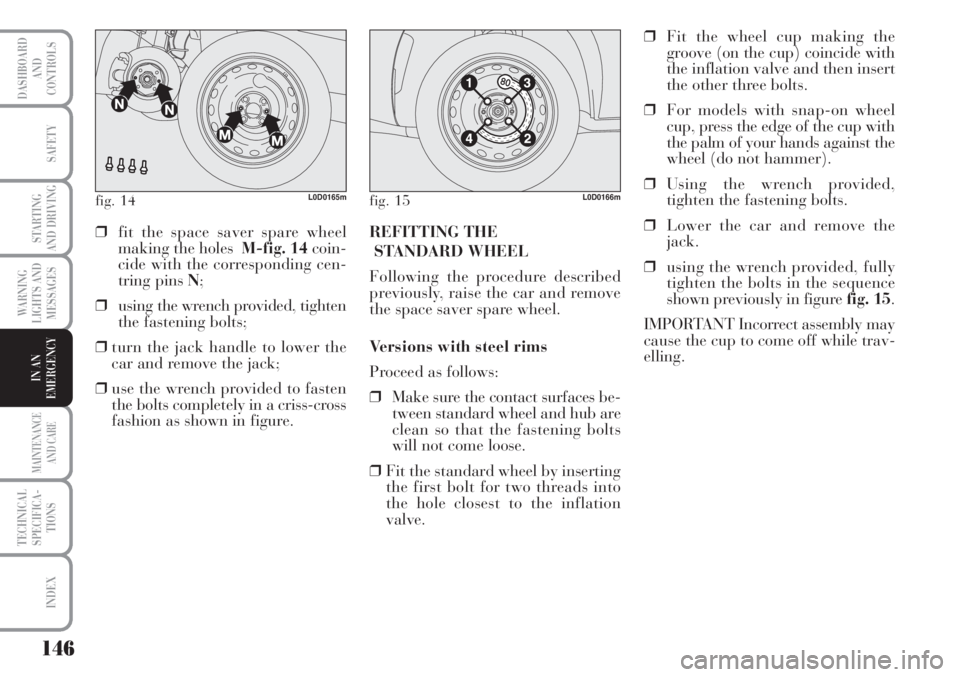

fig. 14L0D0165mfig. 15L0D0166m

❒fit the space saver spare wheel

making the holes M-fig. 14coin-

cide with the corresponding cen-

tring pins N;

❒using the wrench provided, tighten

the fastening bolts;

❒turn the jack handle to lower the

car and remove the jack;

❒use the wrench provided to fasten

the bolts completely in a criss-cross

fashion as shown in figure. REFITTING THE

STANDARD WHEEL

Following the procedure described

previously, raise the car and remove

the space saver spare wheel.

Versions with steel rims

Proceed as follows:

❒Make sure the contact surfaces be-

tween standard wheel and hub are

clean so that the fastening bolts

will not come loose.

❒Fit the standard wheel by inserting

the first bolt for two threads into

the hole closest to the inflation

valve.❒Fit the wheel cup making the

groove (on the cup) coincide with

the inflation valve and then insert

the other three bolts.

❒For models with snap-on wheel

cup, press the edge of the cup with

the palm of your hands against the

wheel (do not hammer).

❒Using the wrench provided,

tighten the fastening bolts.

❒Lower the car and remove the

jack.

❒using the wrench provided, fully

tighten the bolts in the sequence

shown previously in figure fig. 15.

IMPORTANT Incorrect assembly may

cause the cup to come off while trav-

elling.