Lancia Ypsilon 2001 Owner handbook (in English)

Manufacturer: LANCIA, Model Year: 2001, Model line: Ypsilon, Model: Lancia Ypsilon 2001Pages: 191, PDF Size: 2.45 MB

Page 101 of 191

98

G

– Take out the tools and remove the

space-saver spare wheel.

IMPORTANTThe indications

which follow must be complied with

to ensure that the jack and the spare

wheel are used correctly.

It must be remembered that:

– the jack weighs 1.85 kg;

– the jack does not require adjust-

ments;

– the jack cannot be repaired. If it

breaks, it must be changed with an-

other new jack;

– only the jack handle described in

this chapter can be fitted onto the

jack.

3. CHANGING THE WHEEL1)Remove the wheel cup with a

screwdriver (LS versions).

2)Loosen the wheel bolts of the

wheel to be changed by about 1 turn.

3)If the car is fitted with alloy rims,

shake the car to facilitate removing

the rim from the wheel hub.

4)Turn the jack handle Cso that

the jack opens partially.

5)Place the jack at the point marked

by a notch H (fig. 3)near the wheel to

be changed at approximately 10 cm

towards the centre of the car (fig. 3).6)Turn the handle Cto open the

jack until the jack groove is correctly

inserted in the sidemember ribbing.

7)Warn any other people present

that the car is going to be lifted. Other

people must stay clear and not touch

the car until it is back on the ground.

8)Turn jack handle and lift the ve-

hicle until the tyre is a few centime-

tres above the ground.

The jack handle must turn freely,

without touching the ground to avoid

scraping your hand.

Do not touch moving parts of the

jack (screws and joints) as they can

cause injuries. If you dirty your hands

with grease, clean them carefully.

9)Undo the 4 bolts completely and

remove the wheel cover (Nversion)

and wheel.

fig. 6

P4C00161

fig. 7

P4C00403

4C090-119 ING 11-03-2008 12:00 Pagina 98

Page 102 of 191

99

G

10)Ensure that the support surfaces

of the spare wheel are clean and free

from impurities which could succes-

sively cause the wheel bolts to loosen.

Mount the spare wheel so that the

holesI (fig. 4) coincide with the rela-

tive pinsL.

IMPORTANTDo not fit the wheel

cover on the space-saver spare wheel.

11)Tighten the 4 securing bolts.

12)Turn the jack handle to lower

the car, and remove the jack.

13)Tighten up the wheel bolts com-

pletely in criss-cross fashion following

the order shown in(fig. 5).

14)Put the punctured wheel in the

spare wheel compartment.The spare wheel is narrower than

normal wheels and must only be used

to travel to the nearest service station

so that the original tyre can be re-

paired.

Depending on whether the type of

wheels normally fitted to the car are

alloy or steel, the spare wheel (which

always has a steel rim) will differ in

construction so that it is compatible

with the wheel bolts which are specific

to each type of wheel.

If you wish to change the type of

wheel (alloy instead of steel and vice-

versa) the wheel bolts and a new

spare wheel must be employed.

Modifications or repairs

to the electrical system

carried out incorrectly and

without bearing the features of the

system in mind can cause mal-

functions with the risk of fire. REFITTING THE STANDARD

WHEEL

1)Following the above procedure,

raise the car and take off the space-

saver wheel.

4)Fit the wheel cover (1.2

16VM Nblueversion), mak-

ing sure that slit C (fig. 6)

corresponds with the inflation valve.

5)Insert the other three bolts, using

extensionF (fig. 2)(1.2

16VM Nblue

version).

6)Tighten the bolts using the spe-

cial wrench D (fig. 2).

fig. 8

P4C00404

4C090-119 ING 11-03-2008 12:00 Pagina 99

Page 103 of 191

100

G

7)Lower the car and re-

move the jack.

8)Tighten up the bolts com-

pletely in the order given previously in

(fig. 5).

9)Fit the wheel cover (LS version)

making sure that the inflation valve

seat is positioned correctly; press the

cover with the palm of your hands (do

not bang) against the rim shoulder

and ensure that all the retaining flaps

are inserted into the rim.

When you have finished:

– Put the space-saver spare

wheel into its special recess in

the boot.

– Refit the jack in its support mak-

ingA (fig. 7)coincide with the ring B

on the jack and positioning the base

of the jack to match C.

– Refit the tools you used on the sup-

port.

– Arrange the support and close the

fastenerA (fig. 8).

IMPORTANTCheck the inflation

pressure of the tyres and the spare

wheel regularly.

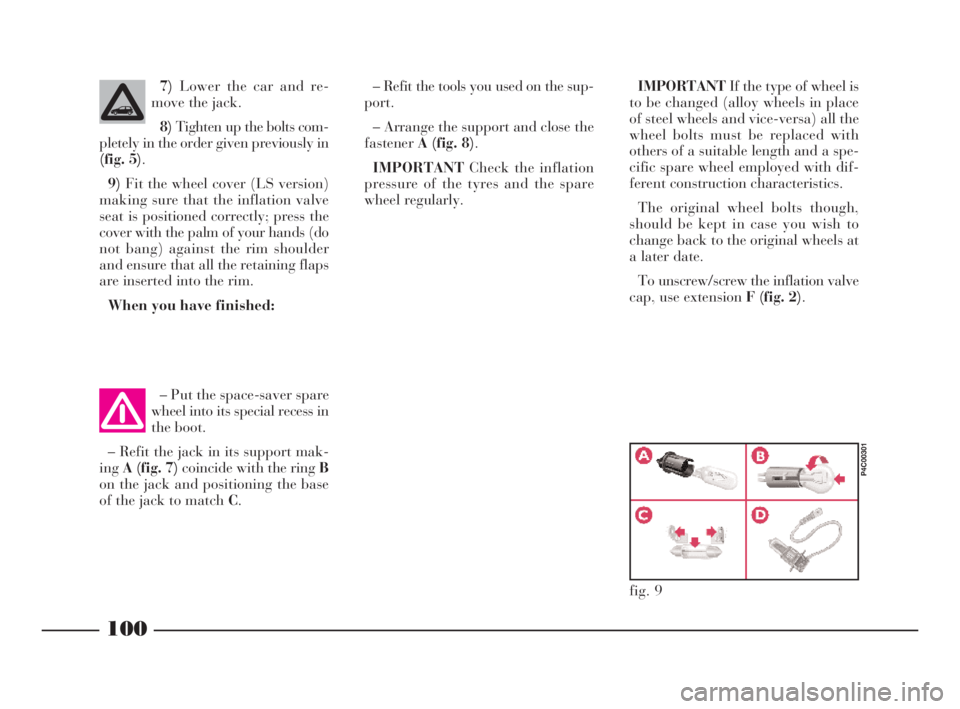

fig. 9

P4C00301

IMPORTANTIf the type of wheel is

to be changed (alloy wheels in place

of steel wheels and vice-versa) all the

wheel bolts must be replaced with

others of a suitable length and a spe-

cific spare wheel employed with dif-

ferent construction characteristics.

The original wheel bolts though,

should be kept in case you wish to

change back to the original wheels at

a later date.

To unscrew/screw the inflation valve

cap, use extension F (fig. 2).

4C090-119 ING 11-03-2008 12:00 Pagina 100

Page 104 of 191

101

fG

C Tubular bulbs

Release these bulbs from rela-

tive contacts to remove them.

D Halogen bulbs

Release the securing spring

from its seat to remove the

bulb.BULB Fig. 9 TYPE POWER

Main beam headlights

Dipped beam headlights

Front side lights

Front direction indicators

Side direction indicators

Rear direction indicators

Foglights

Reverse lights

Rear brake and side lights

Rear side lights

Rear fog lights

Third brake light

Number plate

Ceiling light (1.2 16VM Nblue- LS versions)

Ceiling light:

– with courtesy light

– with map light

BootD H3 12V-55W

D H7 12V-55W

A W5W 12V-5W

B PY21W 12V-21W

A W5W 12V-5W

B PY21W 12V-21W

D H1 12V-55W

B P21W 12V-21W

B R5W 12V-21/5W

B R5W 12V-21W

B P21W 12V-21W

A W5W 12V-5W

C C5W 12V-5W

C – 12V-10W

C – 12V-10W

A – 12V-6W

C C5W 12V-5W

4C090-119 ING 13-03-2008 12:51 Pagina 101

Page 105 of 191

102

fG

FRONT SIDE LIGHTS

To replace the 12V-5W bulb (type

W5W):

1)Remove the cover B (fig.10)by

turning partially in an anti-clockwise

direction.

2)Slide out bulb holder C (fig. 12)

by turning it slightly to make it easier

to release.

3)Remove the bulb.

4)Replace the press-fit bulb and re-

fit the bulb holder and cover.

fig. 12

P4C00025

HEADLIGHTS

To replace the halogen lights (12V-

55W):

1)Remove covers AandB (fig. 10)

by turning them partially in an anti-

clockwise direction.

2)Release the clips C-E (fig. 11)

and remove the burnt-out bulb D

(mainbeam headlight of type H3 with

printed wire already attached) or F

(dippedbeam headlight, type H7).

3)Insert the new bulb, making sure

it is positioned properly.

4)Reattach the securing clips and

close the covers.IF AN EXTERIOR

LIGHT BURNS OUT

fig. 10

P4C00027

fig. 11

P4C00026

Modifications or repairs

to the electrical system

carried out incorrectly and

without bearing the features of the

system in mind can cause mal-

functions with the risk of fire.

4C090-119 ING 13-03-2008 12:51 Pagina 102

Page 106 of 191

103

fG

FRONT DIRECTION

INDICATORS

To replace the 12V-21W bulb (type

PY21W):

1)Release spring clip A (fig. 13)

from support Bby turning in the di-

rection of the arrow.

2)Pull out the lens unit from the

front.

3)The bulb holder Cis connected to

the lens unit. To remove it, turn it

slightly.4)Remove bulbE (fig. 14), by push-

ing it gently and turning it in an an-

ticlockwise direction.

5)Replace the bulb, then refit the

bulb holder to the lens unit.

6)Reposition the lens unit, by intro-

ducing the two tabs Dinto the guides

at the side of the headlamp.

7)Reattach spring clip A.DIRECTION INDICATOR

REPEATERS

To replace the 12V-5W bulb (type

W5W):

1)Push the lens A (fig. 15)in the di-

rection of the arrow to release the fas-

tening tab. Be careful not to damage

the bodywork.

2)Take the unit out.

fig. 13

P4C00029

fig. 14

P4C00405

fig. 15

P4C00382

4C090-119 ING 13-03-2008 12:51 Pagina 103

Page 107 of 191

REAR LIGHT CLUSTER

1)From inside the car boot, lift the

carpeting and undo screw A (fig. 19)

securing the light cluster.

2)Remove the light cluster B.

3)Replace the burnt-out bulb by

pushing it slightly and turning anti-

clockwise.

Bulbs in (fig. 20):

C - 12V-21W (orange) (type PY21W)

for the direction indicators.

D - 12-21W (type P21W) for the re-

versing lights.

104

fG

3)Remove the bulb holder B

(fig. 16)fromCin the lens.

4)Remove press-fit bulb Dand re-

place it.

5)Refit the bulb holder into Cand

then fit the lens.

FRONT FOGLIGHTS

To replace the halogen bulb 12V-

55W (type H1):

1)Turn the wheels to the right to get

at the left light, and to the left to get

at the right light.

2)Unscrew screw A (fig. 17)in the

cover on the wheelarch.3)Turn cover Bin an anticlockwise

direction.

4)Release clip D (fig. 18)and re-

move bulbC.

5)Release the clip Dand screw

coverBback in.

fig. 16

P4C00383

fig. 17

P4C00152

fig. 18

P4C00406

fig. 19

P4C00038

4C090-119 ING 13-03-2008 12:51 Pagina 104

Page 108 of 191

105

fG

E- 12V-21/5W (type R5W) for the

brake and taillights.

F- 12V-5W (type R5W) for the tail-

lights.

G- 12V-21W (type P21W) for the

rear foglights.

5)Refit the lighting cluster, and

tighten screw A (fig. 19), without

forcing it.THIRD BRAKE LIGHT

To change one or more 12V-5W

(type W5W) bulbs:

1)Unscrew the two screws A (fig. 21)

and remove trim B.

2)Loosen the two screws C (fig. 22),

disconnect the connector Dand sep-

arate the lens from the cover B.

3)Loosen the tab E (fig. 23)and

separate the bulbs from the lens.4)Replace the burnt-out bulb F

(fig. 23).

5)Refit the unit by reversing the

various operations.

fig. 20

P4C00039

fig. 21

P4C00407

fig. 22

P4C00408

fig. 23

P4C00409

4C090-119 ING 13-03-2008 12:51 Pagina 105

Page 109 of 191

106

fG

IF AN INTERIOR

LIGHT BURNS OUTrounding it, by inserting the tip of a

screwdriver between the cover frame

and the second frame as illustrated in

(fig. 25).

CEILING LIGHT

(all other versions)

To replace a bulb:

1)Remove the 2 plastic caps Aand

release cover B (fig. 26).

2)Unscrew the 4 screws securing the

ceiling light unit that can be seen.

3)Press tab A (fig. 27)to open the

bulb holder.

4)Replace the burnt-out bulb.

B- 12V-10W bulb for courtesy light.

C- 12V-6W bulb for map-reading

light. NUMBER PLATE LIGHTS

To replace the 12V-5W (type C5W)

bulb, unscrew the securing screws A

(fig. 24)and remove the lens.

CEILING LIGHT (1.2

16VM Nblue

- LS)

To replace the 12V-10W bulb in the

ceiling lamp, remove the transparent

cover, together with the frame sur-Modifications or repairs

to the electrical system

carried out incorrectly and

without bearing the features of the

system in mind can cause mal-

functions with the risk of fire.

fig. 24

P4C00147

fig. 25

P4C00164

fig. 26

P4C00064

4C090-119 ING 13-03-2008 12:51 Pagina 106

Page 110 of 191

Before replacing a fuse,

make sure the key has

been taken out from the ig-

nition and that all users are

switched off or deactivated.

107

fG

BOOT LIGHT

To change the 12V-5W (type C5W)

bulb, remove the lens A (fig. 28), by

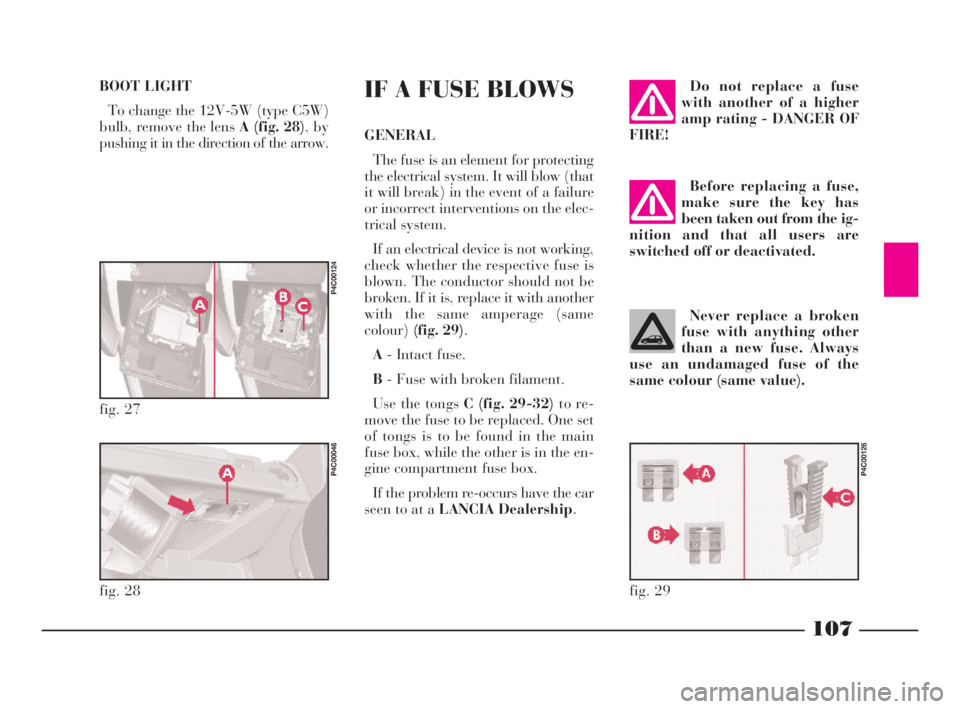

pushing it in the direction of the arrow.IF A FUSE BLOWS

GENERAL

The fuse is an element for protecting

the electrical system. It will blow (that

it will break) in the event of a failure

or incorrect interventions on the elec-

trical system.

If an electrical device is not working,

check whether the respective fuse is

blown. The conductor should not be

broken. If it is, replace it with another

with the same amperage (same

colour)(fig. 29).

A- Intact fuse.

B- Fuse with broken filament.

Use the tongs C (fig. 29-32)to re-

move the fuse to be replaced. One set

of tongs is to be found in the main

fuse box, while the other is in the en-

gine compartment fuse box.

If the problem re-occurs have the car

seen to at a LANCIA Dealership.

Do not replace a fuse

with another of a higher

amp rating - DANGER OF

FIRE!

Never replace a broken

fuse with anything other

than a new fuse. Always

use an undamaged fuse of the

same colour (same value).

fig. 27

P4C00124

fig. 28

P4C00046

fig. 29

P4C00126

4C090-119 ING 13-03-2008 12:51 Pagina 107