service LAND ROVER DEFENDER 1996 Owners Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 209 of 455

FRONT AXLE AND FINAL DRIVE

1

REPAIR REV: 05/99 FRONT AXLE ASSEMBLY

Service repair no - 54.10.01

Remove

WARNING: Remove and refit of axle

requires a further two persons to steady

axle when lowering or repositioning axle.

1.Support chassis front.

2.Remove road wheels.

3.Support axle weight with hydraulic jack.

4.Remove radius arms to chassis frame nuts.

5.Disconnect steering damper from track rod.

Using a extractor remove track rod links from

swivel pin arms.

6.Remove four nuts and bolts securing radius

arms to axle bracket.

7.Remove radius arms.

8.Remove bolts securing brake hose brackets .

Refit bolts to prevent oil leakage.

9.Remove bolts from brake calipers and tie to one

side.

10.Remove nuts and washers securing shock

absorbers to axle.

11.Disconnect drag link from swivel pin housing

arm.

12.Remove two nuts and bolts securing panhard

rod to axle bracket. Lift rod clear of axle.

13.Mark for reassembly drive shaft flanges.

Remove four nuts and bolts, tie propeller shaft to

one side.

14.Release axle ventilation pipe banjo and lower

axle assembly. Remove road springs.

15.Disconnect anti-roll bar link

See FRONT

SUSPENSION, Repair, Anti-roll bar ball

.

16.Remove axle assembly.

Refit

17.Position axle under vehicle, supporting left side

of axle, and fit anti-roll bar links

See FRONT

SUSPENSION, Repair, Anti-roll bar links

.

18.Fit propeller shaft. Tighten bolts to

47 Nm (35

lbf/ft).

19.Fit panhard rod to axle bracket. Tighten bolts to

88 Nm (65 lbf/ft).

20.Fit drag link to swivel pin arm. Tighten fixings to

40 Nm (30 lbf/ft).

21.Fit shock absorbers to axle.

22.Fit brake calipers. Tighten bolts to

82 Nm (60

lbf/ft).

23.Tighten upper swivel pin bolts to78 Nm (58

lbf/ft).

24.Fit radius arms to axle brackets. Tighten bolts to

197 Nm (145 lbf/ft).

25.Fit steering damper to track rod.

26.Fit radius arms to chassis side member. Tighten

fixings to

197 Nm (145 lbf/ft).

27.Tighten track rod end to40 Nm (30 lbf/ft)and fit

new split pin.

28.Remove chassis supports, fit road wheels and

tighten to correct torque:

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 210 of 455

54FRONT AXLE AND FINAL DRIVE

2

REPAIR FRONT HUB ASSEMBLY

Service repair no - 60.25.01.

Remove

1.Loosen front wheel nuts, jack up vehicle and

lower onto axle stands and remove road wheel.

2.Release brake hose clips and remove brake

caliper and brake disc shield bolts. Secure to

one side.3.Lever off dust cap.

4.Remove circlip and drive shaft shim from

driveshaft.

5.Remove 5 bolts and withdraw driving member

and joint washer.

6.Bend back lock washer tabs.

7.Remove locknut and lock washer.

8.Remove hub adjusting nut.

9.Remove spacing washer.

10.Remove hub and brake disc assembly complete

with bearings.

HUB COMPONENTS

1.Dust cap.

2.Drive shaft circlip.

3.Drive shaft shim.

4.Drive member.

5.Drive member joint washer.

6.Drive member retaining bolt.

7.Lock nut.

8.Lock washer.9.Hub adjusting nut.

10.Spacing washer.

11.Outer bearing.

12.Hub.

13.Inner bearing.

14.Grease seal.

15.Brake disc

16.Disc retaining bolt.

Page 212 of 455

FRONT AXLE AND FINAL DRIVE

1

OVERHAUL FRONT DIFFERENTIAL

Service repair no - 54.10.07.

Overhaul

NOTE: The front axle differential, for all

models, is the same as that fitted to the 90

rear axle and can only be serviced as a

complete assembly

See REAR AXLE AND FINAL

DRIVE, Repair, Differential assembly - 90

.

FRONT HUB

Service repair no - 60.25.14.

Overhaul

1.Remove hub assembly

See Repair, Front hub

assembly

.

2.Remove outer bearing.

3.Mark, for reassembly, relationship between hub

and brake disc, if original hub is to be refitted.

4.Remove 5 bolts and separate hub from brake

disc.

5.Drift out grease seal and inner bearing from hub

and discard seal.

6.Drift out inner and outer bearing tracks.

7.Clean hub and drift in inner and outer bearing

tracks.

8.Pack hub inner bearing with recommended

grease and fit to hub.

9.With lip side leading fit new seal to hub using

special toolLST 137seal replacer and drift18G

134. Drive in seal flush with rear face of hub.

Apply grease between seal lips.

10.Fit brake disc to hub, lining up to marks made

during dismantling. Applying Loctite 270, fit

retaining bolts. Tighten to

73 Nm (54 lbf/ft).

11.Grease and fit outer bearing to hub.

12.Fit hub assembly

See Repair, Front hub

assembly

.

Page 213 of 455

54FRONT AXLE AND FINAL DRIVE

2

OVERHAUL FRONT STUB AXLE, CONSTANT VELOCITY JOINT

AND SWIVEL PIN HOUSING

Service repair no - 60.15.43.

Remove stub axle, axle shaft and constant

velocity joint.

1.Remove front hub assembly

See Repair, Front

hub assembly

.

2.Drain swivel pin housing and refit plug.

NOTE: On later vehicles the swivel pin

housing is filled with grease for life, the

level and drain plugs being deleted.

3.Remove 6 bolts retaining stub axle to swivel

housing.

4.Remove mud shield.

5.Remove stub axle and joint washer.

6.Wthdraw axle shaft and constant velocity joint

from axle casing.

Remove constant velocity joint from axle shaft

7.Hold axle shaft firmly in a soft jawed vice.

8.Using a soft mallet drive constant velocity joint

from shaft.

9.Remove circlip and collar from axle shaft.

Constant velocity joint

10.Mark positions of constant velocity joint, inner

and outer race and cage for reassembly.

11.Swivel cage and inner race to remove balls.

Page 235 of 455

STEERING

1

ADJUSTMENT POWER STEERING BOX - ADJUST

Service repair no - 57.35.01

WARNING: Adjustments of steering box

should not be required while in warranty

period. If box is stiff or tight and within

warranty, it must be returned to manufacturer. No

attempt must be made to introduce backlash.

1.Apply park brake brake, chock wheels and Jack

up front of vehicle until wheels are clear of

ground.

2.Support chassis front on axle stands.

3.Disconnect drag link from steering drop arm.

4.Check torque to turn

See Fault diagnosis,

Stiff Steering Checklist

.

5.Centralise steering box

See Centralise

Steering Box

.

NOTE: Only check for no backlash when

steering box is in central position.

NOTE: If steering wheel is not straight, it

should be repositioned

See Repair,

Steering Wheel

.

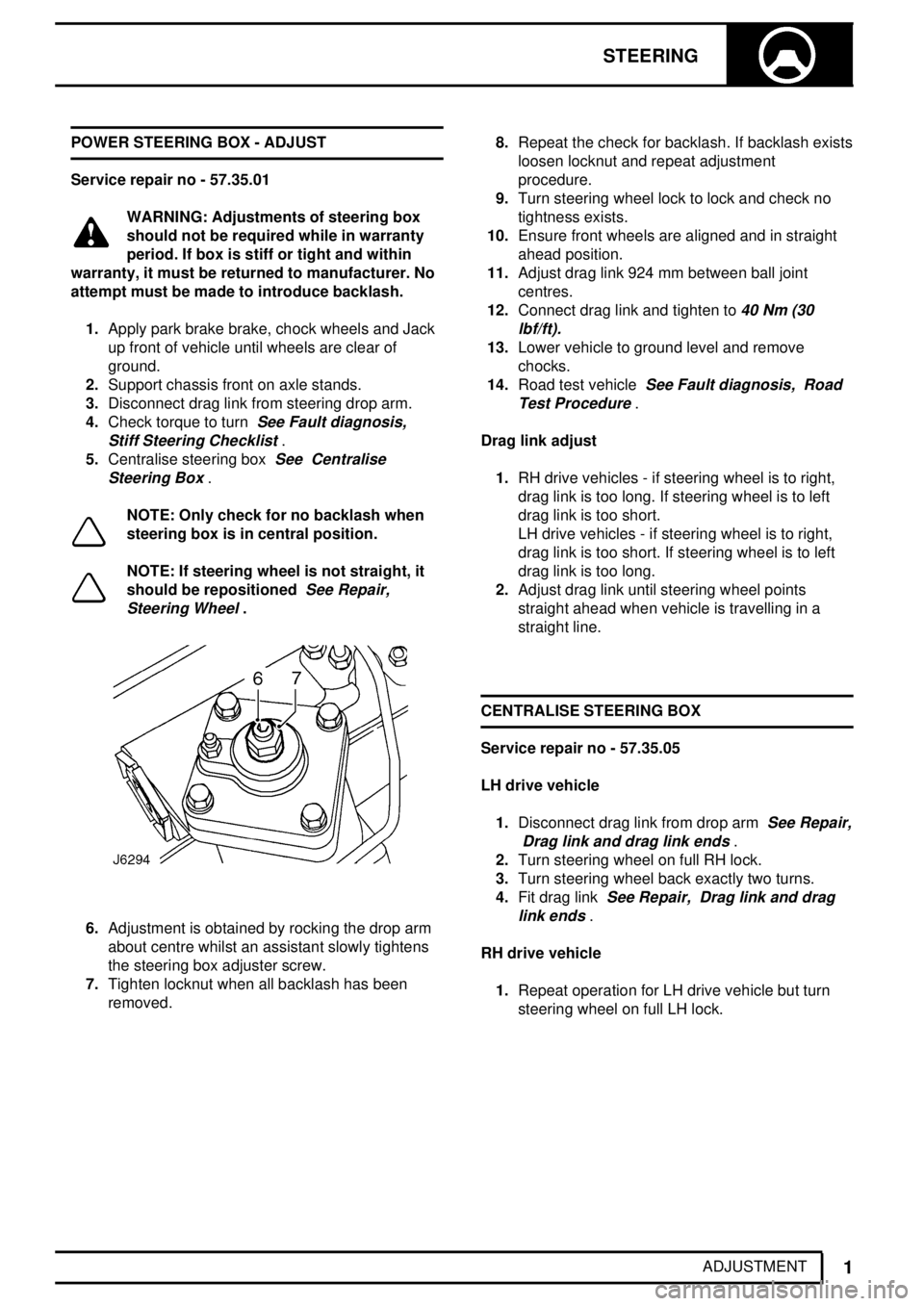

6.Adjustment is obtained by rocking the drop arm

about centre whilst an assistant slowly tightens

the steering box adjuster screw.

7.Tighten locknut when all backlash has been

removed.8.Repeat the check for backlash. If backlash exists

loosen locknut and repeat adjustment

procedure.

9.Turn steering wheel lock to lock and check no

tightness exists.

10.Ensure front wheels are aligned and in straight

ahead position.

11.Adjust drag link 924 mm between ball joint

centres.

12.Connect drag link and tighten to

40 Nm (30

lbf/ft).

13.Lower vehicle to ground level and remove

chocks.

14.Road test vehicle

See Fault diagnosis, Road

Test Procedure

.

Drag link adjust

1.RH drive vehicles - if steering wheel is to right,

drag link is too long. If steering wheel is to left

drag link is too short.

LH drive vehicles - if steering wheel is to right,

drag link is too short. If steering wheel is to left

drag link is too long.

2.Adjust drag link until steering wheel points

straight ahead when vehicle is travelling in a

straight line.

CENTRALISE STEERING BOX

Service repair no - 57.35.05

LH drive vehicle

1.Disconnect drag link from drop arm

See Repair,

Drag link and drag link ends

.

2.Turn steering wheel on full RH lock.

3.Turn steering wheel back exactly two turns.

4.Fit drag link

See Repair, Drag link and drag

link ends

.

RH drive vehicle

1.Repeat operation for LH drive vehicle but turn

steering wheel on full LH lock.

Page 236 of 455

57STEERING

2

ADJUSTMENT STEERING LOCK STOPS

Service repair no - 57.65.03

Check

1.Measure clearance between tyre wall and radius

arm at full lock. This must be not less than 20

mm.

Adjust

2.Loosen stop bolt locknut.

3.Turn stop bolt as required.

4.Tighten locknut.

5.Check clearance between tyre wall and radius

arm on each lock.

NOTE: Alternatively lock stop adjustment

may be carried out using following

procedure.

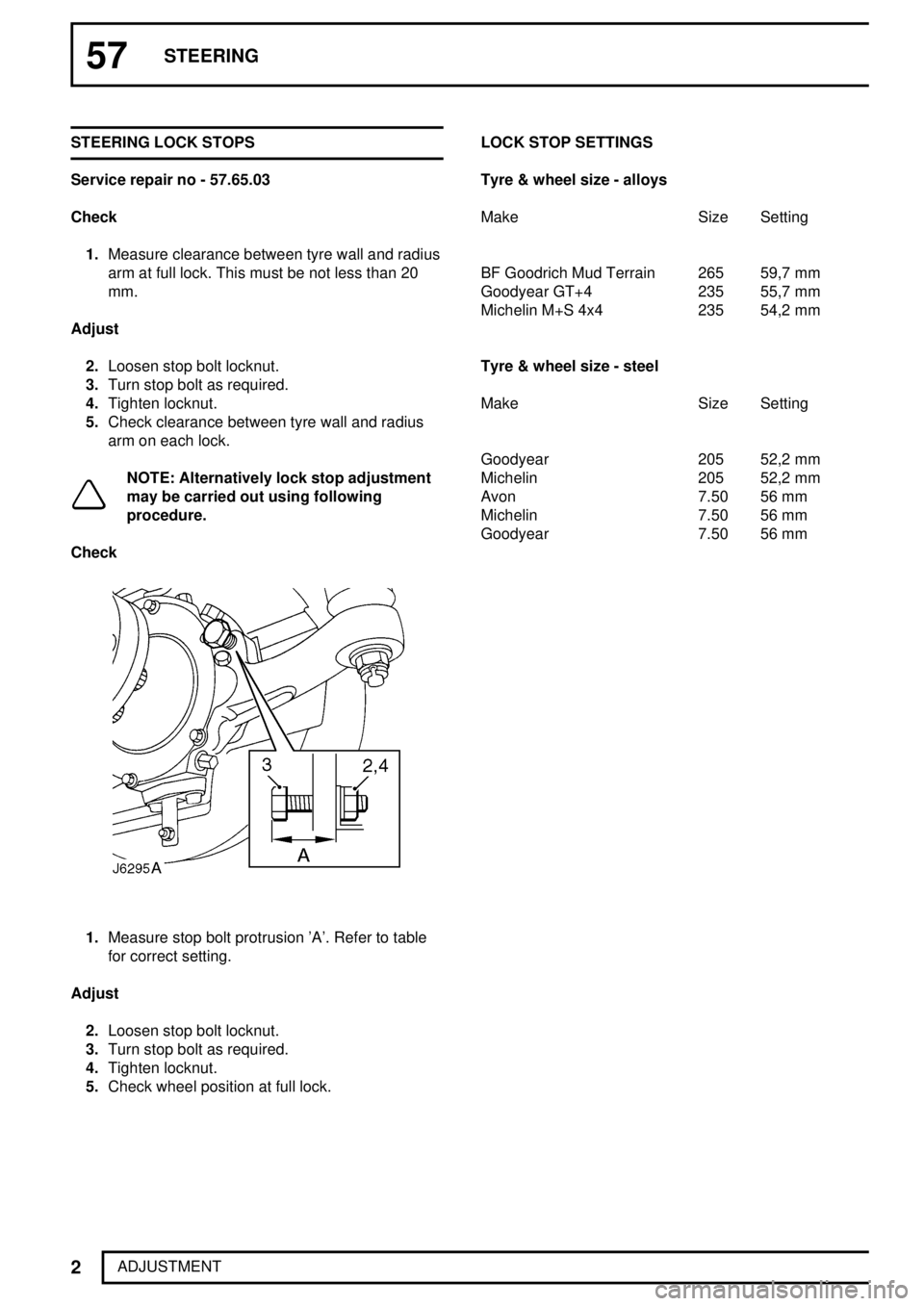

Check

1.Measure stop bolt protrusion 'A'. Refer to table

for correct setting.

Adjust

2.Loosen stop bolt locknut.

3.Turn stop bolt as required.

4.Tighten locknut.

5.Check wheel position at full lock.LOCK STOP SETTINGS

Tyre & wheel size - alloys

Make Size Setting

BF Goodrich Mud Terrain 265 59,7 mm

Goodyear GT+4 235 55,7 mm

Michelin M+S 4x4 235 54,2 mm

Tyre & wheel size - steel

Make Size Setting

Goodyear 205 52,2 mm

Michelin 205 52,2 mm

Avon 7.50 56 mm

Michelin 7.50 56 mm

Goodyear 7.50 56 mm

Page 237 of 455

STEERING

3

ADJUSTMENT FRONT WHEEL ALIGNMENT

Service repair no - 57.65.01

Checking Toe-out dimensions

NOTE: Recognised front wheel alignment

and tracking equipment should be used

for this operation. Only the use of basic

equipment is described below. No Adjustment is

provided for castor, camber or swivel pin

inclinations.

1.Set vehicle on level ground with road wheels

positioned straight ahead.

2.Push vehicle back and forwards to settle linkage.

3.Set up the equipment to manufacturers

instructions and check alignment as advised by

equipment supplier.

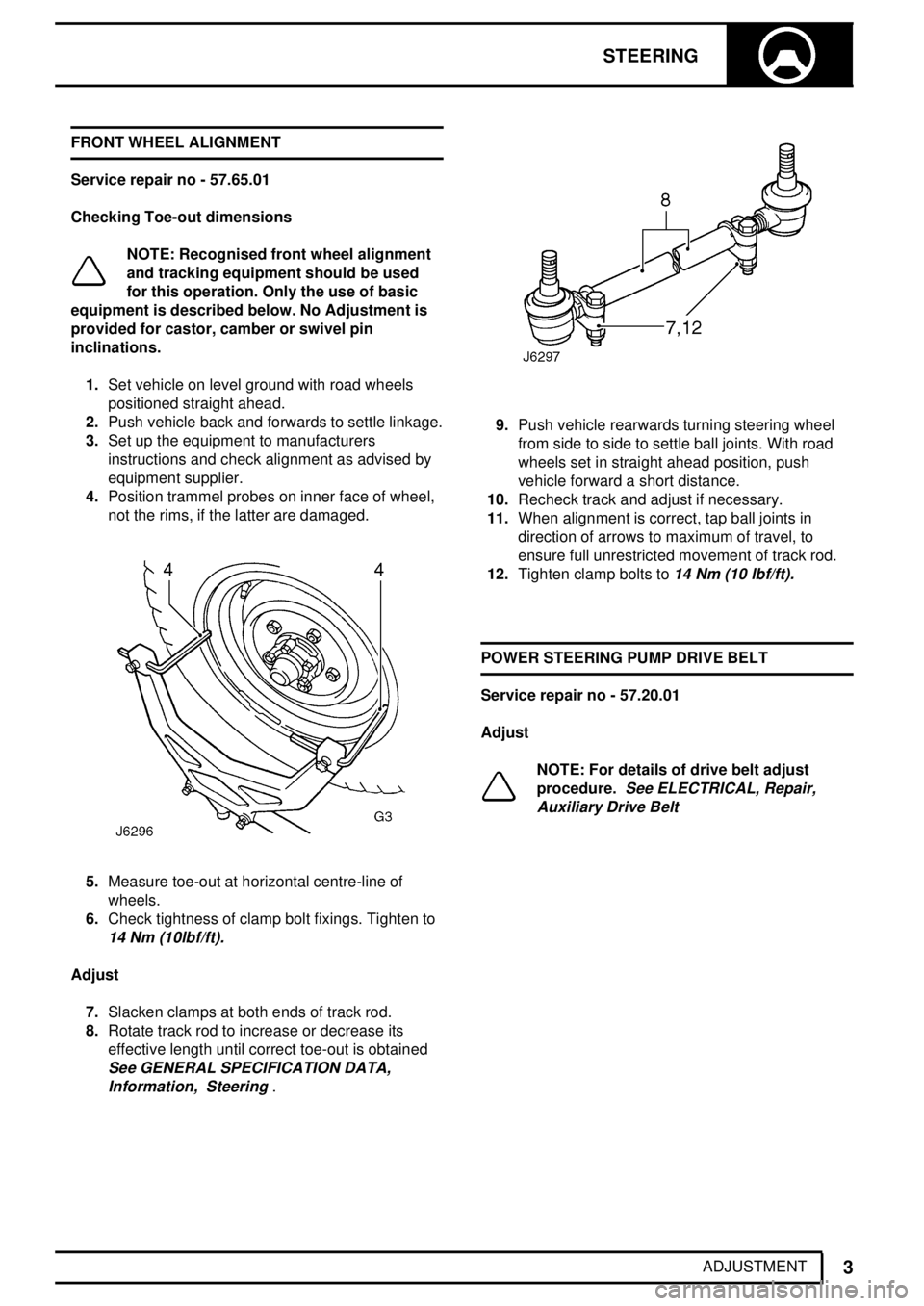

4.Position trammel probes on inner face of wheel,

not the rims, if the latter are damaged.

5.Measure toe-out at horizontal centre-line of

wheels.

6.Check tightness of clamp bolt fixings. Tighten to

14 Nm (10lbf/ft).

Adjust

7.Slacken clamps at both ends of track rod.

8.Rotate track rod to increase or decrease its

effective length until correct toe-out is obtained

See GENERAL SPECIFICATION DATA,

Information, Steering

.

9.Push vehicle rearwards turning steering wheel

from side to side to settle ball joints. With road

wheels set in straight ahead position, push

vehicle forward a short distance.

10.Recheck track and adjust if necessary.

11.When alignment is correct, tap ball joints in

direction of arrows to maximum of travel, to

ensure full unrestricted movement of track rod.

12.Tighten clamp bolts to

14 Nm (10 lbf/ft).

POWER STEERING PUMP DRIVE BELT

Service repair no - 57.20.01

Adjust

NOTE: For details of drive belt adjust

procedure.

See ELECTRICAL, Repair,

Auxiliary Drive Belt

Page 238 of 455

STEERING

1

REPAIR STEERING COLUMN

Service repair no - 57.40.01

Remove

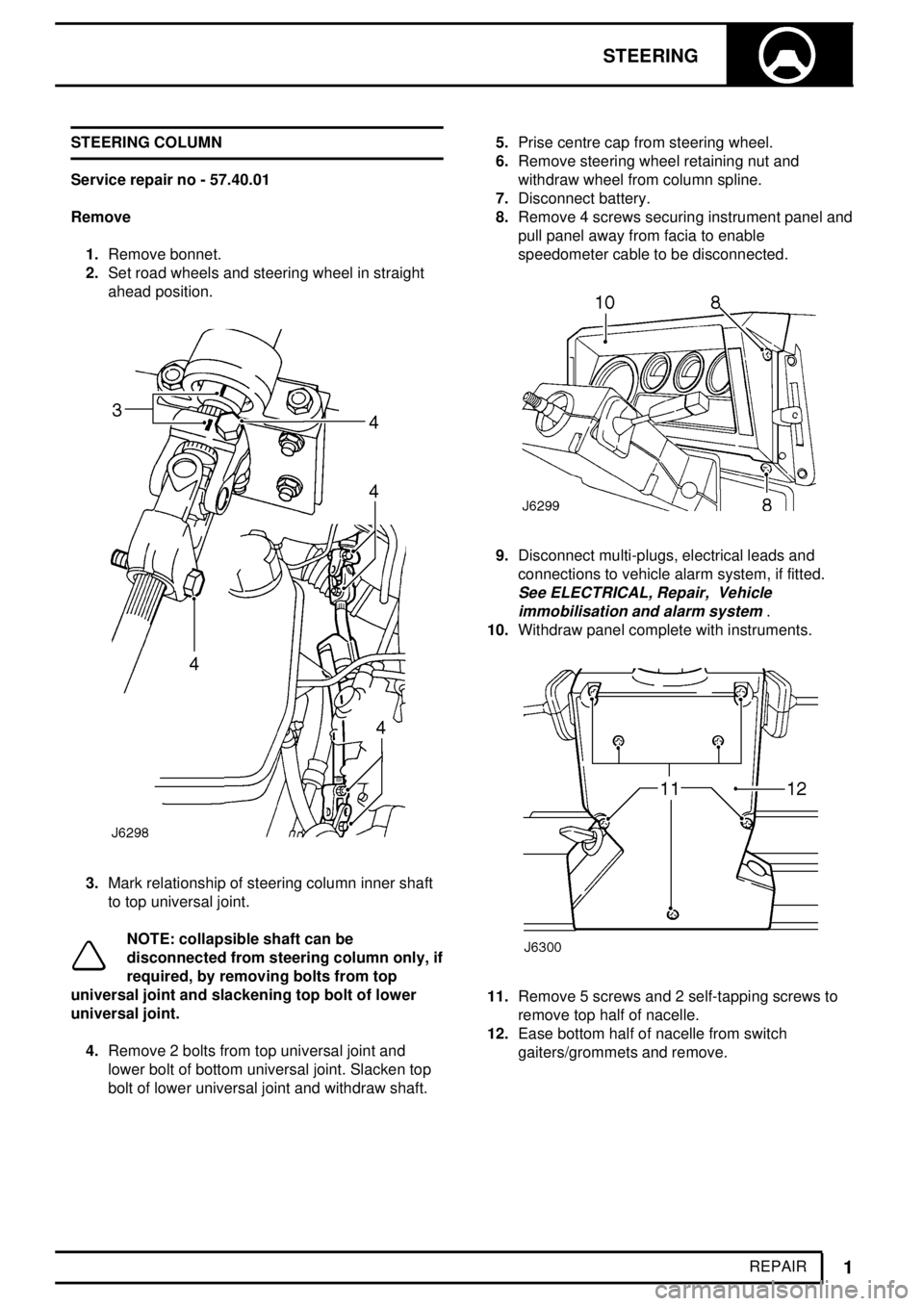

1.Remove bonnet.

2.Set road wheels and steering wheel in straight

ahead position.

3.Mark relationship of steering column inner shaft

to top universal joint.

NOTE: collapsible shaft can be

disconnected from steering column only, if

required, by removing bolts from top

universal joint and slackening top bolt of lower

universal joint.

4.Remove 2 bolts from top universal joint and

lower bolt of bottom universal joint. Slacken top

bolt of lower universal joint and withdraw shaft.5.Prise centre cap from steering wheel.

6.Remove steering wheel retaining nut and

withdraw wheel from column spline.

7.Disconnect battery.

8.Remove 4 screws securing instrument panel and

pull panel away from facia to enable

speedometer cable to be disconnected.

9.Disconnect multi-plugs, electrical leads and

connections to vehicle alarm system, if fitted.

See ELECTRICAL, Repair, Vehicle

immobilisation and alarm system

.

10.Withdraw panel complete with instruments.

11.Remove 5 screws and 2 self-tapping screws to

remove top half of nacelle.

12.Ease bottom half of nacelle from switch

gaiters/grommets and remove.

Page 240 of 455

STEERING

3

REPAIR REV: 05/99

NOTE: The steering column is a non

serviceable component and can only be

serviced as a complete assembly.

25.Fit main support bracket and padding to steering

column and manoeuvre column into position in

vehicle.

26.Loosely secure main support bracket and

harness bracket to bulkhead.

27.Loosely fit clamp and rubber packing strip to

column.

28.Loosely secure lower end of column to lower

support bracket.

29.Loosely secure clamp bracket to main support

bracket.

30.Working inside vehicle cab, fit tie-bar to column

bracket and secure with single bolt to

22 Nm (16

lbf/ft).

31.Finally, tighten main support bracket, clamp

bracket, upper clamp, and lower support bracket

nuts and bolts. (M6 bolts

9 Nm (6 lbf/ft),M8

bolts

22 Nm (16 lbf/ft).

32.Fit brake pedal boxSee BRAKES, Repair,

Brake pedal

.

33.Fit steering lock/switch in position and rotate

steering column inner shaft to line up slot with

switch plunger.

34.Secure lock to column with clamp and shear

bolts. Evenly tighten bolts but do not shear them.

35.Temporarily fit steering wheel and operate

switch and lock mechanism several times to

ensure it functions correctly.

36.Fully tighten switch retaining bolts until heads

shear.

37.Connect electrical leads to rear of switch. Fit

alarm system passive coil, if applicable.

See

ELECTRICAL, Repair, Vehicle immobilisation

and alarm system

.

38.Fit switch assembly on steering column and

tighten clamping screw.

39.Connect switch assembly multi-plugs and

electrical leads to main harness.

40.Offer up instrument panel, connect speedometer

cable, multi-plugs and electrical leads to main

harness. If applicable, fit vehicle alarm system

connections.

See ELECTRICAL, Repair,

Vehicle immobilisation and alarm system

.

41.Secure panel with 4 screws.

42.Locate top half of nacelle in position and fit to

switch gaiters/grommets.43.Fit lower half of nacelle and loosely tighten fixing

screws.

44.Ensure switch gaiters/grommets are correctly

located and fully tighten fixings.

45.Turn indicator cancelling ring so that slots are

vertical and lug with arrow points to the left, in

direction of indicator switch.

46.Fit steering wheel with finisher attachment lug at

bottom, ensuring that indicator cancelling forks

locate in cancelling ring slots.

47.Secure wheel with nut and new shake-proof

washer. Tighten to

43 Nm (32 lbf/ft).

48.Fit steering wheel decal.

49.If necessary, fit new universal joints to support.

Note that long joint is fitted to short length of

shaft and short joint to long end. Joints can only

be fitted one way to shaft.

50.With steering lock engaged and road wheels in

straight ahead position, align reassembly marks,

and fit collapsible shaft assembly with long leg of

shaft to steering box. Fit pinch bolts and tighten

to

25 Nm (18 lbf/ft).

Page 241 of 455

57STEERING

4

REPAIR POWER STEERING BOX

Service repair no - 57.10.01

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray

See

CHASSIS AND BODY, Repair, Front undertray

.

General precautions

·Whenever any part of system, is removed or

disconnected, utmost cleanliness must be

observed.

·Disconnected ports and hoses must be

plugged to prevent ingress of dirt. If metal

sediment is found in system, establish cause,

rectify and flush system.

·Do not start engine until reservoir is full as

pump will be damaged.

·Metric pipe fittings are used with 'O' ring pipe

ends on fittings to steering box.

·Follow normal 'O' ring replacement procedure

whenever pipes are disconnected.

·Ensure compatible metric components when

fitting replacement pipes.

CAUTION: After refitting steering linkage

parts follow correct procedure to ensure

that road wheels, steering box and

steering wheel are correctly positioned relative to

each other when in straight ahead condition.

NOTE: When drag link is disconnected

from steering box, travel available at

steering wheel to each full lock is not

equal.

Remove

1.Site vehicle on level surface.

2.Apply park brake, chock rear wheels, raise

vehicle and locate axle stands. Alternatively,

raise vehicle on a hoist.

3.Remove road wheel.

4.Remove panhard rod

See FRONT

SUSPENSION, Repair, Panhard rod

.

5.Disconnect steering damper from drag link.

6.Disconnect drag link from drop arm, see J6305

on opposite page, using a suitable extractor.

7.Slacken, but do not remove nut securing tie bar

to mounting arm.8.Remove 2 bolts securing tie bar to steering box

and move aside.

9.Remove filler cap from power steering fluid

reservoir.

10.Position suitable container under steering box.

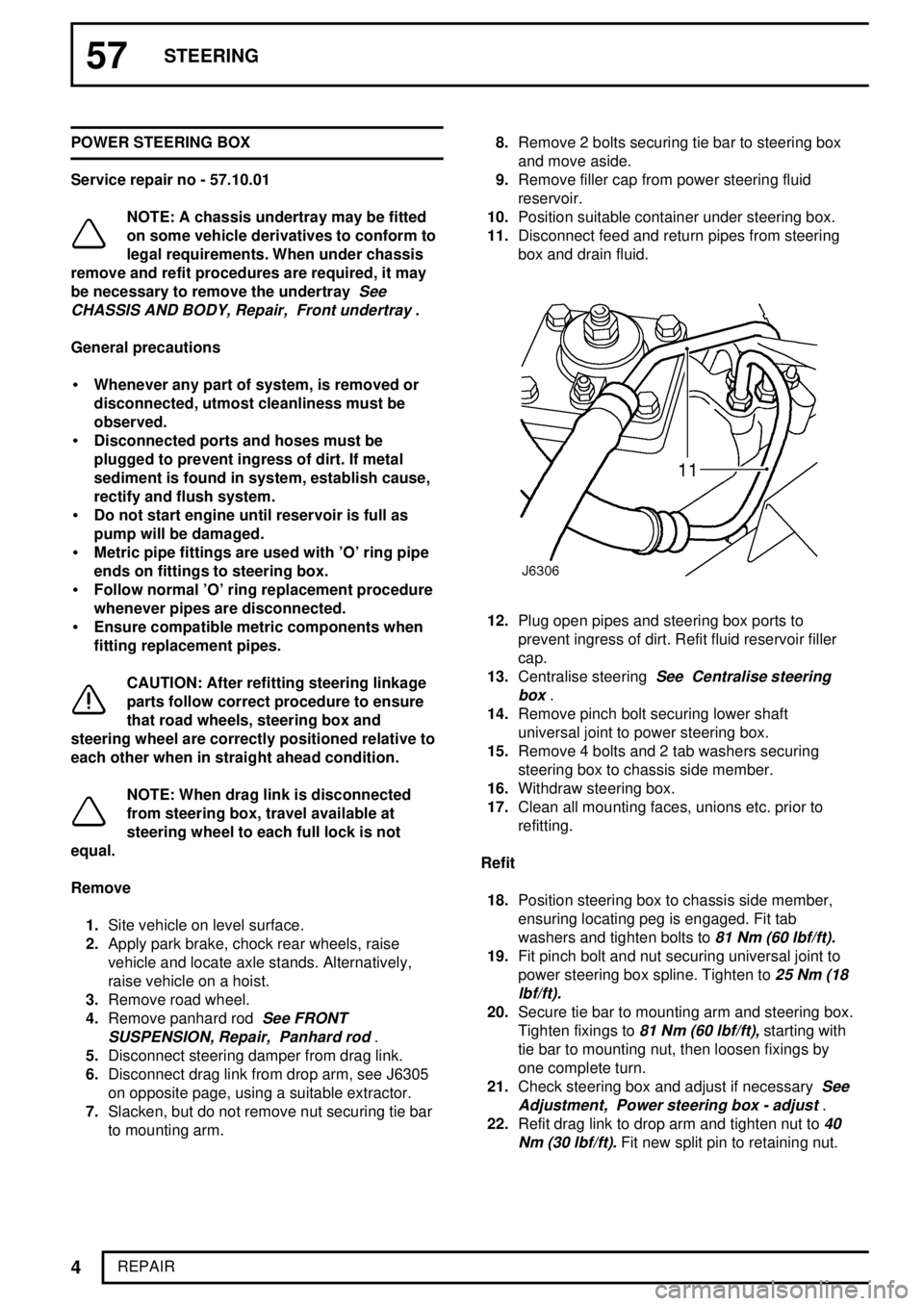

11.Disconnect feed and return pipes from steering

box and drain fluid.

12.Plug open pipes and steering box ports to

prevent ingress of dirt. Refit fluid reservoir filler

cap.

13.Centralise steering

See Centralise steering

box

.

14.Remove pinch bolt securing lower shaft

universal joint to power steering box.

15.Remove 4 bolts and 2 tab washers securing

steering box to chassis side member.

16.Withdraw steering box.

17.Clean all mounting faces, unions etc. prior to

refitting.

Refit

18.Position steering box to chassis side member,

ensuring locating peg is engaged. Fit tab

washers and tighten bolts to

81 Nm (60 lbf/ft).

19.Fit pinch bolt and nut securing universal joint to

power steering box spline. Tighten to

25 Nm (18

lbf/ft).

20.Secure tie bar to mounting arm and steering box.

Tighten fixings to

81 Nm (60 lbf/ft),starting with

tie bar to mounting nut, then loosen fixings by

one complete turn.

21.Check steering box and adjust if necessary

See

Adjustment, Power steering box - adjust

.

22.Refit drag link to drop arm and tighten nut to

40

Nm (30 lbf/ft).

Fit new split pin to retaining nut.