gearbox LAND ROVER DEFENDER 1996 User Guide

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 40 of 455

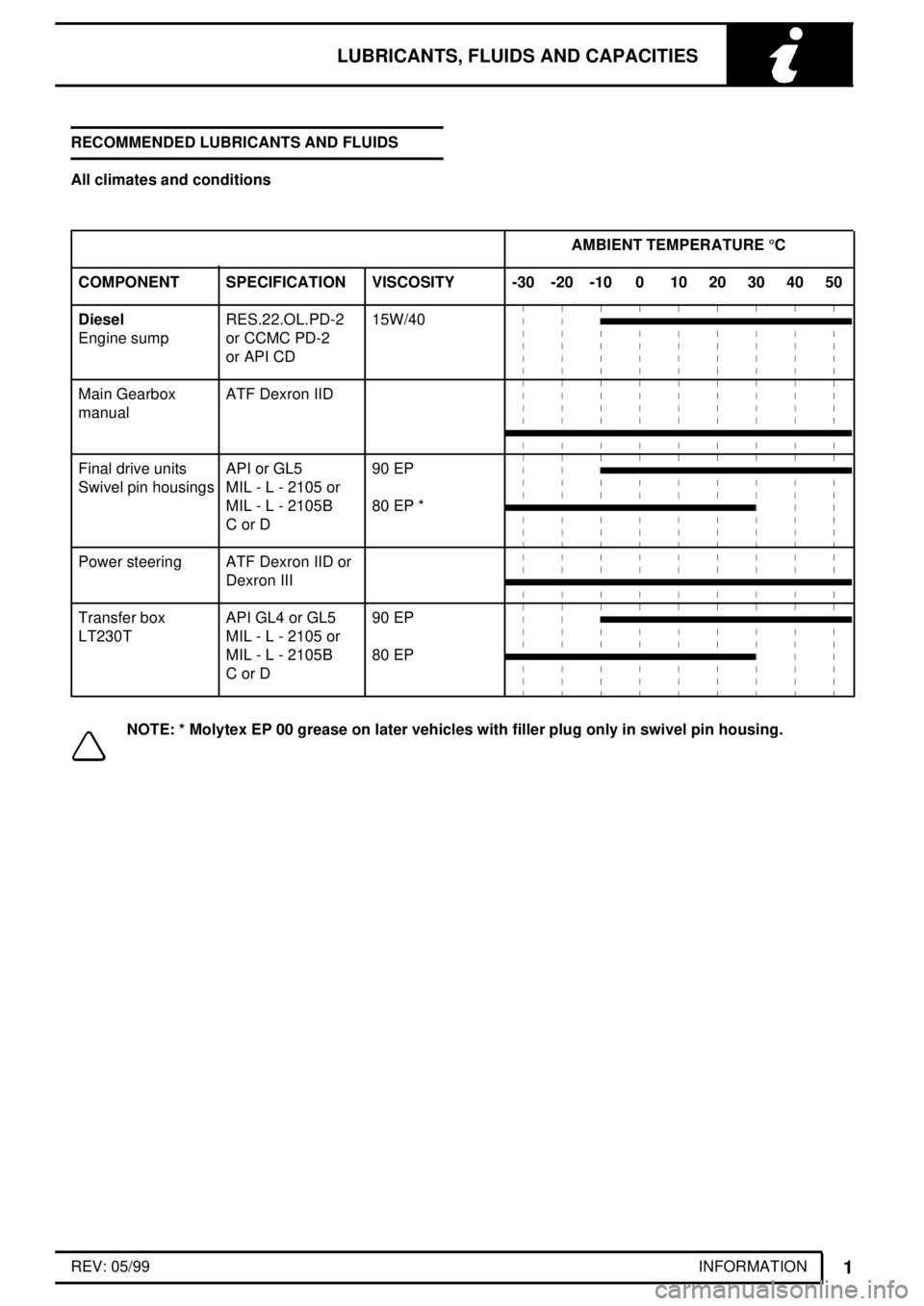

LUBRICANTS, FLUIDS AND CAPACITIES

1

INFORMATION REV: 05/99 RECOMMENDED LUBRICANTS AND FLUIDS

All climates and conditions

AMBIENT TEMPERATURE°C

COMPONENT SPECIFICATION VISCOSITY -30 -20 -10 0 10 20 30 40 50

DieselRES.22.OL.PD-2 15W/40

Engine sump or CCMC PD-2

or API CD

Main Gearbox

manualATF Dexron IID

Final drive units API or GL5 90 EP

Swivel pin housings MIL - L - 2105 or

MIL - L - 2105B 80 EP *

CorD

Power steering ATF Dexron IID or

Dexron III

Transfer box API GL4 or GL5 90 EP

LT230T MIL - L - 2105 or

MIL - L - 2105B 80 EP

CorD

NOTE: * Molytex EP 00 grease on later vehicles with filler plug only in swivel pin housing.

Page 42 of 455

LUBRICANTS, FLUIDS AND CAPACITIES

3

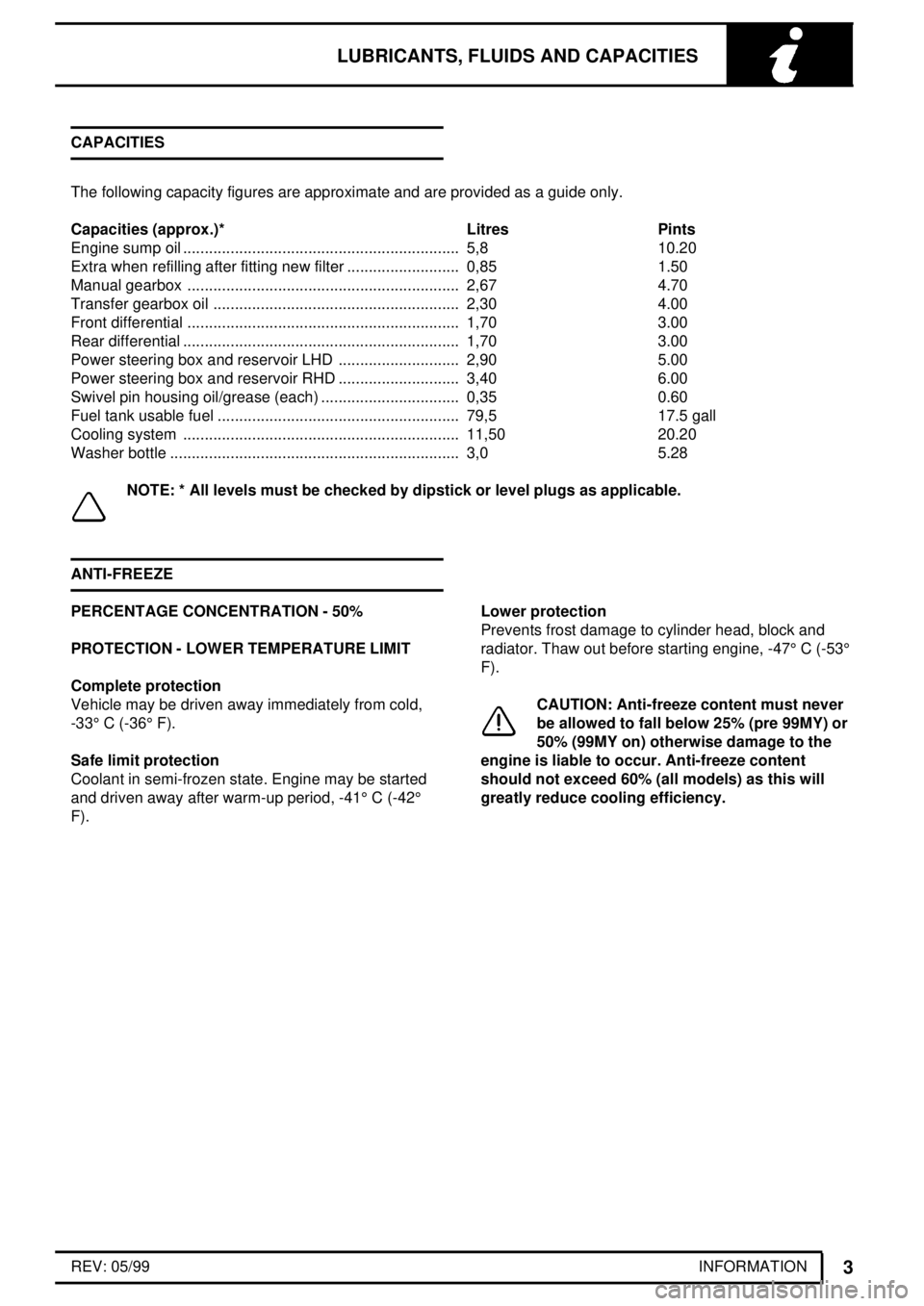

INFORMATION REV: 05/99 CAPACITIES

The following capacity figures are approximate and are provided as a guide only.

Capacities (approx.)* Litres Pints

Engine sump oil 5,8................................................................ 10.20

Extra when refilling after fitting new filter 0,85.......................... 1.50

Manual gearbox 2,67............................................................... 4.70

Transfer gearbox oil 2,30......................................................... 4.00

Front differential 1,70............................................................... 3.00

Rear differential 1,70................................................................ 3.00

Power steering box and reservoir LHD 2,90............................ 5.00

Power steering box and reservoir RHD 3,40............................ 6.00

Swivel pin housing oil/grease (each) 0,35................................ 0.60

Fuel tank usable fuel 79,5........................................................ 17.5 gall

Cooling system 11,50................................................................ 20.20

Washer bottle 3,0................................................................... 5.28

NOTE: * All levels must be checked by dipstick or level plugs as applicable.

ANTI-FREEZE

PERCENTAGE CONCENTRATION - 50%

PROTECTION - LOWER TEMPERATURE LIMIT

Complete protection

Vehicle may be driven away immediately from cold,

-33°C (-36°F).

Safe limit protection

Coolant in semi-frozen state. Engine may be started

and driven away after warm-up period, -41°C (-42°

F).Lower protection

Prevents frost damage to cylinder head, block and

radiator. Thaw out before starting engine, -47°C (-53°

F).

CAUTION: Anti-freeze content must never

be allowed to fall below 25% (pre 99MY) or

50% (99MY on) otherwise damage to the

engine is liable to occur. Anti-freeze content

should not exceed 60% (all models) as this will

greatly reduce cooling efficiency.

Page 53 of 455

10MAINTENANCE

10

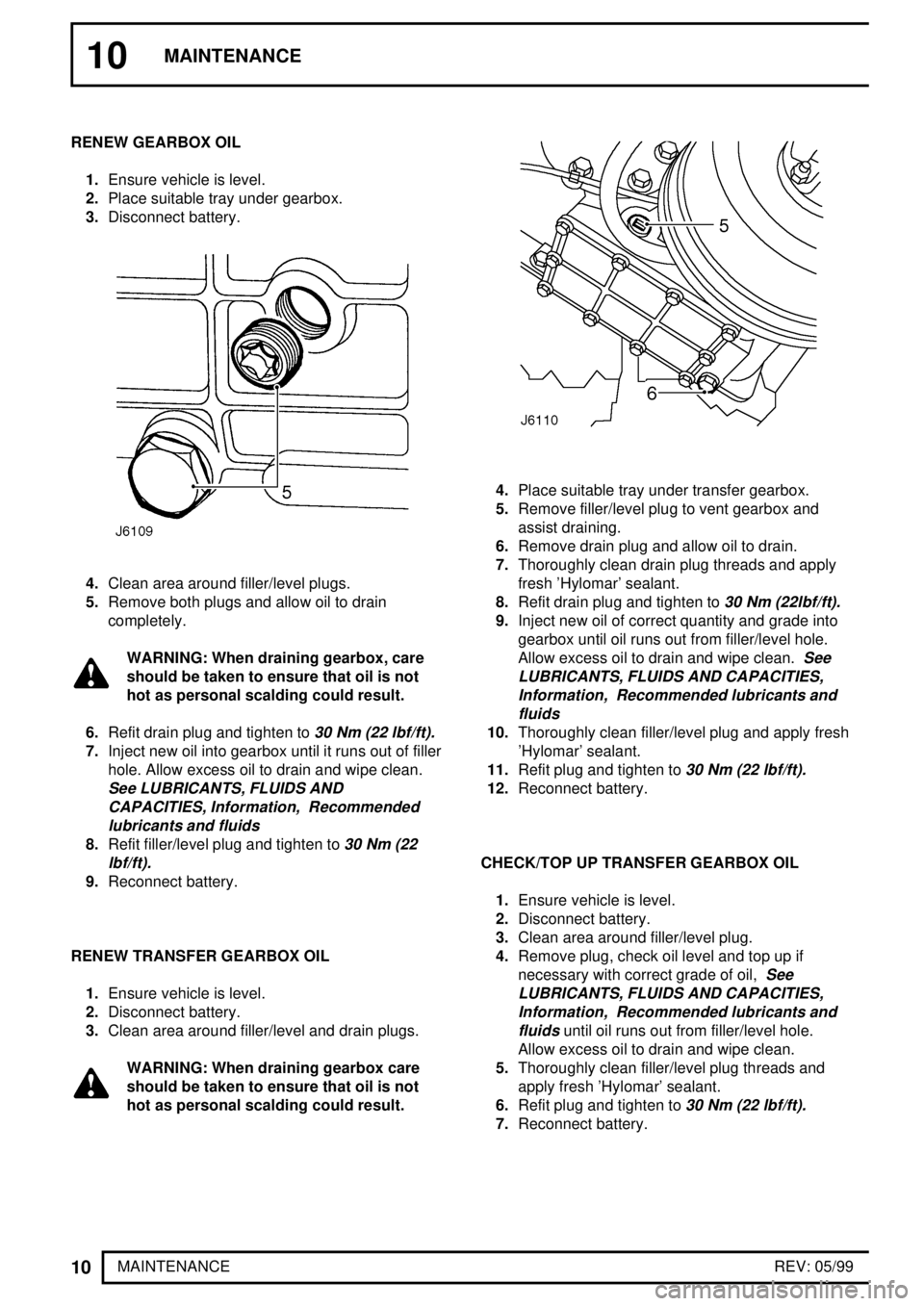

MAINTENANCEREV: 05/99 RENEW GEARBOX OIL

1.Ensure vehicle is level.

2.Place suitable tray under gearbox.

3.Disconnect battery.

4.Clean area around filler/level plugs.

5.Remove both plugs and allow oil to drain

completely.

WARNING: When draining gearbox, care

should be taken to ensure that oil is not

hot as personal scalding could result.

6.Refit drain plug and tighten to

30 Nm (22 lbf/ft).

7.Inject new oil into gearbox until it runs out of filler

hole. Allow excess oil to drain and wipe clean.

See LUBRICANTS, FLUIDS AND

CAPACITIES, Information, Recommended

lubricants and fluids

8.Refit filler/level plug and tighten to30 Nm (22

lbf/ft).

9.Reconnect battery.

RENEW TRANSFER GEARBOX OIL

1.Ensure vehicle is level.

2.Disconnect battery.

3.Clean area around filler/level and drain plugs.

WARNING: When draining gearbox care

should be taken to ensure that oil is not

hot as personal scalding could result.

4.Place suitable tray under transfer gearbox.

5.Remove filler/level plug to vent gearbox and

assist draining.

6.Remove drain plug and allow oil to drain.

7.Thoroughly clean drain plug threads and apply

fresh 'Hylomar' sealant.

8.Refit drain plug and tighten to

30 Nm (22lbf/ft).

9.Inject new oil of correct quantity and grade into

gearbox until oil runs out from filler/level hole.

Allow excess oil to drain and wipe clean.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

10.Thoroughly clean filler/level plug and apply fresh

'Hylomar' sealant.

11.Refit plug and tighten to

30 Nm (22 lbf/ft).

12.Reconnect battery.

CHECK/TOP UP TRANSFER GEARBOX OIL

1.Ensure vehicle is level.

2.Disconnect battery.

3.Clean area around filler/level plug.

4.Remove plug, check oil level and top up if

necessary with correct grade of oil,

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

until oil runs out from filler/level hole.

Allow excess oil to drain and wipe clean.

5.Thoroughly clean filler/level plug threads and

apply fresh 'Hylomar' sealant.

6.Refit plug and tighten to

30 Nm (22 lbf/ft).

7.Reconnect battery.

Page 57 of 455

10MAINTENANCE

14

MAINTENANCEREV: 05/99 ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulphur

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 58 of 455

MAINTENANCE

15

MAINTENANCE ADDITIONAL MAINTENANCE SCHEDULES

Camshaft drive belt

The engine timing gears are driven by a toothed

rubber belt which must be renewed at intervals

determined by the severity of operating conditions. In

reasonable, temperate climate operation, the belt

should be renewed every 120,000 km (72,000 miles)

or every six years whichever occurs earlier.

In adverse operating conditions, such as work in dusty

atmospheres, high ambient temperatures, desert and

tropical zones, renew the belt every 60,000 km

(36,000 miles) or every three years, whichever occurs

earlier.

CAUTION: If the drive belt is not renewed

at the correct interval, it could fail,

resulting in serious engine damage.

Oil change diesel engines

If the vehicle is operated on fuel with a high sulpher

content (over 1%) the oil change intervals must not

exceed 5000 km (3000 miles).

Anti-freeze

At two yearly intervals or at the onset of the second

winter, the cooling system should be drained, flushed

and refilled with the required water and anti-freeze

solution.

Hydraulic brake fluid.

It is recommended that at 40,000 km (24,000 miles)

intervals or every two years, whichever is the earlier,

the hydraulic brake fluid should be completely

renewed.

At 80,000 km (48,000 miles) intervals or every four

years, whichever is the earlier, all hydraulic brake fluid

seals and flexible hoses should be renewed. All

working surfaces of the master cylinder and caliper

cylinders should be examined and renewed where

necessary.Air cleaner

When the vehicle is used in dusty or field conditions or

deep wading, frequent attention to the air cleaner may

be required.

Dampers

At 60,000 km (36,000 miles) intervals remove all

suspension dampers, test for correct operation, refit or

renew as necessary.

SPECIAL OPERATING CONDITIONS

When the vehicle is operated in extremely arduous

conditions or on dusty, wet or muddy terrain, more

frequent attention should be paid to all servicing

requirements.

Additional daily or weekly attention depending on

operating conditions:

Check/top-up transfer box oil.

Check steering rubber boots for security and

condition. Renew if damaged.

Check brake fluid level: Investigate cause if any fluid

loss is suspected.

Clean brake discs and calipers.

Lubricate front and rear propeller shaft

universal/sliding joints. Under tropical or severe

conditions, particularly where sand is encountered,

the sliding joints must be lubricated very frequently to

prevent ingress of abrasive material.

Every week and every maintenance inspection check

tyre pressures and inspect tyre treads and side walls.

Under arduous cross-country conditions the tyre

pressures should be checked much more frequently,

even to the extent of a daily check.

Monthly

Renew gearbox oil.

Renew transfer box oil.

Check air cleaner element and renew every 6 months

or as necessary.

Page 62 of 455

ENGINE

3

REPAIR ENGINE

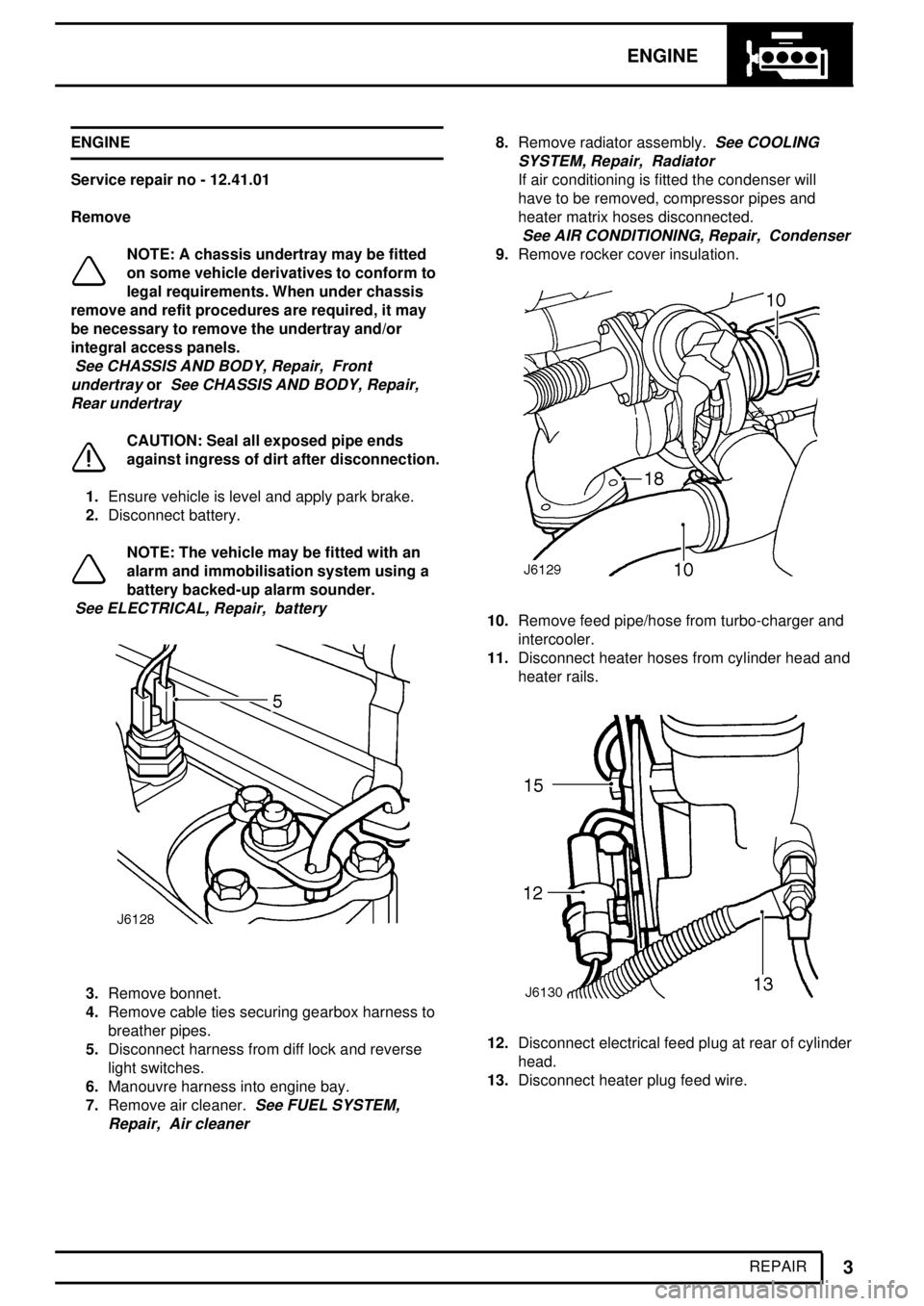

Service repair no - 12.41.01

Remove

NOTE: A chassis undertray may be fitted

on some vehicle derivatives to conform to

legal requirements. When under chassis

remove and refit procedures are required, it may

be necessary to remove the undertray and/or

integral access panels.

See CHASSIS AND BODY, Repair, Front

undertray

orSee CHASSIS AND BODY, Repair,

Rear undertray

CAUTION: Seal all exposed pipe ends

against ingress of dirt after disconnection.

1.Ensure vehicle is level and apply park brake.

2.Disconnect battery.

NOTE: The vehicle may be fitted with an

alarm and immobilisation system using a

battery backed-up alarm sounder.

See ELECTRICAL, Repair, battery

3.Remove bonnet.

4.Remove cable ties securing gearbox harness to

breather pipes.

5.Disconnect harness from diff lock and reverse

light switches.

6.Manouvre harness into engine bay.

7.Remove air cleaner.

See FUEL SYSTEM,

Repair, Air cleaner

8.Remove radiator assembly.See COOLING

SYSTEM, Repair, Radiator

If air conditioning is fitted the condenser will

have to be removed, compressor pipes and

heater matrix hoses disconnected.

See AIR CONDITIONING, Repair, Condenser

9.Remove rocker cover insulation.

10.Remove feed pipe/hose from turbo-charger and

intercooler.

11.Disconnect heater hoses from cylinder head and

heater rails.

12.Disconnect electrical feed plug at rear of cylinder

head.

13.Disconnect heater plug feed wire.

Page 64 of 455

ENGINE

5

REPAIR

26.Disconnect both pipes from fuel lift pump.

27.Release fuel feed pipe from retaining clip on air

cleaner bracket.

28.Disconnect vacuum hose from brake servo.

29.Remove oil pipes from oil filter adaptor.30.Using suitable hoist, fit chains to lifting brackets

and support engine.

31.Remove nuts and plain washers securing front

engine mountings to chassis.

32.Support gearbox.

33.Remove engine to bell housing fixings, leaving

starter motor attached to engine.

34.Carefully raise engine to release from gearbox.

35.Ensure all relevant connections to engine have

been removed.

36.Remove engine.

Refit

37.Clean bell housing.

38.Apply Hylomar sealant to mating faces of bell

housing and flywheel housing.

39.Lubricate splines of gearbox primary pinion with

Rocol MV 3.

40.Carefully lower engine into position and locate

primary pinion into clutch and engage bell

housing dowels.

41.Fit engine to bell housing fixings. Tighten to

40

Nm (30 lbf/ft).

Page 65 of 455

12ENGINE

6

REPAIR 42.Raise engine, and locate front engine mountings

to chassis.

43.Remove gearbox support and lower engine.

44.Tighten front engine mounting to chassis fixings

to

45 Nm (33 lbf/ft).

45.Release chains from engine lifting brackets and

remove hoist.

46.Connect oil cooler pipes to oil filter adaptor.

47.Fit vacuum hose to brake servo adaptor.

48.Secure fuel feed pipe in retaining clip on air

cleaner bracket.

49.Fit fuel lift pump pipes.

50.Connect feed and spill return pipes to injector

pump.

51.If fitted, reconnect hand throttle cable to

mounting bracket and injector pump.

52.Fit outer cable adjusting nut into injector pump

mounting bracket.

53.Fit inner throttle cable to injector pump and

secure with clevis and split pin.

54.Secure bleed hose in retaining clips on front

timing cover.

55.Fit bleed hose to thermostat housing.

56.Connect inlet and outlet hoses to power steering

pump.

57.Fit down pipe to exhaust manifold and secure

with 3 nuts.

58.Connect starter motor battery and fuse box

leads.

59.If fitted, connect EGR valve multi-plug and

vacuum pipe.

60.Secure breather pipe clip to cylinder head.

61.Connect engine harness multi-plug.

62.Fit heater plug feed wire.

63.Connect electrical feed plug at rear of cylinder

head.

64.Fit heater hoses to cylinder head and heater

rails.

65.Fit feed pipe/hose to turbo-charger and

intercooler.

66.Fit rocker cover insulation.

67.Fit radiator assembly.

See COOLING SYSTEM,

Repair, Radiator

If applicable, fit air

conditioning condenser, compressor pipes and

heater matrix hoses.

See AIR CONDITIONING,

Repair, Condenser

68.Fit bonnet.

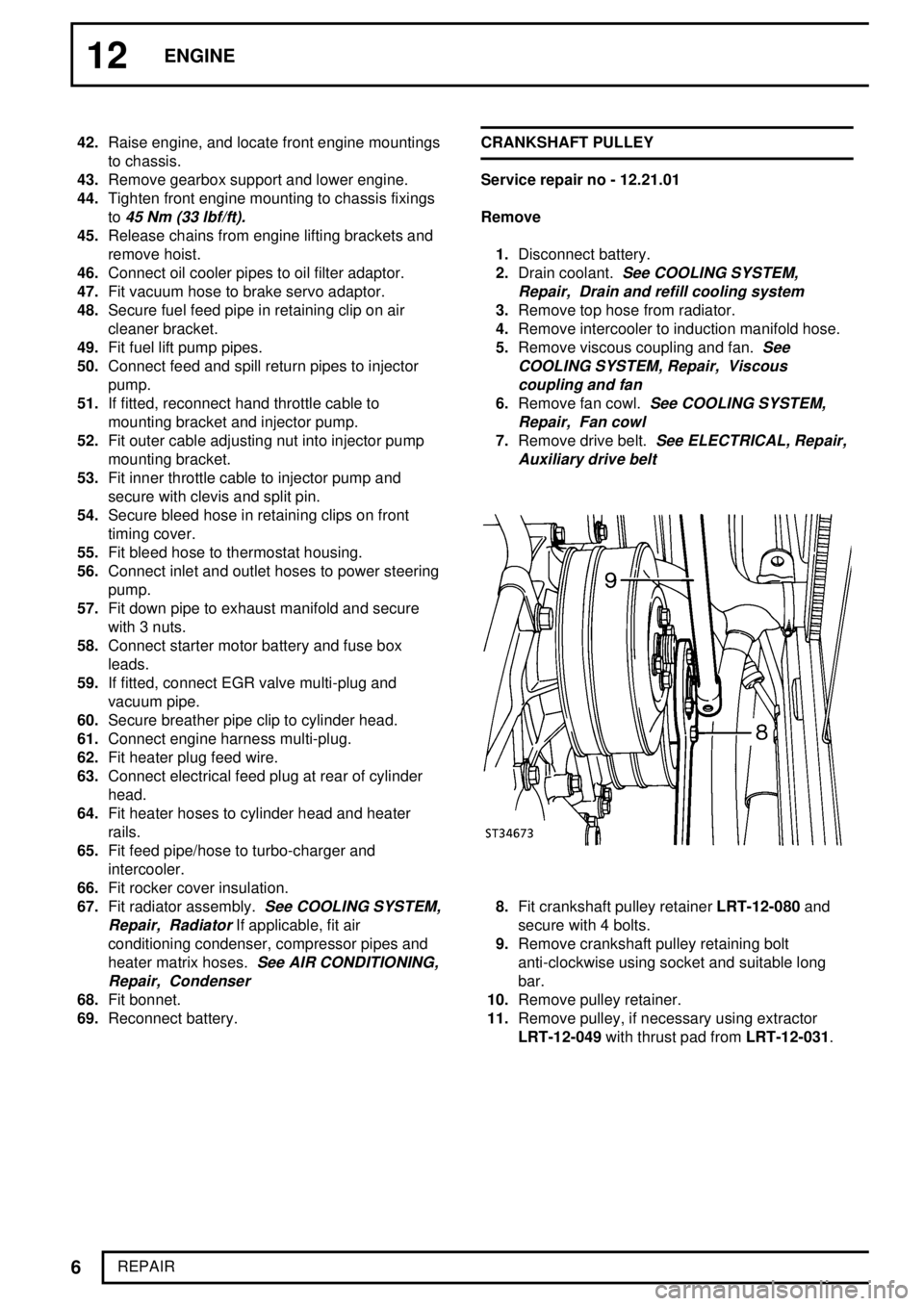

69.Reconnect battery.CRANKSHAFT PULLEY

Service repair no - 12.21.01

Remove

1.Disconnect battery.

2.Drain coolant.

See COOLING SYSTEM,

Repair, Drain and refill cooling system

3.Remove top hose from radiator.

4.Remove intercooler to induction manifold hose.

5.Remove viscous coupling and fan.

See

COOLING SYSTEM, Repair, Viscous

coupling and fan

6.Remove fan cowl.See COOLING SYSTEM,

Repair, Fan cowl

7.Remove drive belt.See ELECTRICAL, Repair,

Auxiliary drive belt

8.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts.

9.Remove crankshaft pulley retaining bolt

anti-clockwise using socket and suitable long

bar.

10.Remove pulley retainer.

11.Remove pulley, if necessary using extractor

LRT-12-049with thrust pad fromLRT-12-031.

Page 74 of 455

ENGINE

15

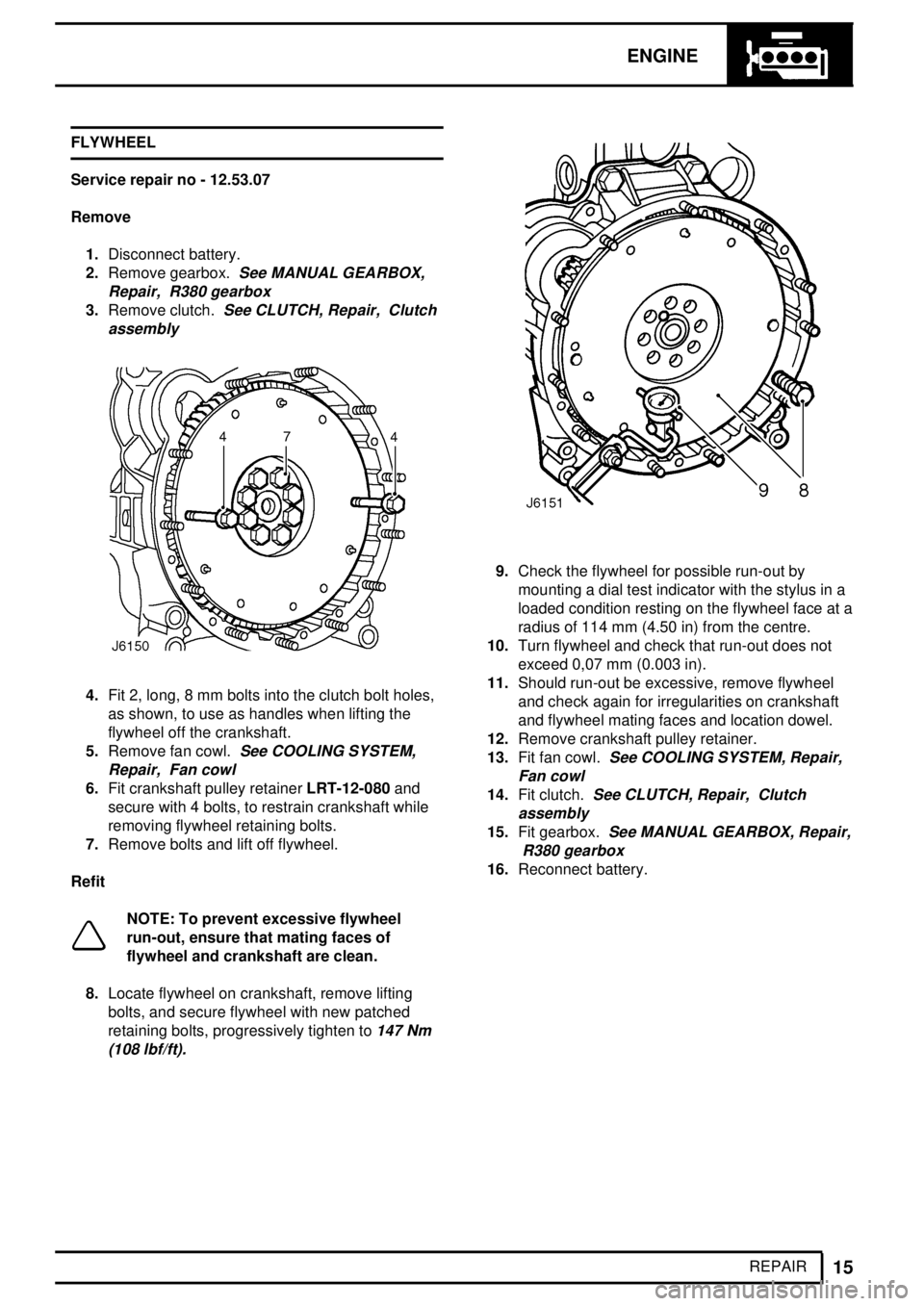

REPAIR FLYWHEEL

Service repair no - 12.53.07

Remove

1.Disconnect battery.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

assembly

4.Fit 2, long, 8 mm bolts into the clutch bolt holes,

as shown, to use as handles when lifting the

flywheel off the crankshaft.

5.Remove fan cowl.

See COOLING SYSTEM,

Repair, Fan cowl

6.Fit crankshaft pulley retainerLRT-12-080and

secure with 4 bolts, to restrain crankshaft while

removing flywheel retaining bolts.

7.Remove bolts and lift off flywheel.

Refit

NOTE: To prevent excessive flywheel

run-out, ensure that mating faces of

flywheel and crankshaft are clean.

8.Locate flywheel on crankshaft, remove lifting

bolts, and secure flywheel with new patched

retaining bolts, progressively tighten to

147 Nm

(108 lbf/ft).

9.Check the flywheel for possible run-out by

mounting a dial test indicator with the stylus in a

loaded condition resting on the flywheel face at a

radius of 114 mm (4.50 in) from the centre.

10.Turn flywheel and check that run-out does not

exceed 0,07 mm (0.003 in).

11.Should run-out be excessive, remove flywheel

and check again for irregularities on crankshaft

and flywheel mating faces and location dowel.

12.Remove crankshaft pulley retainer.

13.Fit fan cowl.

See COOLING SYSTEM, Repair,

Fan cowl

14.Fit clutch.See CLUTCH, Repair, Clutch

assembly

15.Fit gearbox.See MANUAL GEARBOX, Repair,

R380 gearbox

16.Reconnect battery.

Page 75 of 455

12ENGINE

16

REPAIR CRANKSHAFT REAR OIL SEAL

Service repair no - 12.21.20

Remove

NOTE: The crankshaft rear oil seal is

retained in its own housing, if the seal

requires replacing, the complete housing

assembly (1) must be renewed. Housing and seal

assemblies are supplied with their own

former/seal guide (2) already fitted. This former

must not be removed before fitting the assembly

to the engine. If a seal and housing assembly is

received without a former/guide fitted it must be

returned to the supplier. Used formers/guides

must be discarded immediately after use, under

no circumstances should they be reused on other

assemblies.

NOTE: A different rear oil seal housing,

with integral 'O' ring seal and gasket, was

fitted on earlier engines. They must be

replaced with the current housing and gasket (3)

shown below.

1.Disconnect battery.

2.Remove gearbox.

See MANUAL GEARBOX,

Repair, R380 gearbox

3.Remove clutch.See CLUTCH, Repair, Clutch

assembly

4.Remove flywheel.See Flywheel

5.Remove 5 bolts and withdraw seal housing,

complete with gasket.

Refit

NOTE: The raised side of groove at the

bottom of seal housing gasket must be

fitted to cylinder block face.

6.Insert slave studs to locate seal housing gasket.

7.Position new gasket over slave studs and

crankshaft flange onto cylinder block.

8.Fit new seal housing assembly, with

former/guide in-situ, over crankshaft flange. This

action will eject former/guide.

9.Secure assembly to cylinder block, removing

slave studs individually and inserting bolts.

Tighten to

25 Nm (18 lbf/ft).

10.Refit flywheel.See Flywheel