warning LAND ROVER DEFENDER 1996 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1996, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1996Pages: 455, PDF Size: 6.44 MB

Page 280 of 455

70BRAKES

2

DESCRIPTION AND OPERATION REV: 05/99 OPERATION

Master cylinder

A tandem master cylinder, which is assisted by a light

weight, short, compact servo, is fed by a divided fluid

reservoir. The rear section supplies fluid for the

primary circuit and the front section the secondary

circuit.

When the brakes are off, the fluid can move

unrestricted between the dual line system and the

separate reservoirs in the fluid supply tank.

When the footbrake is applied, the primary plunger

assembly moves up the cylinder bore and the

pressure created acts in conjunction with the primary

spring to overcome the secondary springs, thus

moving the secondary plunger assembly up the bore.

At the same time initial movement of both plungers

takes the recuperating seals past the cut-off holes in

the cylinder chambers 'A' and 'C',see J6321, and

applies pressure to the fliud in those chambers, which

is directed to the respective circuits.

The fluid in chambers 'B' and 'D'is unaffected by

movement of the plungers and can move unrestricted

between the separate chambers and respective

reservoirs in the fluid supply tank, both before and

during brake application. When the brakes are

released, the plunger assemblies, aided by the return

springs are retracted faster than the fluid; this creates

a depression between the fluid in chambers 'A' and

'C'and the recuperation seals.

The recuperation seals momentarily collapse allowing

fluid in chambers 'B' and 'D'to flow through the holes

in the plungers, over the collapsed seals and into

chambers 'A' and 'C'respectively. The movement of

fluid from one set of chambers to the other, is

compensated for by fluid from the separate reservoirs

in the supply tank moving through the feed holes in

the cylinder. Conversely, the final return movement of

the plunger assemblies causes the extra fluid in

chambers 'A' and 'C'to move through the cut off holes

into the fluid reservoir.The servo unit provides controlled power assistance

to to the brake pedal when pressure is applied. Power

is obtained from a vacuum pump located on the RH

side of the engine cylinder block. The vacuum is

applied to both sides of a flexing diaphragm, and by

admitting atmosheric pressure to the rear diaphragm,

assistance is obtained. The servo unit is mounted

between the brake pedal and master cylinder and is

linked to these by push rods. Should a vacuum failure

occur, the two push rods will act as a single rod

allowing the brakes to function in the normal way,

although more effort will be required to operate the

brake pedal.

Hydraulic system

A brake fluid loss switch is fitted to the master cylinder

reservoir filler cap. The switch is wired to a warning

light on the vehicle fascia and will illuminate as a bulb

check when the ignition is switched on and

extinguishes when the engine is running and the

handbrake is released. A hydraulic failure in the

system will result in fluid loss, causing the warning

light to illuminate.

On 90 models a pressure reducing valve (PRV), fitted

to the RH bulkhead in the engine compartment,

maintains the braking balance, see J6322. Pressure

to the rear calipers is regulated by the PRV, this valve

is of the failure by-pass type, allowing full system

pressure to the rear brake calipers in the event of a

front (secondary) circuit failure.

NOTE: In some countries, a pressure

reducing valve may be fitted to 110 models

to conform to legal requirements.

Page 282 of 455

BRAKES

1

REPAIR GENERAL BRAKE SERVICE PRACTICE

Brake fluid precautions

WARNING: Do not allow brake fluid to

come into contact with eyes or skin.

CAUTION: Brake fluid can damage

paintwork, if spilled wash off immediately

with plenty of clean water.

CAUTION: Use only correct grade of brake

fluid. If an assembly fluid is required use

ONLY brake fluid. Do NOT use mineral oil,

i.e. engine oil etc.

CAUTION: Thoroughly clean all brake

calipers, pipes and fittings before

commencing work on any part of the brake

system. Failure to do so could cause foreign

matter to enter the system and cause damage to

seals and pistons which will seriously impair the

efficiency of the brake system. To ensure the

brake system efficiency is not impaired the

following warnings must be adhered to :-

·DO NOT use any petroleum based cleaning

fluids or any proprietary fluids containing

petrol.

·DO NOT use brake fluid previously bled from

the system.

·DO NOT flush the brake system with any fluid

other than the recommended brake fluid.

The brake system should be drained and flushed

at the recommended service intervals.

Cover all electrical terminals carefully to make

absolutely certain that no fluid enters the

terminals and plugs.FLUID LEVEL CHECK/TOP UP

WARNING: Clean reservoir body and filler

cap before removing cap. Use only fluid

from a sealed container.

1.Park vehicle on level ground.

2.Check level is between 'MIN' and 'MAX' marks.

3.If level is below 'MIN' mark top up fluid level to

'MAX' mark on reservoir, using correct fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

CAUTION: Do not fill reservoir above

maximum line.

Page 283 of 455

70BRAKES

2

REPAIR BRAKE SYSTEM BLEED

Service repair no - 70.25.02

Preparation

WARNING: Before bleeding the brake

system refer to general brake service

practice.

See General Brake Service

Practice

.

·During bleed procedure, brake fluid level must

not be allowed to fall below the MIN level.

·To bleed the hydraulic circuits, four bleed

nipples are provided, one at each caliper.

·There are two methods by which air can be

removed from the braking system:-

1. MANUAL BLEED PROCEDURE.

2. PRESSURE BLEED PROCEDURE.

Pressure bleed procedure

Purpose designed equipment for pressure filling and

bleeding of hydraulic systems may be used on Land

Rover vehicles. The equipment manufacturer's

instructions must be followed and the pressure must

not exceed 4.5 bar, 65 lb/in

2.

Manual bleed procedure

Equipment required

·Clean glass receptacle

·Bleed hose

·Wrench

·Approx 2 litres (3 pints) brake fluid.

See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information, Recommended lubricants and

fluids

Master cylinder bleed

1.Disconnect battery.

2.Depress brake pedal fully and slowly 5 times.

3.Release the pedal and wait for ten seconds.

4.Air bubbles will rise into the reservoir during

these instructions.

5.Repeat instructions until a firm resistance is felt

at the pedal.

Complete circuit bleed

1.Disconnect battery.

2.Bleed front calipers, driver's side first. Fit bleed

hose to bleed screw.

3.Dip free end of bleed hose into brake fluid in

bleed bottle.

4.Open bleed screw of caliper.

5.Depress brake pedal fully several times until fluid

is clear of air bubbles.

6.Keeping pedal fully depressed, tighten bleed

screw, then release pedal.

7.Repeat procedure on other front caliper followed

by rear calipers.

8.Fit all bleed screw protection caps.

9.Check/top-up fluid level when bleeding is

complete

See Fluid Level Check/Top-Up.

Page 291 of 455

70BRAKES

10

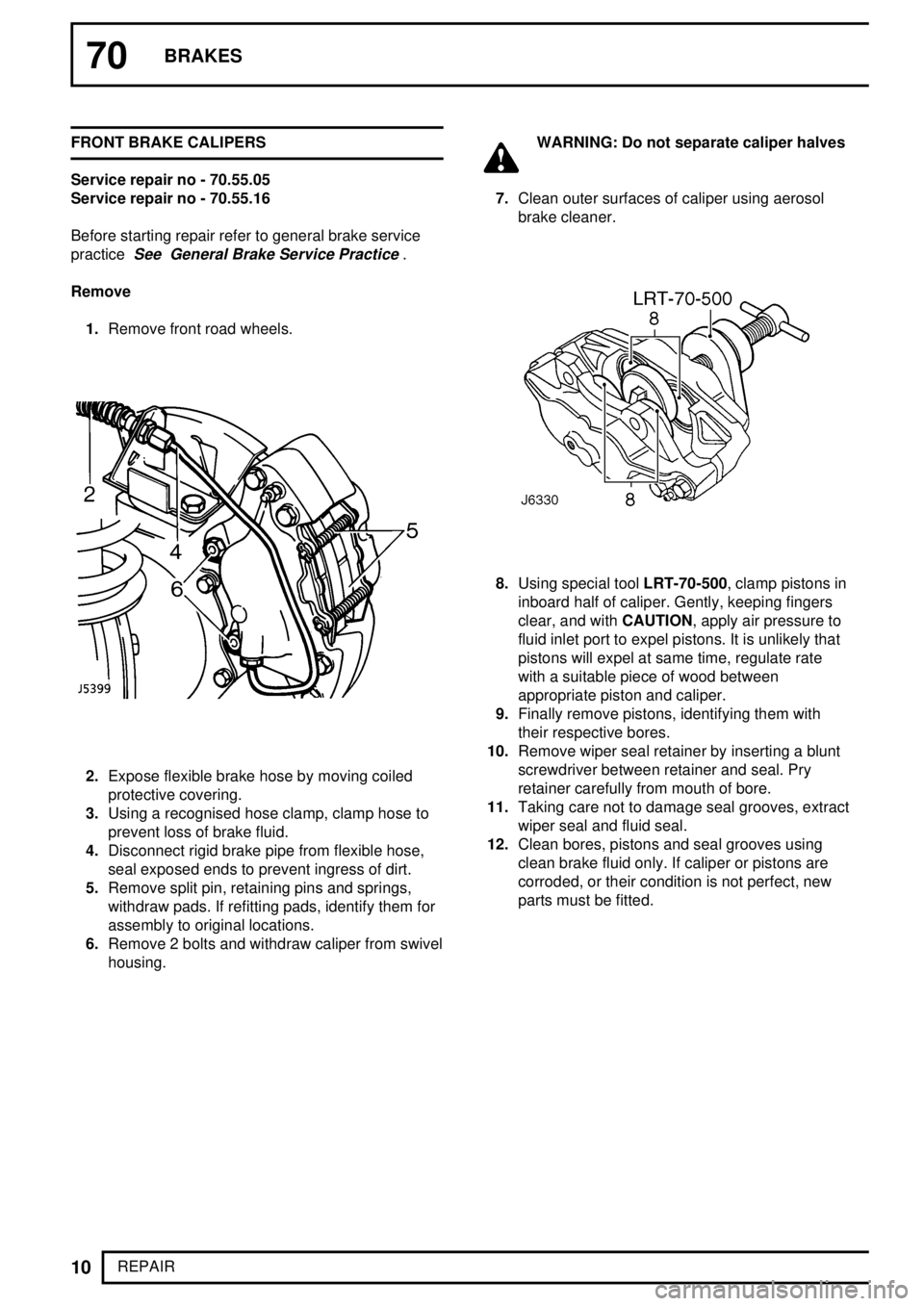

REPAIR FRONT BRAKE CALIPERS

Service repair no - 70.55.05

Service repair no - 70.55.16

Before starting repair refer to general brake service

practice

See General Brake Service Practice.

Remove

1.Remove front road wheels.

2.Expose flexible brake hose by moving coiled

protective covering.

3.Using a recognised hose clamp, clamp hose to

prevent loss of brake fluid.

4.Disconnect rigid brake pipe from flexible hose,

seal exposed ends to prevent ingress of dirt.

5.Remove split pin, retaining pins and springs,

withdraw pads. If refitting pads, identify them for

assembly to original locations.

6.Remove 2 bolts and withdraw caliper from swivel

housing.

WARNING: Do not separate caliper halves

7.Clean outer surfaces of caliper using aerosol

brake cleaner.

8.Using special toolLRT-70-500, clamp pistons in

inboard half of caliper. Gently, keeping fingers

clear, and withCAUTION, apply air pressure to

fluid inlet port to expel pistons. It is unlikely that

pistons will expel at same time, regulate rate

with a suitable piece of wood between

appropriate piston and caliper.

9.Finally remove pistons, identifying them with

their respective bores.

10.Remove wiper seal retainer by inserting a blunt

screwdriver between retainer and seal. Pry

retainer carefully from mouth of bore.

11.Taking care not to damage seal grooves, extract

wiper seal and fluid seal.

12.Clean bores, pistons and seal grooves using

clean brake fluid only. If caliper or pistons are

corroded, or their condition is not perfect, new

parts must be fitted.

Page 294 of 455

BRAKES

13

REPAIR REAR BRAKE CALIPERS

Service repair no - 70.55.06

Service repair no - 70.55.17

Before starting repair refer to General brake service

practice

See General Brake Service Practice.

Remove caliper

1.Remove rear road wheels.

2.Using a recognised hose clamp, clamp flexible

brake hose above rear axle.

90 Models

110/130 Models

3.Remove brake pipe from rear brake caliper.4.Seal pipe ends to prevent ingress of dirt.

5.Remove retaining pins and springs and withdraw

pads. If same pads are to be refitted, identify

them for assembly in original positions.

6.Remove 2 bolts and withdraw caliper from rear

axle.

Repair

WARNING: Do not separate caliper halves.

7.Clean outer surfaces of caliper with aerosol

brake cleaner.

8. WITH CAUTIONexpel pistons from their bores

by applying air pressure to fluid inlet port. It is

unlikely both pistons will expel at same time,

regulate rate with a suitable piece of wood

inserted between two pistons.

9.Finally, remove pistons keeping them identified

with their respective bores.

10.Remove wiper seal retainer by inserting a blunt

screwdriver between retainer and seal and pry

retainer carefully from mouth of bore.

11.Taking care not to damage seal grooves, extract

wiper seal and fluid seal.

12.Clean bores, pistons and particularly seal

grooves using clean brake fluid only. If caliper or

pistons are corroded or their condition is not

perfect new parts must be fitted.

13.Apply brake fluid to new seal. Fit seal into

groove in bore. When seal is seated it feels

raised to touch at edge furthest away from

mouth of bore.

14.Coat piston with brake fluid. Insert it squarely

into bore. Do not tilt piston during insertion and

leave 8mm projecting from bore.

Page 307 of 455

WHEELS AND TYRES

1

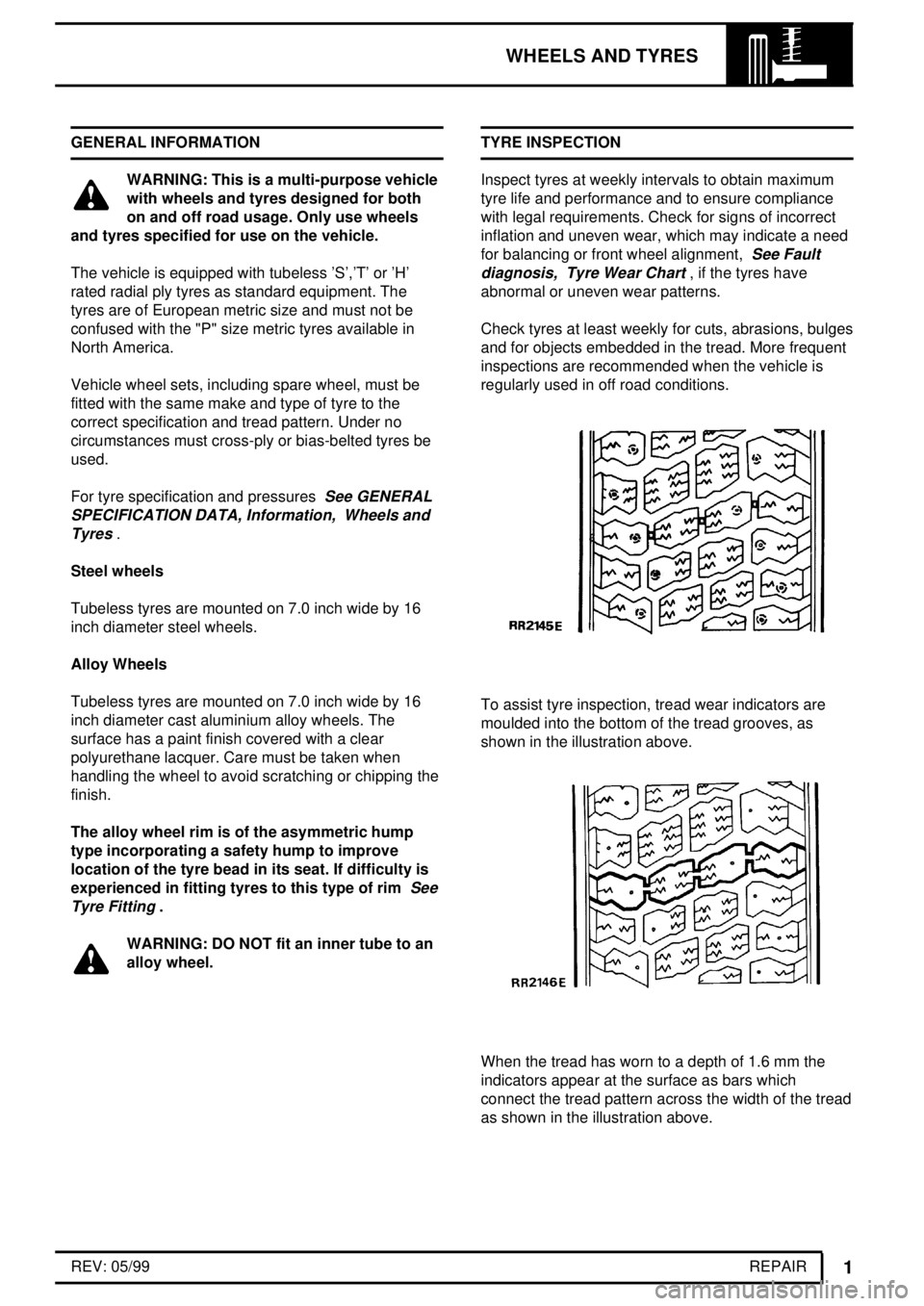

REPAIR REV: 05/99 GENERAL INFORMATION

WARNING: This is a multi-purpose vehicle

with wheels and tyres designed for both

on and off road usage. Only use wheels

and tyres specified for use on the vehicle.

The vehicle is equipped with tubeless 'S','T' or 'H'

rated radial ply tyres as standard equipment. The

tyres are of European metric size and must not be

confused with the "P" size metric tyres available in

North America.

Vehicle wheel sets, including spare wheel, must be

fitted with the same make and type of tyre to the

correct specification and tread pattern. Under no

circumstances must cross-ply or bias-belted tyres be

used.

For tyre specification and pressures

See GENERAL

SPECIFICATION DATA, Information, Wheels and

Tyres

.

Steel wheels

Tubeless tyres are mounted on 7.0 inch wide by 16

inch diameter steel wheels.

Alloy Wheels

Tubeless tyres are mounted on 7.0 inch wide by 16

inch diameter cast aluminium alloy wheels. The

surface has a paint finish covered with a clear

polyurethane lacquer. Care must be taken when

handling the wheel to avoid scratching or chipping the

finish.

The alloy wheel rim is of the asymmetric hump

type incorporating a safety hump to improve

location of the tyre bead in its seat. If difficulty is

experienced in fitting tyres to this type of rim

See

Tyre Fitting

.

WARNING: DO NOT fit an inner tube to an

alloy wheel.TYRE INSPECTION

Inspect tyres at weekly intervals to obtain maximum

tyre life and performance and to ensure compliance

with legal requirements. Check for signs of incorrect

inflation and uneven wear, which may indicate a need

for balancing or front wheel alignment,

See Fault

diagnosis, Tyre Wear Chart

, if the tyres have

abnormal or uneven wear patterns.

Check tyres at least weekly for cuts, abrasions, bulges

and for objects embedded in the tread. More frequent

inspections are recommended when the vehicle is

regularly used in off road conditions.

To assist tyre inspection, tread wear indicators are

moulded into the bottom of the tread grooves, as

shown in the illustration above.

When the tread has worn to a depth of 1.6 mm the

indicators appear at the surface as bars which

connect the tread pattern across the width of the tread

as shown in the illustration above.

Page 312 of 455

74WHEELS AND TYRES

6

REPAIRREV: 05/99 WHEELS

Remove

WARNING: The parking brake acts on

transmission, not rear wheels, and may

not hold vehicle when jacking unless

following procedure is used. If one front wheel

and one rear wheel is raised no vehicle holding or

braking effect is possible. Wheels MUST be

chocked in all circumstances.

Apply parking brake, select a gear in main

gearbox and engage low gear in transfer box.

1.Loosen 5 wheel nuts.

2.Using a suitable trolley jack, raise vehicle and

place on axle stands

See INTRODUCTION,

Information, Jacking

.

3.Remove wheel nuts and carefully withdraw

wheel over studs.

Refit

4.Ensure that retaining studs and nuts are clean.

5.Alloy wheels: Lightly coat wheel mounting spigot

face with a suitable anti-seize compound to

minimise possibility of adhesion between wheel

and spigot face.

6.Refit wheel taking care not to damage stud

threads. (Do not apply oil).

7.Fit wheel nuts and turn by hand for at least three

full threads before using any form of wheel

wrench.

8.Tighten nuts as much as possible using a

suitable wrench.

9.Lower vehicle and finally tighten nuts to correct

torque sequence shown.

Alloy wheels -

130 Nm (96 lbf/ft)

Steel wheels -100 Nm (80 lbf/ft)

Heavy duty wheels -170 Nm (125 lbf/ft)

Page 376 of 455

AIR CONDITIONING

1

ADJUSTMENT GENERAL PRECAUTIONS

The refrigerant used in the air conditioning system is

HFC (Hydrofluorocarbon) R134a.

WARNING: R134a is a hazardous liquid

and when handled incorrectly can cause

serious injury. Suitable protective clothing

must be worn when carrying out servicing

operations on the air conditioning system.

WARNING: R134a is odourless and

colourless. Do not handle or discharge in

an enclosed area, or in any area where the

vapour or liquid can come in contact with naked

flame or hot metal. R134a is not flammable, but

can form a highly toxic gas.

WARNING: Do not smoke or weld in areas

where R134a is in use. Inhalation of

concentrations of the vapour can cause

dizziness, disorientation. uncoordination,

narcosis, nausea or vomiting.

WARNING: Do not allow fluids other than

R134a or compressor lubricant to enter the

air conditioning system. Spontaneous

combustion may occur.

WARNING: R134a splashed on any part of

the body will cause immediate freezing of

that area. Also refrigerant cylinders and

replenishment trolleys when discharging will

freeze skin to them if contact is made.

WARNING: The refrigerant used in an air

conditioning system must be reclaimed in

accordance with the recommendations

given with a Refrigerant Recovery Recycling

Recharging Station.

NOTE: Suitable protective clothing

comprises: Wrap around safety glasses or

helmet, heatproof gloves, rubber apron or

waterproof overalls and rubber boots.REMEDIAL ACTIONS

1.If liquid R134a strikes the eye, do not rub it.

Gently run large quantities of eyewash over the

eye to raise the temperature. If eyewash is not

available cool, clean water may be used. Cover

eye with clean pad and seek immediate medical

attention.

2.If liquid R134a is splashed on the skin run large

quantities of water over the area as soon as

possible to raise the temperature. Carry out the

same actions if skin comes into contact with

discharging cylinders. Wrap affected parts in

blankets or similar material and seek immediate

medical attention.

3.If suspected of being overcome by inhalation of

R134a vapour seek fresh air. If unconscious

remove to fresh air. Apply artificial respiration

and/or oxygen and seek immediate medical

attention.

NOTE: Due to its low evaporating

temperature of -30°C, R134a should be

handled with care.

WARNING: Do not allow a refrigerant

container to be heated by a direct flame or

to be placed near any heating appliance. A

refrigerant container must not be heated above

50°C.

WARNING: Do not leave a container of

refrigerant without its cap fitted. Do not

transport a container of refrigerant that is

unrestrained, especially in the boot of a car.

Page 378 of 455

AIR CONDITIONING

3

ADJUSTMENT REFRIGERANT RECOVERY, RECYCLING,

RECHARGING

WARNING: The air conditioning system is

charged with a high pressure, potentially

toxic refrigerant. Repairs or servicing must

only be carried out by an operator familiar with

both the vehicle system and the charging and

testing equipment.

All operations must be carried out in a

well-ventilated area away from open flame and

heat sources.

Always wear safety goggles and gloves when

opening refrigerant connections.

WARNING: Wear eye and hand safety

protection. Open connections slowly in

case liquid or pressure is present. Allow to

bleed off slowly.

CAUTION: Overcharging air conditioning

system will cause excessive head

pressure.

An air conditioning portable Refrigerant Recovery

Recycling Recharging Station for use with R134a

refrigerant incorporates all the features necessary to

recover refrigerant R134a from the air conditioning

system, to filter and remove moisture, to evacuate and

recharge with the reclaimed refrigerant. The unit can

also be used for performance testing and air

conditioning system analysis.

The operator must adhere to the equipment

manufacturers' instructions.

Recovery and recycling

1.Connect a Refrigerant Station to the high and

low pressure servicing connections.

2.Operate the refrigerant recovery system

according to the manufacturers instructions.

3.Measure the amount of oil discharged from the

system. Add an equal amount of new refrigerant

oil to compressor before evacuation sequence.

WARNING: Refrigerant must always be

recycled before reuse, to ensure that the

purity of the refrigerant is high enough for

safe use in the air conditioning system. Recycling

should always be carried out with equipment

which is design certified by Underwriter

Laboratory Inc. for compliance with SAE-J1991.

Other equipment may not recycle refrigerant to

the required level of purity.

A R134a Refrigerant Recovery Recycling

Recharging Station must not be used with any

other type of refrigerant.

Refrigerant R134a from domestic and commercial

sources must not be used in motor vehicle air

conditioning systems.

Evacuation and recharging

1.Add refrigerant oil to compressor if necessary.

2.Renew the receiver/drier.

CAUTION: When a major repair has been

carried out, a leak test should be carried

out using inert gas.

3.Connect a Refrigerant Station to the high and

low pressure servicing connections.

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

4.Operate the refrigerant evacuation system

according to the manufactures instructions.

NOTE: If the vacuum reading is below

700mmHg after 15 minutes, suspect a leak

in the system. Partially recharge the

system and check for leaks using an electronic

leak tester. Check suction lines first, then run the

compressor for 5 minutes and then check the high

pressure lines.

CAUTION: The system must be Evacuated

immediately before recharging

commences. Delay between Evacuation

and Recharging is not permitted.

Page 380 of 455

AIR CONDITIONING

5

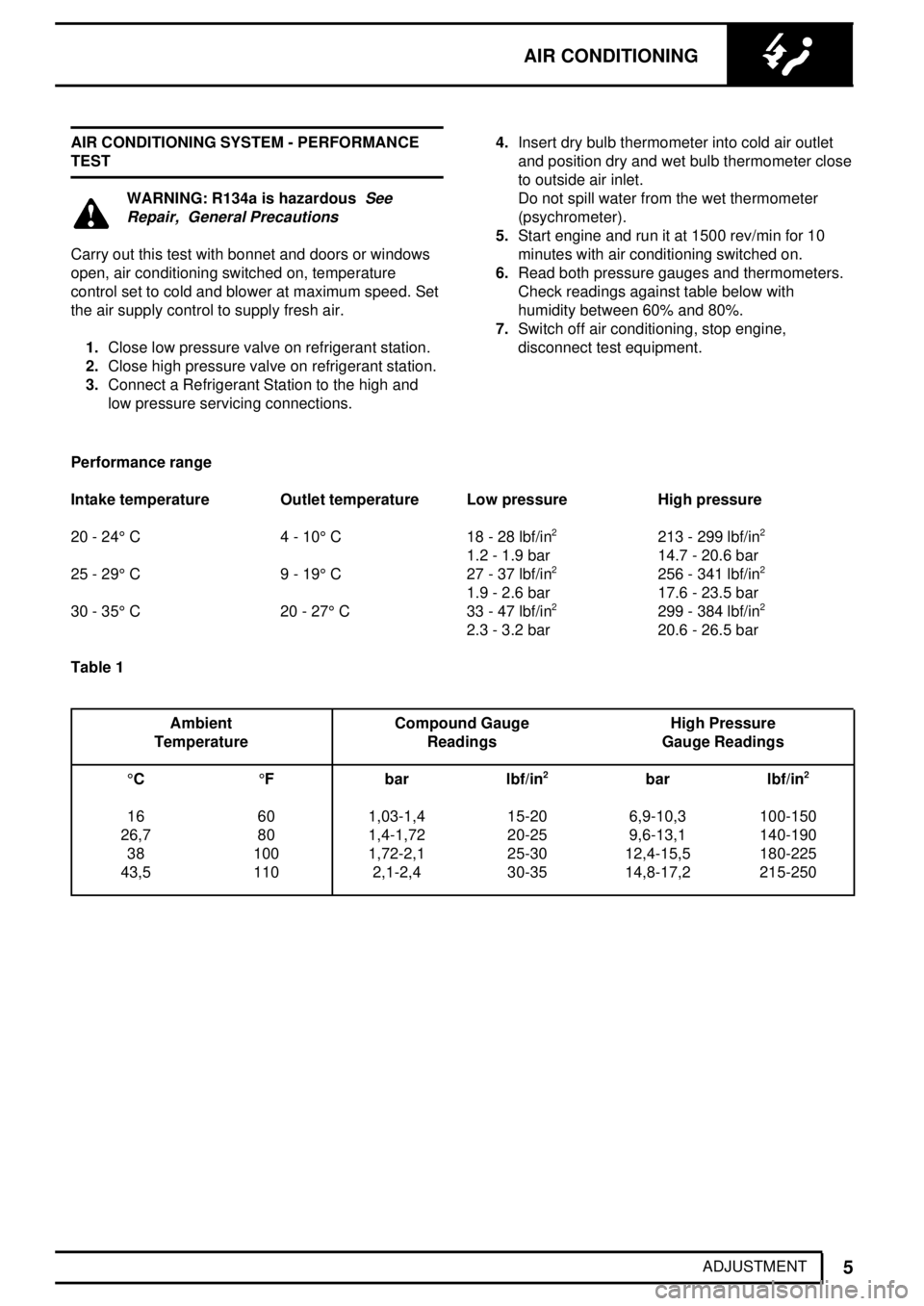

ADJUSTMENT AIR CONDITIONING SYSTEM - PERFORMANCE

TEST

WARNING: R134a is hazardousSee

Repair, General Precautions

Carry out this test with bonnet and doors or windows

open, air conditioning switched on, temperature

control set to cold and blower at maximum speed. Set

the air supply control to supply fresh air.

1.Close low pressure valve on refrigerant station.

2.Close high pressure valve on refrigerant station.

3.Connect a Refrigerant Station to the high and

low pressure servicing connections.4.Insert dry bulb thermometer into cold air outlet

and position dry and wet bulb thermometer close

to outside air inlet.

Do not spill water from the wet thermometer

(psychrometer).

5.Start engine and run it at 1500 rev/min for 10

minutes with air conditioning switched on.

6.Read both pressure gauges and thermometers.

Check readings against table below with

humidity between 60% and 80%.

7.Switch off air conditioning, stop engine,

disconnect test equipment.

Performance range

Intake temperature Outlet temperature Low pressure High pressure

20 - 24°C4-10°C 18 - 28 lbf/in

2213 - 299 lbf/in2

1.2 - 1.9 bar 14.7 - 20.6 bar

25 - 29°C9-19°C 27 - 37 lbf/in2256 - 341 lbf/in2

1.9 - 2.6 bar 17.6 - 23.5 bar

30 - 35°C20-27°C 33 - 47 lbf/in2299 - 384 lbf/in2

2.3 - 3.2 bar 20.6 - 26.5 bar

Table 1

Ambient Compound Gauge High Pressure

Temperature Readings Gauge Readings

°C°F bar lbf/in

2bar lbf/in2

16 60 1,03-1,4 15-20 6,9-10,3 100-150

26,7 80 1,4-1,72 20-25 9,6-13,1 140-190

38 100 1,72-2,1 25-30 12,4-15,5 180-225

43,5 110 2,1-2,4 30-35 14,8-17,2 215-250