engine LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 165 of 667

12ENGINE

6

OVERHAUL 14.Clean fixed guide Allen screw and apply Loctite

242 to screw threads.

15.Fit fixed timing chain guide Allen screw and

tighten to25 Nm (18 lbf.ft).

16.Clean timing chain tensioner and fit new sealing

washer.

17.Fit timing chain tensioner and tighten to45 Nm

(33 lbf.ft).

18.Tighten camshaft sprocket bolts to36 Nm (27

lbf.ft).

19.Remove toolLRT-12-058from camshaft.

20.Lubricate a new’O’ring with engine oil and fit to

camshaft sprocket access plug.

21.Fit camshaft sprocket access plug.

22.Clean alternator/vacuum pump oil feed hose

union.

23.Lubricate a new’O’ring with engine oil and fit to

alternator/vacuum pump hose union.

24.Fit and tighten alternator/vacuum pump oil hose

union to10 Nm (7 lbf.ft).

25.Fit bolt securing alternator strap bracket to

cylinder head and tighten to25 Nm (18 lbf.ft).

26.Connect multiplugs to ECT sensor and EUIs.

CAUTION: Following cylinder head

overhaul, it will be necessary, before

fitting the camshaft cover, to adjust the

fuel injector rockers using the following

procedures:

27.Rotate engine clockwise until No. 1 EUI lobe is

at full lift.

28.Tighten No.1 rocker adjusting screw until the EUI

plunger is felt to’bottom out’.

29.Loosen rocker adjusting screw 1 complete turn

to give EUI plunger the required bump clearance

and tighten rocker adjusting screw locknut to16

Nm (12 lbf.ft).

CAUTION: Ensure screw does not turn as

locknut is tightened.30.Carry out above procedures for the remaining 4

rocker arms.

31.After completion of rocker adjustment, slowly

rotate engine clockwise 2 complete turns by

hand to ensure that no EUI’s are bottoming out

on their plungers.

32.Clean camshaft cover and mating face.

33.Fit new sealing washers and isolators as

necessary to camshaft cover.

34.Fit new camshaft cover gasket to cover.

CAUTION: Gasket must be fitted dry.

35.Fit camshaft cover to camshaft carrier, fit bolts

and working from the centre outwards, tighten

bolts to10 Nm (7 lbf.ft).

36.Fit inlet manifold gasket.See MANIFOLD AND

EXHAUST SYSTEM, Repair.

37.Fit exhaust manifold gasket.See MANIFOLD

AND EXHAUST SYSTEM, Repair.

38. EGR cooler fitted:-Position EGR pipe to cooler,

fit new Allen screws and tighten to10 Nm (7

lbf.ft).

ProCarManuals.com

Page 166 of 667

ENGINE

7

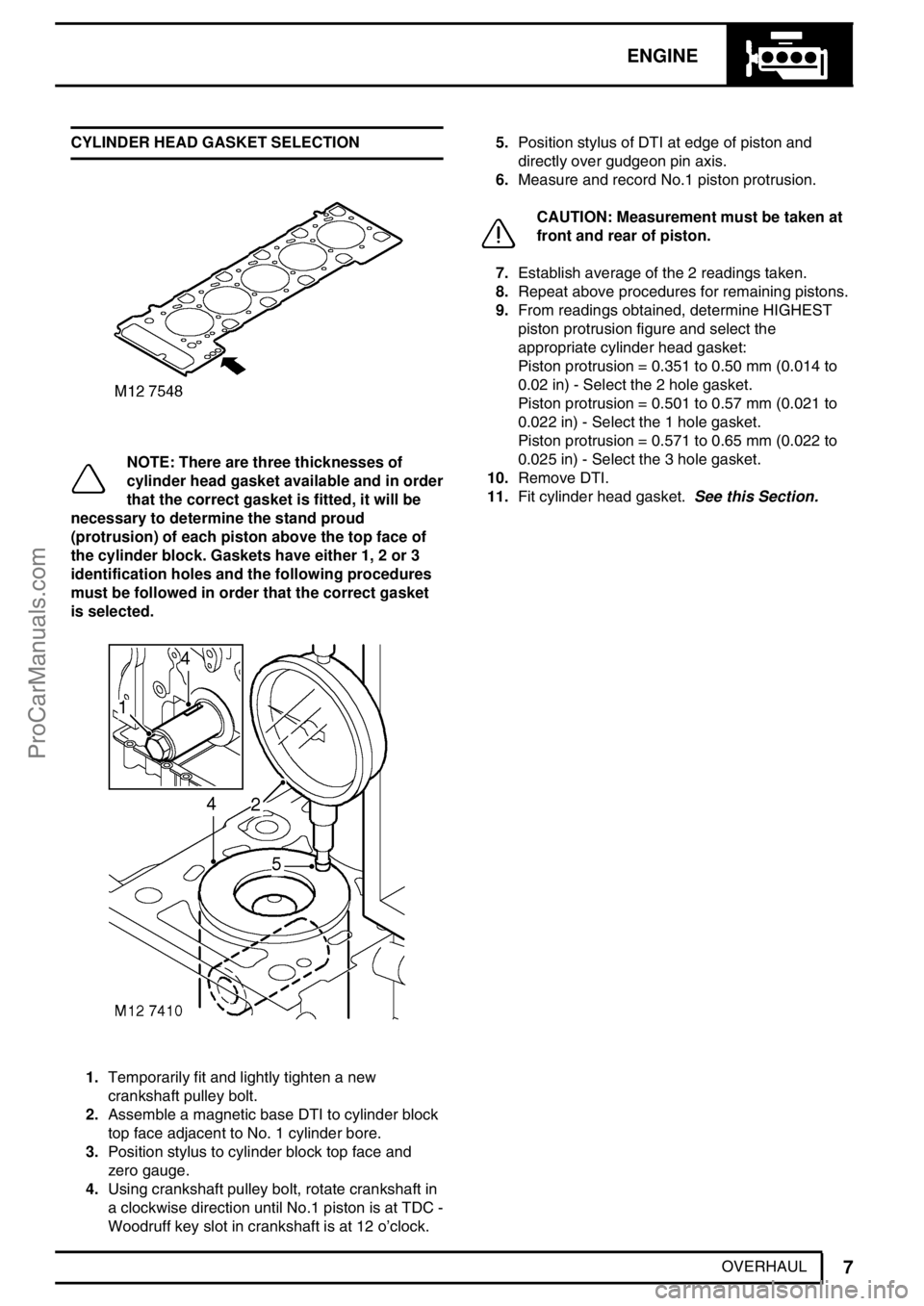

OVERHAUL CYLINDER HEAD GASKET SELECTION

NOTE: There are three thicknesses of

cylinder head gasket available and in order

that the correct gasket is fitted, it will be

necessary to determine the stand proud

(protrusion) of each piston above the top face of

the cylinder block. Gaskets have either 1, 2 or 3

identification holes and the following procedures

must be followed in order that the correct gasket

is selected.

1.Temporarily fit and lightly tighten a new

crankshaft pulley bolt.

2.Assemble a magnetic base DTI to cylinder block

top face adjacent to No. 1 cylinder bore.

3.Position stylus to cylinder block top face and

zero gauge.

4.Using crankshaft pulley bolt, rotate crankshaft in

a clockwise direction until No.1 piston is at TDC -

Woodruff key slot in crankshaft is at 12 o’clock.5.Position stylus of DTI at edge of piston and

directly over gudgeon pin axis.

6.Measure and record No.1 piston protrusion.

CAUTION: Measurement must be taken at

front and rear of piston.

7.Establish average of the 2 readings taken.

8.Repeat above procedures for remaining pistons.

9.From readings obtained, determine HIGHEST

piston protrusion figure and select the

appropriate cylinder head gasket:

Piston protrusion = 0.351 to 0.50 mm (0.014 to

0.02 in) - Select the 2 hole gasket.

Piston protrusion = 0.501 to 0.57 mm (0.021 to

0.022 in) - Select the 1 hole gasket.

Piston protrusion = 0.571 to 0.65 mm (0.022 to

0.025 in) - Select the 3 hole gasket.

10.Remove DTI.

11.Fit cylinder head gasket.See this Section.

ProCarManuals.com

Page 167 of 667

12ENGINE

8

OVERHAUL CYLINDER HEAD - OVERHAUL

Service repair no - 12.29.19.01

Dismantling

1.Remove cylinder head gasket.See this

Section.

CAUTION: Due to the design of the

cylinder head which incorporates drillings

for the fuel injection system, it is important

that absolute cleanliness is adhered to when

carrying out overhaul procedures.

2.Note the gasket thickness indicator and ensure

the same thickness gasket is used on refitment

of cylinder head.

CAUTION: If new pistons, connecting rods

or crankshaft are fitted, it will be

necessary to determine thickness of

gasket required.See this Section.

3.Remove 4 glow plugs.

4.Disconnect multiplugs from EUI’s and remove

harness from camshaft carrier. Remove and

discard’O’ring from harness multiplug.

5.Loosen lock nuts and fully unscrew rocker

adjusting screws; discard locknuts and screws.

6.Remove and discard 6 bolts securing rocker

shaft, remove shaft.

NOTE: Dowel located.

7.Using sequence shown, progressively loosen 13

bolts securing camshaft carrier to cylinder head

until valve spring pressure is released; remove

bolts.

CAUTION: Do not discard bolts at this

stage.

ProCarManuals.com

Page 168 of 667

ENGINE

9

OVERHAUL

8.Gently tap camshaft carrier upwards to break

sealant bond, remove carrier.

NOTE: Dowel located.

9.Remove camshaft.

10.Remove and discard camshaft rear oil seal.

11.Remove finger followers and lash adjusters.

CAUTION: Store lash adjusters and finger

followers in their fitted order and store

lash adjusters upright. Maintain absolute

cleanliness when handling components.

12.Remove and discard 5 bolts securing EUI

retainers.

13.Using toolLRT-12-154/1remove EUI units from

cylinder head and collect retainers. Remove

reaction posts and keep in their fitted order.

14.Using toolLRT-12-154/4, remove and discard

sealing washer and’O’ring from each EUI unit.

15.Support cylinder head clear of valves, use a

hollow drift and tap each valve spring cap to free

collets.

16.Using toolLRT-12-034, compress valve spring.

17.Remove 2 collets from valve stem using a stick

magnet.

18.Remove toolLRT-12-034.

19.Remove valve spring cap, valve spring and

valve.

CAUTION: Keep components in their fitted

order.

ProCarManuals.com

Page 169 of 667

12ENGINE

10

OVERHAUL

20.Using toolLRT-12-071, remove and discard

valve stem oil seal.

21.Repeat above operations to remove remaining

valves.

22. Engine Serial No. Prefixes 15P to 19P:-

Disconnect spill return pipe from cylinder head

and fuel connector block, remove and discard’O’

rings.

ProCarManuals.com

Page 170 of 667

ENGINE

11

OVERHAUL

23.Remove 3 bolts and remove fuel connector

block from cylinder head.

24.Remove and discard gasket,’O’ring and fuel

filter.

25.Remove spacer block and gasket (if fitted).Cylinder head and camshaft carrier - cleaning

1.Thoroughly clean cylinder head mating faces,

ensure oil and coolant passages are clear and

bolt holes are clean and dry.

CAUTION: Take care to ensure that EUI

drillings are clear.

2.Using suitable solvent, remove all traces of

sealant and gasket material.

CAUTION: Do not use metal scrapers.

3.Remove all traces of oil from camshaft bearings

and journals.

4.Clean glow plug threads.

Cylinder head - Inspection

1.Check core plugs for signs of leakage and

corrosion, seal replacement plugs with Loctite

243.

2.Check cylinder head for warping across centre

and from corner to corner.

Maximum cylinder head warp =0.1 mm (0.004

in).

CAUTION: Cylinder heads may not be

refaced, replace the head assembly if

warping exceeds the limit given.

ProCarManuals.com

Page 171 of 667

12ENGINE

12

OVERHAUL Lash adjusters and finger followers - Inspection

1.Check lash adjuster bores for scoring and signs

of wear or damage.

2.Check lash adjusters for signs of wear, scoring

and overheating, replace as necessary. Ensure

oil hole in each lash adjuster is clear.

CAUTION: Store lash adjusters upright

and in their fitted order.

3.Check finger followers for wear and that rollers

are free to rotate.

CAUTION: Store finger followers in their

fitted order.

Camshaft - Inspection

1.Check camshaft lobes and bearing journals for

signs of scoring and wear.

2.Check bearing surfaces in cylinder head and

camshaft carrier for signs of scoring and wear.

CAUTION: Cylinder head and camshaft

carrier are machined together as an

assembly, if bearing surfaces in either

component are damaged, both components must

be replaced as an assembly.Camshaft - Check end-float

1.Position camshaft in camshaft carrier.

2.Check end-float of camshaft using a DTI.

Camshaft end-float =0.06 to 0.16 mm (0.002 to

0.006 in).

3.Renew components as necessary to achieve

correct end-float.

ProCarManuals.com

Page 172 of 667

ENGINE

13

OVERHAUL Camshaft bearings - check clearance

1.Position camshaft in cylinder head.

2.Place a piece of Plastigage along the centre line

of each camshaft bearing journal.

3.Carefully fit the camshaft carrier ensuring it is

located on dowels.

CAUTION: Do not rotate camshaft.

4.Fit original camshaft carrier retaining bolts and

tighten in sequence shown to25 Nm (18 lbf.ft).

5.Using sequence shown, loosen then remove

camshaft carrier retaining bolts.

CAUTION: Do not discard bolts at this

stage.

6.Carefully remove camshaft carrier.

7.Measure and record widest portion of Plastigage

on each camshaft bearing journal.

8.Compare figures obtained with camshaft bearing

clearance.

Camshaft bearing clearance =0.04 to 0.10

mm (0.002 to 0.004 in).

9.If any bearing clearance is found to exceed

figures given, repeat the above procedure using

a new camshaft.

CAUTION: If, after repeating the bearing

clearance check with a new camshaft the

bearing clearances are still excessive, a

new cylinder head and camshaft carrier assembly

must be fitted.

10.Remove all traces of Plastigage using an oily

cloth, do not use a scraper.

11.Discard camshaft carrier bolts.

ProCarManuals.com

Page 173 of 667

12ENGINE

14

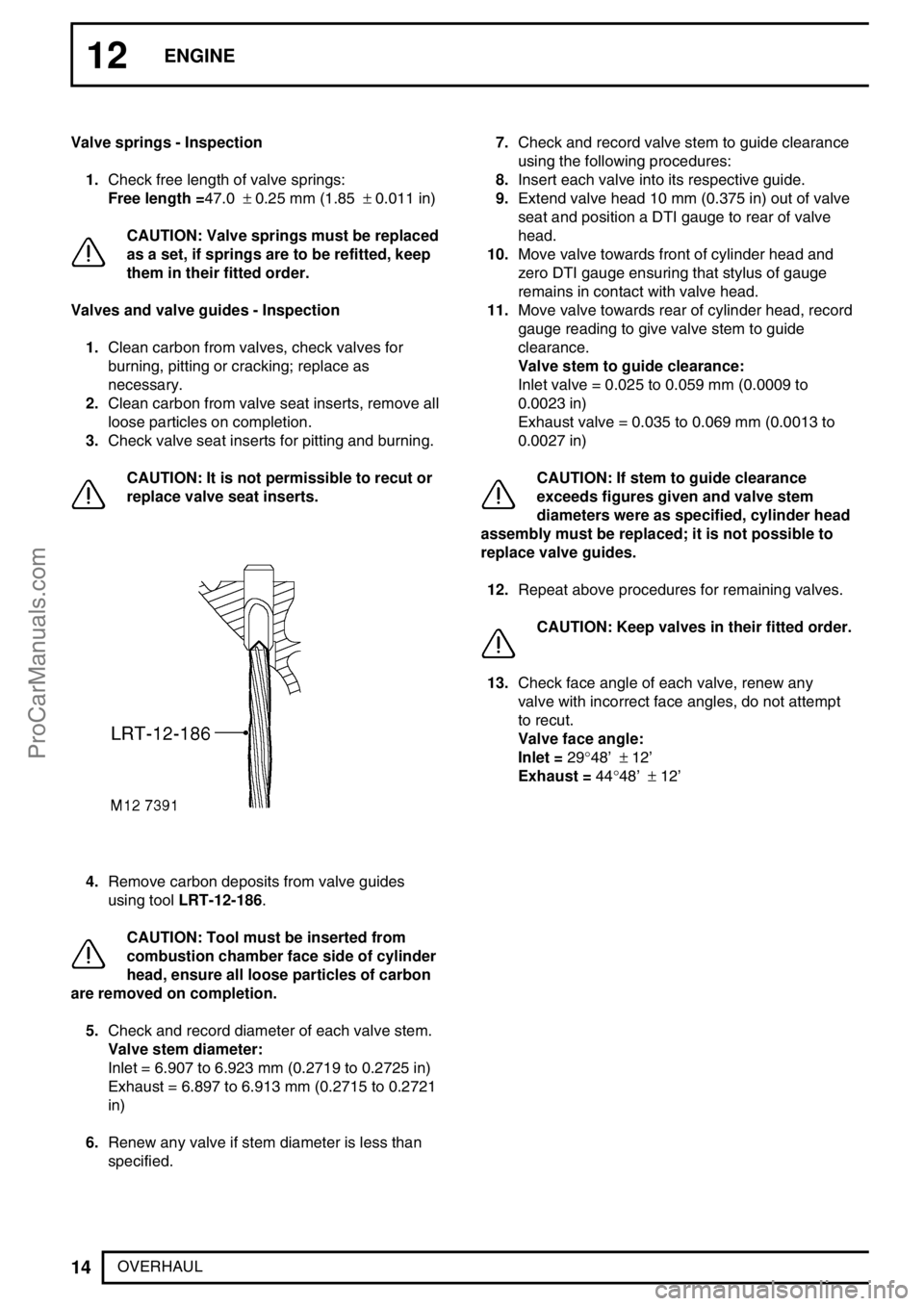

OVERHAUL Valve springs - Inspection

1.Check free length of valve springs:

Free length =47.0±0.25 mm (1.85±0.011 in)

CAUTION: Valve springs must be replaced

as a set, if springs are to be refitted, keep

them in their fitted order.

Valves and valve guides - Inspection

1.Clean carbon from valves, check valves for

burning, pitting or cracking; replace as

necessary.

2.Clean carbon from valve seat inserts, remove all

loose particles on completion.

3.Check valve seat inserts for pitting and burning.

CAUTION: It is not permissible to recut or

replace valve seat inserts.

4.Remove carbon deposits from valve guides

using toolLRT-12-186.

CAUTION: Tool must be inserted from

combustion chamber face side of cylinder

head, ensure all loose particles of carbon

are removed on completion.

5.Check and record diameter of each valve stem.

Valve stem diameter:

Inlet = 6.907 to 6.923 mm (0.2719 to 0.2725 in)

Exhaust = 6.897 to 6.913 mm (0.2715 to 0.2721

in)

6.Renew any valve if stem diameter is less than

specified.7.Check and record valve stem to guide clearance

using the following procedures:

8.Insert each valve into its respective guide.

9.Extend valve head 10 mm (0.375 in) out of valve

seat and position a DTI gauge to rear of valve

head.

10.Move valve towards front of cylinder head and

zero DTI gauge ensuring that stylus of gauge

remains in contact with valve head.

11.Move valve towards rear of cylinder head, record

gauge reading to give valve stem to guide

clearance.

Valve stem to guide clearance:

Inlet valve = 0.025 to 0.059 mm (0.0009 to

0.0023 in)

Exhaust valve = 0.035 to 0.069 mm (0.0013 to

0.0027 in)

CAUTION: If stem to guide clearance

exceeds figures given and valve stem

diameters were as specified, cylinder head

assembly must be replaced; it is not possible to

replace valve guides.

12.Repeat above procedures for remaining valves.

CAUTION: Keep valves in their fitted order.

13.Check face angle of each valve, renew any

valve with incorrect face angles, do not attempt

to recut.

Valve face angle:

Inlet =29°48’±12’

Exhaust =44°48’±12’

ProCarManuals.com

Page 174 of 667

ENGINE

15

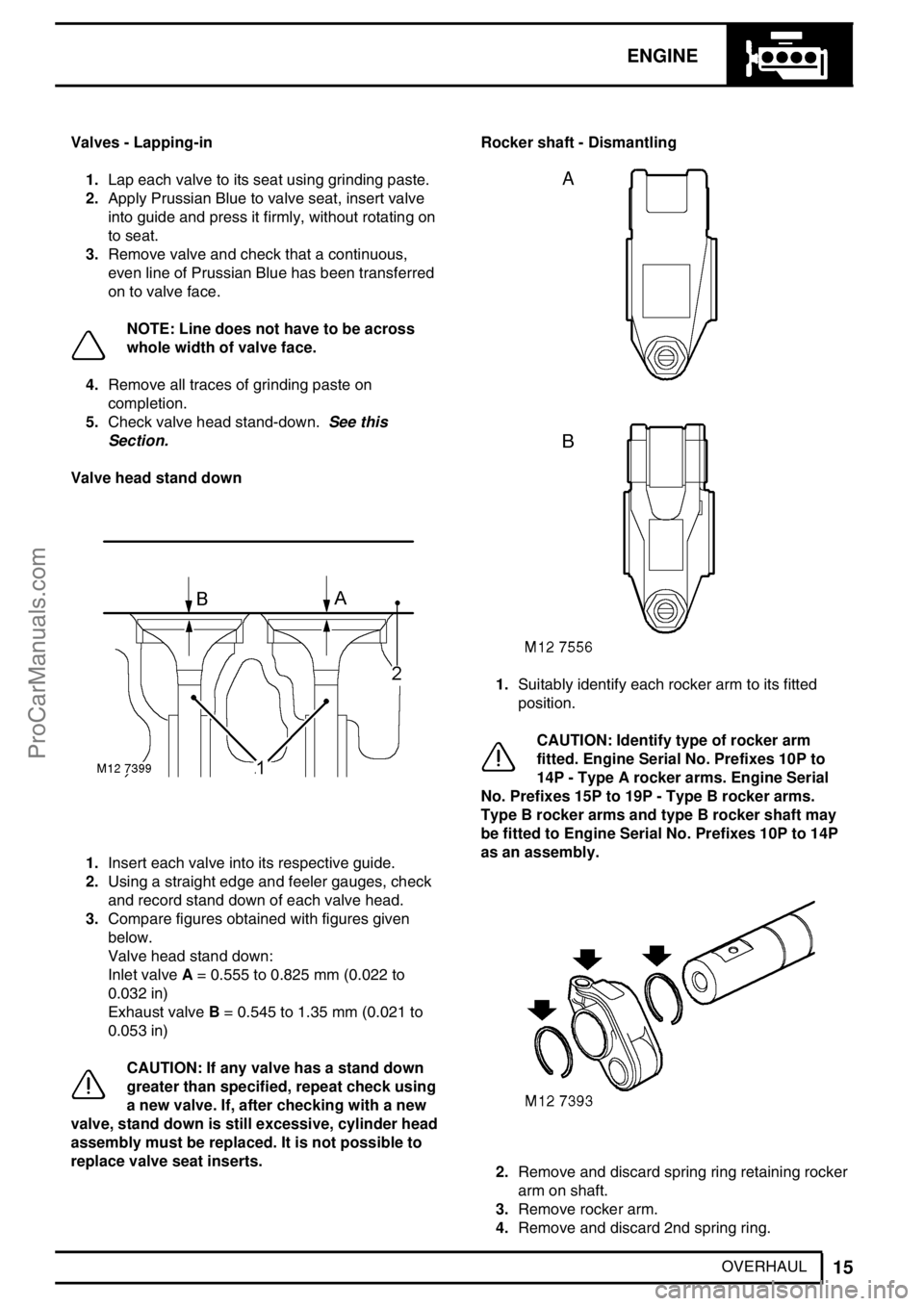

OVERHAUL Valves - Lapping-in

1.Lap each valve to its seat using grinding paste.

2.Apply Prussian Blue to valve seat, insert valve

into guide and press it firmly, without rotating on

to seat.

3.Remove valve and check that a continuous,

even line of Prussian Blue has been transferred

on to valve face.

NOTE: Line does not have to be across

whole width of valve face.

4.Remove all traces of grinding paste on

completion.

5.Check valve head stand-down.See this

Section.

Valve head stand down

1.Insert each valve into its respective guide.

2.Using a straight edge and feeler gauges, check

and record stand down of each valve head.

3.Compare figures obtained with figures given

below.

Valve head stand down:

Inlet valveA= 0.555 to 0.825 mm (0.022 to

0.032 in)

Exhaust valveB= 0.545 to 1.35 mm (0.021 to

0.053 in)

CAUTION: If any valve has a stand down

greater than specified, repeat check using

a new valve. If, after checking with a new

valve, stand down is still excessive, cylinder head

assembly must be replaced. It is not possible to

replace valve seat inserts.Rocker shaft - Dismantling

1.Suitably identify each rocker arm to its fitted

position.

CAUTION: Identify type of rocker arm

fitted. Engine Serial No. Prefixes 10P to

14P - Type A rocker arms. Engine Serial

No. Prefixes 15P to 19P - Type B rocker arms.

Type B rocker arms and type B rocker shaft may

be fitted to Engine Serial No. Prefixes 10P to 14P

as an assembly.

2.Remove and discard spring ring retaining rocker

arm on shaft.

3.Remove rocker arm.

4.Remove and discard 2nd spring ring.

ProCarManuals.com