engine LAND ROVER DEFENDER 1999 Workshop Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 175 of 667

12ENGINE

16

OVERHAUL 5.Repeat above procedures for remaining rocker

arms.

CAUTION: Keep rocker arms in their fitted

order.Rocker arms and shaft - Inspection

1.Clean rocker arms and shaft, ensure oilways are

clear.

CAUTION: Identify type of rocker shaft

fitted. Engine Serial No. Prefixes 10P to

14P - Type A rocker shaft. Engine Serial

No. Prefixes 15P to 19P - Type B rocker shaft.

Type B rocker arms and shaft may be fitted to

Engine Serial No. Prefixes 10P to 14P as an

assembly.

2.Check diameter of each rocker arm journal on

shaft, take 2 measurements at 180°in centre of

journal.

Journal diameter =26.971 to 26.998 mm

(1.062 to 1.063 in)

CAUTION: Any ovality must be within

limits given.

ProCarManuals.com

Page 176 of 667

ENGINE

17

OVERHAUL

3.Using a vernier, check internal diameter of each

rocker arm, take 2 measurements at 180°.

Rocker arm internal diameter =27.0 to 27.013

mm (1.102 to 1.103 in)

CAUTION: Any ovality must be within

limits given.Rocker shaft - Assembling

1.Fit new spring ring to groove in rocker shaft.

2.Lubricate rocker shaft journals and rocker arms

with engine oil.

3.Fit rocker arm to shaft ensuring that it is in its

original fitted order.

4.Fit new spring ring to retain rocker arm.

5.Repeat above procedures for remaining rocker

arms ensuring they are in their original fitted

order.

6.Fit new rocker adjusting screws and locknuts to

rocker arms; do not tighten screws fully into

arms at this stage.

CAUTION: Ensure screws are correct for

type of rocker arms fitted. Replacement

screws for Engine Serial No. Prefixes 15P

to 19P have a centre punch mark adjacent to the

adjusting slot. These screws are not

interchangeable with those fitted to Engine Serial

No. Prefixes 10P to 14P.

Cylinder head - Assembling

1.Lubricate new valve stem oil seals with engine

oil.

2.Using toolLRT-12-071, fit valve stem oil seals.

3.Lubricate valve guides, valve stems, valve

spring caps and springs with engine oil.

ProCarManuals.com

Page 177 of 667

12ENGINE

18

OVERHAUL

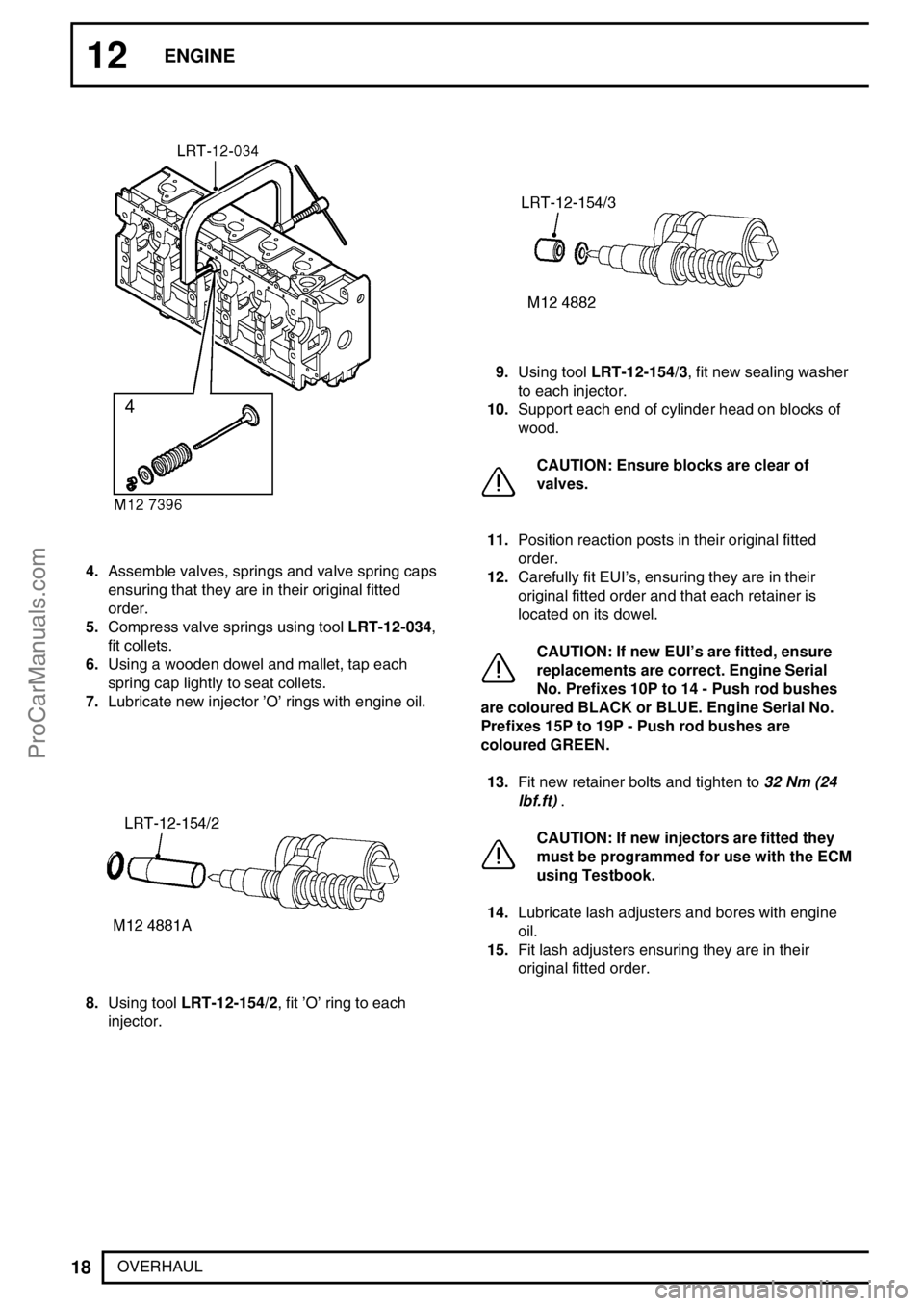

4.Assemble valves, springs and valve spring caps

ensuring that they are in their original fitted

order.

5.Compress valve springs using toolLRT-12-034,

fit collets.

6.Using a wooden dowel and mallet, tap each

spring cap lightly to seat collets.

7.Lubricate new injector’O’rings with engine oil.

8.Using toolLRT-12-154/2, fit’O’ring to each

injector.

9.Using toolLRT-12-154/3, fit new sealing washer

to each injector.

10.Support each end of cylinder head on blocks of

wood.

CAUTION: Ensure blocks are clear of

valves.

11.Position reaction posts in their original fitted

order.

12.Carefully fit EUI’s, ensuring they are in their

original fitted order and that each retainer is

located on its dowel.

CAUTION: If new EUI’s are fitted, ensure

replacements are correct. Engine Serial

No. Prefixes 10P to 14 - Push rod bushes

are coloured BLACK or BLUE. Engine Serial No.

Prefixes 15P to 19P - Push rod bushes are

coloured GREEN.

13.Fit new retainer bolts and tighten to32 Nm (24

lbf.ft).

CAUTION: If new injectors are fitted they

must be programmed for use with the ECM

using Testbook.

14.Lubricate lash adjusters and bores with engine

oil.

15.Fit lash adjusters ensuring they are in their

original fitted order.

ProCarManuals.com

Page 178 of 667

ENGINE

19

OVERHAUL 16.Lubricate finger followers with engine oil.

17.Fit finger followers ensuring they are in their

original fitted order.

18.Lubricate cams and bearing journals on

camshaft, cylinder head and camshaft carrier

with engine oil.

19.Position camshaft in cylinder head with the

timing pin hole in the vertical position.

20.Apply an even film of sealant, Part No. STC

4600 to camshaft carrier face and spread to an

even film using a roller.

CAUTION: Ensure sealant does not block

oilways (arrowed) or contaminate

camshaft bearings. Assembly and bolt

tightening must be completed within 20 minutes

of applying sealant.

21.Fit camshaft carrier ensuring it is correctly

located on dowels.

22.Fit and lightly tighten new camshaft carrier bolts.

23.Using sequence shown, progressively tighten

bolts to25 Nm (18 lbf.ft).

24.Lubricate a new camshaft rear oil seal with

engine oil, fit seal using a suitable mandrel.

25.Position rocker shaft on camshaft carrier,

ensuring rocker shaft is located on dowel.

26.Fit new rocker shaft retaining bolts and working

from the centre outwards, tighten bolts

progressively to32 Nm (24 lbf.ft).27.Lubricate a new’O’ring with engine oil and fit to

injector harness multiplug.

28.Fit injector harness and connect multiplugs.

29.Clean fuel connector block and mating face.

30.Lubricate a new fuel filter’O’ring with engine oil.

31.Fit new fuel filter,’O’ring and gasket.

CAUTION: Gasket must be fitted dry.

32.Fit fuel connector block spacer and gasket (if

fitted).

33.Fit fuel connector block, fit bolts and tighten to

25 Nm (18 lbf.ft).

34.Clean glow plugs.

35.Fit glow plugs to cylinder head and tighten to16

Nm (12 lbf.ft).

36. Engine Serial No. Prefixes 15P to 19P:-

Lubricate new’O’rings with engine oil and fit to

spill return pipe; fit pipe and tighten connectors

to20 Nm (15 lbf.ft).

37.Fit new cylinder head gasket.See this Section.

CAUTION: Ensure that the fuel injector

rockers are adjusted following the

procedures given in Gasket - Cylinder

head - Refit.

ProCarManuals.com

Page 179 of 667

12ENGINE

20

OVERHAUL GASKET - ENGINE SUMP

Service repair no - 12.60.38.01

Remove

1.Remove 2 bolts securing centrifuge oil drain pipe

to sump, remove and discard gasket.

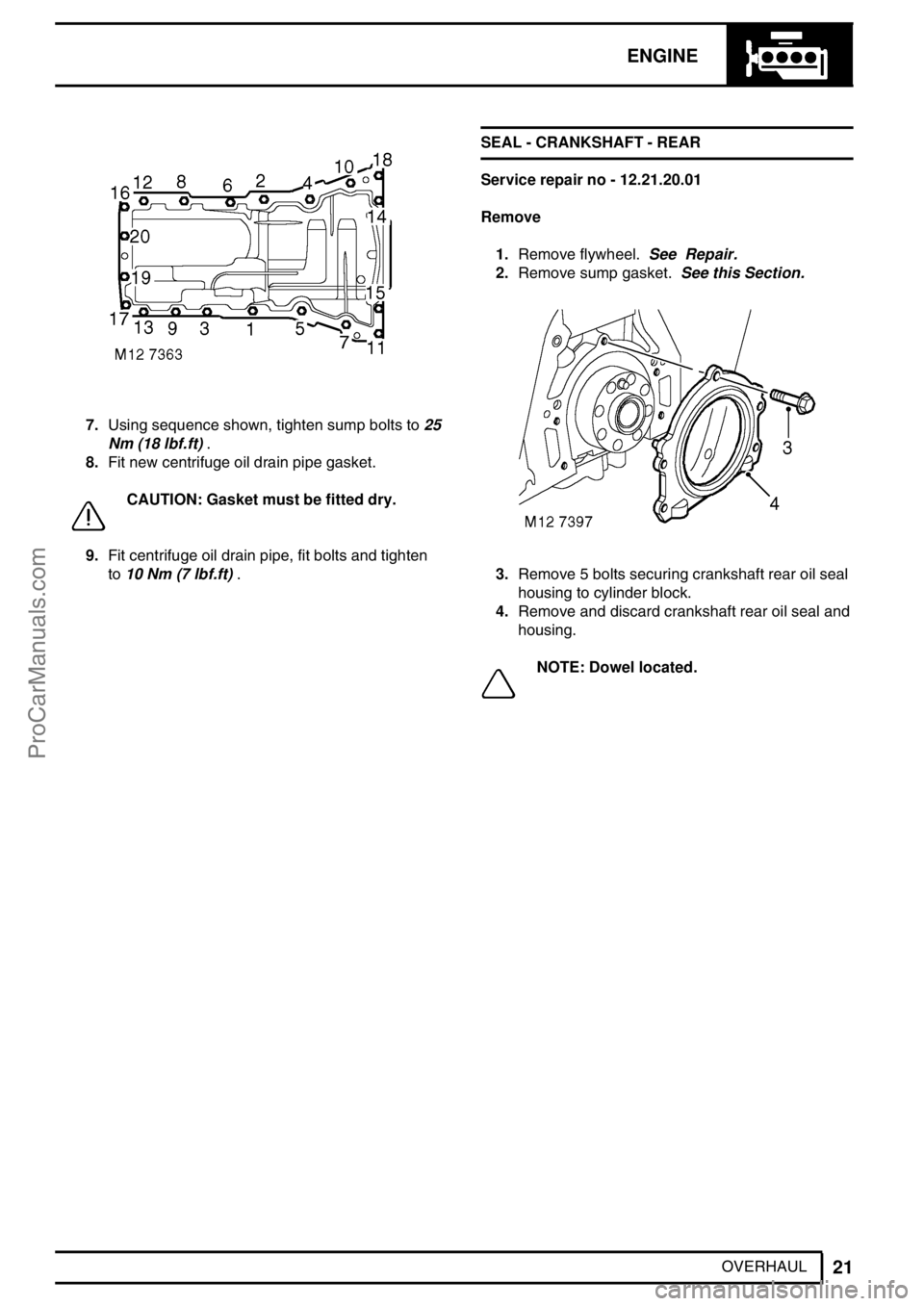

2.Using sequence shown and noting their fitted

positions, remove 20 bolts securing sump to

cylinder block.

3.Remove sump, remove and discard gasket.

CAUTION: Do not lever between sump and

cylinder block.Refit

1.Clean sump and mating faces, ensure bolt holes

in cylinder block are clean and dry.

2.Using suitable solvent, remove all traces of

sealant from joint faces of timing chain cover and

crankshaft rear oil seal housing.

3.Clean centrifugal filter oil drain pipe and mating

faces.

4.Apply a bead of sealant, Part No. STC 3254 to

joint faces of timing chain cover and crankshaft

rear oil seal housing.

CAUTION: Assembly and bolt tightening

must be completed within 20 minutes of

applying sealant.

5.Position new sump gasket.

CAUTION: Gasket must be fitted dry.

6.Position sump, fit and lightly tighten bolts

ensuring they are in their original fitted positions.

ProCarManuals.com

Page 180 of 667

ENGINE

21

OVERHAUL

7.Using sequence shown, tighten sump bolts to25

Nm (18 lbf.ft).

8.Fit new centrifuge oil drain pipe gasket.

CAUTION: Gasket must be fitted dry.

9.Fit centrifuge oil drain pipe, fit bolts and tighten

to10 Nm (7 lbf.ft).SEAL - CRANKSHAFT - REAR

Service repair no - 12.21.20.01

Remove

1.Remove flywheel.See Repair.

2.Remove sump gasket.See this Section.

3.Remove 5 bolts securing crankshaft rear oil seal

housing to cylinder block.

4.Remove and discard crankshaft rear oil seal and

housing.

NOTE: Dowel located.

ProCarManuals.com

Page 181 of 667

12ENGINE

22

OVERHAUL Refit

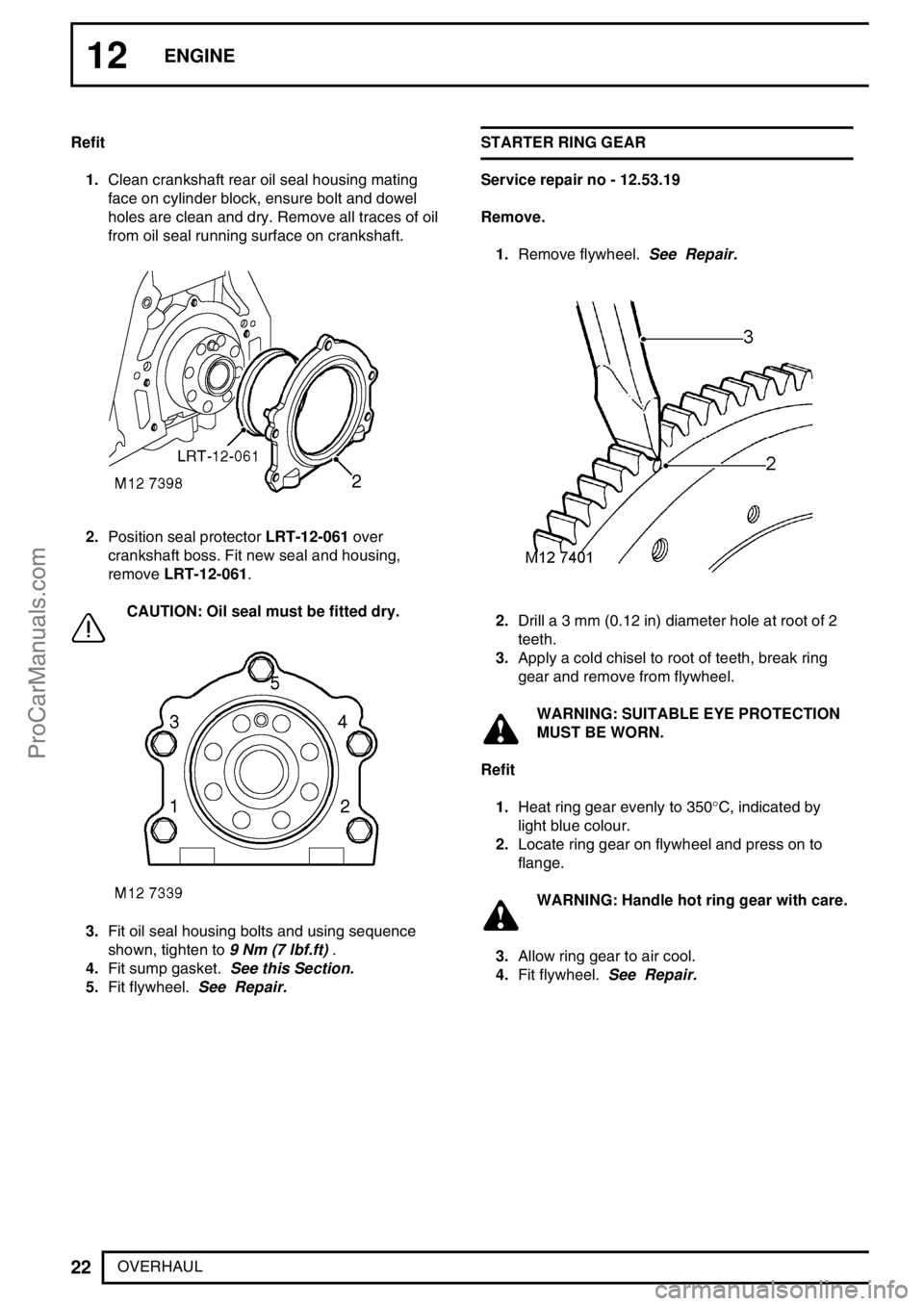

1.Clean crankshaft rear oil seal housing mating

face on cylinder block, ensure bolt and dowel

holes are clean and dry. Remove all traces of oil

from oil seal running surface on crankshaft.

2.Position seal protectorLRT-12-061over

crankshaft boss. Fit new seal and housing,

removeLRT-12-061.

CAUTION: Oil seal must be fitted dry.

3.Fit oil seal housing bolts and using sequence

shown, tighten to9 Nm (7 lbf.ft).

4.Fit sump gasket.See this Section.

5.Fit flywheel.See Repair.STARTER RING GEAR

Service repair no - 12.53.19

Remove.

1.Remove flywheel.See Repair.

2.Drill a 3 mm (0.12 in) diameter hole at root of 2

teeth.

3.Apply a cold chisel to root of teeth, break ring

gear and remove from flywheel.

WARNING: SUITABLE EYE PROTECTION

MUST BE WORN.

Refit

1.Heat ring gear evenly to 350°C, indicated by

light blue colour.

2.Locate ring gear on flywheel and press on to

flange.

WARNING: Handle hot ring gear with care.

3.Allow ring gear to air cool.

4.Fit flywheel.See Repair.

ProCarManuals.com

Page 182 of 667

ENGINE

23

OVERHAUL PUMP - OIL

Service repair no - 12.60.26.02

Remove

1.Remove sump gasket.See this Section.

2.Remove bolt securing oil pump drive sprocket.

3.Release drive sprocket from chain, remove

sprocket.

4.Remove 3 Torx screws securing oil pick-up

strainer, remove strainer.

5.Remove and discard’O’ring.

6.Using sequence shown, remove and discard 22

bolts securing oil pump and stiffener plate

assembly to cylinder block.

7.Remove oil pump and stiffener plate assembly.

NOTE: Dowel located.

8.Remove and discard’O’ring from oil pump

housing outlet.

ProCarManuals.com

Page 183 of 667

12ENGINE

24

OVERHAUL Inspection

CAUTION: Inspection/overhaul procedures

for the oil pump are limited to carrying out

dimensional checks. In the event of wear

or damage being found, a replacement pump and

stiffener plate assembly must be fitted.

Oil pump

1.Remove and discard 5 screws securing cover to

oil pump, remove cover.

2.Using a felt tipped pen, make suitable alignment

marks between inner and outer rotors and pump

body.

3.Remove inner and outer rotors.

4.Check rotors, cover and pump body for signs of

scoring and wear.

5.Fit rotors ensuring that reference marks are

aligned and identification mark on inner rotor is

facing outwards.

6.Using feeler gauges, check pump body to outer

rotor clearance:

Pump body to outer rotor clearance =0.295

to 0.375 mm (0.012 to 0.015 in)

7.Using feeler gauges, check clearance of inner to

outer rotor in 2 positions, both clearances must

be within limit given:

Inner to outer rotor clearance =0.13 mm (0.05

in)

ProCarManuals.com

Page 184 of 667

ENGINE

25

OVERHAUL

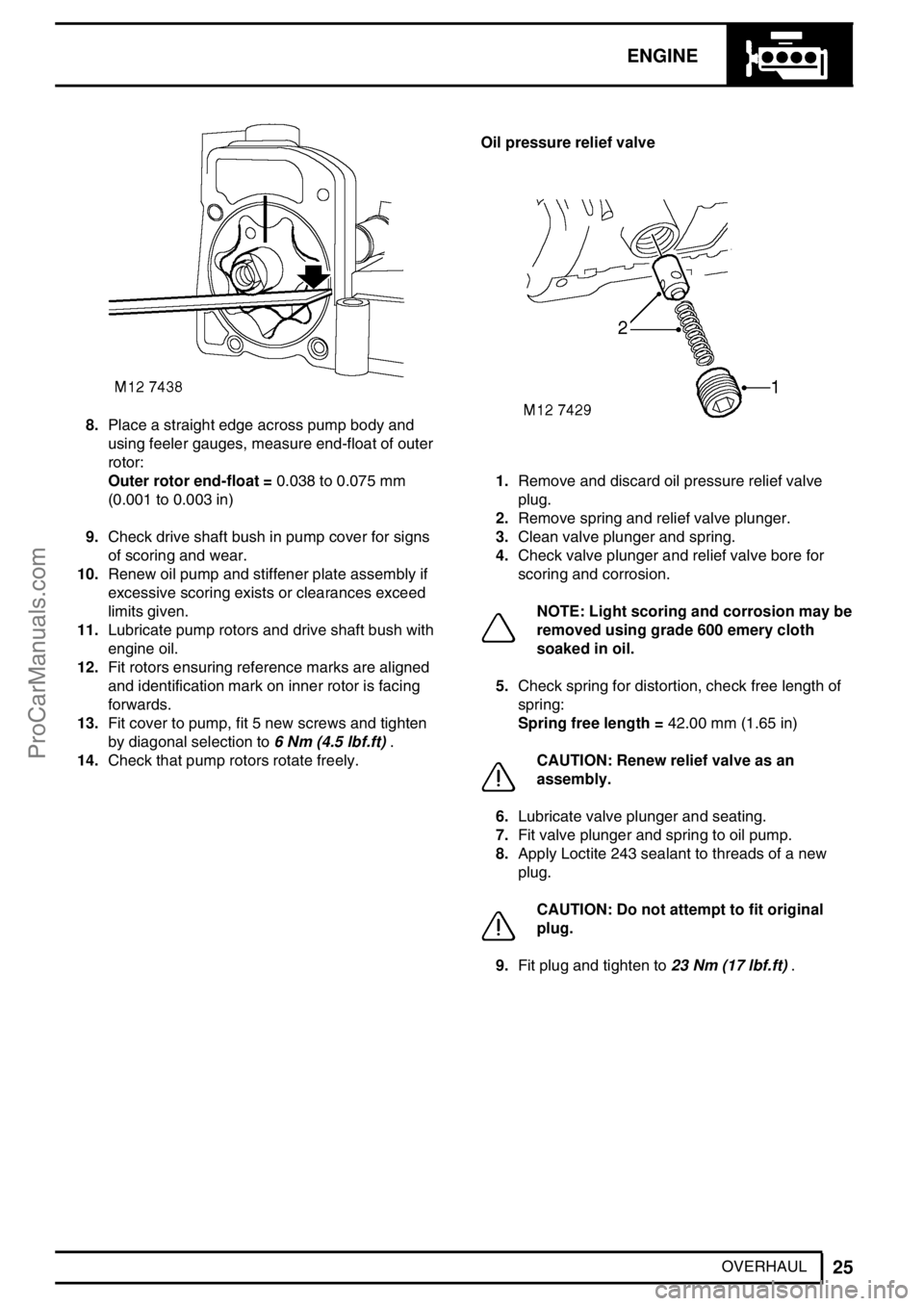

8.Place a straight edge across pump body and

using feeler gauges, measure end-float of outer

rotor:

Outer rotor end-float =0.038 to 0.075 mm

(0.001 to 0.003 in)

9.Check drive shaft bush in pump cover for signs

of scoring and wear.

10.Renew oil pump and stiffener plate assembly if

excessive scoring exists or clearances exceed

limits given.

11.Lubricate pump rotors and drive shaft bush with

engine oil.

12.Fit rotors ensuring reference marks are aligned

and identification mark on inner rotor is facing

forwards.

13.Fit cover to pump, fit 5 new screws and tighten

by diagonal selection to6 Nm (4.5 lbf.ft).

14.Check that pump rotors rotate freely.Oil pressure relief valve

1.Remove and discard oil pressure relief valve

plug.

2.Remove spring and relief valve plunger.

3.Clean valve plunger and spring.

4.Check valve plunger and relief valve bore for

scoring and corrosion.

NOTE: Light scoring and corrosion may be

removed using grade 600 emery cloth

soaked in oil.

5.Check spring for distortion, check free length of

spring:

Spring free length =42.00 mm (1.65 in)

CAUTION: Renew relief valve as an

assembly.

6.Lubricate valve plunger and seating.

7.Fit valve plunger and spring to oil pump.

8.Apply Loctite 243 sealant to threads of a new

plug.

CAUTION: Do not attempt to fit original

plug.

9.Fit plug and tighten to23 Nm (17 lbf.ft).

ProCarManuals.com