battery LAND ROVER DEFENDER 1999 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 360 of 667

TRANSFER GEARBOX

1

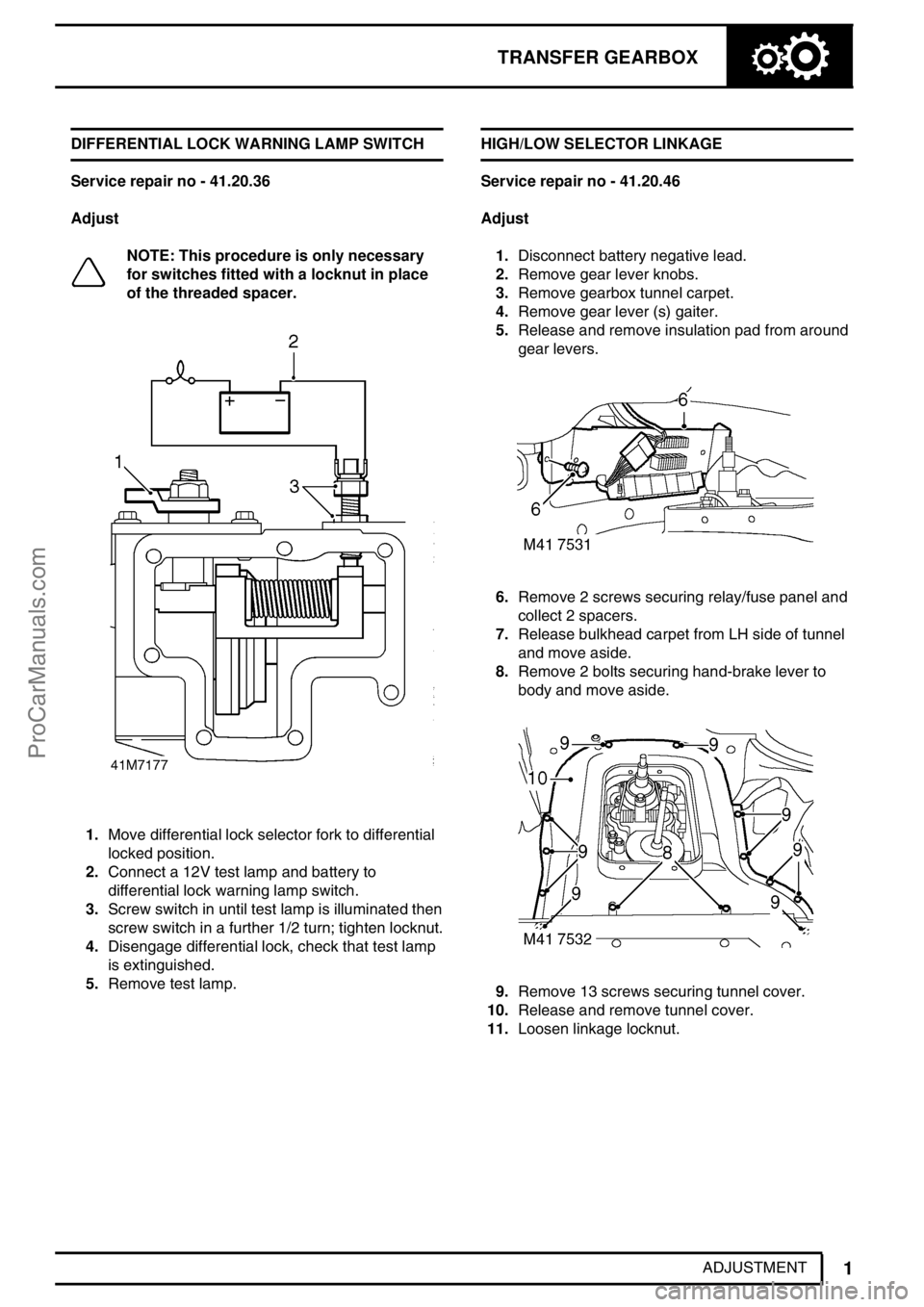

ADJUSTMENT DIFFERENTIAL LOCK WARNING LAMP SWITCH

Service repair no - 41.20.36

Adjust

NOTE: This procedure is only necessary

for switches fitted with a locknut in place

of the threaded spacer.

1.Move differential lock selector fork to differential

locked position.

2.Connect a 12V test lamp and battery to

differential lock warning lamp switch.

3.Screw switch in until test lamp is illuminated then

screw switch in a further 1/2 turn; tighten locknut.

4.Disengage differential lock, check that test lamp

is extinguished.

5.Remove test lamp.HIGH/LOW SELECTOR LINKAGE

Service repair no - 41.20.46

Adjust

1.Disconnect battery negative lead.

2.Remove gear lever knobs.

3.Remove gearbox tunnel carpet.

4.Remove gear lever (s) gaiter.

5.Release and remove insulation pad from around

gear levers.

6.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

7.Release bulkhead carpet from LH side of tunnel

and move aside.

8.Remove 2 bolts securing hand-brake lever to

body and move aside.

9.Remove 13 screws securing tunnel cover.

10.Release and remove tunnel cover.

11.Loosen linkage locknut.

ProCarManuals.com

Page 361 of 667

41TRANSFER GEARBOX

2

ADJUSTMENT

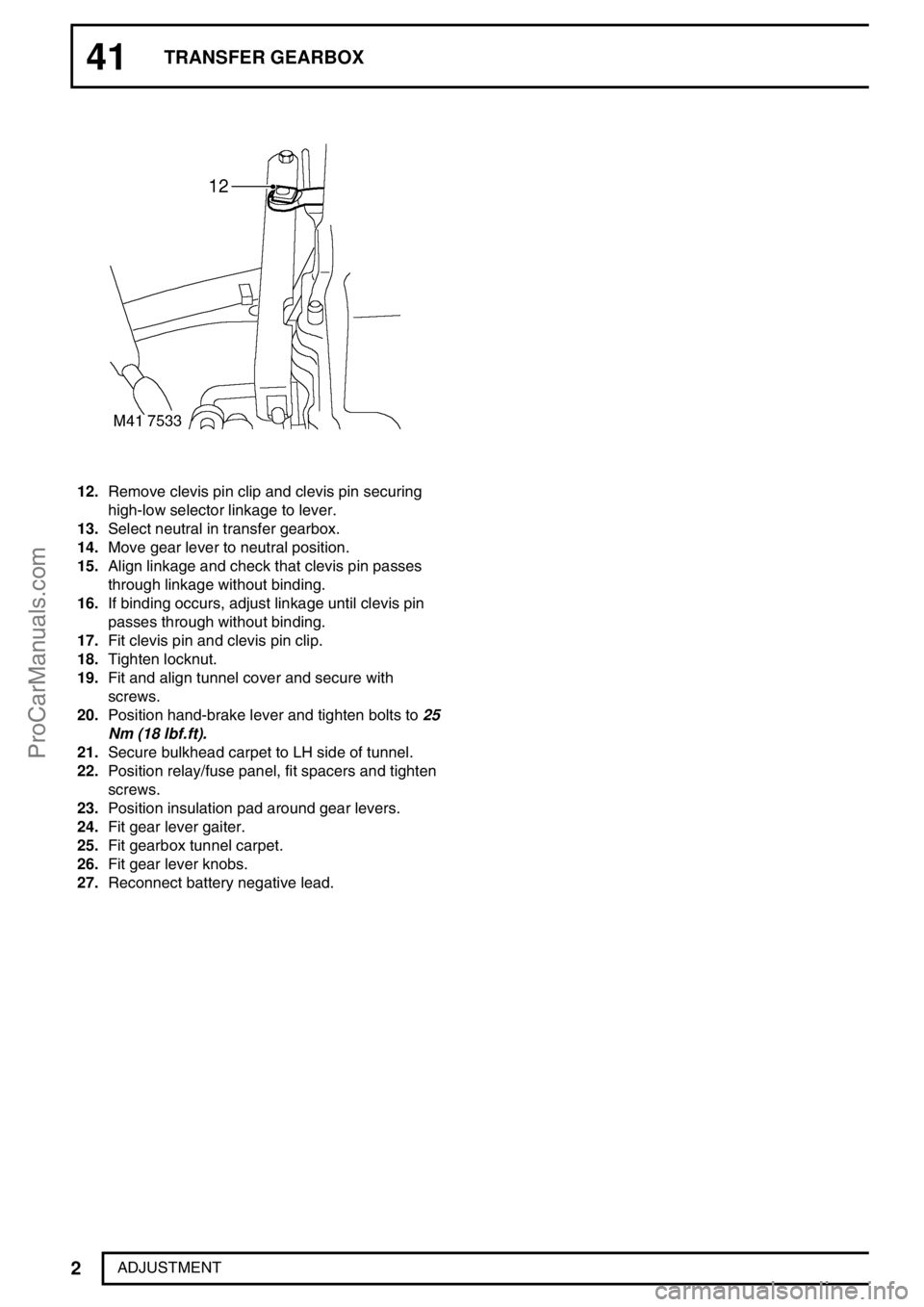

12.Remove clevis pin clip and clevis pin securing

high-low selector linkage to lever.

13.Select neutral in transfer gearbox.

14.Move gear lever to neutral position.

15.Align linkage and check that clevis pin passes

through linkage without binding.

16.If binding occurs, adjust linkage until clevis pin

passes through without binding.

17.Fit clevis pin and clevis pin clip.

18.Tighten locknut.

19.Fit and align tunnel cover and secure with

screws.

20.Position hand-brake lever and tighten bolts to25

Nm (18 lbf.ft).

21.Secure bulkhead carpet to LH side of tunnel.

22.Position relay/fuse panel, fit spacers and tighten

screws.

23.Position insulation pad around gear levers.

24.Fit gear lever gaiter.

25.Fit gearbox tunnel carpet.

26.Fit gear lever knobs.

27.Reconnect battery negative lead.

ProCarManuals.com

Page 362 of 667

TRANSFER GEARBOX

1

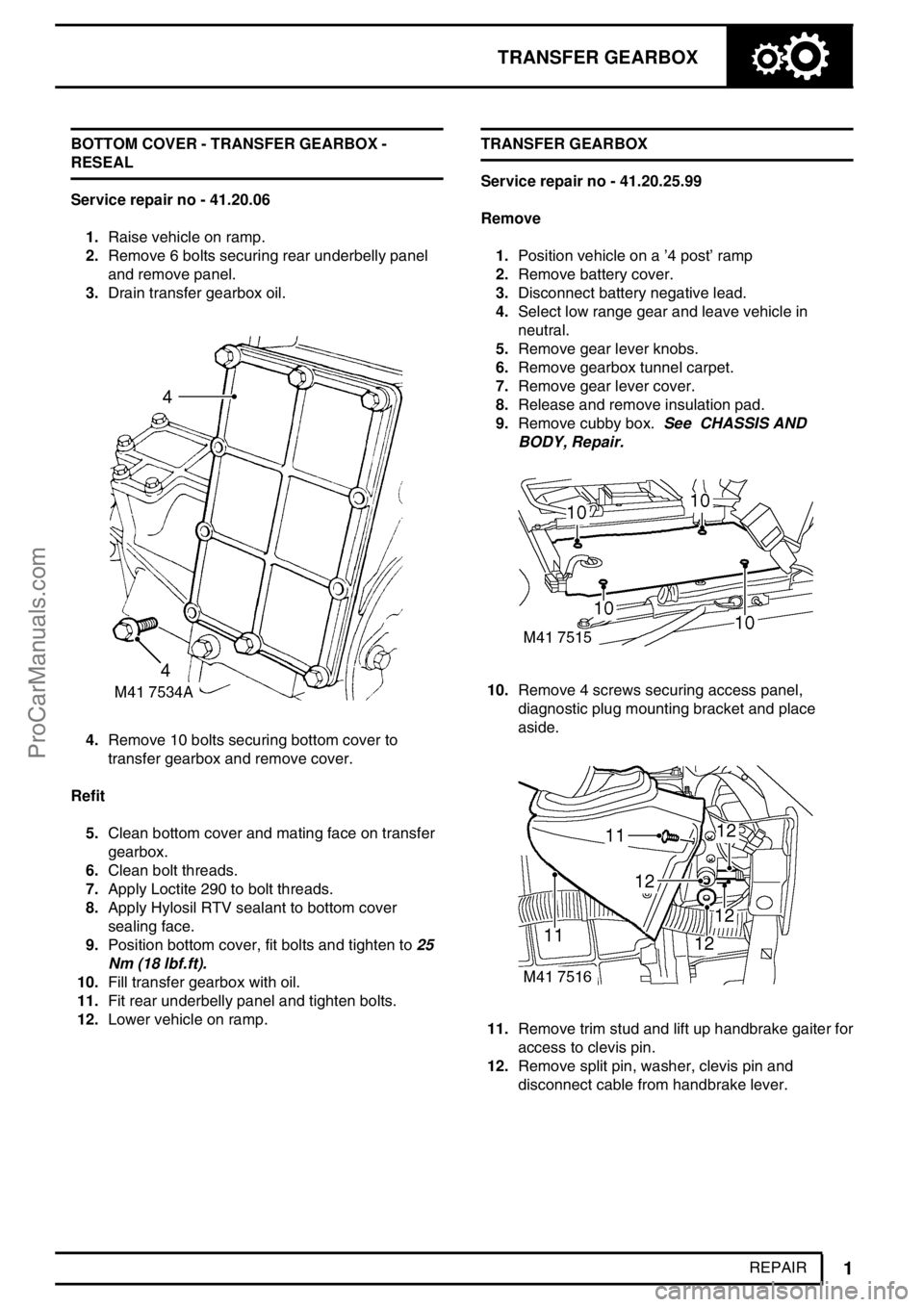

REPAIR BOTTOM COVER - TRANSFER GEARBOX -

RESEAL

Service repair no - 41.20.06

1.Raise vehicle on ramp.

2.Remove 6 bolts securing rear underbelly panel

and remove panel.

3.Drain transfer gearbox oil.

4.Remove 10 bolts securing bottom cover to

transfer gearbox and remove cover.

Refit

5.Clean bottom cover and mating face on transfer

gearbox.

6.Clean bolt threads.

7.Apply Loctite 290 to bolt threads.

8.Apply Hylosil RTV sealant to bottom cover

sealing face.

9.Position bottom cover, fit bolts and tighten to25

Nm (18 lbf.ft).

10.Fill transfer gearbox with oil.

11.Fit rear underbelly panel and tighten bolts.

12.Lower vehicle on ramp.TRANSFER GEARBOX

Service repair no - 41.20.25.99

Remove

1.Position vehicle on a’4 post’ramp

2.Remove battery cover.

3.Disconnect battery negative lead.

4.Select low range gear and leave vehicle in

neutral.

5.Remove gear lever knobs.

6.Remove gearbox tunnel carpet.

7.Remove gear lever cover.

8.Release and remove insulation pad.

9.Remove cubby box.See CHASSIS AND

BODY, Repair.

10.Remove 4 screws securing access panel,

diagnostic plug mounting bracket and place

aside.

11.Remove trim stud and lift up handbrake gaiter for

access to clevis pin.

12.Remove split pin, washer, clevis pin and

disconnect cable from handbrake lever.

ProCarManuals.com

Page 365 of 667

41TRANSFER GEARBOX

4

REPAIR

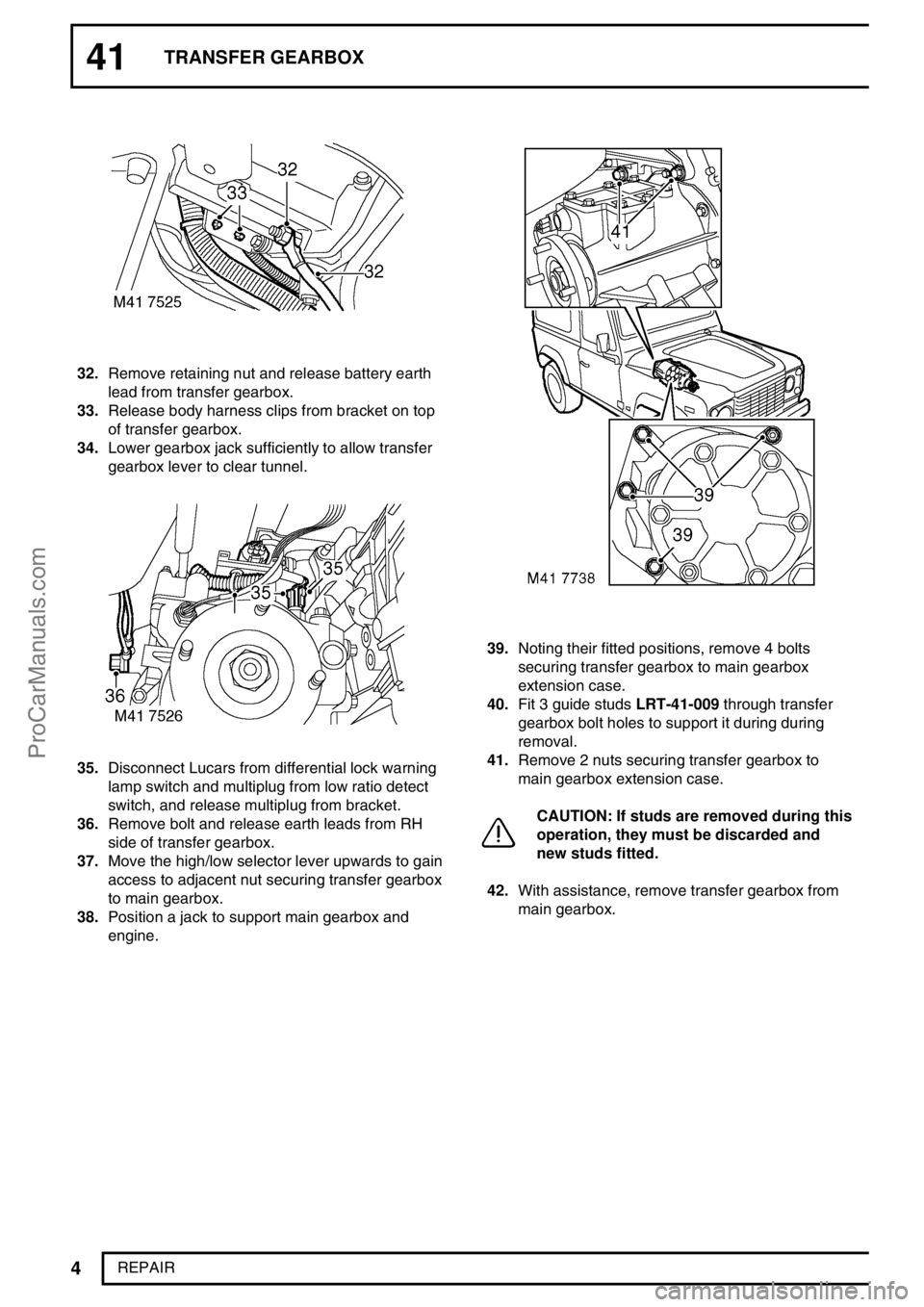

32.Remove retaining nut and release battery earth

lead from transfer gearbox.

33.Release body harness clips from bracket on top

of transfer gearbox.

34.Lower gearbox jack sufficiently to allow transfer

gearbox lever to clear tunnel.

35.Disconnect Lucars from differential lock warning

lamp switch and multiplug from low ratio detect

switch, and release multiplug from bracket.

36.Remove bolt and release earth leads from RH

side of transfer gearbox.

37.Move the high/low selector lever upwards to gain

access to adjacent nut securing transfer gearbox

to main gearbox.

38.Position a jack to support main gearbox and

engine.

39.Noting their fitted positions, remove 4 bolts

securing transfer gearbox to main gearbox

extension case.

40.Fit 3 guide studsLRT-41-009through transfer

gearbox bolt holes to support it during during

removal.

41.Remove 2 nuts securing transfer gearbox to

main gearbox extension case.

CAUTION: If studs are removed during this

operation, they must be discarded and

new studs fitted.

42.With assistance, remove transfer gearbox from

main gearbox.

ProCarManuals.com

Page 367 of 667

41TRANSFER GEARBOX

6

REPAIR 71.Release propeller shaft, align flange markings

and connect to studs.

72.Fit nuts securing propeller shaft and tighten to48

Nm (33 lbf.ft).

73.Clean front propeller to transfer gearbox flange

mating faces.

74.Fit propeller shaft, align flange markings and

tighten nuts to48 Nm (33 lbf.ft).

75.Using new gasket, fit intermediate silencer and

tighten nuts to25 Nm (18 lbf.ft).

76.Fit exhaust front pipe.See MANIFOLD AND

EXHAUST SYSTEM, Repair.

77.Refill transfer gearbox with recommended oil.

78.Fit cooling fan cowl.

79.Fit high/low operating rod and secure with

retaining clip.

80.Position handbrake outer cable to heelboard.

81.Position handbrake cable to lever, fit clevis pin,

washer and new split pin.

82.Position handbrake gaiter and secure with trim

studs.

83.Fit insulation pad to tunnel.

84.Fit gear lever cover.

85.Fit gear lever knobs.

86.Position diagnostic plug bracket, access panel

and tighten screws.

87.Fit carpet to transmission tunnel.

88.Fit cubby box.See CHASSIS AND BODY,

Repair.

89.Fit cooling fan.See COOLING SYSTEM,

Repair.

90.Reconnect battery negative lead.

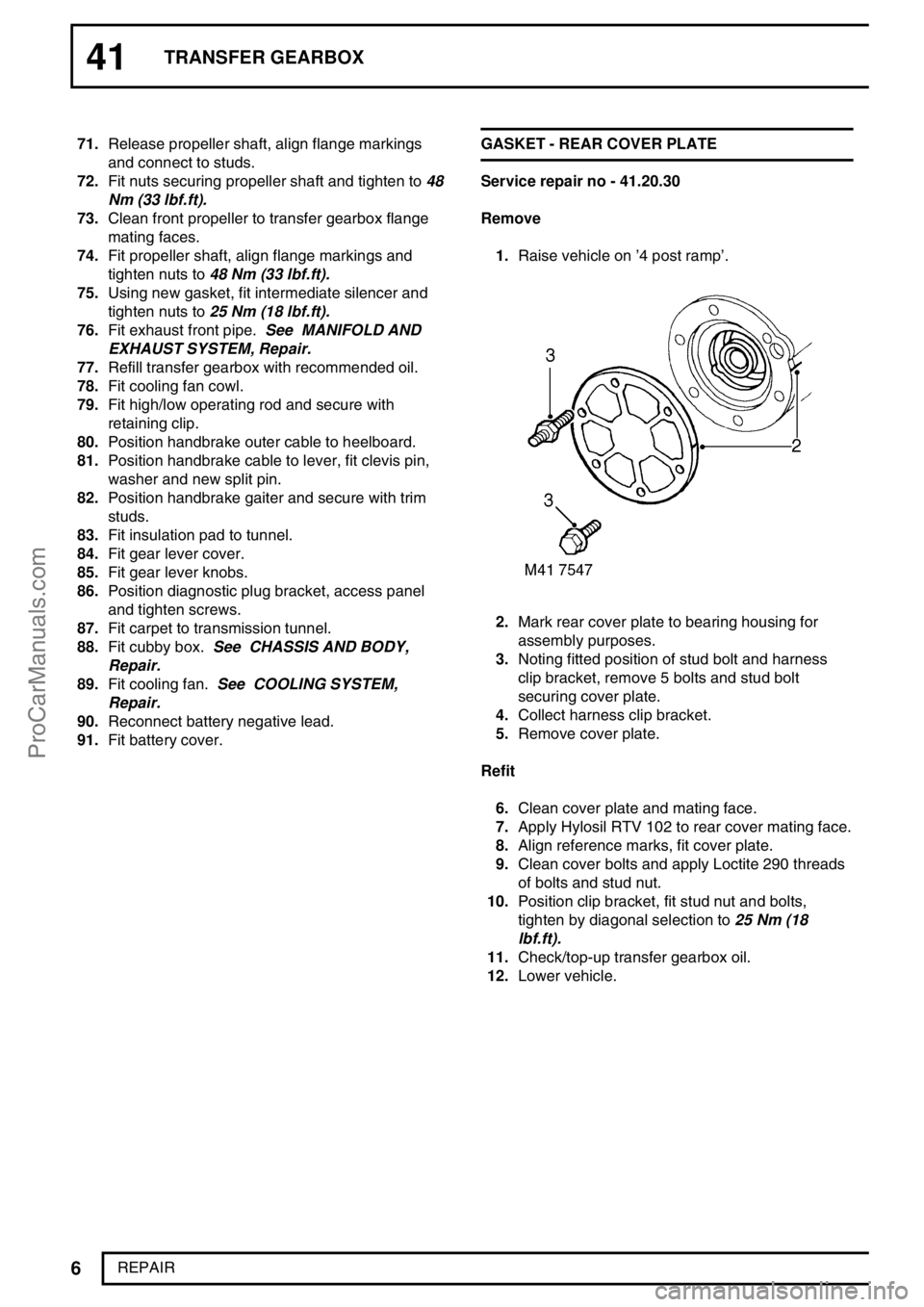

91.Fit battery cover.GASKET - REAR COVER PLATE

Service repair no - 41.20.30

Remove

1.Raise vehicle on’4 post ramp’.

2.Mark rear cover plate to bearing housing for

assembly purposes.

3.Noting fitted position of stud bolt and harness

clip bracket, remove 5 bolts and stud bolt

securing cover plate.

4.Collect harness clip bracket.

5.Remove cover plate.

Refit

6.Clean cover plate and mating face.

7.Apply Hylosil RTV 102 to rear cover mating face.

8.Align reference marks, fit cover plate.

9.Clean cover bolts and apply Loctite 290 threads

of bolts and stud nut.

10.Position clip bracket, fit stud nut and bolts,

tighten by diagonal selection to25 Nm (18

lbf.ft).

11.Check/top-up transfer gearbox oil.

12.Lower vehicle.

ProCarManuals.com

Page 368 of 667

TRANSFER GEARBOX

7

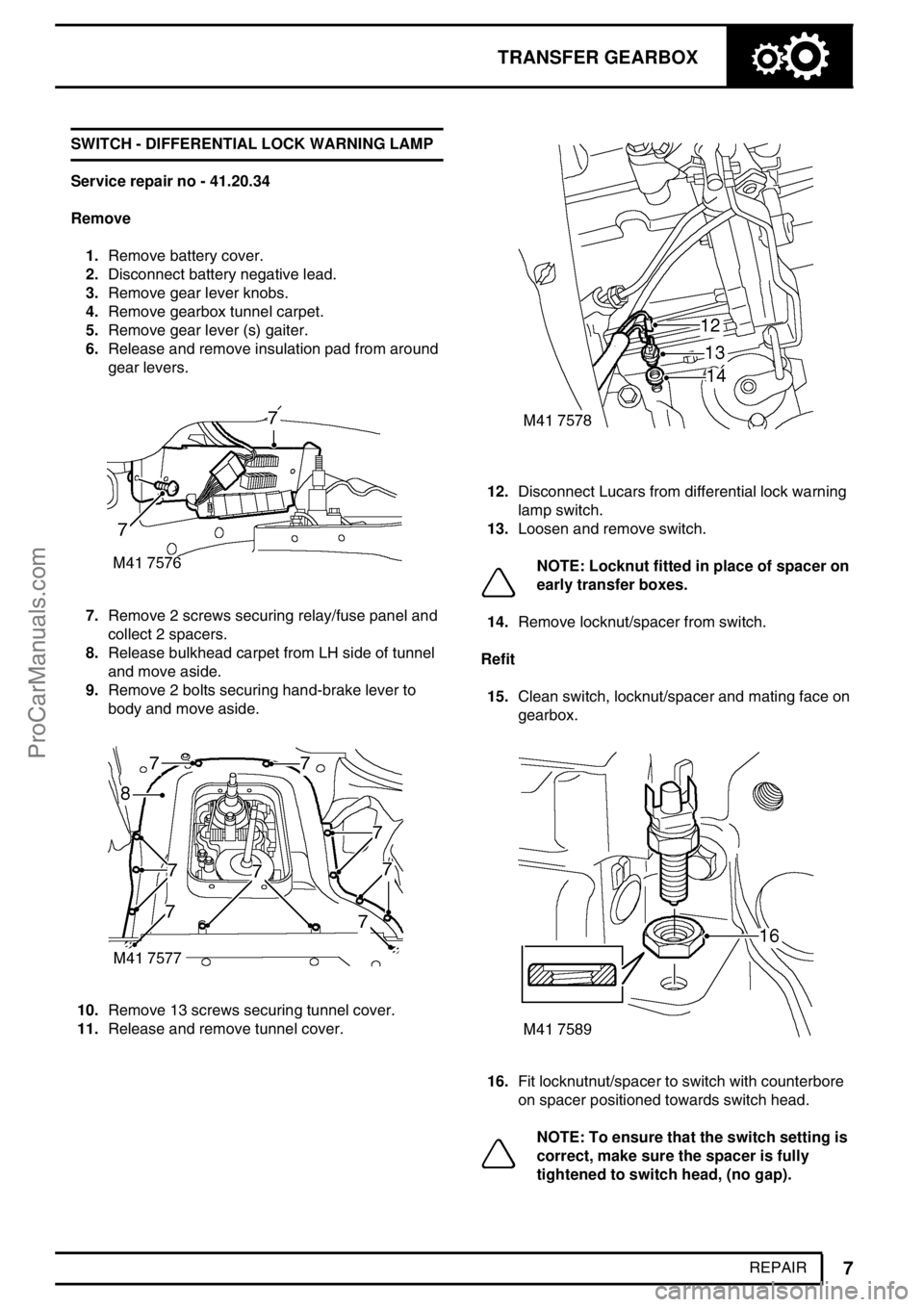

REPAIR SWITCH - DIFFERENTIAL LOCK WARNING LAMP

Service repair no - 41.20.34

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove gear lever knobs.

4.Remove gearbox tunnel carpet.

5.Remove gear lever (s) gaiter.

6.Release and remove insulation pad from around

gear levers.

7.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

8.Release bulkhead carpet from LH side of tunnel

and move aside.

9.Remove 2 bolts securing hand-brake lever to

body and move aside.

10.Remove 13 screws securing tunnel cover.

11.Release and remove tunnel cover.

12.Disconnect Lucars from differential lock warning

lamp switch.

13.Loosen and remove switch.

NOTE: Locknut fitted in place of spacer on

early transfer boxes.

14.Remove locknut/spacer from switch.

Refit

15.Clean switch, locknut/spacer and mating face on

gearbox.

16.Fit locknutnut/spacer to switch with counterbore

on spacer positioned towards switch head.

NOTE: To ensure that the switch setting is

correct, make sure the spacer is fully

tightened to switch head, (no gap).

ProCarManuals.com

Page 369 of 667

41TRANSFER GEARBOX

8

REPAIR 17.Apply Hylomar PL32 sealant to switch threads.

18.Position switch into gearbox housing until

locknut/spacer bottoms out on housing.

19. Switches fitted with spacer:Tighten spacer

securing differential lock switch to11 Nm (8

lbf.ft).

20.Connect Lucars to switch.

21. Switches fitted with locknut:Adjust switch.

See Adjustment.

22.Fit and align tunnel cover, fit and tighten screws.

23.Fit hand-brake lever and tighten bolts to25 Nm

(18 lbf.ft).

24.Secure bulkhead carpet to LH side of tunnel.

25.Position relay/fuse panel, fit spacers and tighten

screws.

26.Fit insulation pad around gear levers.

27.Fit gear lever (s) gaiter.

28.Fit gearbox tunnel carpet.

29.Fit gear lever knobs.

30.Reconnect battery negative lead.

31.Fit battery cover.SEAL - INPUT SHAFT

Service repair no - 41.20.50

Remove

1.Remove transfer gearbox.See this Section.

2.Remove and discard input shaft oil seal from

transfer gearbox.

Refit

3.Clean oil seal recess in transfer gearbox.

4.Lubricate new oil seal with transfer gearbox oil.

5.UsingLRT-37-014, fit input shaft seal to transfer

gearbox.

6.Fit transfer gearbox.See this Section.

ProCarManuals.com

Page 374 of 667

TRANSFER GEARBOX

13

REPAIR SWITCH - LOW DETECT

Service repair no - 41.30.05

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove gear lever knobs.

4.Remove gearbox tunnel carpet.

5.Remove gear lever(s) gaiter.

6.Release and remove insulation pad from around

gear levers.

7.Remove 2 screws securing relay/fuse panel and

collect 2 spacers.

8.Release bulkhead carpet from LH side of tunnel

and move aside.

9.Remove 2 bolts securing hand-brake lever to

body and move lever aside.

10.Remove 13 screws securing tunnel cover.

11.Release and remove tunnel cover.12.Release switch multiplug from bracket on

transfer gearbox, disconnect from harness.

13.Remove switch.

Refit

14.Clean switch and mating face on transfer

gearbox.

15.Fit nut/spacer to switch with counterbore

positioned towards switch head.

16.Apply Hylomar PL32 sealant to switch threads.

17.Fit switch and tighten to24 Nm (19 lbf.ft).

18.Connect multiplug to harness.

19.Fit and align tunnel cover, fit and tighten screws.

20.Position hand-brake lever and tighten bolts to25

Nm (18 lbf.ft).

21.Secure bulkhead carpet to LH side of tunnel.

22.Position relay/fuse panel, fit spacers and tighten

screws.

23.Fit insulation pad around gear levers.

24.Fit gear lever (s) gaiter.

25.Fit gearbox tunnel carpet.

26.Fit gear lever knobs.

27.Reconnect battery negative lead.

28.Fit battery cover.

ProCarManuals.com

Page 448 of 667

BRAKES

1

ADJUSTMENT BRAKE SYSTEM BLEED

Service repair no - 70.25.02

Preparation

WARNING: Before bleeding the brake

system refer to general brake service

practice.See this Section. general brake

service practice

During bleed procedure, brake fluid level must

not be allowed to fall below the MIN mark. Keep

reservoir topped up to the MAX mark.

To bleed the hydraulic circuits, four bleed

nipples are provided, one at each caliper.

There are two methods by which air can be removed

from the braking system:-

1.MANUAL BLEED PROCEDURE

2.PRESSURE BLEED PROCEDURE

Pressure bleed procedure

Purpose designed equipment for pressure filling and

bleeding of hydraulic systems may be used on Land

Rover vehicles. The equipment manufacturers

instructions must be followed and the pressure must

not exceed 4.5 bar, 65 lb/in.

Manual bleed procedure

Equipment required

Clean glass receptacle

Bleed hose

Wrench

Approx. 2 litres (3 pts) brake fluid

Master cylinder bleed

1.Disconnect battery negative lead.

2.Depress brake pedal fully and slowly 5 times.

3.Release pedal and wait 10 seconds.

4.Repeat until firm resistance is felt at the pedal.Complete circuit bleed

1.Disconnect battery negative lead.

2.Fit bleed hose to caliper bleed screw.

3.Dip free end of bleed hose into brake fluid in

bleed bottle.

4.Open bleed nipple.

5.Depress brake pedal fully several times until fluid

is clear of air bubbles.

6.Keeping pedal fully depresses, tighten bleed

nipple then release pedal.

7.Repeat procedure for remaining calipers.

8.Fit bleed screw protection caps.

9.Check/top-up fluid level when bleeding is

complete.

ProCarManuals.com

Page 450 of 667

BRAKES

1

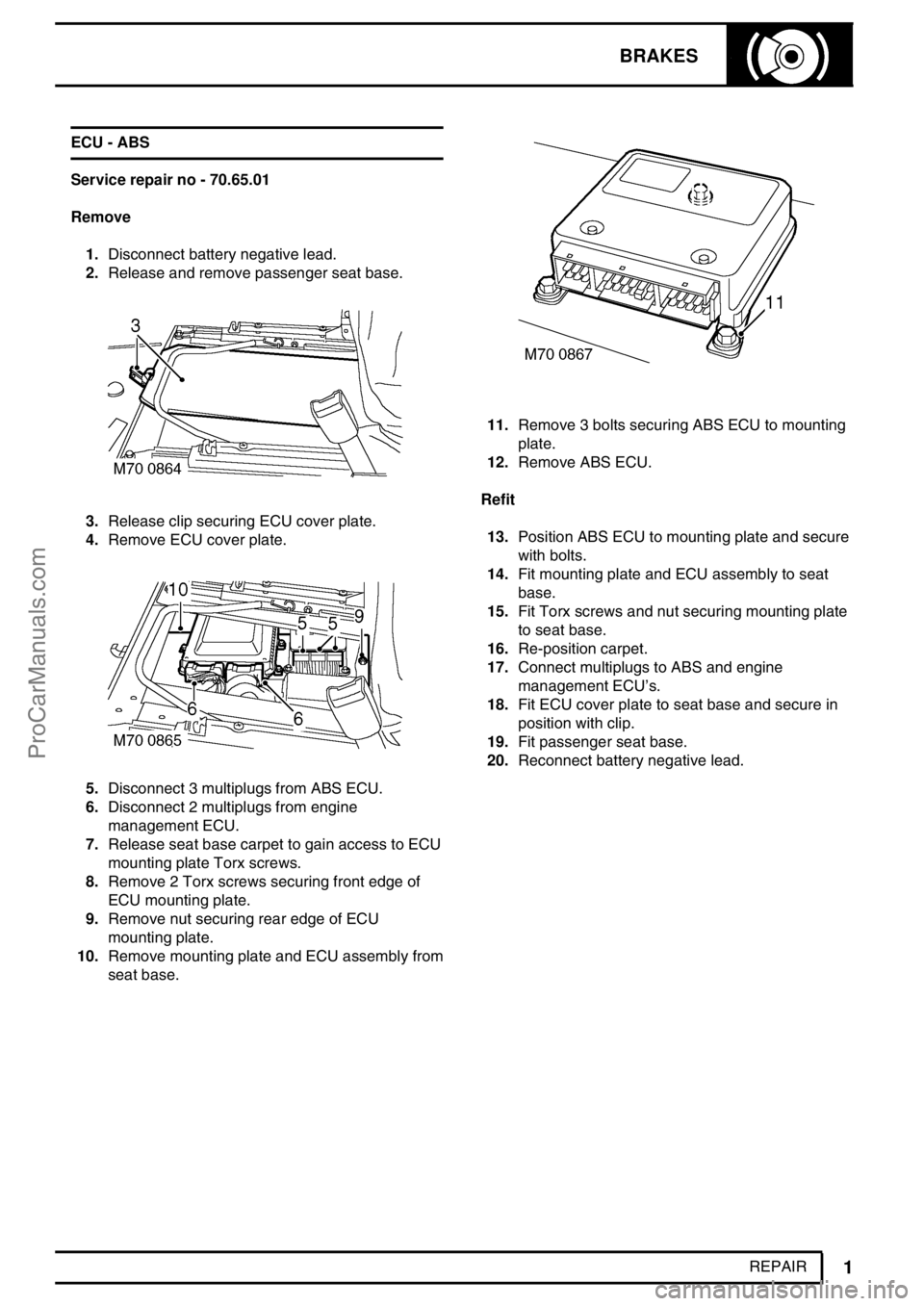

REPAIR ECU - ABS

Service repair no - 70.65.01

Remove

1.Disconnect battery negative lead.

2.Release and remove passenger seat base.

3.Release clip securing ECU cover plate.

4.Remove ECU cover plate.

5.Disconnect 3 multiplugs from ABS ECU.

6.Disconnect 2 multiplugs from engine

management ECU.

7.Release seat base carpet to gain access to ECU

mounting plate Torx screws.

8.Remove 2 Torx screws securing front edge of

ECU mounting plate.

9.Remove nut securing rear edge of ECU

mounting plate.

10.Remove mounting plate and ECU assembly from

seat base.

11.Remove 3 bolts securing ABS ECU to mounting

plate.

12.Remove ABS ECU.

Refit

13.Position ABS ECU to mounting plate and secure

with bolts.

14.Fit mounting plate and ECU assembly to seat

base.

15.Fit Torx screws and nut securing mounting plate

to seat base.

16.Re-position carpet.

17.Connect multiplugs to ABS and engine

management ECU’s.

18.Fit ECU cover plate to seat base and secure in

position with clip.

19.Fit passenger seat base.

20.Reconnect battery negative lead.

ProCarManuals.com