battery LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 453 of 667

70BRAKES

4

REPAIR MASTER CYLINDER

Service repair no - 70.30.08

Remove

1.Disconnect battery negative lead.

2.Place a container under the master cylinder to

collect any brake fluid spillage.

CAUTION: Do not allow brake fluid to

contact paint finished surfaces as paint

may be damaged. If spilled, remove fluid

and clean area with clean warm water.

3.Clean area around master cylinder ports.

4.Loosen 2 unions securing brake pipes to master

cylinder ports.

5.Disconnect both brake pipes from master

cylinder. Cover, not plug, pipe ends to prevent

entry of dirt.

6.Disconnect 2 Lucars from reservoir cap.

7.Remove 2 nuts securing master cylinder to

brake servo.

8.Withdraw master cylinder from servo and

remove.

Do not carry out further dismantling if

component is removed for access only.9.Carefully ease reservoir from master cylinder by

rolling it from seals.

10.Remove seals from master cylinder.

NOTE: Master cylinder to reservoir seals

are different sizes.

11.Fit NEW seals to master cylinder, ensuring seals

are fitted to correct ports.

12.Fit reservoir to master cylinder.

Refit

13.Ensuring that water ingress seal is in position, fit

master cylinder to servo.

14.Fit nuts securing master cylinder to servo and

tighten to26 Nm (19 lbf.ft).

15.Connect brake pipes to master cylinder and

tighten unions to15 Nm (11 lbf.ft).

16.Connect Lucars to reservoir cap.

17.Fill reservoir with recommended brake fluid.See

LUBRICANTS, FLUIDS AND CAPACITIES,

Information.

18.Bleed the brake system.See Adjustment.

19.Reconnect battery negative lead.

ProCarManuals.com

Page 488 of 667

CHASSIS AND BODY

19

REPAIR LOWER FASCIA PANEL - UP TO 02MY

Service repair no - 76.46.05

Remove

1.Disconnect battery negative lead.

2.Remove steering wheel.See STEERING,

Repair.

3.Remove 7 screws securing nacelle to steering

column.

4.Remove 2 halves of nacelle from steering

column.

5.Remove instrument pack.See ELECTRICAL,

Repair.

6.Remove 3 screws securing heater control cable

assembly to end of fascia.

7.Release heater control cable assembly from

fascia and move aside.

8.Release HRW, Rear Fog Guard Lamp, and

Hazard Warning switches from fascia.

9.Disconnect multiplugs and Lucars from switches.

10.Collect switches.

11.Remove locking rings from both front speakers.

12.Remove 4 screws securing each speaker to

fascia.

13.Disconnect multiplugs from speakers and

remove both front speakers.

ProCarManuals.com

Page 492 of 667

CHASSIS AND BODY

23

REPAIR 59.Fit radio housing to fascia and secure with trim

studs.

60.Position radio to fascia and connect multiplugs

and aerial.

61.Fit radio to fascia.

62.Fit crash pad to fascia and secure with screws.

63.Fit both demister vents to crash pad and secure

with screws.

64.Fit grab handle to fascia and secure with screws.

65.Fit Land Rover decal to grab handle.

66.Position both front speakers to fascia and

connect multiplugs.

67.Fit speakers to fascia and secure with screws.

68.Fit locking rings to speakers.

69.Connect multiplugs and Lucars to HRW, Rear

Fog Guard Lamp, and Hazard Warning

Switches.

70.Fit switches to fascia.

71.Position heater controls to fascia and secure

with screws.

72.Fit instrument pack.See ELECTRICAL,

Repair.

73.Fit 2 halves of nacelle to steering column and

secure with screws.

74.Fit steering wheel.See STEERING, Repair.

75.Reconnect battery negative lead.PANEL - MOUNTING - FRONT DOOR - FROM 02MY

Service repair no - 76.11.28

Remove

1.Remove plastic sheet.See this Section.

2.Lower glass and remove 2 bolts securing door

glass to regulator.

3.Release glass from regulator, raise and wedge

in raised position.

ProCarManuals.com

Page 496 of 667

CHASSIS AND BODY

27

REPAIR FACIA CONSOLE - FROM 02MY

Service repair no - 76.25.03

Remove

1.Disconnect battery earth lead.See

ELECTRICAL, Repair.

2.Remove radio.See ELECTRICAL, Repair.

3.Remove 4 screws securing instrument pack and

release pack from fascia.

4.Disconnect 2 multiplugs from warning lamp

panel.

5.Disconnect instrument pack multiplug from main

harness.

6.Remove instrument pack.

7.Remove 3 screws securing heater control and

release control from fascia.

8.Carefully prise Land Rover decal from grab

handle.

9.Remove 2 screws securing grab handle and

remove handle.

10.Remove 4 screws and remove demister vents.

ProCarManuals.com

Page 498 of 667

CHASSIS AND BODY

29

REPAIR 25.Position console and connect Lucar and

multiplug to cigar lighter.

26.Connect multiplugs to remaining switches.

27.Fit console and secure with screws.

28.Fit crash pad and secure with screws.

29.Fit demister vents and secure with screws.

30.Fit grab handle, secure with screws and fit Land

Rover decal.

31.Fit heater control to fascia and secure with

screws.

32.Position instrument pack and connect multiplugs.

33.Fit instrument pack to fascia and secure with

screws.

34.Fit radio.See ELECTRICAL, Repair.

35.Connect battery earth lead.See ELECTRICAL,

Repair.GLASS - REAR DOOR - FROM 02MY

Service repair no - 76.31.02

Remove

1.Remove rear door mounting panel.See this

Section.

2.Loosen 2 nuts and remove door check strap

torsion bar and plate.

3.Remove check strap.

4.Remove inner and outer waist seal.

5.Remove screw from each glass channel.

6.Lower glass to bottom of door, lift over lower

edge and withdraw from door.

ProCarManuals.com

Page 505 of 667

76CHASSIS AND BODY

36

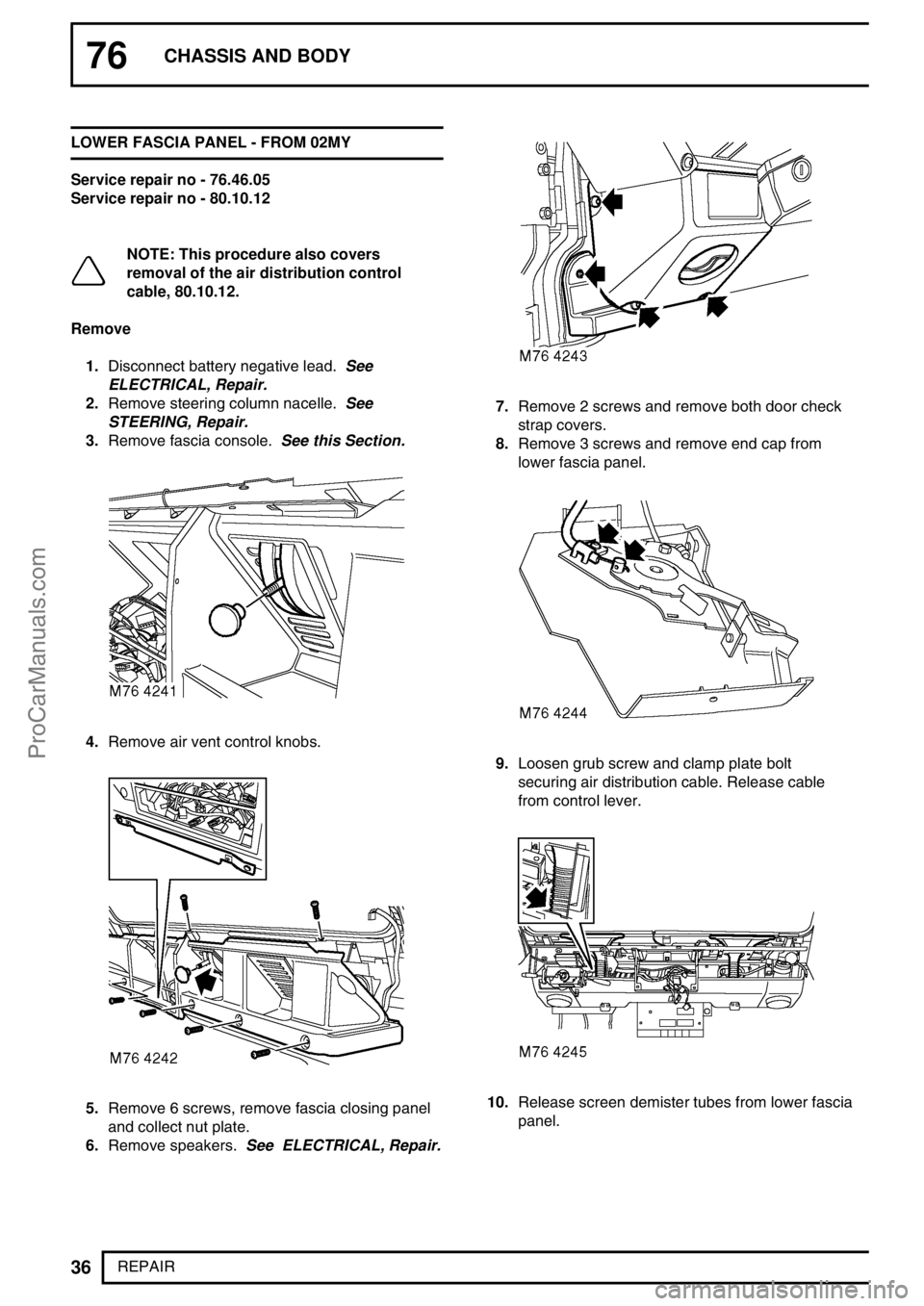

REPAIR LOWER FASCIA PANEL - FROM 02MY

Service repair no - 76.46.05

Service repair no - 80.10.12

NOTE: This procedure also covers

removal of the air distribution control

cable, 80.10.12.

Remove

1.Disconnect battery negative lead.See

ELECTRICAL, Repair.

2.Remove steering column nacelle.See

STEERING, Repair.

3.Remove fascia console.See this Section.

4.Remove air vent control knobs.

5.Remove 6 screws, remove fascia closing panel

and collect nut plate.

6.Remove speakers.See ELECTRICAL, Repair.

7.Remove 2 screws and remove both door check

strap covers.

8.Remove 3 screws and remove end cap from

lower fascia panel.

9.Loosen grub screw and clamp plate bolt

securing air distribution cable. Release cable

from control lever.

10.Release screen demister tubes from lower fascia

panel.

ProCarManuals.com

Page 506 of 667

CHASSIS AND BODY

37

REPAIR

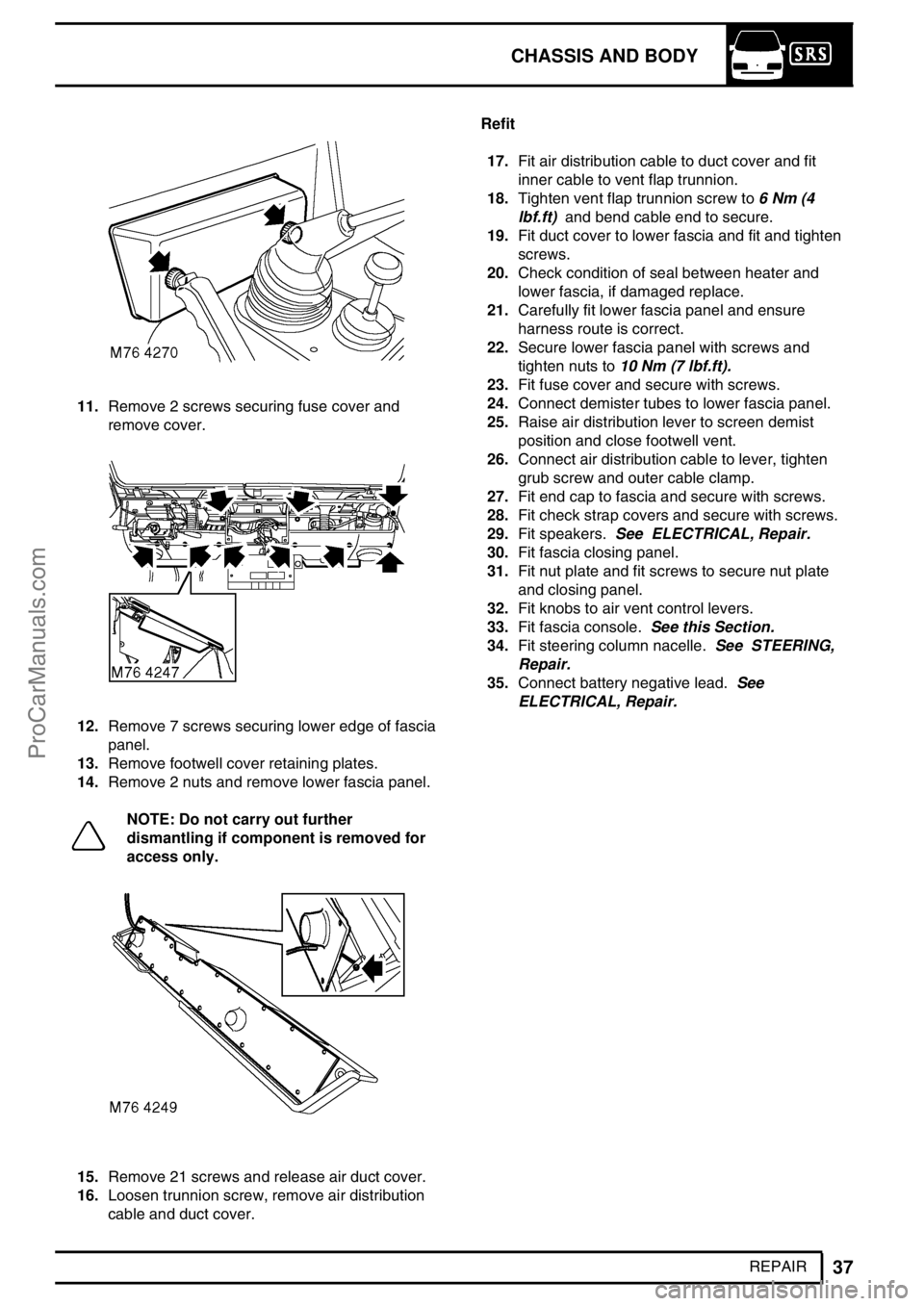

11.Remove 2 screws securing fuse cover and

remove cover.

12.Remove 7 screws securing lower edge of fascia

panel.

13.Remove footwell cover retaining plates.

14.Remove 2 nuts and remove lower fascia panel.

NOTE: Do not carry out further

dismantling if component is removed for

access only.

15.Remove 21 screws and release air duct cover.

16.Loosen trunnion screw, remove air distribution

cable and duct cover.Refit

17.Fit air distribution cable to duct cover and fit

inner cable to vent flap trunnion.

18.Tighten vent flap trunnion screw to6Nm(4

lbf.ft)and bend cable end to secure.

19.Fit duct cover to lower fascia and fit and tighten

screws.

20.Check condition of seal between heater and

lower fascia, if damaged replace.

21.Carefully fit lower fascia panel and ensure

harness route is correct.

22.Secure lower fascia panel with screws and

tighten nuts to10 Nm (7 lbf.ft).

23.Fit fuse cover and secure with screws.

24.Connect demister tubes to lower fascia panel.

25.Raise air distribution lever to screen demist

position and close footwell vent.

26.Connect air distribution cable to lever, tighten

grub screw and outer cable clamp.

27.Fit end cap to fascia and secure with screws.

28.Fit check strap covers and secure with screws.

29.Fit speakers.See ELECTRICAL, Repair.

30.Fit fascia closing panel.

31.Fit nut plate and fit screws to secure nut plate

and closing panel.

32.Fit knobs to air vent control levers.

33.Fit fascia console.See this Section.

34.Fit steering column nacelle.See STEERING,

Repair.

35.Connect battery negative lead.See

ELECTRICAL, Repair.

ProCarManuals.com

Page 553 of 667

77PANEL REPAIRS

28

SEALING AND CORROSION PROTECTION WATER LEAKS

Sealing charts in this section show those areas of the

bodyshell most likely to be affected by accident

damage and water leaks, and which could therefore

require re-treatment in repair. They do not show those

joint areas which only apply to factory assembly

operations and which are unlikely to be disturbed in

service (e.g. centre tunnel), or where the damage

would be so severe that the entire bodyshell would

normally be written off.

When water leakage occurs, always adopt a logical

approach to the problem using a combination of skill,

experience and intuition. Do not attempt to reach a

conclusion based only on visual evidence, such as

assuming that a leak emanates from the windscreen

because the footwell is wet. It will often be found that

the source of the leak is elsewhere. The correct

procedure will increase the chance of locating a leak,

however obscure it may seem.

Tools and Equipment

The following tools and equipment are recommended

for detection and rectification of water leaks:

1. Garden sprayer (hand-operated).

2. Wet/dry vacuum cleaner.

3. Dry absorbent cloths.

4. Battery torch.

5. Small mirror.

6. Weatherstrip locating tool.

7. Trim panel remover.

8. Small wooden or plastic wedges.

9. Dry compressed air supply.

10. Hot air blower.

11. Sealer applicators.

12. Ultrasonic leak detector.

During leak detection, the vehicle should be

considered in three basic sections:

The front interior space,

The rear passenger space (where

applicable), and

The rear loadspace or boot.Testing

From the information supplied by the customer it

should be possible for the bodyshop operator to locate

the starting point from which the leak may be

detected. After the area of the leak has been

identified, find the actual point of entry into the vehicle.

A simple and effective means initially is an ordinary

garden spray with provision for pressure and jet

adjustment. This will allow water to be directed in a jet

or turned into a fine spray. Use a mirror and a

battery-powered torch (NOT a mains voltage

inspection lamp) to see into dark corners.

The sequence of testing is particularly important. Start

at the lowest point and work slowly upwards, to avoid

testing in one area while masking the leak in another.

For example, if testing started at the level of the

windscreen, any water cascading into the plenum

chamber could leak through a bulkhead grommet and

into the footwells. Even at this point it could still be

wrongly assumed that the windscreen seal was at

fault.

Another important part of identifying a water leak is by

visual examination of door aperture seals, grommets

and weatherstrips for damage, deterioration or

misalignment, together with the fit of the door itself

against the seals.

Sealing

When the point of the leak has been detected,

proceed to rectify it using the following procedure:

1. Renew all door aperture seals and weatherstrips

which have suffered damage, misalignment or

deterioration.

2. Check all body seals to ensure that they are

correctly located on their mounting flanges/faces

using a locating tool if necessary.

3. Dry out body seams to be treated using

compressed air and/or a hot air blower as

necessary.

4. Apply sealant on the outside of the joint

wherever possible to ensure the exclusion of

water.

5. When rectifying leaks between a screen glass

and its weatherstrip (or in the case of direct

glazing, between the glass and bodywork), avoid

removing the glass if possible. Apply the

approved material either at the glass to

weatherstrip or glass to body.

ProCarManuals.com

Page 566 of 667

PANEL REPAIRS

1

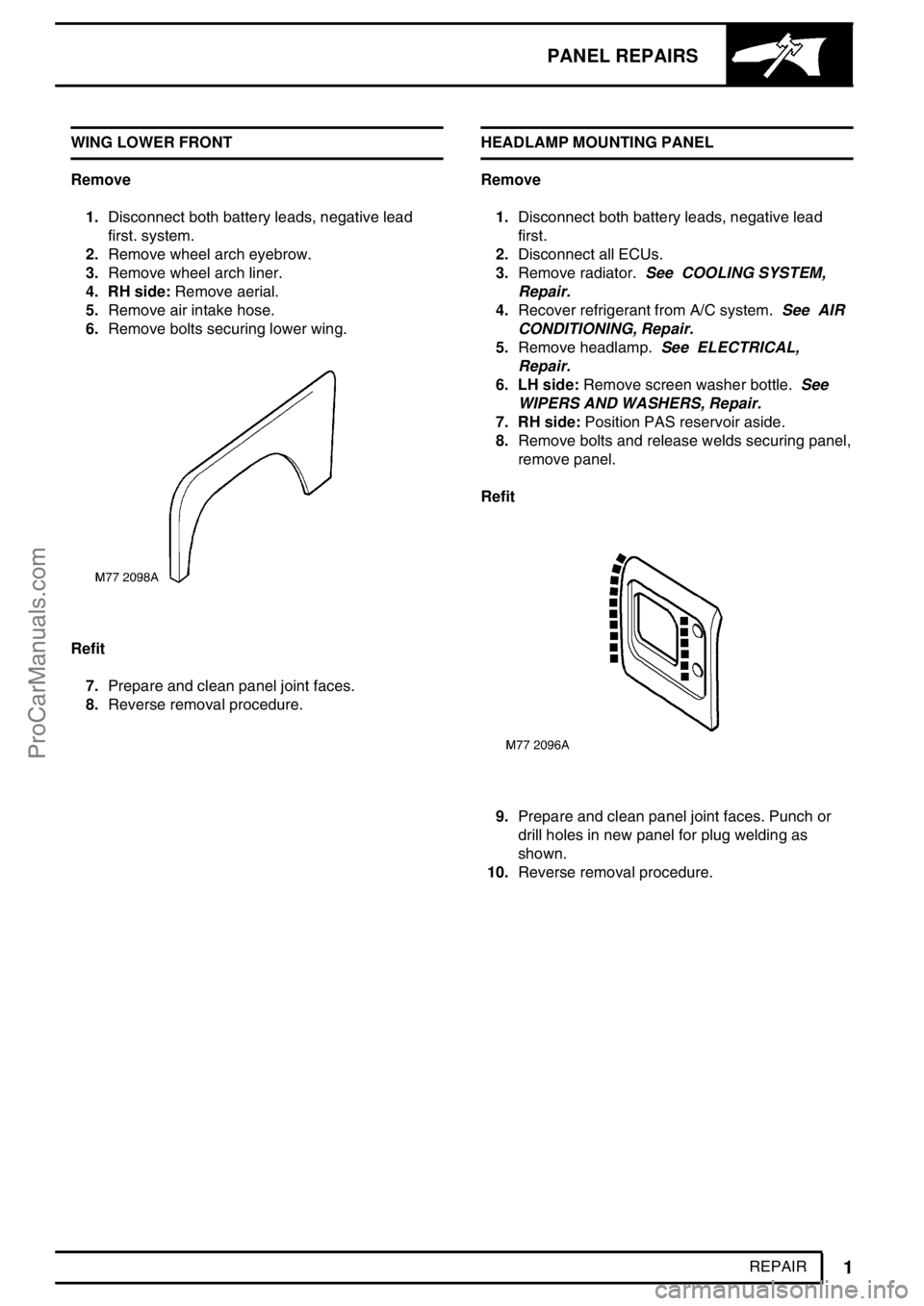

REPAIR WING LOWER FRONT

Remove

1.Disconnect both battery leads, negative lead

first. system.

2.Remove wheel arch eyebrow.

3.Remove wheel arch liner.

4. RH side:Remove aerial.

5.Remove air intake hose.

6.Remove bolts securing lower wing.

Refit

7.Prepare and clean panel joint faces.

8.Reverse removal procedure.HEADLAMP MOUNTING PANEL

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect all ECUs.

3.Remove radiator.See COOLING SYSTEM,

Repair.

4.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

5.Remove headlamp.See ELECTRICAL,

Repair.

6. LH side:Remove screen washer bottle.See

WIPERS AND WASHERS, Repair.

7. RH side:Position PAS reservoir aside.

8.Remove bolts and release welds securing panel,

remove panel.

Refit

9.Prepare and clean panel joint faces. Punch or

drill holes in new panel for plug welding as

shown.

10.Reverse removal procedure.

ProCarManuals.com

Page 567 of 667

77PANEL REPAIRS

2

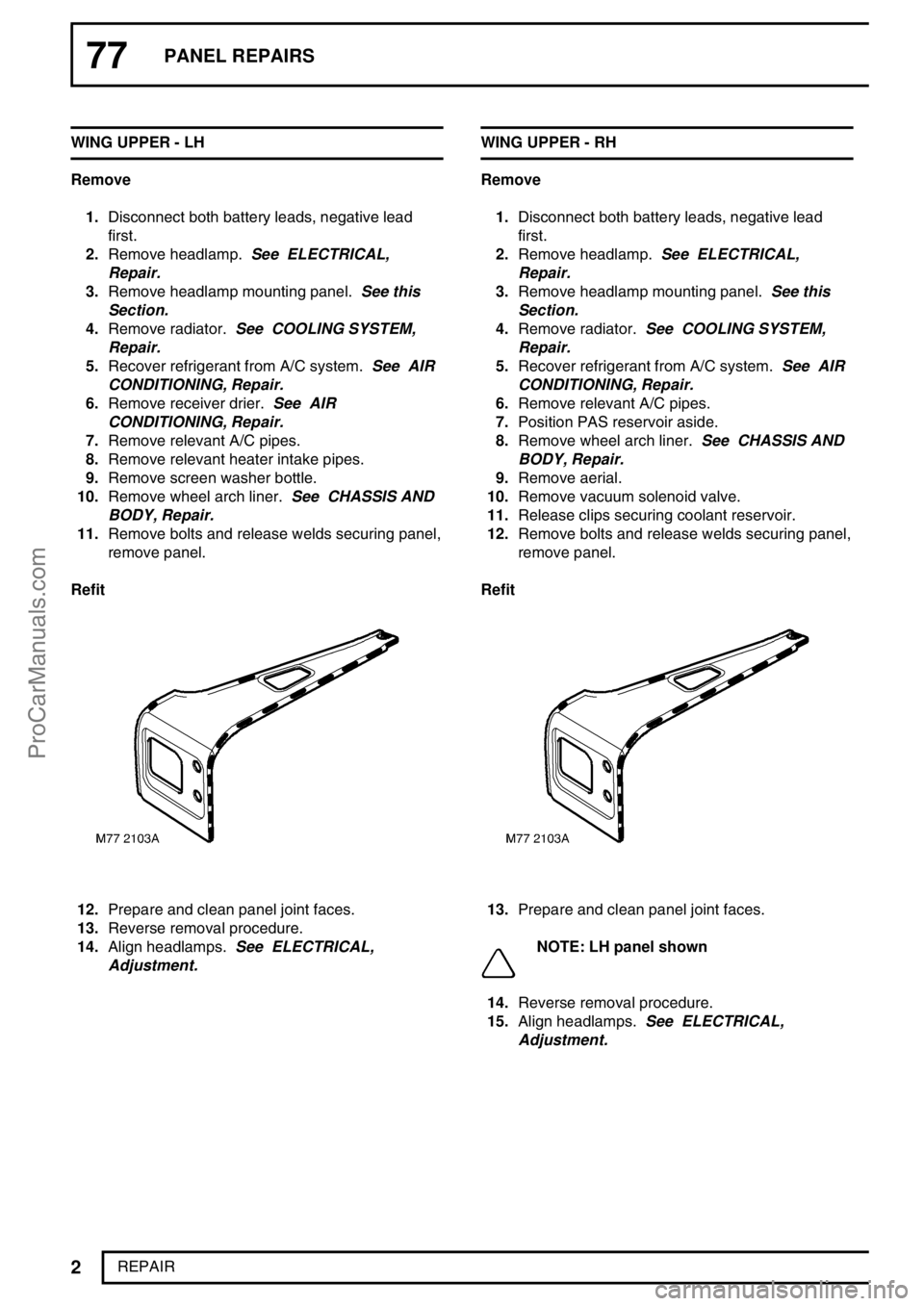

REPAIR WING UPPER - LH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove headlamp.See ELECTRICAL,

Repair.

3.Remove headlamp mounting panel.See this

Section.

4.Remove radiator.See COOLING SYSTEM,

Repair.

5.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

6.Remove receiver drier.See AIR

CONDITIONING, Repair.

7.Remove relevant A/C pipes.

8.Remove relevant heater intake pipes.

9.Remove screen washer bottle.

10.Remove wheel arch liner.See CHASSIS AND

BODY, Repair.

11.Remove bolts and release welds securing panel,

remove panel.

Refit

12.Prepare and clean panel joint faces.

13.Reverse removal procedure.

14.Align headlamps.See ELECTRICAL,

Adjustment.WING UPPER - RH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove headlamp.See ELECTRICAL,

Repair.

3.Remove headlamp mounting panel.See this

Section.

4.Remove radiator.See COOLING SYSTEM,

Repair.

5.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

6.Remove relevant A/C pipes.

7.Position PAS reservoir aside.

8.Remove wheel arch liner.See CHASSIS AND

BODY, Repair.

9.Remove aerial.

10.Remove vacuum solenoid valve.

11.Release clips securing coolant reservoir.

12.Remove bolts and release welds securing panel,

remove panel.

Refit13.Prepare and clean panel joint faces.

NOTE: LH panel shown

14.Reverse removal procedure.

15.Align headlamps.See ELECTRICAL,

Adjustment.

ProCarManuals.com