LAND ROVER DEFENDER 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 571 of 667

77PANEL REPAIRS

6

REPAIR CORNER CAPPING

The Corner Capping is not replaced as a single panel.

It is replaced in conjunction with either the Body Side

Lower Panel or Body Side Assembly. The procedure

to replace the Corner Capping is shown in the Body

Side Lower Panel procedure.

BODY SIDE CAPPING

The Body Side Capping is not replaced as a single

panel. It is replaced in conjunction with either the

Body Side Lower Panel or Body Side Assembly. The

procedure to replace the Body Side Capping is shown

in the Body Side Lower Panel procedure.

BODY SIDE REAR - UPPER

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove front, centre and rear sections of

headlining.

3.Release upper edge of front door aperture seal.

4.Release upper edge of rear door aperture seal.

5.Remove fixings from front edge of roof, and

along side being replaced.

6.Release sealant securing front edge of roof.

7.Insert wedges into top of both’B/C’posts. This

will allow access for removal of body side.

8. RH side:Remove tail door.See CHASSIS

AND BODY, Repair.

9.Remove side window.

10.Remove rear sixth light.

11.Remove all bolts securing upper body side.

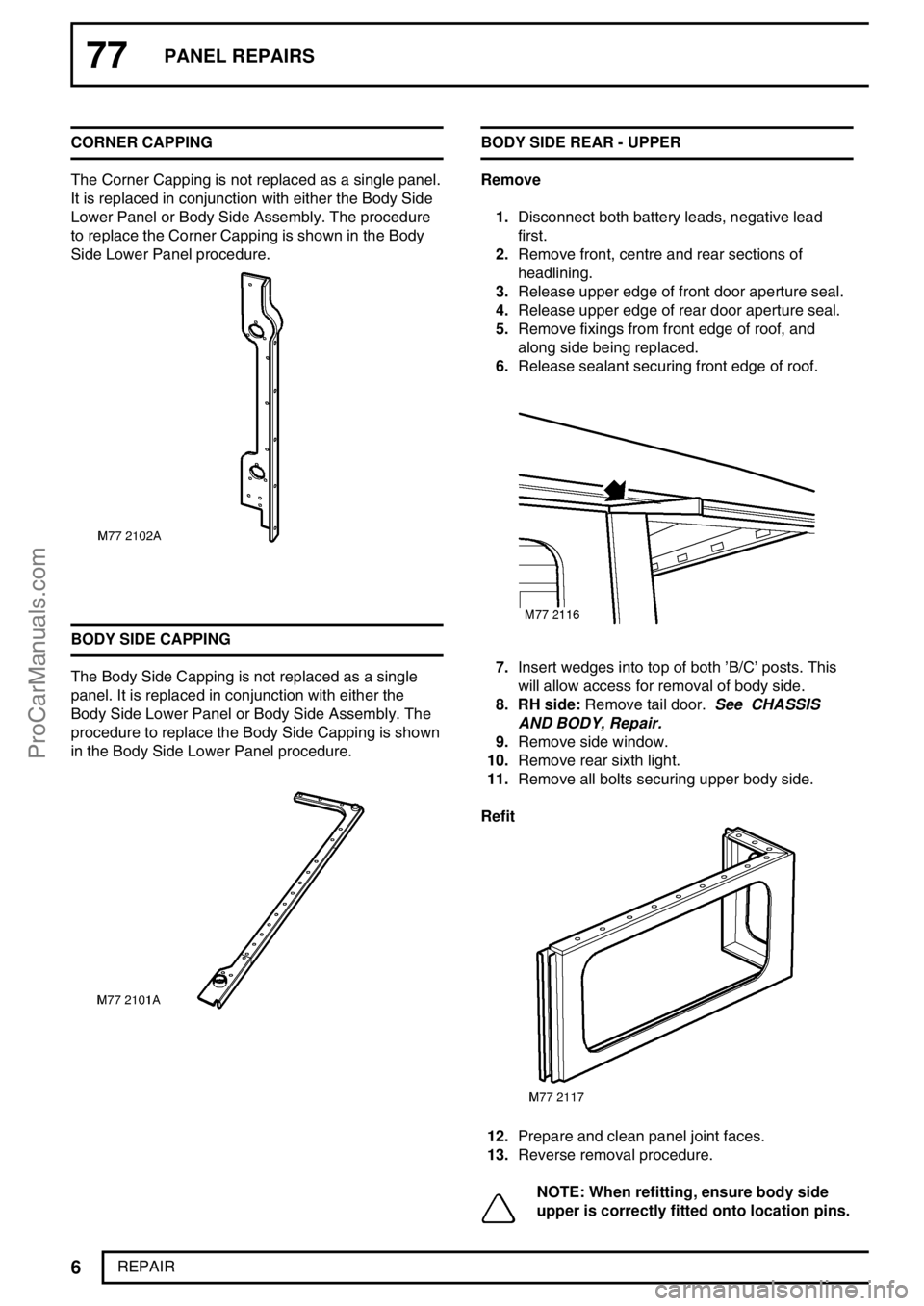

Refit

12.Prepare and clean panel joint faces.

13.Reverse removal procedure.

NOTE: When refitting, ensure body side

upper is correctly fitted onto location pins.

ProCarManuals.com

Page 572 of 667

PANEL REPAIRS

7

REPAIR BODY SIDE REAR - LOWER - ASSEMBLY

In this procedure the Body Side Capping and the

Corner Capping are also changed.

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove body side upper rear.See this

Section.

3.Remove all rear lamps and reflectors.

4. LH side:Remove number plate and lamp.

5. LH side:Remove tail door striker.

6. RH side:Remove fuel filler and grommet.

7.Remove all bolts and rivets securing lower body

side assembly.

Refit

8.Prepare and clean panel joint faces.

9.Reverse removal procedure.

NOTE: When refitting, ensure body side

upper is correctly fitted onto location pins.

ProCarManuals.com

Page 573 of 667

77PANEL REPAIRS

8

REPAIR BODY SIDE REAR - PANEL

Remove

In this procedure the Body Side Capping and the

Corner Capping are also changed.

1.Disconnect both battery leads, negative lead

first.

2.Remove body side upper rear.See this

Section.

3.Remove rear lamp panel.See this Section.

4. LH side:Remove number plate and lamp.

5. LH side:Remove tail door striker.

6. RH side:Remove fuel filler and grommet.

Refit

7.Prepare and clean panel joint faces. Drill holes in

new body side lower panel for riveting. Spacing

of holes, dimension’A’= 100 mm (3.937’). In

conjunction with the rivets apply suitable

adhesive.

8.Prepare and clean panel joint faces.

9.Reverse removal procedure.

NOTE: When refitting, ensure body side

upper is correctly fitted onto location pins.

ProCarManuals.com

Page 574 of 667

PANEL REPAIRS

9

REPAIR REAR LAMP PANEL

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect alternator.

3.Remove rear bench seat.

4. RH side:Remove tail door.See CHASSIS

AND BODY, Repair.

5.Remove rear lights and reflector.

6. LH side:Remove number plate and tail door

striker.

Refit

7.Prepare and clean panel joint faces.

8.Reverse removal procedure.REAR CROSSMEMBER PANEL

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove both rear lamp panels.See this

Section.

Refit

3.Prepare and clean panel joint faces.

4.Reverse removal procedure.

ProCarManuals.com

Page 575 of 667

77PANEL REPAIRS

10

REPAIR ROOF ASSEMBLY

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove rear bench seats.

3.Remove front, centre and rear sections of

headlining.

4.Remove all bolts securing roof.

NOTE: Carefully cut sealant securing front

edge of roof to windscreen aperture.

Refit

5.Prepare and clean panel joint faces.

6.Reverse removal procedure.

ProCarManuals.com

Page 576 of 667

PANEL REPAIRS

11

REPAIR TIME SCHEDULES

The following information shows the total time taken to

replace single panels and complete assemblies. This

time includes removal of Mechanical, Electrical and

Trim (MET) items, plus paint times based on Metallic

Clear Over Base Paint.

The times shown were generated by Thatcham (the

Motor Insurance Repair and Research Centre) and

are to be used as a guide only. The operations were

carried out on a 110 Station Wagon.

Panel/assembly replacement times

Panel Description Total time

Bonnet 6.1

Bulkhead 24.2

Door front - each 7.8

Door rear - each 6.9

Door tail 7.7

Headlamp mounting panel LH 8.4

Headlamp mounting panel RH 8.3

Rear lamp mounting panel 9.3

Front screen aperture 7.4

Roof assembly 18.0

Sill and’B’post assembly LH 9.4

Sill and’B’post assembly RH 9.3

Sill panel - front section 4.2

Sill panel - rear section 4.1

Wing front lower 7.0

Wing front upper 8.7

Body side rear assembly - LH 16.7

Body side rear assembly - RH 17.7

Body side lower panel - LH 17.6

Body side lower panel - RH 18.6Combination panel replacement times

The following panel combination times show the total

time to remove/refit body panels, MET items and any

paint processes.

Front end combination panel times

Panel Description Total Time

Grille

Bumper front

Wheelarch eyebrow

Wing - upper

Wing - lower

12.7 LH

12.6 RH

Grille

Bumper front

Wheelarch eyebrow LH & RH

Wing - upper LH & RH

Wing - lower LH & RH

18.2

Grille

Bumper front

Wheelarch eyebrow

Wheelarch front

Wing - upper

Wing - lower

13.1 LH

13.0 RH

Grille

Bumper front

Wheelarch eyebrow LH & RH

Wheelarch front LH & RH

Wing - upper LH & RH

Wing - lower LH & RH

19.0

ProCarManuals.com

Page 577 of 667

77PANEL REPAIRS

12

REPAIR Bodyside combination panel times

Panel description Total time

Front door

Wheelarch eyebrow

Wing - lower

Wing - upper

15.4 LH

15.5 RH

Front door

Rear door

Sill and’B’post

16.6 LH

16.5 RH

Rear door

Body side lower assembly

Body side upper assembly

Wheel arch eyebrow

’D’post outer reinforcement

Corner capping

Rear lamp panel

31.0 LH

32.1 RH

Rear door

Front door

Wing lower

Wing upper

Body side lower assembly

Body side upper assembly

Wheel arch eyebrow - front & rear

’D’post outer reinforcement

Corner capping

Rear lamp panel

41.9 LH

42.8 RHRear end combination panel times

Panel description Total time

Corner capping

Rear lamp panel

11.0

Body side lower assembly

Body side upper assembly

Wheel arch eyebrow

’D’post outer reinforcement

Corner capping

Rear lamp panel

Rear panel

28.9 LH

29.9 RH

Body side lower assembly

Body side upper assembly

Wheel arch eyebrow

’D’post outer reinforcement

Corner capping

Rear lamp panel

Rear panel

28.5 LH

29.4 RH

ProCarManuals.com

Page 578 of 667

PANEL REPAIRS

13

REPAIR

ProCarManuals.com

Page 579 of 667

ProCarManuals.com

Page 580 of 667

PANEL REPAIRS

1

PAINT PAINT PROCEDURES

Replacement Panels

Service panels are supplied with a cathodic primer

coating as part of the panel protection, and in

compliance with the vehicle’s Corrosion Warranty

where applicable.DO NOT remove this primer

before paint refinishing. In the event of localised

surface damage or imperfections, ensure that the

minimum of primer is removed during rectification

work for effective repair.

Rectify damage by panel beating or straightening. To

remove corrosion or paint runs on outer surfaces,

abrade primer coat in the affected area as necessary

using the following procedure:

1. Clean the panel using a solvent wipe.

2. Treat exposed areas of metal with an etch

phosphate process.

3. Re-treat the affected area using either a

separate acid-etch primer and two-pack

surfacer, or an integrated etch primer/filler.

Bolted Panels

Before fitting bolt-on panels, ensure that all mating

and adjacent surfaces on the vehicle and replacement

panel are free from damage and distortion. Rectify if

necessary as described in this section, and apply

preformed strip sealer where specified.Welded Panels

1. Remove primer from the immediate vicinity of

new and existing panel flanges, cleaning to

bright metal finish.

2. On joints to be spot welded, apply weld-through

zinc rich primer to joint faces of both flanges.

Make spot welds while primer is still wet or

according to the manufacturer’s instructions.

3. Dress accessible weld seams.

4. Clean panel using solvent wipe.

5. Treat bare metal with an etch phosphate

process.

6. Re-treat repaired areas.

NOTE: It is not satisfactory to use

weld-through, zinc rich primers in

conjunction with MIG welding.

Sectioned Panels

When replacing part or sectioned panels, the basic

procedure is the same as for welded panels described

above, with the following variations:

1. Remove primer from both new and existing joint

faces, cleaning to a bright metal finish.

2. Where an overlap joint with the existing panel is

to be spot welded, apply weld-through, zinc rich

primer to both joint faces and spot weld while the

primer is still wet or according to the

manufacturer’s instructions.

3. MIG weld joints where applicable.

4. Clean the panel with a solvent wipe.

5. Treat bare metal areas using an etch phosphate

process.

6. Re-prime affected areas as necessary as for

rectifying transit damage.See this section.

7. Treat the inner faces of lap or butt joints with a

suitable cavity wax.See Sealing and Corrosion

Protection.

ProCarManuals.com