LAND ROVER DEFENDER 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 561 of 667

77PANEL REPAIRS

2

PROCEDURES PANEL REPLACEMENT PROCEDURE

General

This information is designed to explain the basic panel

removal and replacement method. This standard

method may vary slightly from one vehicle to another.

The main criterion in removal and replacement of

body panels is that Land Rover’s original standard is

maintained as far as possible.

All repair processes and procedures shown relate to

Aluminium panels.

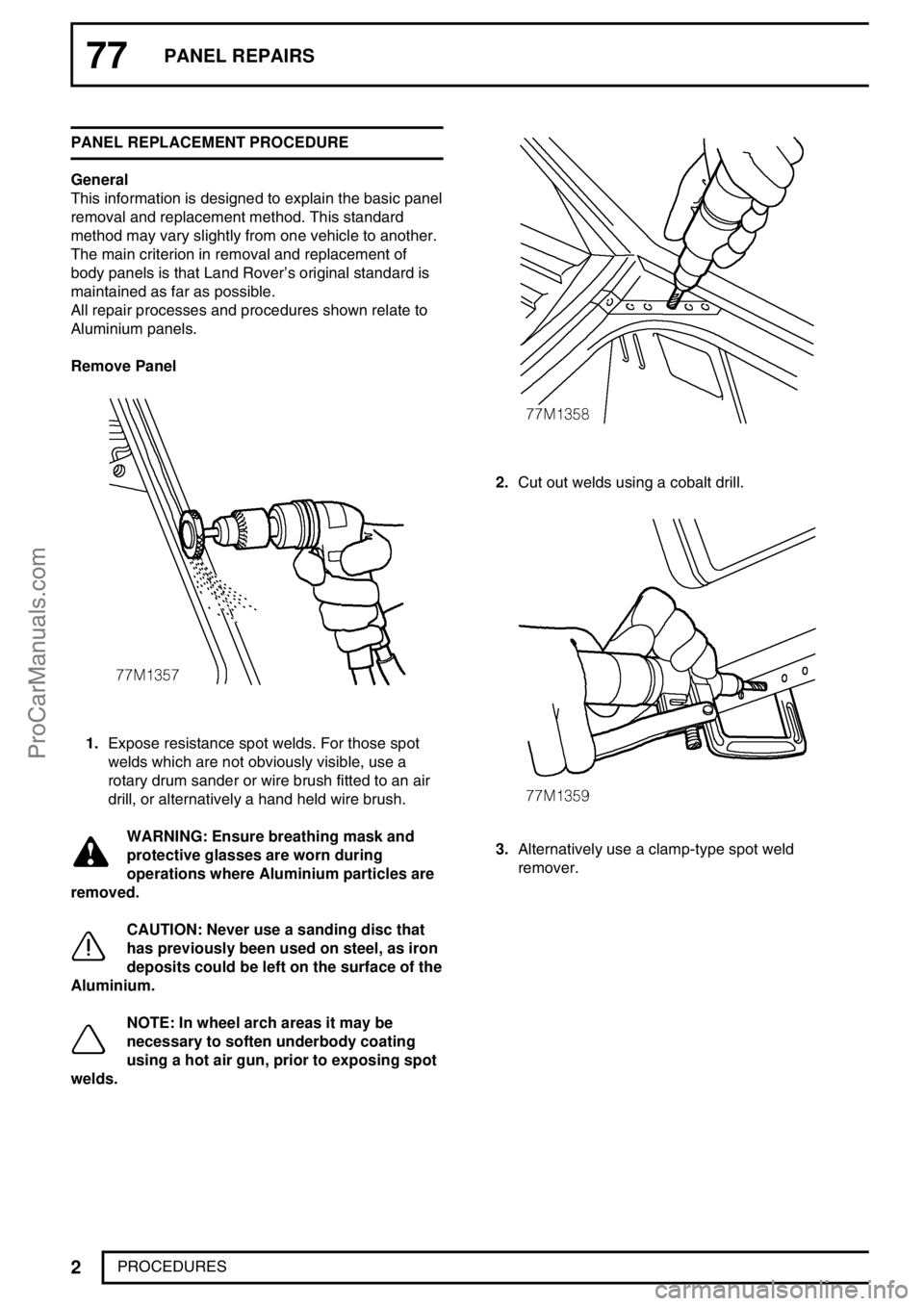

Remove Panel

1.Expose resistance spot welds. For those spot

welds which are not obviously visible, use a

rotary drum sander or wire brush fitted to an air

drill, or alternatively a hand held wire brush.

WARNING: Ensure breathing mask and

protective glasses are worn during

operations where Aluminium particles are

removed.

CAUTION: Never use a sanding disc that

has previously been used on steel, as iron

deposits could be left on the surface of the

Aluminium.

NOTE: In wheel arch areas it may be

necessary to soften underbody coating

using a hot air gun, prior to exposing spot

welds.

2.Cut out welds using a cobalt drill.

3.Alternatively use a clamp-type spot weld

remover.

ProCarManuals.com

Page 562 of 667

PANEL REPAIRS

3

PROCEDURES

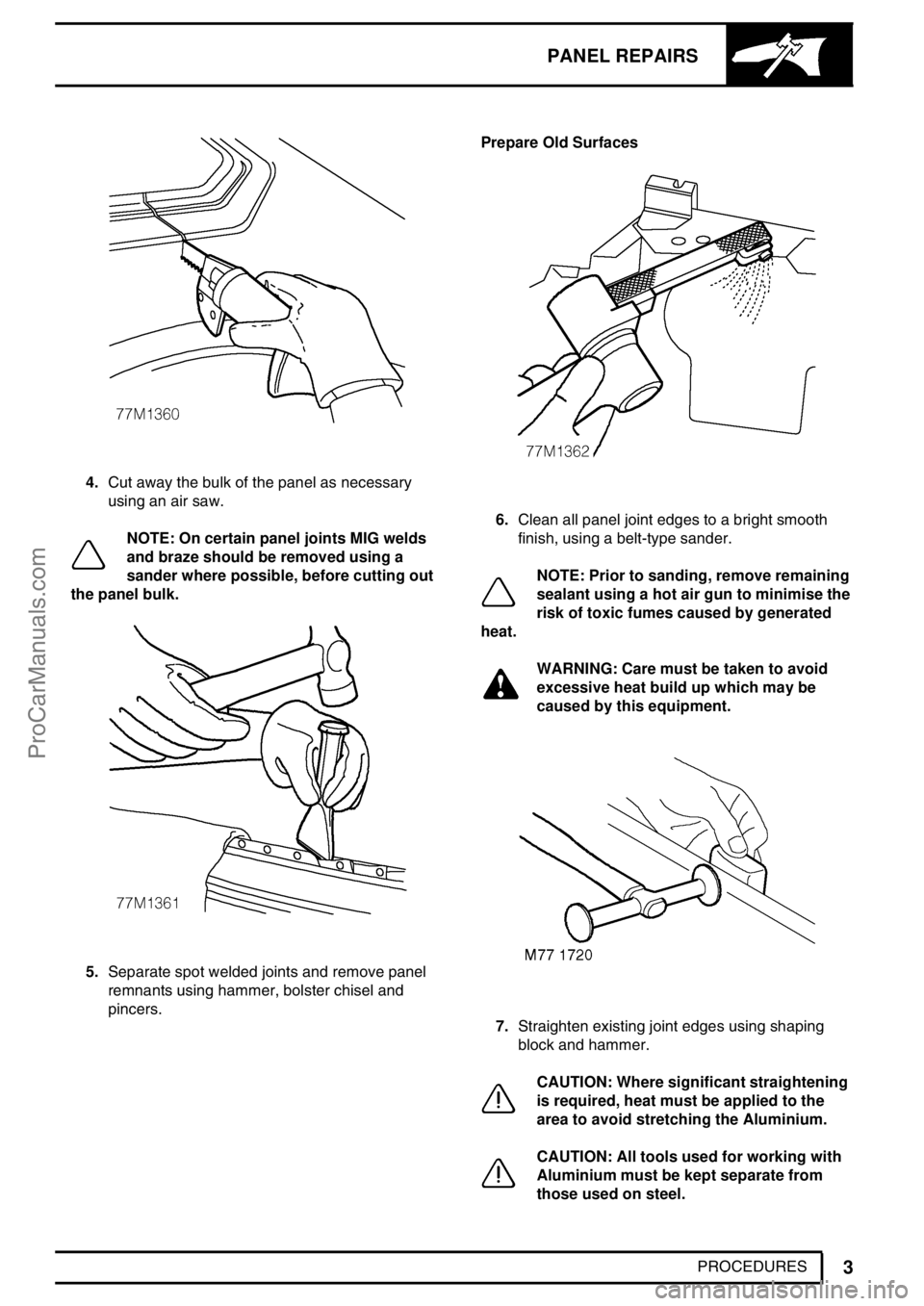

4.Cut away the bulk of the panel as necessary

using an air saw.

NOTE: On certain panel joints MIG welds

and braze should be removed using a

sander where possible, before cutting out

the panel bulk.

5.Separate spot welded joints and remove panel

remnants using hammer, bolster chisel and

pincers.Prepare Old Surfaces

6.Clean all panel joint edges to a bright smooth

finish, using a belt-type sander.

NOTE: Prior to sanding, remove remaining

sealant using a hot air gun to minimise the

risk of toxic fumes caused by generated

heat.

WARNING: Care must be taken to avoid

excessive heat build up which may be

caused by this equipment.

7.Straighten existing joint edges using shaping

block and hammer.

CAUTION: Where significant straightening

is required, heat must be applied to the

area to avoid stretching the Aluminium.

CAUTION: All tools used for working with

Aluminium must be kept separate from

those used on steel.

ProCarManuals.com

Page 563 of 667

77PANEL REPAIRS

4

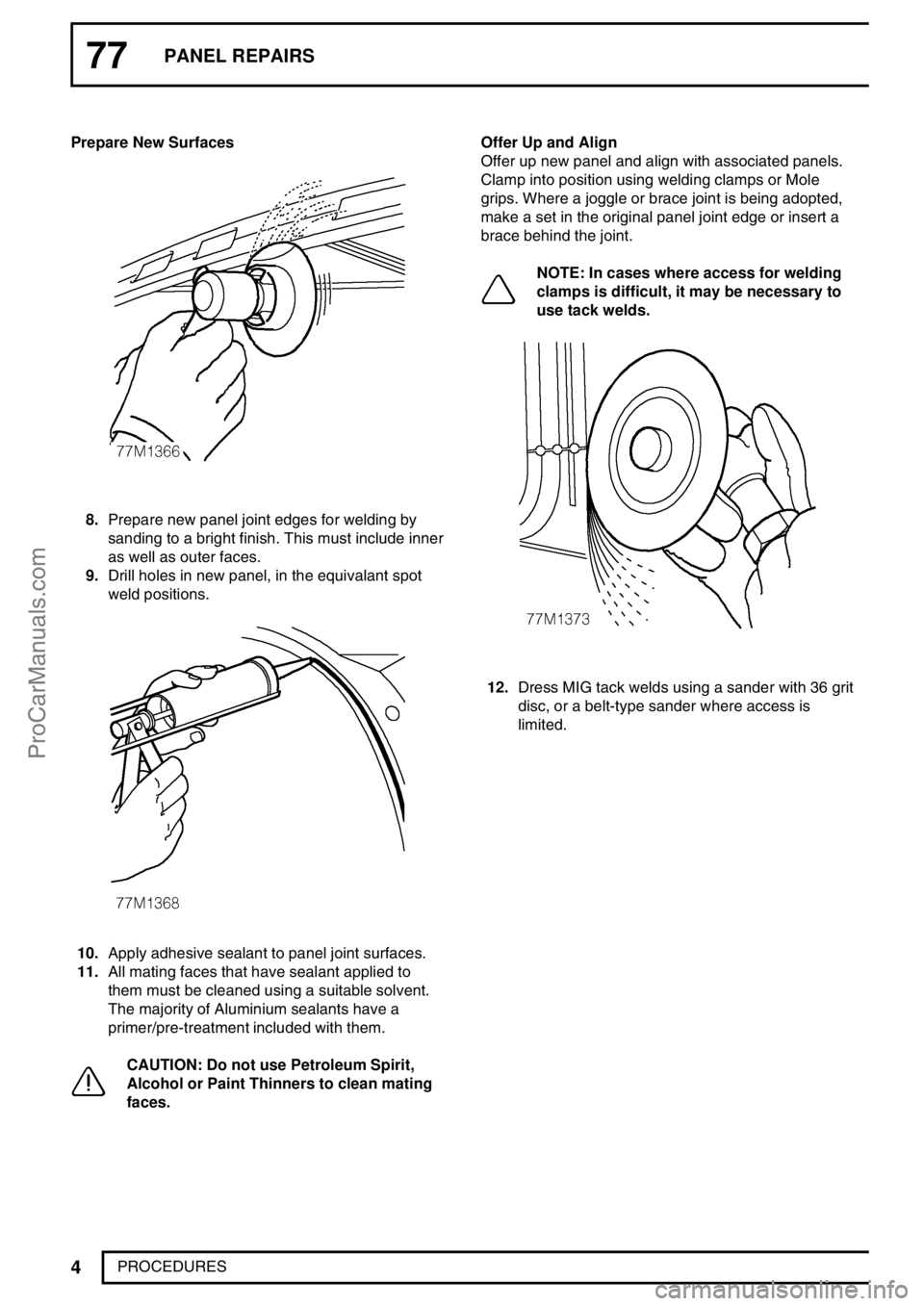

PROCEDURES Prepare New Surfaces

8.Prepare new panel joint edges for welding by

sanding to a bright finish. This must include inner

as well as outer faces.

9.Drill holes in new panel, in the equivalant spot

weld positions.

10.Apply adhesive sealant to panel joint surfaces.

11.All mating faces that have sealant applied to

them must be cleaned using a suitable solvent.

The majority of Aluminium sealants have a

primer/pre-treatment included with them.

CAUTION: Do not use Petroleum Spirit,

Alcohol or Paint Thinners to clean mating

faces.Offer Up and Align

Offer up new panel and align with associated panels.

Clamp into position using welding clamps or Mole

grips. Where a joggle or brace joint is being adopted,

make a set in the original panel joint edge or insert a

brace behind the joint.

NOTE: In cases where access for welding

clamps is difficult, it may be necessary to

use tack welds.

12.Dress MIG tack welds using a sander with 36 grit

disc, or a belt-type sander where access is

limited.

ProCarManuals.com

Page 564 of 667

PANEL REPAIRS

5

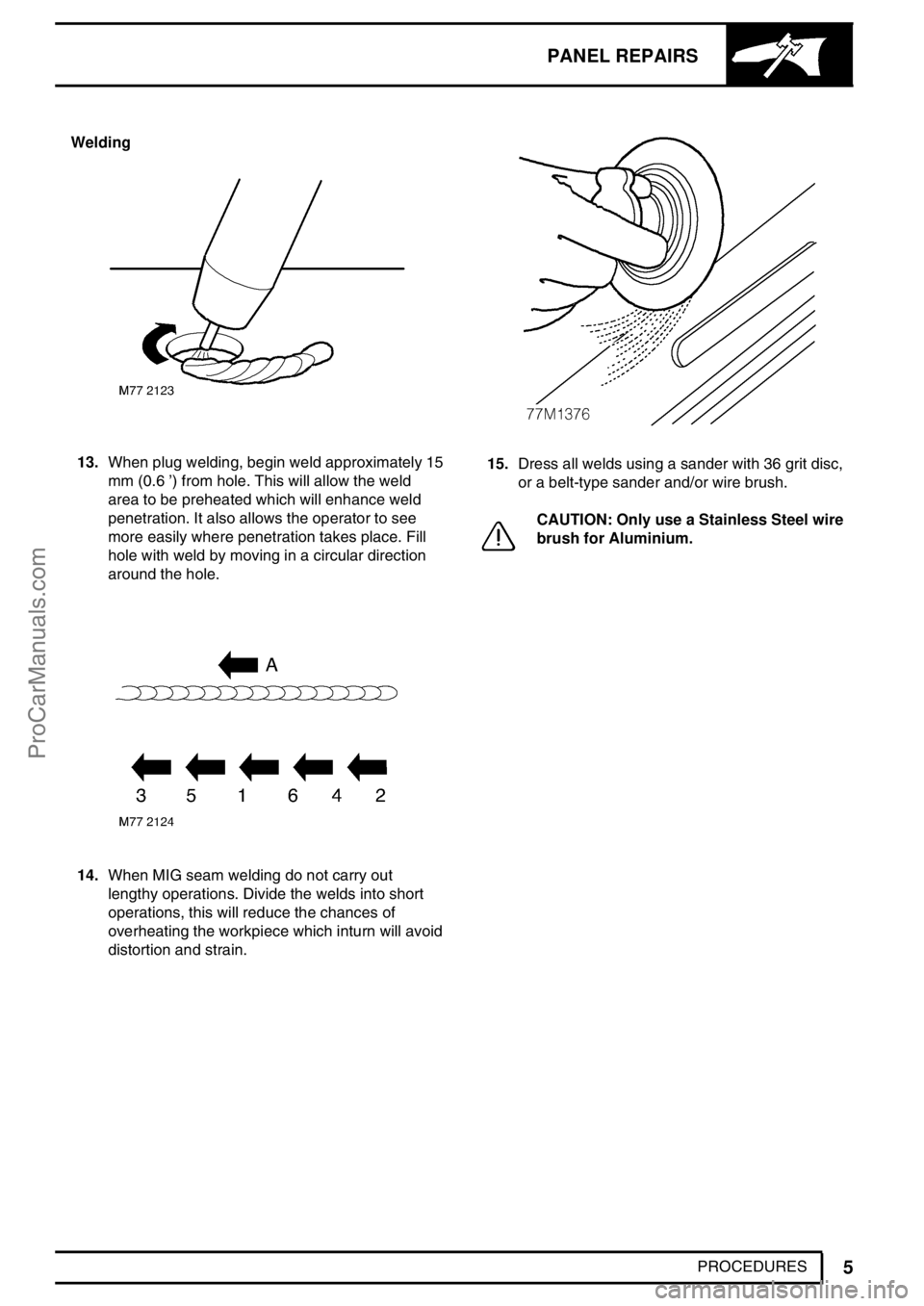

PROCEDURES Welding

13.When plug welding, begin weld approximately 15

mm (0.6’) from hole. This will allow the weld

area to be preheated which will enhance weld

penetration. It also allows the operator to see

more easily where penetration takes place. Fill

hole with weld by moving in a circular direction

around the hole.

14.When MIG seam welding do not carry out

lengthy operations. Divide the welds into short

operations, this will reduce the chances of

overheating the workpiece which inturn will avoid

distortion and strain.

15.Dress all welds using a sander with 36 grit disc,

or a belt-type sander and/or wire brush.

CAUTION: Only use a Stainless Steel wire

brush for Aluminium.

ProCarManuals.com

Page 565 of 667

77PANEL REPAIRS

6

PROCEDURES REPAIR PROCEDURES

Body Trim

The following panel repair operations itemise body

trim components which must be removed for access

during each repair.See Repairs section.

Because of the unpredictable nature of accident

damage, the items listed make no allowance for any

difficulties which may be found in removal and only

apply to an undamaged vehicle. No allowance is

made for any difficulties which may be found during

panel removal. Damaged body trim items must be

renewed as necessary following body repairs.

ProCarManuals.com

Page 566 of 667

PANEL REPAIRS

1

REPAIR WING LOWER FRONT

Remove

1.Disconnect both battery leads, negative lead

first. system.

2.Remove wheel arch eyebrow.

3.Remove wheel arch liner.

4. RH side:Remove aerial.

5.Remove air intake hose.

6.Remove bolts securing lower wing.

Refit

7.Prepare and clean panel joint faces.

8.Reverse removal procedure.HEADLAMP MOUNTING PANEL

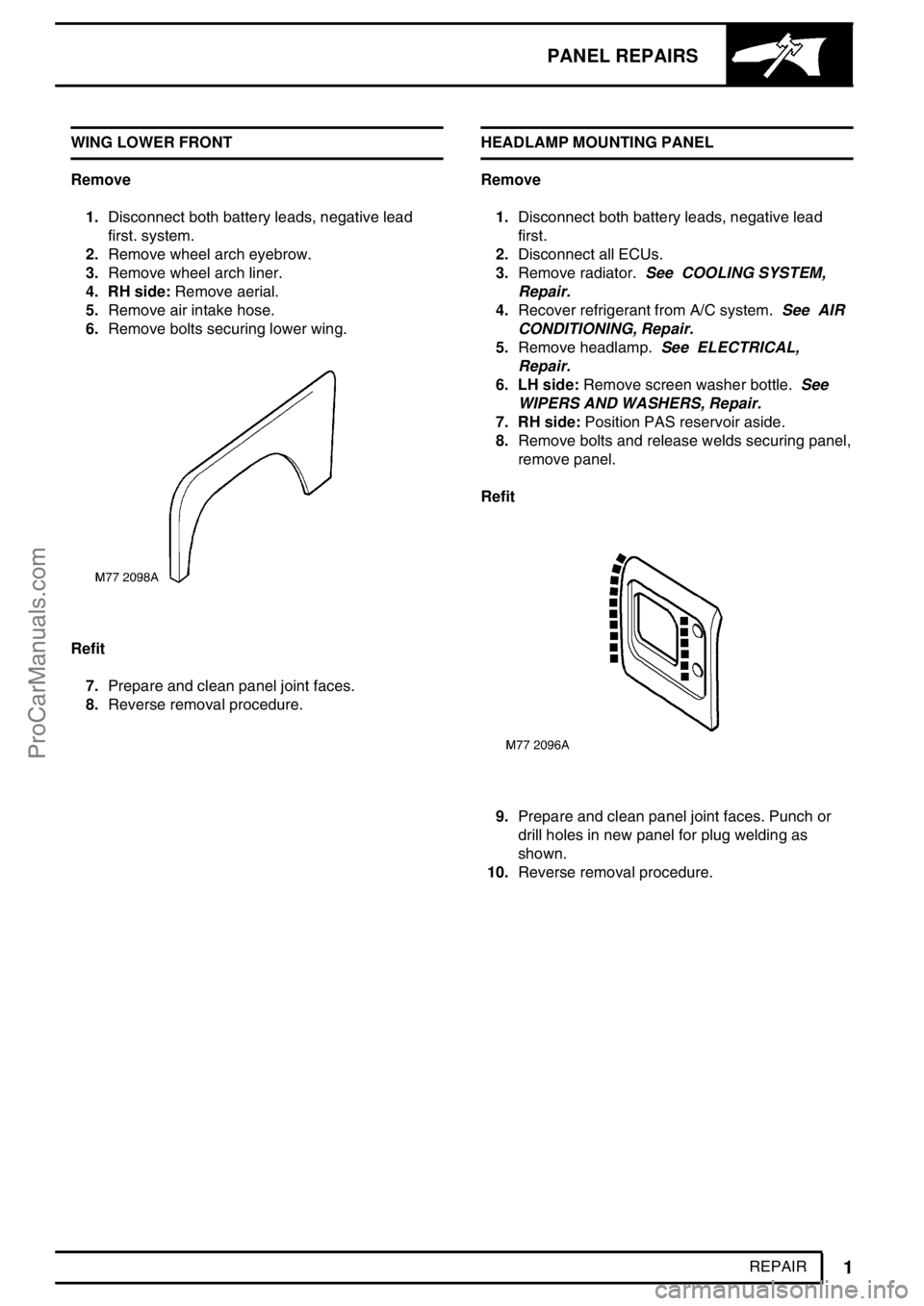

Remove

1.Disconnect both battery leads, negative lead

first.

2.Disconnect all ECUs.

3.Remove radiator.See COOLING SYSTEM,

Repair.

4.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

5.Remove headlamp.See ELECTRICAL,

Repair.

6. LH side:Remove screen washer bottle.See

WIPERS AND WASHERS, Repair.

7. RH side:Position PAS reservoir aside.

8.Remove bolts and release welds securing panel,

remove panel.

Refit

9.Prepare and clean panel joint faces. Punch or

drill holes in new panel for plug welding as

shown.

10.Reverse removal procedure.

ProCarManuals.com

Page 567 of 667

77PANEL REPAIRS

2

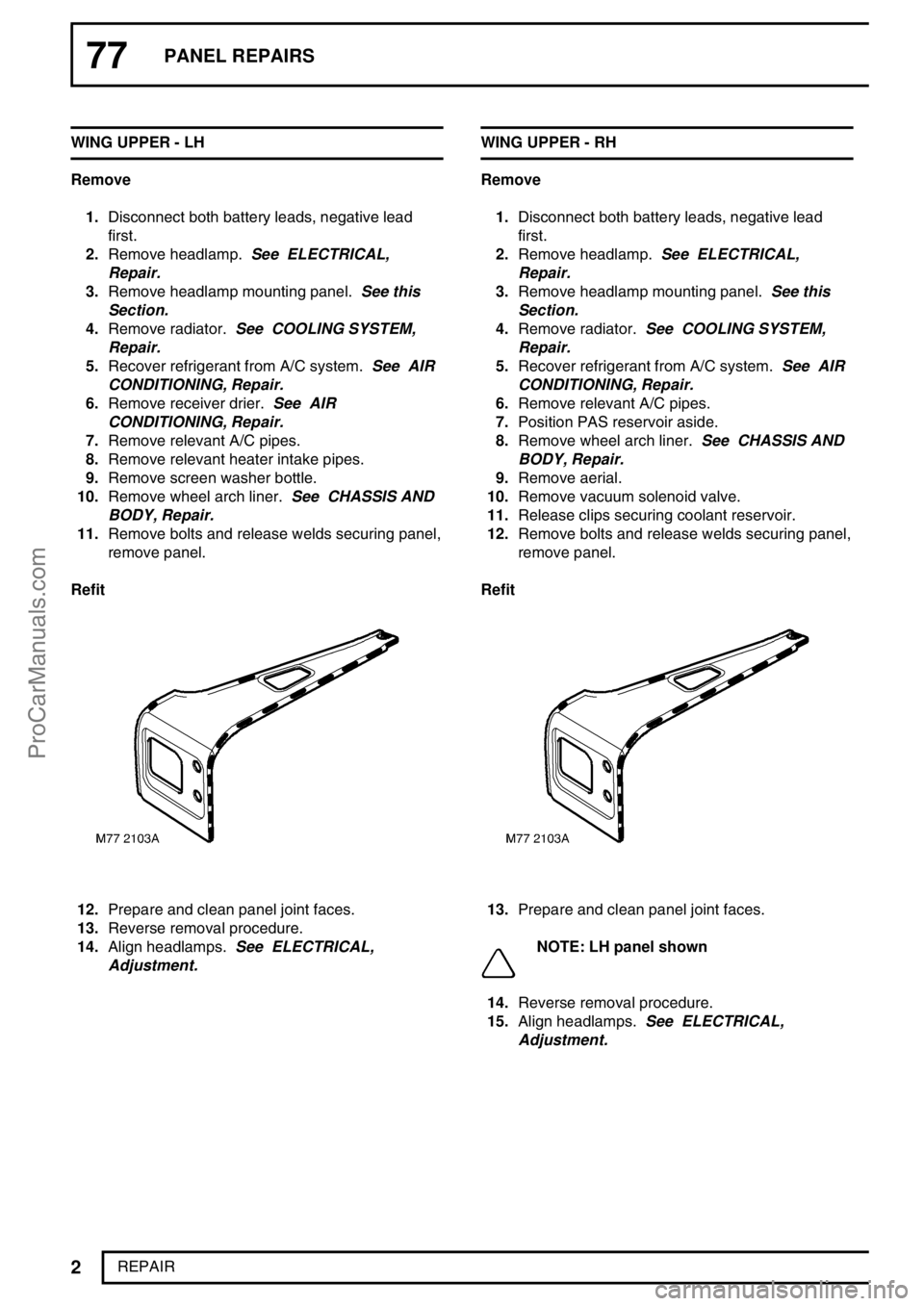

REPAIR WING UPPER - LH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove headlamp.See ELECTRICAL,

Repair.

3.Remove headlamp mounting panel.See this

Section.

4.Remove radiator.See COOLING SYSTEM,

Repair.

5.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

6.Remove receiver drier.See AIR

CONDITIONING, Repair.

7.Remove relevant A/C pipes.

8.Remove relevant heater intake pipes.

9.Remove screen washer bottle.

10.Remove wheel arch liner.See CHASSIS AND

BODY, Repair.

11.Remove bolts and release welds securing panel,

remove panel.

Refit

12.Prepare and clean panel joint faces.

13.Reverse removal procedure.

14.Align headlamps.See ELECTRICAL,

Adjustment.WING UPPER - RH

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove headlamp.See ELECTRICAL,

Repair.

3.Remove headlamp mounting panel.See this

Section.

4.Remove radiator.See COOLING SYSTEM,

Repair.

5.Recover refrigerant from A/C system.See AIR

CONDITIONING, Repair.

6.Remove relevant A/C pipes.

7.Position PAS reservoir aside.

8.Remove wheel arch liner.See CHASSIS AND

BODY, Repair.

9.Remove aerial.

10.Remove vacuum solenoid valve.

11.Release clips securing coolant reservoir.

12.Remove bolts and release welds securing panel,

remove panel.

Refit13.Prepare and clean panel joint faces.

NOTE: LH panel shown

14.Reverse removal procedure.

15.Align headlamps.See ELECTRICAL,

Adjustment.

ProCarManuals.com

Page 568 of 667

PANEL REPAIRS

3

REPAIR WHEEL ARCH - FRONT

Remove

The procedure to change the Inner Front Wheelarch is

the same as for the Wing Upper, except for removal of

the ABS sensors and shield, if fitted.

BULKHEAD ASSEMBLY

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove front lower wing.See this Section.

3.Remove RH and LH front upper wing.See this

Section.

4.Remove headlamp mounting panels.See this

Section.

5.Remove screen aperture.See this Section.

6.Remove both front doors.

7.Remove lower fascia panel.See CHASSIS

AND BODY, Repair.

8. Models with A/C:Remove relevant A/C pipes.

9.Remove front grille.

10.Drain cooling system.See COOLING

SYSTEM, Adjustment.

11.Remove radiator and intercooler.

12. Models with A/C:Remove condensor.

13.Remove air cleaner assembly.

14.Remove heater unit.See HEATING AND

VENTILATION, Repair.

15.Remove brake servo assembly.

16.Remove heater ducts.

17.Remove both front seats.

18.Remove front carpets.

19.Release all relevant harnesses and position

aside.

20.Remove facia support bracket.

Refit

21.Prepare and clean panel joint faces. Ensure all

necessary grommets and sealant is applied to

new bulkhead.

22.Reverse removal procedure.

23.Bleed brake system.See BRAKES,

Adjustment.

24.Align headlamps.See ELECTRICAL,

Adjustment.

25.Water test after refitting.

ProCarManuals.com

Page 569 of 667

77PANEL REPAIRS

4

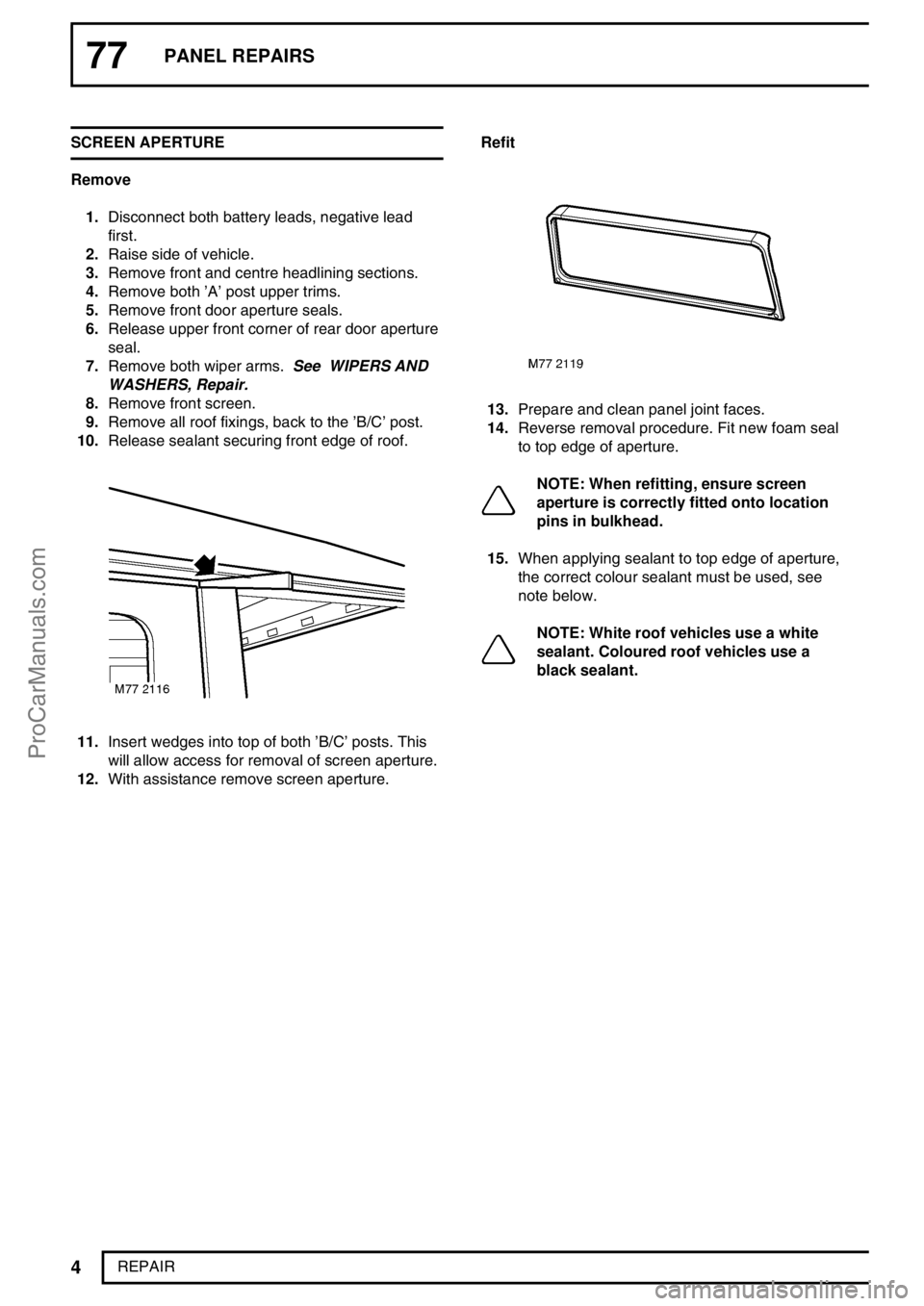

REPAIR SCREEN APERTURE

Remove

1.Disconnect both battery leads, negative lead

first.

2.Raise side of vehicle.

3.Remove front and centre headlining sections.

4.Remove both’A’post upper trims.

5.Remove front door aperture seals.

6.Release upper front corner of rear door aperture

seal.

7.Remove both wiper arms.See WIPERS AND

WASHERS, Repair.

8.Remove front screen.

9.Remove all roof fixings, back to the’B/C’post.

10.Release sealant securing front edge of roof.

11.Insert wedges into top of both’B/C’posts. This

will allow access for removal of screen aperture.

12.With assistance remove screen aperture.Refit

13.Prepare and clean panel joint faces.

14.Reverse removal procedure. Fit new foam seal

to top edge of aperture.

NOTE: When refitting, ensure screen

aperture is correctly fitted onto location

pins in bulkhead.

15.When applying sealant to top edge of aperture,

the correct colour sealant must be used, see

note below.

NOTE: White roof vehicles use a white

sealant. Coloured roof vehicles use a

black sealant.

ProCarManuals.com

Page 570 of 667

PANEL REPAIRS

5

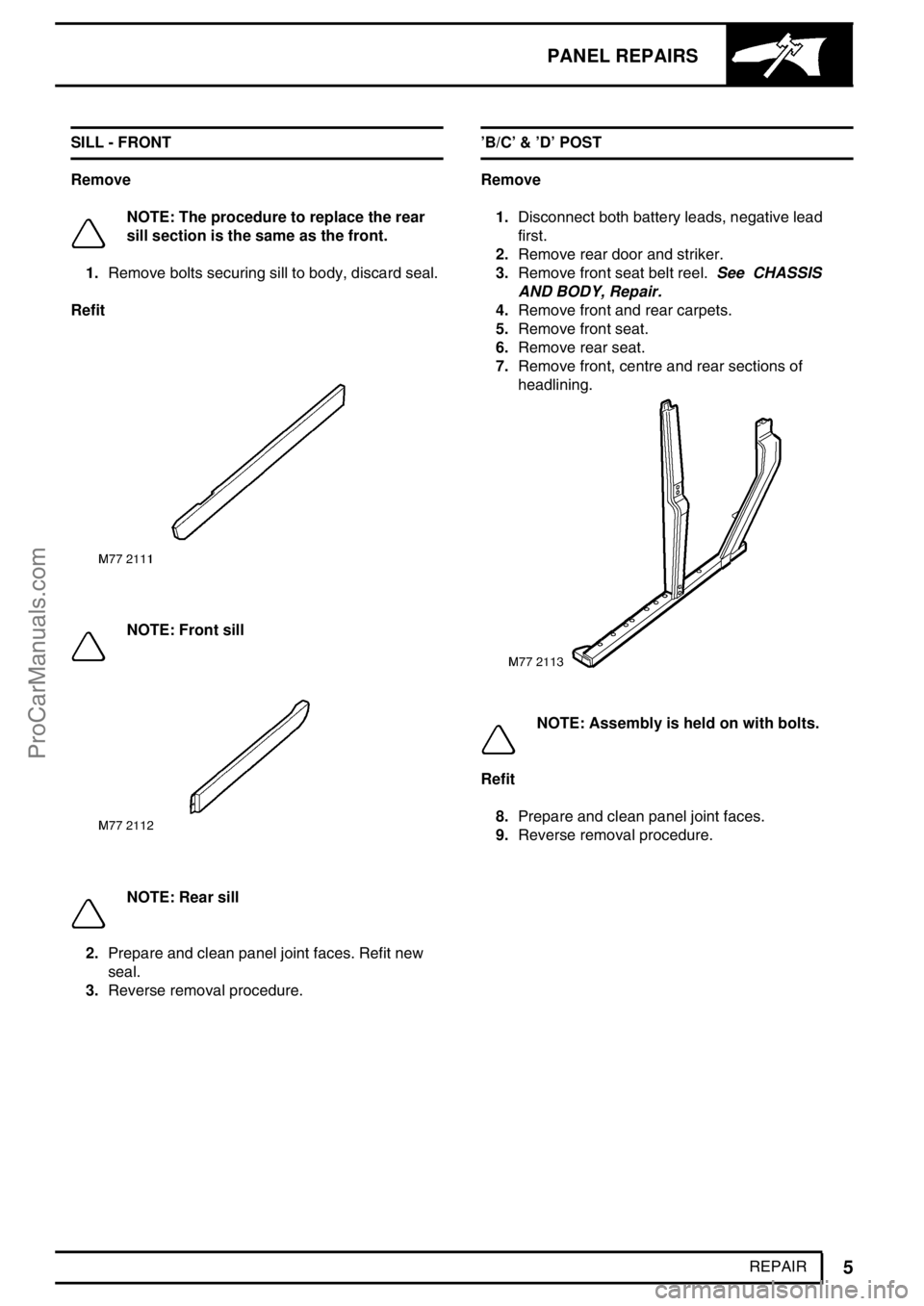

REPAIR SILL - FRONT

Remove

NOTE: The procedure to replace the rear

sill section is the same as the front.

1.Remove bolts securing sill to body, discard seal.

Refit

NOTE: Front sill

NOTE: Rear sill

2.Prepare and clean panel joint faces. Refit new

seal.

3.Reverse removal procedure.’B/C’&’D’POST

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove rear door and striker.

3.Remove front seat belt reel.See CHASSIS

AND BODY, Repair.

4.Remove front and rear carpets.

5.Remove front seat.

6.Remove rear seat.

7.Remove front, centre and rear sections of

headlining.

NOTE: Assembly is held on with bolts.

Refit

8.Prepare and clean panel joint faces.

9.Reverse removal procedure.

ProCarManuals.com