LAND ROVER DEFENDER 1999 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 581 of 667

77PANEL REPAIRS

2

PAINT Clinch Panels (eg Door skins etc.)

1. Abrade primer on new and existing panel joint

faces, and clean using a solvent wipe.

2. Apply metal-to-metal adhesive where applicable.

3. Where joints are to be spot welded, apply

suitable weld-through, zinc rich primer to weld

areas.

4. Where joints are to be MIG welded, apply zinc

rich primer in adjacent areasbut leave the

welded area untreated.

5. To retain the panel whilst clinching the flanges,

tack spot weld or plug weld as appropriate.

6. Clean the panel with a solvent wipe.

7. Treat bare metal areas with a suitable etch

phosphate process.

8. Re-prime affected areas as necessary as for

rectifying transit damage.See this section.

NOTE: Replacement doors, bonnets and

tailgates must be treated with a suitable

seam sealer on clinched seams, following

the primer coat.

Paint Refinishing

1. Seal all accessible exterior and interior seams

with an approved seam sealer. Certain joints

such as sill lower flange seams must be left

unsealed.

2. Apply a suitable anti-chip primer where

specified.

3. Apply a two-pack paint refinishing system.

4. Repair any damage to underbody sealers either

at this stage or before paint operations.Paint Repairs

Before carrying out paintwork repairs, the vehicle

must be thoroughly cleaned using either a steam

cleaner or high-pressure washer.

Wash locally repaired areas using a mild

water-mixable detergent and wipe them clean with

solvent, immediately prior to paint application.

Abrade damaged paintwork where bare metal has

been exposed until the metal is clean and extends

beyond the area of immediate damage. Treat the bare

metal with an etch phosphate to remove all traces of

rust and provide a key for new paint coats. Re-treat

the affected area using either a separate acid-etch

primer and two-pack surfacer or an integrated etch

primer/filler, and follow with a two-pack paint system.

Those surfaces not receiving paint must be treated

with a cavity wax following paint operations.

M77 2108B

A

B

C

A. Two-pack top coat

B. Two-pack primer filler and etch primer

C. Etch phosphate

ProCarManuals.com

Page 582 of 667

82 - AIR CONDITIONING

CONTENTS

Page

ADJUSTMENT

REFRIGERANT RECOVERY, RECYCLING, RECHARGING 1.............................

REPAIR

COMPRESSOR 1...................................................................................................

MOTOR - CONDENSER FAN 2..............................................................................

RECEIVER DRIER 2...............................................................................................

RELAY - TEMPERATURE CONTROL - FROM 02MY 3.........................................

EVAPORATOR 4....................................................................................................

ProCarManuals.com

Page 583 of 667

ProCarManuals.com

Page 584 of 667

AIR CONDITIONING

1

ADJUSTMENT REFRIGERANT RECOVERY, RECYCLING,

RECHARGING

Service repair no - 82.30.02

WARNING: The air conditioning system is

charged with a high pressure, potentially

toxic refrigerant. Repairs or servicing must

only be carried out by an operator familiar with

both the vehicle system and the charging and

testing equipment.

WARNING: All operations must be carried

out in a well ventillated area away from

open flame and heat sources.

WARNING: Wear eye and hand safety

protection.

CAUTION: Overcharging air conditioning

system will cause excessive head

pressure.

An air conditioning portable Refrigerant Recovery

Recycling Recharging Station for use with R134a

refrigerant incorporates all the features necessary to

recover R134a refrigerant from the air conditioning

system; to filter and remove moisture; to evacuate and

recharge with the reclaimed refrigerant. The unit can

also be used for performance testing and air

conditioning system analysis.

The operator must adhere to the equipment

manufacturer’s instructions.

Refrigerant Recovery

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

NOTE: Operate the refrigerant station in

accordance with the manufacturers

instructions.

5.Turn Process switch to correct position.

6.Turn Main switch to’ON’.

7.Allow station to recover refrigerant from system.8.Close valves on refrigerant station.

9.Turn Main switch to’OFF’.

10.Close valves on connectors.

11.Disconnect high and low pressure hoses from

connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant oil

recovered from system.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn Main switch to’ON’.

7.Allow station to evacuate system.

NOTE: If the vacuum reading is below

700mmHg after 15 minutes, suspect a leak

in the system. Partially recharge the

system and check for leaks using an electronic

leak tester. Check suction lines first, then run the

compressor for 5 minutes. Next check the high

pressure lines.

NOTE: The system must be evacuated

immediately before recharging

commences. Delay between evacuation

and recharging is not permitted.

ProCarManuals.com

Page 585 of 667

82AIR CONDITIONING

2

ADJUSTMENT Recharging

WARNING: Refrigerant must always be

recycled before re-use, to ensure that the

purity of the refrigerant is high enough for

safe use within the air conditioning system.

Recycling should always be carried out with

equipment which is design certified by

Underwriter Laboratory Inc. for compliance with

SAE-J1991. Other equipment may not re-cycle the

refrigerant to the required level of purity.

WARNING: A R134a Refrigerant Recovery

Recycling Recharging station must not be

used with any other type of refrigerant.

WARNING: R134a refrigerant from

domestic and commercial sources must

not be used in motor vehicle air

conditioning systems.

CAUTION: When a major repair has been

carried out, a leak test should be carried

out using inert gas.

1.Close valves on refrigerant station.

2.Close valve on oil charger.

3.Disconnect yellow hose from refrigerant station.

4.Remove lid from oil charger.

5.Pour correct quantity of refrigerant oil into oil

charger.

6.Fit lid to oil charger.

7.Connect yellow hose to refrigerant station.

8.Open valve on oil charger.

9.Move pointer on refrigerant gauge to mark

position of refrigerant drop.

10.Slowly open correct valve on refrigerant station

and allow vacuum to pull refrigerant into system.

11.Close valve on refrigerant station when correct

amount of refrigerant has been drawn into air

conditioning system.

12.If the full charge is not accepted by the system,

start the engine and run it at 1,500 rev/min for a

minimum of 2 minutes. Switch on the air

conditioning system, open the vehicle windows,

set the temperature control to cold and the

blower switch to maximum.

13.Consult Refrigerant station instruction manual for

correct procedure to complete the charge.

14.Turn Main switch to’OFF’.

15.Close valves on connectors.

16.Disconnect high and low pressure hoses from

connectors.

17.Fit dust caps to connectors.

18.Carry out performance test on air conditioning

system.

ProCarManuals.com

Page 586 of 667

AIR CONDITIONING

1

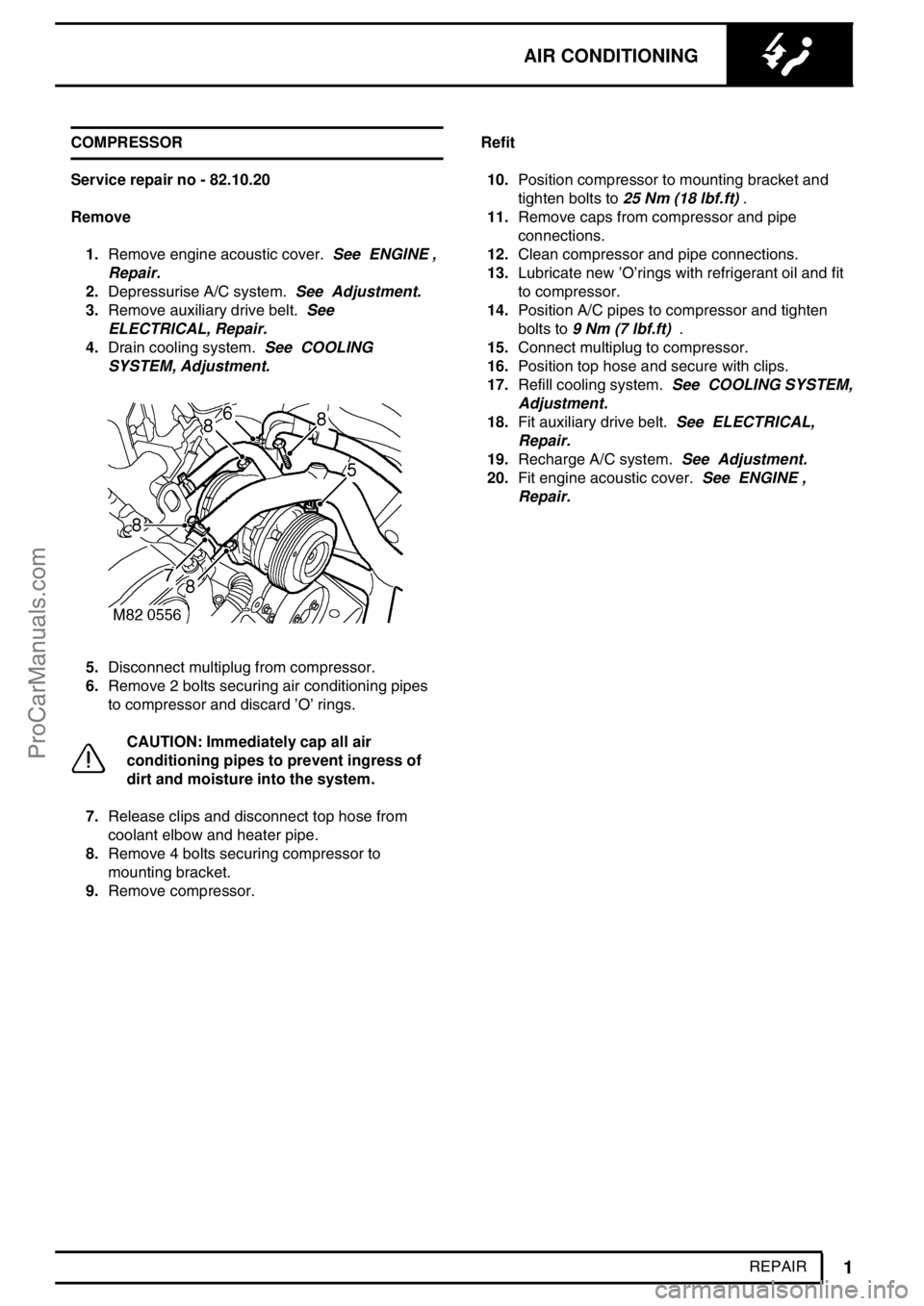

REPAIR COMPRESSOR

Service repair no - 82.10.20

Remove

1.Remove engine acoustic cover.See ENGINE ,

Repair.

2.Depressurise A/C system.See Adjustment.

3.Remove auxiliary drive belt.See

ELECTRICAL, Repair.

4.Drain cooling system.See COOLING

SYSTEM, Adjustment.

5.Disconnect multiplug from compressor.

6.Remove 2 bolts securing air conditioning pipes

to compressor and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

7.Release clips and disconnect top hose from

coolant elbow and heater pipe.

8.Remove 4 bolts securing compressor to

mounting bracket.

9.Remove compressor.Refit

10.Position compressor to mounting bracket and

tighten bolts to25 Nm (18 lbf.ft).

11.Remove caps from compressor and pipe

connections.

12.Clean compressor and pipe connections.

13.Lubricate new’O’rings with refrigerant oil and fit

to compressor.

14.Position A/C pipes to compressor and tighten

bolts to9 Nm (7 lbf.ft).

15.Connect multiplug to compressor.

16.Position top hose and secure with clips.

17.Refill cooling system.See COOLING SYSTEM,

Adjustment.

18.Fit auxiliary drive belt.See ELECTRICAL,

Repair.

19.Recharge A/C system.See Adjustment.

20.Fit engine acoustic cover.See ENGINE ,

Repair.

ProCarManuals.com

Page 587 of 667

82AIR CONDITIONING

2

REPAIR MOTOR - CONDENSER FAN

Service repair no - 82.15.01

Remove

1.Remove 6 screws and remove radiator grille.

2.Disconnect fan multiplug and release multiplug

holder from retaining clip.

3.With assistance remove 4 nuts and bolts

securing motor to condenser.

4.Remove motor.

Refit

5.Position motor to condenser and with assistance

tighten nuts and bolts to8 Nm (6 lbf.ft).

6.Connect motor multiplug.

7.Position radiator grille and secure with screws.RECEIVER DRIER

Service repair no - 82.17.03

Remove

1.Recover refrigerant from A/C system.See

Adjustment.

2.Remove 2 bolts securing pipe unions to receiver

drier.

3.Release pipes and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

4.Remove 2 bolts securing receiver drier mounting

bracket to chassis.

5.Remove receiver drier, slacken clamp bolt and

remove bracket.

ProCarManuals.com

Page 588 of 667

AIR CONDITIONING

3

REPAIR Refit

6.Position bracket to receiver drier and tighten

clamp bolt.

7.Position receiver to chassis and tighten bolts.

8.Remove plugs from A/C pipes.

9.Lubricate new’O’rings with refrigerent oil.

10.Fit’O’rings, position pipes and tighten bolts to8

Nm (6 lbf.ft).

11.Recharge A/C system.See Adjustment.RELAY - TEMPERATURE CONTROL - FROM 02MY

Service repair no - 82.20.40

Remove

1.Remove front speaker from drivers side.See

ELECTRICAL, Repair.

2.Release relay from support bracket.

3.Disconnect multiplug and remove relay.

Refit

4.Connect multiplug to relay and fit relay to

bracket.

5.Fit front speaker.See ELECTRICAL, Repair.

ProCarManuals.com

Page 589 of 667

82AIR CONDITIONING

4

REPAIR EVAPORATOR

Service repair no - 82.25.20

Remove

1.Remove battery cover.

2.Recover refrigerant from A/C system.See

Adjustment.

3.Remove 2 bolts securing A/C pipes to

evaporator.

4.Release pipes and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

5.Remove 2 screws and release fuse/relay bracket

from body and collect 2 spacers.

6.Remove 8 screws securing speakers to A/C

duct.

7.Disconnect speaker Lucars and remove

speakers.

8.Remove 4 screws and bolt securing A/C duct to

fascia panel.

ProCarManuals.com

Page 590 of 667

AIR CONDITIONING

5

REPAIR

9.Disconnect multiplug from auxiliary relay

bracket.

10.Release drain pipe from evaporator.

11.Release evaporator from bulkhead grommet.

12.With assistance remove A/C duct assembly from

vehicle.

NOTE: Do not carry out further

dismantling if component is removed for

access only.

13.Disconnect blower motor multiplugs.

14.Remove 5 screws and remove blower unit from

A/C duct.

15.Disconnect multiplug from trinary switch.

16.Remove Allen screw, remove pipe assembly

from evaporator and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

17.Remove 7 screws and remove evaporator cover

from A/C duct.

18.Release temperature sensor and remove

evaporator.

19.Remove 2 Allen screws, remove TXV from

evaporator and discard’O’rings.

ProCarManuals.com