sensor LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 366 of 667

TRANSFER GEARBOX

5

REPAIR

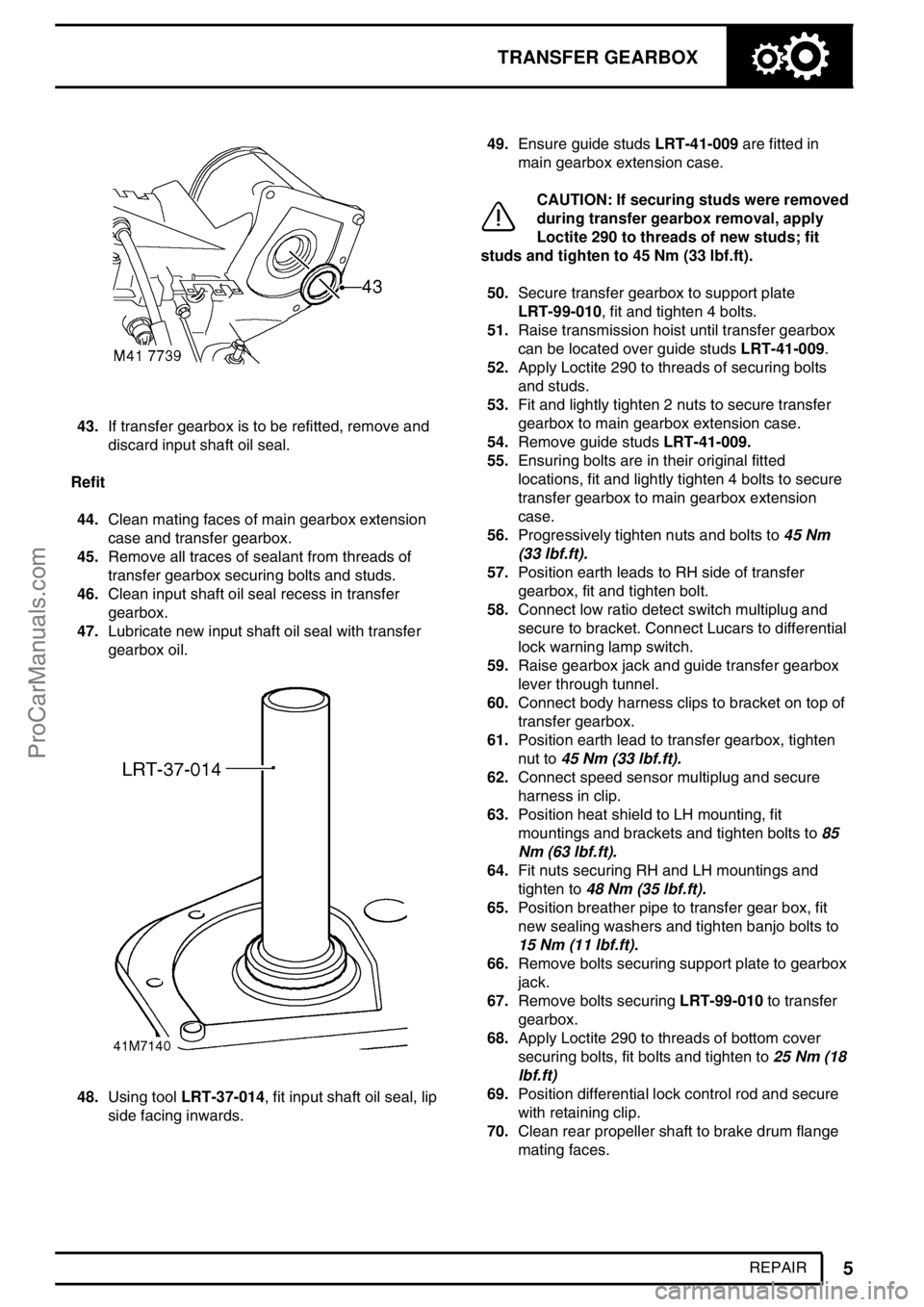

43.If transfer gearbox is to be refitted, remove and

discard input shaft oil seal.

Refit

44.Clean mating faces of main gearbox extension

case and transfer gearbox.

45.Remove all traces of sealant from threads of

transfer gearbox securing bolts and studs.

46.Clean input shaft oil seal recess in transfer

gearbox.

47.Lubricate new input shaft oil seal with transfer

gearbox oil.

48.Using toolLRT-37-014, fit input shaft oil seal, lip

side facing inwards.49.Ensure guide studsLRT-41-009are fitted in

main gearbox extension case.

CAUTION: If securing studs were removed

during transfer gearbox removal, apply

Loctite 290 to threads of new studs; fit

studs and tighten to 45 Nm (33 lbf.ft).

50.Secure transfer gearbox to support plate

LRT-99-010, fit and tighten 4 bolts.

51.Raise transmission hoist until transfer gearbox

can be located over guide studsLRT-41-009.

52.Apply Loctite 290 to threads of securing bolts

and studs.

53.Fit and lightly tighten 2 nuts to secure transfer

gearbox to main gearbox extension case.

54.Remove guide studsLRT-41-009.

55.Ensuring bolts are in their original fitted

locations, fit and lightly tighten 4 bolts to secure

transfer gearbox to main gearbox extension

case.

56.Progressively tighten nuts and bolts to45 Nm

(33 lbf.ft).

57.Position earth leads to RH side of transfer

gearbox, fit and tighten bolt.

58.Connect low ratio detect switch multiplug and

secure to bracket. Connect Lucars to differential

lock warning lamp switch.

59.Raise gearbox jack and guide transfer gearbox

lever through tunnel.

60.Connect body harness clips to bracket on top of

transfer gearbox.

61.Position earth lead to transfer gearbox, tighten

nut to45 Nm (33 lbf.ft).

62.Connect speed sensor multiplug and secure

harness in clip.

63.Position heat shield to LH mounting, fit

mountings and brackets and tighten bolts to85

Nm (63 lbf.ft).

64.Fit nuts securing RH and LH mountings and

tighten to48 Nm (35 lbf.ft).

65.Position breather pipe to transfer gear box, fit

new sealing washers and tighten banjo bolts to

15 Nm (11 lbf.ft).

66.Remove bolts securing support plate to gearbox

jack.

67.Remove bolts securingLRT-99-010to transfer

gearbox.

68.Apply Loctite 290 to threads of bottom cover

securing bolts, fit bolts and tighten to25 Nm (18

lbf.ft)

69.Position differential lock control rod and secure

with retaining clip.

70.Clean rear propeller shaft to brake drum flange

mating faces.

ProCarManuals.com

Page 442 of 667

70 - BRAKES

CONTENTS

Page

DESCRIPTION AND OPERATION

REAR BRAKE CALIPERS - FROM 02MY 2...........................................................

ADJUSTMENT

BRAKE SYSTEM BLEED 1.....................................................................................

PARK BRAKE - ADJUST 2.....................................................................................

REPAIR

ECU - ABS 1...........................................................................................................

SENSOR - ABS - FRONT WHEEL 2......................................................................

SENSORS - ABS - REAR WHEELS 3....................................................................

MASTER CYLINDER 4...........................................................................................

SERVO ASSEMBLY 5............................................................................................

MODULATOR UNIT - ABS 6...................................................................................

BRAKE CALIPER - FRONT 7.................................................................................

BRAKE CALIPER - REAR 8....................................................................................

SWITCH - STOP LIGHT 9.......................................................................................

FRONT BRAKE PADS - FROM 02MY 10...............................................................

REAR BRAKE PADS - FROM 02MY 11.................................................................

ProCarManuals.com

Page 451 of 667

70BRAKES

2

REPAIR SENSOR - ABS - FRONT WHEEL

Service repair no - 70.65.30

Remove

1.Raise vehicle on a 2 post ramp.

2.Carefully prize ABS sensor from front hub.

3.Release clip securing ABS sensor harness to

brake pipe.

4.Release clip securing ABS sensor harness to

inner wing.

5.Lower vehicle.

6.Release second clip securing ABS harness to

inner wing.

7.Disconnect sensor harness multiplug.

8.Remove sensor and harness.

Refit

9.Connect sensor harness multiplug.

10.Position sensor harness and secure to inner

wing with clip.

11.Raise vehicle.

12.Secure harness to inner wing and brake pipe

with clips.

13.Apply grease to sensor.

14.Carefully fit sensor to hub assembly.

15.Lower vehicle.

ProCarManuals.com

Page 452 of 667

BRAKES

3

REPAIR SENSORS - ABS - REAR WHEELS

Service repair no - 70.65.31

Remove

1.Raise vehicle on a 2 post ramp.

2.Remove both rear wheels.

3.Remove 3 bolts securing each brake disc

backplate to hub assemblies.

4.Remove both back plates.

5.Remove 2 cable ties securing sensor harness to

outer ends of axle.

6.Carefully prise both sensors from hub

assemblies.

7.Release 4 clips securing sensor harness to axle.

8.Release cable tie securing harness to

differential.

9.Release 3 cable ties securing harness to chassis

longitudinal.

10.Disconnect sensor multiplug.

11.Remove harness and sensor assembly.

Refit

12.Position harness and sensor assembly to vehicle

and connect multiplug.

13.Apply grease to both sensors.

14.Carefully fit both sensors to hub assemblies.

15.Secure harness to axle and differential with

cable ties.

16.Secure harness to axle with clips.

17.Secure harness to chassis with cable ties.

18.Fit both back plates to hub assemblies and

secure with bolts.

19.Fit rear wheels and tighten to130 Nm (95 lbf.ft)

.

20.Lower vehicle.

ProCarManuals.com

Page 568 of 667

PANEL REPAIRS

3

REPAIR WHEEL ARCH - FRONT

Remove

The procedure to change the Inner Front Wheelarch is

the same as for the Wing Upper, except for removal of

the ABS sensors and shield, if fitted.

BULKHEAD ASSEMBLY

Remove

1.Disconnect both battery leads, negative lead

first.

2.Remove front lower wing.See this Section.

3.Remove RH and LH front upper wing.See this

Section.

4.Remove headlamp mounting panels.See this

Section.

5.Remove screen aperture.See this Section.

6.Remove both front doors.

7.Remove lower fascia panel.See CHASSIS

AND BODY, Repair.

8. Models with A/C:Remove relevant A/C pipes.

9.Remove front grille.

10.Drain cooling system.See COOLING

SYSTEM, Adjustment.

11.Remove radiator and intercooler.

12. Models with A/C:Remove condensor.

13.Remove air cleaner assembly.

14.Remove heater unit.See HEATING AND

VENTILATION, Repair.

15.Remove brake servo assembly.

16.Remove heater ducts.

17.Remove both front seats.

18.Remove front carpets.

19.Release all relevant harnesses and position

aside.

20.Remove facia support bracket.

Refit

21.Prepare and clean panel joint faces. Ensure all

necessary grommets and sealant is applied to

new bulkhead.

22.Reverse removal procedure.

23.Bleed brake system.See BRAKES,

Adjustment.

24.Align headlamps.See ELECTRICAL,

Adjustment.

25.Water test after refitting.

ProCarManuals.com

Page 590 of 667

AIR CONDITIONING

5

REPAIR

9.Disconnect multiplug from auxiliary relay

bracket.

10.Release drain pipe from evaporator.

11.Release evaporator from bulkhead grommet.

12.With assistance remove A/C duct assembly from

vehicle.

NOTE: Do not carry out further

dismantling if component is removed for

access only.

13.Disconnect blower motor multiplugs.

14.Remove 5 screws and remove blower unit from

A/C duct.

15.Disconnect multiplug from trinary switch.

16.Remove Allen screw, remove pipe assembly

from evaporator and discard’O’rings.

CAUTION: Immediately cap all air

conditioning pipes to prevent ingress of

dirt and moisture into the system.

17.Remove 7 screws and remove evaporator cover

from A/C duct.

18.Release temperature sensor and remove

evaporator.

19.Remove 2 Allen screws, remove TXV from

evaporator and discard’O’rings.

ProCarManuals.com

Page 591 of 667

82AIR CONDITIONING

6

REPAIR Refit

20.Clean TXV and mating face.

21.Lubricate new’O’rings with refrigerant oil and fit

’O’rings to pipes.

22.Position TXV and tighten Allen screws.

23.Position evaporator and fit sensor.

24.Position cover and tighten screws.

25.Clean pipes and mating faces.

26.Lubricate and fit new’O’rings, position pipes

and tighten Allen screw.

27.Connect trinary switch multiplug.

28.Position blower unit,tighten screws and connect

multiplugs.

29.With assistance position A/C duct assembly to

vehicle.

30.Connect drain pipe to evaporator.

31.Connect multiplug to relay bracket.

32.Align A/C duct to fascia, tighten securing bolt

and screws.

33.Position speakers and connect Lucars.

34.Position relay bracket and tighten bolts.

35.Clean pipes and mating face.

36.Lubricate and fit new’O’rings to evaporator

pipes.

37.Position pipes and tighten bolts to6Nm(4

lbf.ft).

38.Renew receiver drier.See this Section.

39.Recharge A/C system.See Adjustment.

ProCarManuals.com

Page 610 of 667

ELECTRICAL

1

DESCRIPTION AND OPERATION SECURITY AND CENTRAL DOOR LOCKING

SYSTEM - FROM 02MY

The following description details the functionality and operation of the 10AS Security and Central Door Locking

(CDL) System fitted to 2002MY Defender. The system contains some new features and also retains some

features from previous Defender models. The alarm system and CDL system are controlled by the 10AS anti-theft

alarm ECU.

New door lock barrels are introduced and use the same key as the ignition switch barrel, thereby eliminating the

requirement for a separate key for the doors.

NOTE: Some markets will only have some of the features described and some will have no

security or central door locking functions.

The security system comprises the following components:

10AS anti-theft alarm ECU

Remote handset transmitters

Transponder coil

Volumetric sensor

CDL actuators

Bonnet switch

Driver’s door key barrel switch

Door switches

Bonnet switch

Battery Backed-Up Sounder (BBUS) or alarm sounder

Security LED

Engine immobilised warning lamp

Direction indicators

ProCarManuals.com

Page 611 of 667

86ELECTRICAL

2

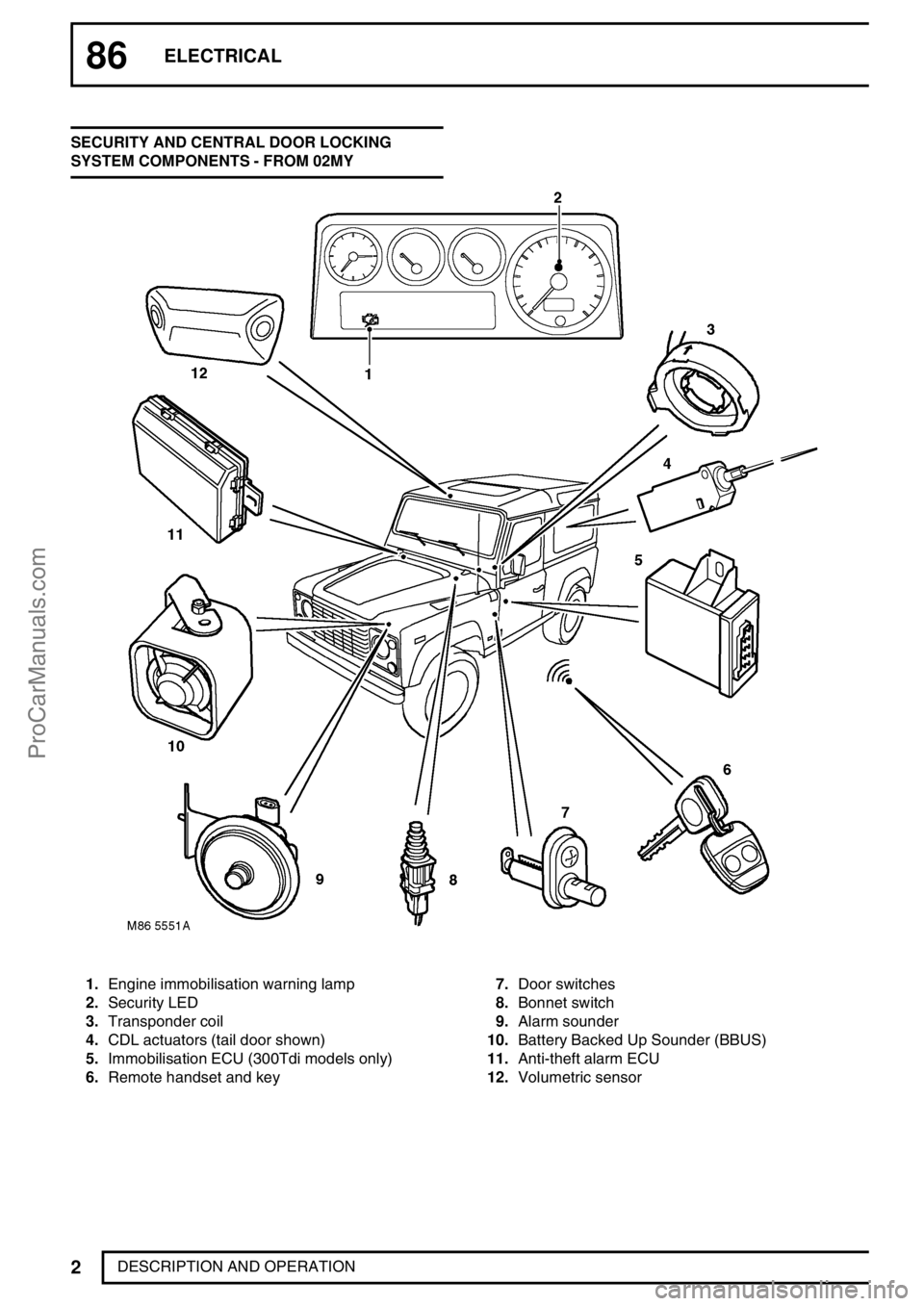

DESCRIPTION AND OPERATION SECURITY AND CENTRAL DOOR LOCKING

SYSTEM COMPONENTS - FROM 02MY

1.Engine immobilisation warning lamp

2.Security LED

3.Transponder coil

4.CDL actuators (tail door shown)

5.Immobilisation ECU (300Tdi models only)

6.Remote handset and key7.Door switches

8.Bonnet switch

9.Alarm sounder

10.Battery Backed Up Sounder (BBUS)

11.Anti-theft alarm ECU

12.Volumetric sensor

ProCarManuals.com

Page 612 of 667

ELECTRICAL

3

DESCRIPTION AND OPERATION ANTI-THEFT ALARM - FROM 02MY

The alarm and immobilisation system on 2002MY Defender is similar to that used on Discovery Series I (LJ)

models from 1996MY. The alarm system comprises the anti-theft alarm ECU, bonnet and door switches and a

volumetric sensor.

Anti-Theft Alarm ECU

The anti-theft alarm ECU is located behind the instrument pack and receives a permanent battery supply via fuses

6 and 7 in the under seat fuse box. The ECU also receives a battery supply via the ignition switch position II and

fuse 1 in the passenger compartment fuse box. The ECU is connected to the various supporting components by

two harness connectors.

The ECU controls the alarm system (perimetric and volumetric security), CDL system, engine immobilisation

system (Td5 only) and various other vehicle functions including direction indicators and interior lamps.

The anti-theft alarm ECU incorporates an RF receiver and antenna for reception of RF signals from the remote

handset for locking and alarm arming. The antenna is unterminated at one end, and for optimum performance the

antenna must not be wound around adjoining harnesses.

The anti-theft alarm ECU operates at one of two frequencies which are identified by a label on the unit. The

frequencies are:

433 MHz - Europe, Gulf States, South Africa

315 MHz - North America, South East Asia, Japan, Australia.

The anti-theft alarm ECU also incorporates an integral inertia switch. In the event of an impact of sufficient severity

to trigger the inertia switch when the ignition is on, the ECU will unlock all doors and operate the hazard warning

lamps. The ECU will remain in this condition for a pre-programmed period of 2 minutes. To reinstate CDL

functionality and to deactivate the hazard warning lamps, the ignition should be turned off and then on after the 2

minute timer has expired.

NOTE: There is a separate inertia switch for fuel cut off.

ProCarManuals.com