sensor LAND ROVER DEFENDER 1999 Service Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 260 of 667

FUEL SYSTEM

5

DESCRIPTION AND OPERATION FUEL PRESSURE REGULATOR

NOTE: Non EU3 Model illustrated.

1.Gasket

2.Housing

3.Bolt

4.Fuel feed union and pipe

5.Fuel return union and hose

6.Fuel temperature sensor

7.Bonded seal8.’O’ring

9.Circlip

10.Fuel pressure regulator

11.’O’ring

12.’O’ring

13.Gauze filter

The fuel pressure regulator is located in a cast alloy housing which is attached to the rear right hand corner of the

cylinder head with three flanged bolts and sealed with a metal gasket. Two ports in the housing connect with ports

in the cylinder head for fuel pressure feed and return. A gauze filter is located in the pressure feed port in the

cylinder head, and filters the fuel before it reaches the injectors. The filter is a fit for life item but can be changed if

required. An’O’ring is located in a recess in the cylinder head and provides additional sealing for the pressure

feed port between the gauze filter, the cylinder head, and the housing.

A union and pipe is attached to the feed port in the housing and connects with a quick release coupling to the fuel

pressure feed pipe from the fuel pump. A second union and hose is located in the return port and provides the fuel

return connection to the fuel cooler. A third port provides location for the fuel temperature sensor, which is sealed

to the housing with a bonded seal. The fuel temperature sensor is used by the ECM for engine management.

ProCarManuals.com

Page 264 of 667

FUEL SYSTEM

9

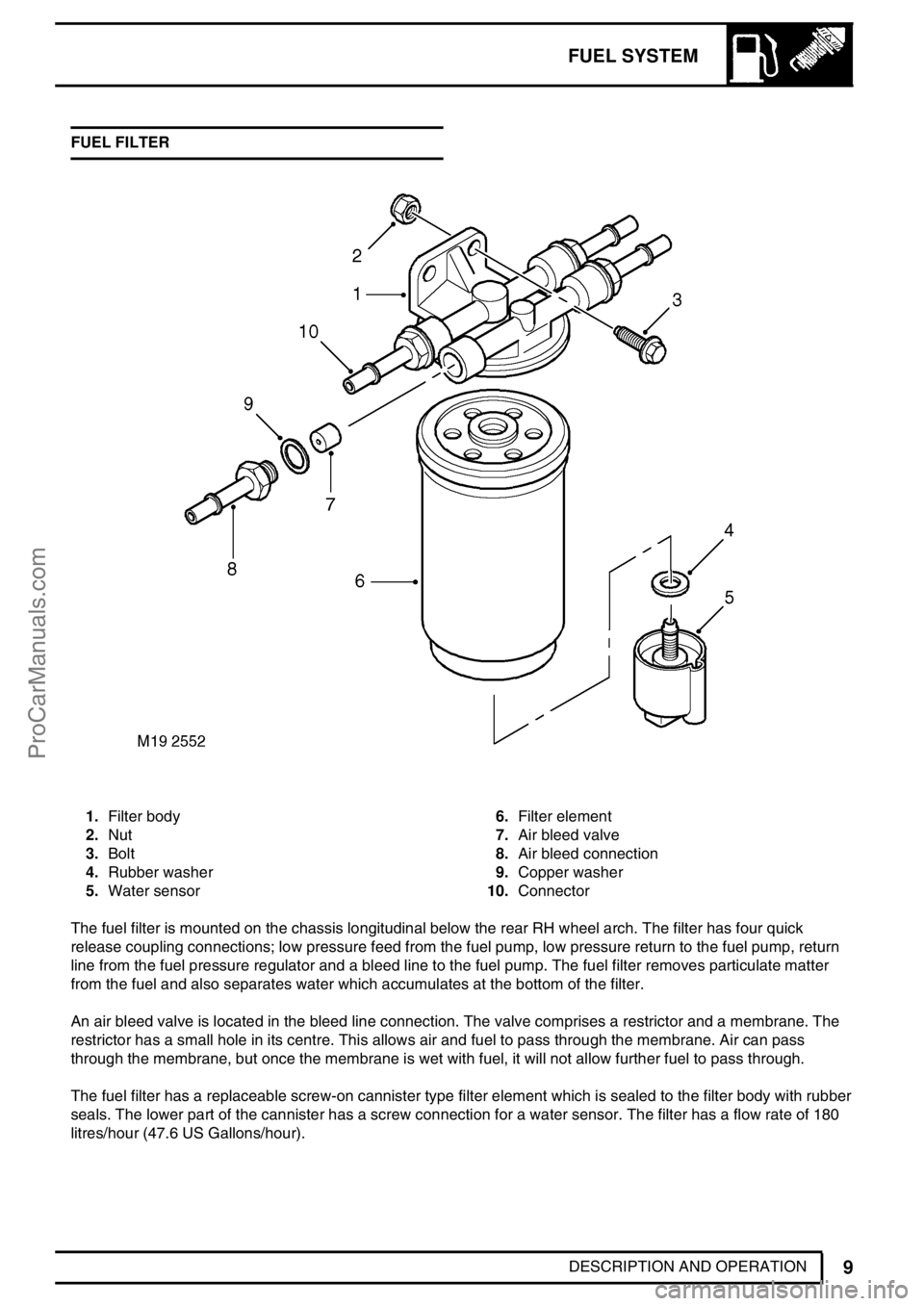

DESCRIPTION AND OPERATION FUEL FILTER

1.Filter body

2.Nut

3.Bolt

4.Rubber washer

5.Water sensor6.Filter element

7.Air bleed valve

8.Air bleed connection

9.Copper washer

10.Connector

The fuel filter is mounted on the chassis longitudinal below the rear RH wheel arch. The filter has four quick

release coupling connections; low pressure feed from the fuel pump, low pressure return to the fuel pump, return

line from the fuel pressure regulator and a bleed line to the fuel pump. The fuel filter removes particulate matter

from the fuel and also separates water which accumulates at the bottom of the filter.

An air bleed valve is located in the bleed line connection. The valve comprises a restrictor and a membrane. The

restrictor has a small hole in its centre. This allows air and fuel to pass through the membrane. Air can pass

through the membrane, but once the membrane is wet with fuel, it will not allow further fuel to pass through.

The fuel filter has a replaceable screw-on cannister type filter element which is sealed to the filter body with rubber

seals. The lower part of the cannister has a screw connection for a water sensor. The filter has a flow rate of 180

litres/hour (47.6 US Gallons/hour).

ProCarManuals.com

Page 265 of 667

19FUEL SYSTEM

10

DESCRIPTION AND OPERATION WATER SENSOR

The water sensor has a three pin electrical connector. When the sensor detects water in the fuel filter it illuminates

a warning lamp in the instrument pack.

The water sensor attachment thread has a slot machined down one side. The filter can be purged of water by

partially unscrewing the sensor which aligns the slot in the threads with a corresponding hole in the sensor. When

aligned, water and fuel can flow down the slot and flows from a small cast tube on the side of the sensor.

Re-tightening the sensor mis-aligns the slot and stops the flow of fuel.

The sensor operates by measuring the resistance between its two electrodes, which are submerged in fuel, and

activated by the presence of water. When the ignition switch is moved to position’II’, the warning lamp will

illuminate for approximately 2 seconds to check warning lamp functionality.

When the filter is full with fuel and no water is present, the resistance of the Diesel fuel will show a reading of 15

mA maximum on the feed wire to the instrument pack. When sufficient water surrounds both electrodes, the

resistance of the water will show a reading of 130 mA maximum. This will supply sufficient voltage to the

instrument pack to illuminate the warning lamp, and alert the driver to the presence of water in the fuel system.

ProCarManuals.com

Page 270 of 667

FUEL SYSTEM

1

REPAIR ELEMENT - AIR FILTER

Service repair no - 19.10.10

Remove

1.Release 2 clips and disconnect air flow meter

from air filter cover.

2.Disconnect multiplug from AAP sensor.

3.Release 2 clips and remove cover from air filter.

4.Remove air filter element.

Refit

5.Clean air filter body and cover.

6.Fit new air filter element.

7.Position air cleaner cover and secure clips.

8.Position air flow meter and secure clips.

9.Connect AAP sensor multiplug.SENSOR - FUEL TEMPERATURE

Service repair no - 19.22.08

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Release fixings and remove battery cover.

3.Disconnect battery negative lead.

4.Disconnect multiplug from fuel temperature

sensor.

5.Thoroughly clean area around fuel temperature

sensor before removal.

6.Remove fuel temperature sensor and discard

sealing washer.

Refit

7.Clean fuel temperature sensor mating faces.

8.Fit new sealing washer and tighten fuel

temperature sensor to13 Nm (9 lbf. ft).

9.Connect multiplug to fuel temperature sensor.

10.Reconnect battery negative lead.

11.Fit battery cover and secure fixings.

12.Fit engine acoustic cover and secure with bolts.

ProCarManuals.com

Page 271 of 667

19FUEL SYSTEM

2

REPAIR SWITCH - INERTIA - FUEL CUT OFF

Service repair no - 19.22.09

Remove

1.Disconnect multiplug from fuel cut off switch.

2.Remove 2 screws securing switch to bulkhead.

3.Remove switch.

Refit

4.Position switch to bulkhead.

5.Fit screws securing switch to bulkhead.

6.Connect multiplug.

7.Press top of switch to set switch.SENSOR - MASS AIR FLOW (MAF)

Service repair no - 19.22.25

Remove

1.Disconnect multiplug from MAF sensor.

2.Loosen clip screw and release air intake hose

from MAF sensor.

3.Release 2 clips and remove sensor from air

cleaner.

Refit

4.Position sensor to air cleaner and secure clips.

5.Position air intake hose and tighten clip screw.

6.Connect multiplug.

ProCarManuals.com

Page 272 of 667

FUEL SYSTEM

3

REPAIR SENSOR - COMBINED MAP AND IAT

Service repair no - 19.22.26

Remove

1.Remove 3 bolts and remove engine acoustic

cover.

2.Disconnect multiplug from combined MAP and

IAT sensor,

3.Remove 2 bolts securing sensor to inlet

manifold.

4.Remove sensor and discard’O’ring.

Refit

5.Clean sensor and mating face.

6.Fit new’O’ring and position sensor to manifold.

7.Fit and tighten MAF and IAT sensor bolts to9

Nm (7 lbf.ft)

8.Fit engine acoustic cover and secure with bolts.SENSOR - AMBIENT AIR PRESSURE (AAP)

Service repair no - 19.22.27

Remove

1.Disconnect multiplug from AAP sensor.

2.Remove 2 screws and remove sensor.

3.Remove and discard’O’ring.

Refit

4.Clean sensor and air cleaner cover.

5.Fit new’O’ring, fit sensor and tighten screws.

6.Connect multiplug to AAP sensor.

ProCarManuals.com

Page 275 of 667

19FUEL SYSTEM

6

REPAIR Refit

17.Clean turbocharger and oil drain pipe mating

faces.

18.Using a NEW gasket, fit turbocharger drain pipe

and tighten bolts to10 Nm (7 lbf.ft).

19.Using a new gasket fit turbocharger to exhaust

manifold and tighten nuts to30 Nm (22 lbf. ft).

20.Position oil drain pipe to cylinder block and

tighten union.

21.Using new gasket, align exhaust front pipe and

tighten nuts to30 Nm (22 lbf.ft)

22.Fit banjo bolt to oil feed pipe using new sealing

washers and tighten to25 Nm (18 lbf.ft).

23.Position air outlet hose to turbocharger and

tighten clip screw.

24.Position and secure vacuum hose to

turbocharger wastegate.

25.Position exhaust manifold heat shield and

tighten M6 bolts to9 Nm (7 lbf.ft)and M8 bolt to

25 Nm (18 lbf.ft).

26.Position air inlet hose to turbocharger and

tighten clip screw.

27.Connect air flow meter to air filter and secure

clips.

28.Connect air flow meter multiplug.

29.Connect breather hose and secure clip.

30.Fit engine acoustic cover and secure with bolts.

31.Reconnect battery negative lead.

32.Fit battery cover.FILTER ASSEMBLY - AIR

Service repair no - 19.10.01

Remove

1.Loosen clip screw and release intake hose from

air filter.

2.Release 2 clips securing air flow meter.

3.Release air flow meter from air filter cover and

position aside.

4.Disconnect multiplug from AAP sensor.

5.Release air filter from 3 grommets, remove

assembly and discard’O’ring.

6.Remove 2 screws, remove AAP sensor and

discard’O’ring.

ProCarManuals.com

Page 276 of 667

FUEL SYSTEM

7

REPAIR Refit

7.Clean air flow meter faces.

8.Fit new’O’ring to air filter.

9.Clean AAP sensor.

10.Using new’O’ring, fit AAP sensor and tighten

screws.

11.Position air filter assembly and secure in

grommets.

12.Position air flow meter and secure clips.

13.Position intake hose to air filter and tighten clip

screw.INJECTOR - SET

Service repair no - 19.60.12

Remove

1.Remove cooling fan.See COOLING SYSTEM,

Repair.

2.Remove rocker shaft.See ENGINE , Repair.

3.Position container to catch fuel spillage.

4.Disconnect quick release fuel hose connectors

from fuel connector block on cylinder head and

fuel cooler to drain fuel from cylinder head.

5.Disconnect 5 multiplugs from injectors.

6.Remove Torx bolt securing injector unit to

cylinder head.

ProCarManuals.com

Page 280 of 667

FUEL SYSTEM

11

REPAIR REGULATOR - FUEL PRESSURE

Service repair no - 19.45.06

Remove

1.Remove battery cover.

2.Disconnect battery negative lead.

3.Remove 3 bolts and remove engine acoustic

cover.

4.Release hose from fuel cooler.

5.Release fuel hoses from pressure regulator.

CAUTION: Plug the connections.

6.Disconnect multiplug from fuel temperature

sensor.

7.Remove 3 bolts, remove pressure regulator from

cylinder head and collect gasket and’O’ring.

8.Remove fuel filter from cylinder head.

9.Remove fuel temperature sensor and discard

sealing washer.

10.Remove fuel hose and fuel pipe and discard’O’

rings.

Refit

11.Clean fuel pressure regulator, mating face and

fuel filter.

12.Clean fuel pipe unions.

13.Fit fuel pipe and fuel hose to pressure regulator

using new’O’rings.

14.Fit fuel temperature sensor using new sealing

washer and tighten to14 Nm (11 lbf.ft).

15.Fit fuel filter to cylinder head.

16.Using a new gasket and’O’ring position

pressure regulator and tighten bolts to25 Nm

(18 lbf.ft).

17.Connect fuel temperature sensor.

18.Connect fuel hoses to pressure regulator and

fuel cooler.

19.Fit engine acoustic cover.

20.Reconnect battery negative lead.

21.Fit battery cover.

ProCarManuals.com

Page 290 of 667

COOLING SYSTEM

3

DESCRIPTION AND OPERATION

NOTE: Inset A shows differences for Pre

EU3 models

1.Pressure cap

2.Overflow pipe

3.Heater return hose

4.Heater matrix

5.Heater inlet hose

6.Oil cooler return pipe - EU3 models

7.Connecting hose

8.Oil cooler housing assembly

9.Heater inlet pipe

10.Connecting hose

11.Outlet housing

12.Engine Coolant Temperature (ECT) sensor

13.Bleed screw

14.Radiator top hose

15.Radiator - upper

16.Intercooler

17.Gearbox oil cooler

18.Radiator - lower

19.Viscous fan

20.Drain plug

21.Connecting hose

22.Fuel cooler feed hose

23.Radiator bottom hose

24.Thermostat housing

25.Connecting hose

26.Coolant pump feed pipe

27.Coolant by-pass pipe

28.Radiator bleed pipe

29.Connecting hose

30.Coolant pump

31.Fuel cooler

32.Heater/expansion tank return hose

33.Expansion tank

34.EGR Cooler - EU3 models

35.Connecting hose - EU3 models

36.Connecting hose - EU3 models

37.Hose - EGR Cooler to oil cooler return pipe -

EU3 models

38.Radiator lower feed hose - Pre EU3 models

39.Oil cooler return pipe - Pre EU3 models

ProCarManuals.com