warning LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 561 of 667

77PANEL REPAIRS

2

PROCEDURES PANEL REPLACEMENT PROCEDURE

General

This information is designed to explain the basic panel

removal and replacement method. This standard

method may vary slightly from one vehicle to another.

The main criterion in removal and replacement of

body panels is that Land Rover’s original standard is

maintained as far as possible.

All repair processes and procedures shown relate to

Aluminium panels.

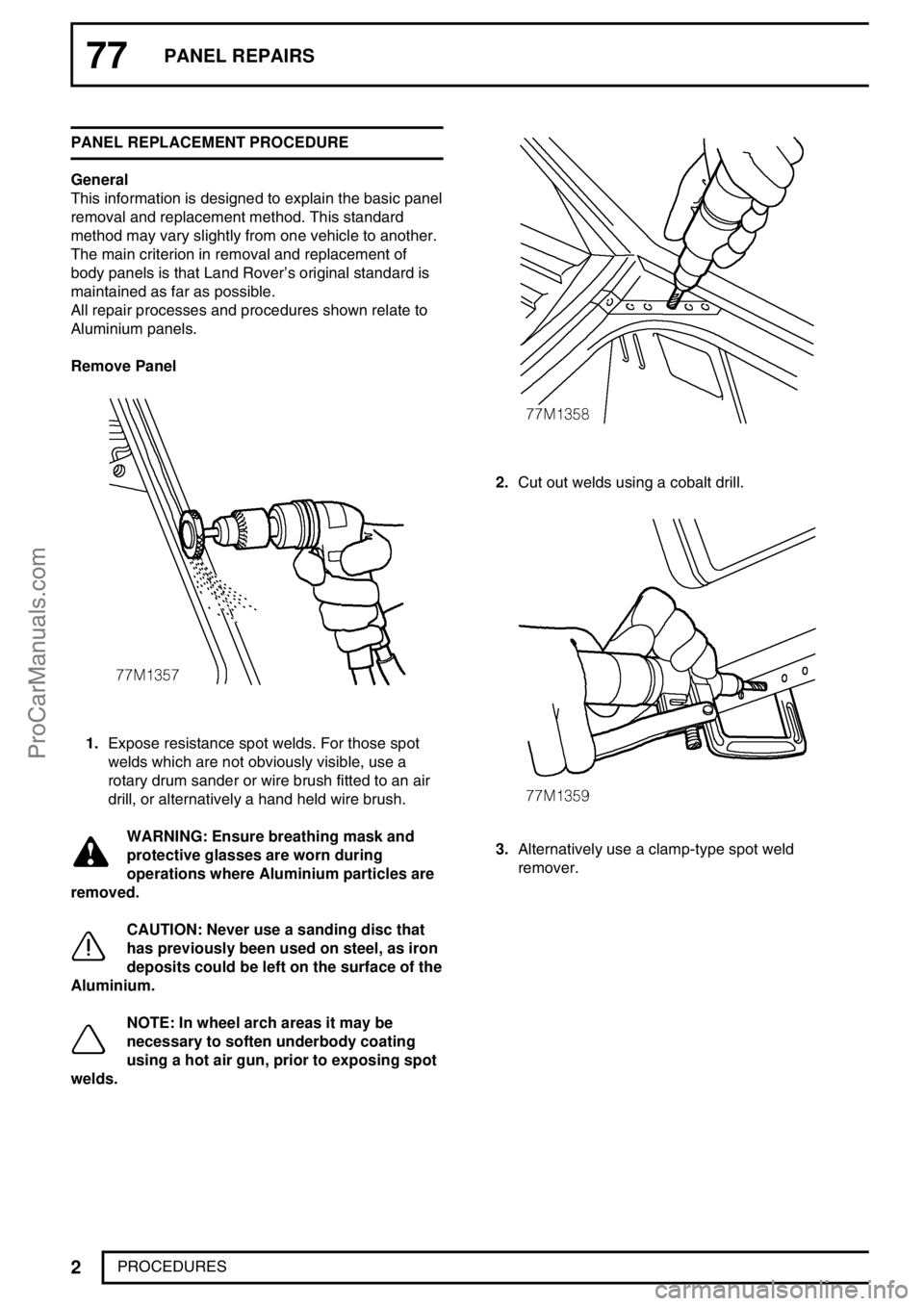

Remove Panel

1.Expose resistance spot welds. For those spot

welds which are not obviously visible, use a

rotary drum sander or wire brush fitted to an air

drill, or alternatively a hand held wire brush.

WARNING: Ensure breathing mask and

protective glasses are worn during

operations where Aluminium particles are

removed.

CAUTION: Never use a sanding disc that

has previously been used on steel, as iron

deposits could be left on the surface of the

Aluminium.

NOTE: In wheel arch areas it may be

necessary to soften underbody coating

using a hot air gun, prior to exposing spot

welds.

2.Cut out welds using a cobalt drill.

3.Alternatively use a clamp-type spot weld

remover.

ProCarManuals.com

Page 562 of 667

PANEL REPAIRS

3

PROCEDURES

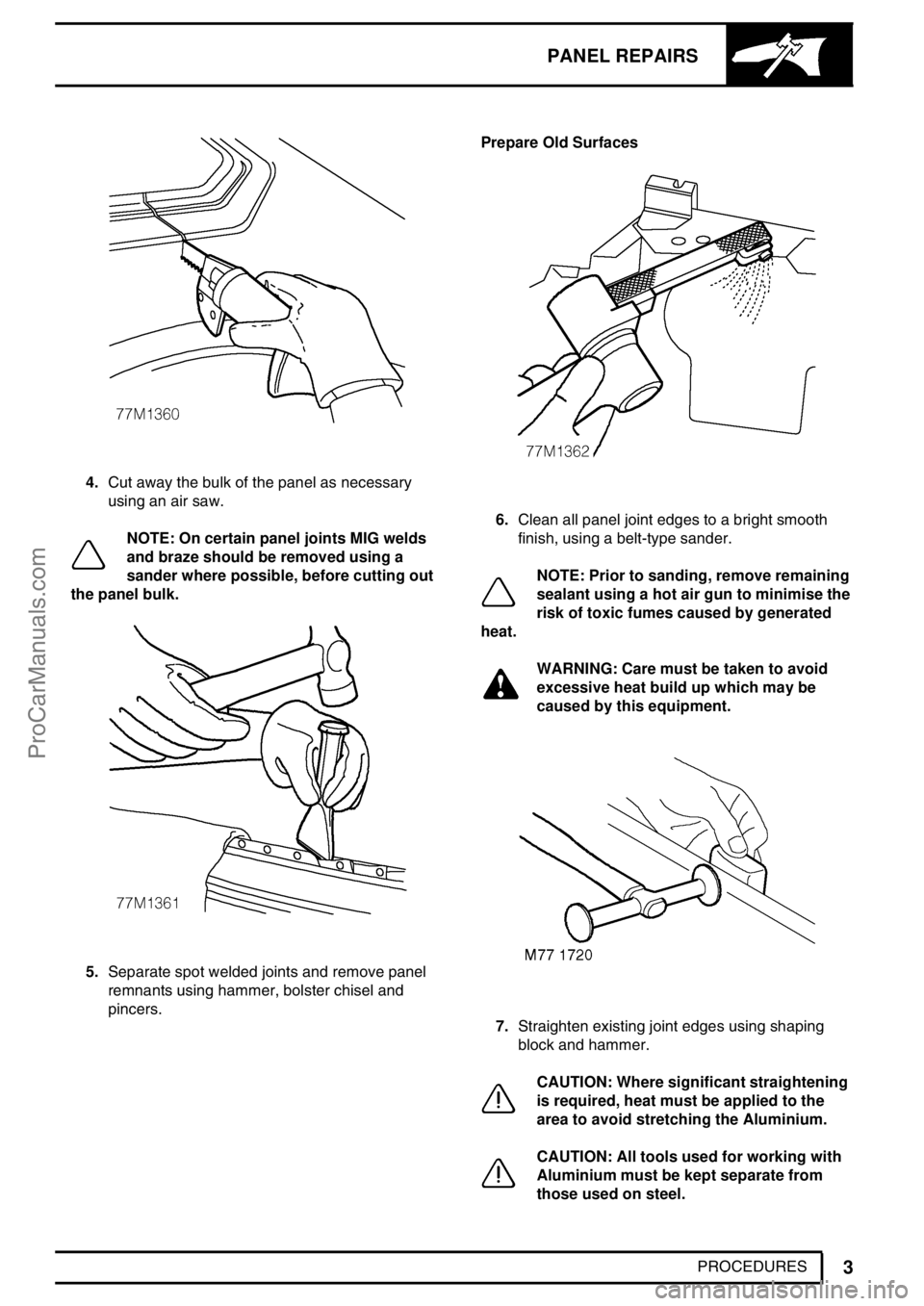

4.Cut away the bulk of the panel as necessary

using an air saw.

NOTE: On certain panel joints MIG welds

and braze should be removed using a

sander where possible, before cutting out

the panel bulk.

5.Separate spot welded joints and remove panel

remnants using hammer, bolster chisel and

pincers.Prepare Old Surfaces

6.Clean all panel joint edges to a bright smooth

finish, using a belt-type sander.

NOTE: Prior to sanding, remove remaining

sealant using a hot air gun to minimise the

risk of toxic fumes caused by generated

heat.

WARNING: Care must be taken to avoid

excessive heat build up which may be

caused by this equipment.

7.Straighten existing joint edges using shaping

block and hammer.

CAUTION: Where significant straightening

is required, heat must be applied to the

area to avoid stretching the Aluminium.

CAUTION: All tools used for working with

Aluminium must be kept separate from

those used on steel.

ProCarManuals.com

Page 584 of 667

AIR CONDITIONING

1

ADJUSTMENT REFRIGERANT RECOVERY, RECYCLING,

RECHARGING

Service repair no - 82.30.02

WARNING: The air conditioning system is

charged with a high pressure, potentially

toxic refrigerant. Repairs or servicing must

only be carried out by an operator familiar with

both the vehicle system and the charging and

testing equipment.

WARNING: All operations must be carried

out in a well ventillated area away from

open flame and heat sources.

WARNING: Wear eye and hand safety

protection.

CAUTION: Overcharging air conditioning

system will cause excessive head

pressure.

An air conditioning portable Refrigerant Recovery

Recycling Recharging Station for use with R134a

refrigerant incorporates all the features necessary to

recover R134a refrigerant from the air conditioning

system; to filter and remove moisture; to evacuate and

recharge with the reclaimed refrigerant. The unit can

also be used for performance testing and air

conditioning system analysis.

The operator must adhere to the equipment

manufacturer’s instructions.

Refrigerant Recovery

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

NOTE: Operate the refrigerant station in

accordance with the manufacturers

instructions.

5.Turn Process switch to correct position.

6.Turn Main switch to’ON’.

7.Allow station to recover refrigerant from system.8.Close valves on refrigerant station.

9.Turn Main switch to’OFF’.

10.Close valves on connectors.

11.Disconnect high and low pressure hoses from

connectors.

12.Fit dust caps to connectors.

13.Open tap at rear of station to drain refrigerant oil

recovered from system.

14.Measure and record quantity of refrigerant oil

recovered from system.

15.Close tap at rear of station.

Evacuation

CAUTION: Whenever the refrigerant

system is opened, the receiver/drier must

be renewed immediately before evacuating

and recharging the system.

1.Remove dust caps from high and low pressure

connectors.

2.Connect high and low pressure hoses to

appropriate connections.

3.Open valves on connectors.

4.Turn valves on refrigerant station to correct

positions.

5.Turn Process switch to correct position.

6.Turn Main switch to’ON’.

7.Allow station to evacuate system.

NOTE: If the vacuum reading is below

700mmHg after 15 minutes, suspect a leak

in the system. Partially recharge the

system and check for leaks using an electronic

leak tester. Check suction lines first, then run the

compressor for 5 minutes. Next check the high

pressure lines.

NOTE: The system must be evacuated

immediately before recharging

commences. Delay between evacuation

and recharging is not permitted.

ProCarManuals.com

Page 585 of 667

82AIR CONDITIONING

2

ADJUSTMENT Recharging

WARNING: Refrigerant must always be

recycled before re-use, to ensure that the

purity of the refrigerant is high enough for

safe use within the air conditioning system.

Recycling should always be carried out with

equipment which is design certified by

Underwriter Laboratory Inc. for compliance with

SAE-J1991. Other equipment may not re-cycle the

refrigerant to the required level of purity.

WARNING: A R134a Refrigerant Recovery

Recycling Recharging station must not be

used with any other type of refrigerant.

WARNING: R134a refrigerant from

domestic and commercial sources must

not be used in motor vehicle air

conditioning systems.

CAUTION: When a major repair has been

carried out, a leak test should be carried

out using inert gas.

1.Close valves on refrigerant station.

2.Close valve on oil charger.

3.Disconnect yellow hose from refrigerant station.

4.Remove lid from oil charger.

5.Pour correct quantity of refrigerant oil into oil

charger.

6.Fit lid to oil charger.

7.Connect yellow hose to refrigerant station.

8.Open valve on oil charger.

9.Move pointer on refrigerant gauge to mark

position of refrigerant drop.

10.Slowly open correct valve on refrigerant station

and allow vacuum to pull refrigerant into system.

11.Close valve on refrigerant station when correct

amount of refrigerant has been drawn into air

conditioning system.

12.If the full charge is not accepted by the system,

start the engine and run it at 1,500 rev/min for a

minimum of 2 minutes. Switch on the air

conditioning system, open the vehicle windows,

set the temperature control to cold and the

blower switch to maximum.

13.Consult Refrigerant station instruction manual for

correct procedure to complete the charge.

14.Turn Main switch to’OFF’.

15.Close valves on connectors.

16.Disconnect high and low pressure hoses from

connectors.

17.Fit dust caps to connectors.

18.Carry out performance test on air conditioning

system.

ProCarManuals.com

Page 604 of 667

WIPERS AND WASHERS

5

REPAIR

9.Remove cable ties securing washer tube to

windscreen wiper rack tube.

10.Loosen fully 4 nuts securing backplates to wheel

boxes and remove windscreen wiper rack tubes.

11.Remove seals from wheel box spindles.

12.Remove 2 nuts securing wheel boxes and

remove sealing washers.

13.Carefully pull fascia support rail from bulkhead

sufficiently to remove wheel boxes.

Refit

14.Loosen fully but do not remove nuts securing

wheel box back plates.

15.Grease wheel boxes.

16.Fit wheel boxes, fit sealing washers and tighten

nuts to5 Nm (3.7 lbf.ft).

17.Fit spindle seals.

18.Fit wiper rack tubes and tighten wheel box back

plate nuts sufficiently to hold tubes. Tighten

wheel box back plate nuts to6 Nm (4 lbf.ft)

after fitting windscreen wiper motor.

19.Align washer tube to rack tube and secure with

cable ties.

20.Align fascia support rail and secure with screws.

21.Fit steering column support bracket and tighten

bolt and nut and bolt to45 Nm (33 lbf.ft).

22.Fit demister duct to tube, align relay bracket and

secure duct with screws.

23.Position heater fan switch and secure with

screws.

24.Fit wiper motor and drive rack.See this

Section.

25.Fit steering column nacelle.See STEERING,

Repair.

26.Connect battery negative lead.See

ELECTRICAL, Repair.RELAY - WIPER DELAY - FROM 02MY

Service repair no - 84.15.37

Remove

1.Disconnect battery negative lead.See

ELECTRICAL, Repair.

2.Remove 4 screws securing instrument pack and

release pack from fascia.

3.Disconnect 2 multiplugs from warning lamp

panel.

4.Disconnect instrument pack multiplug from main

harness.

5.Remove instrument pack.

ProCarManuals.com

Page 609 of 667

86 - ELECTRICAL

CONTENTS

Page

LAMP ASSEMBLY - CENTRE HIGH MOUNTED STOP LIGHT (CHMSL) -

FROM 02MY 16......................................................................................................

FLASHER UNIT - HAZARD WARNING - FROM 02MY 16.....................................

RELAY - HEATED FRONT SCREEN - FROM 02MY 17........................................

RELAY - REAR FOG GUARD - FROM 02MY 18...................................................

RELAY - STARTER - FROM 02MY 19...................................................................

SWITCH - HEADLAMP LEVELLING - FROM 02MY 19.........................................

CIGAR LIGHTER - FRONT - FROM 02MY 20........................................................

ProCarManuals.com

Page 610 of 667

ELECTRICAL

1

DESCRIPTION AND OPERATION SECURITY AND CENTRAL DOOR LOCKING

SYSTEM - FROM 02MY

The following description details the functionality and operation of the 10AS Security and Central Door Locking

(CDL) System fitted to 2002MY Defender. The system contains some new features and also retains some

features from previous Defender models. The alarm system and CDL system are controlled by the 10AS anti-theft

alarm ECU.

New door lock barrels are introduced and use the same key as the ignition switch barrel, thereby eliminating the

requirement for a separate key for the doors.

NOTE: Some markets will only have some of the features described and some will have no

security or central door locking functions.

The security system comprises the following components:

10AS anti-theft alarm ECU

Remote handset transmitters

Transponder coil

Volumetric sensor

CDL actuators

Bonnet switch

Driver’s door key barrel switch

Door switches

Bonnet switch

Battery Backed-Up Sounder (BBUS) or alarm sounder

Security LED

Engine immobilised warning lamp

Direction indicators

ProCarManuals.com

Page 611 of 667

86ELECTRICAL

2

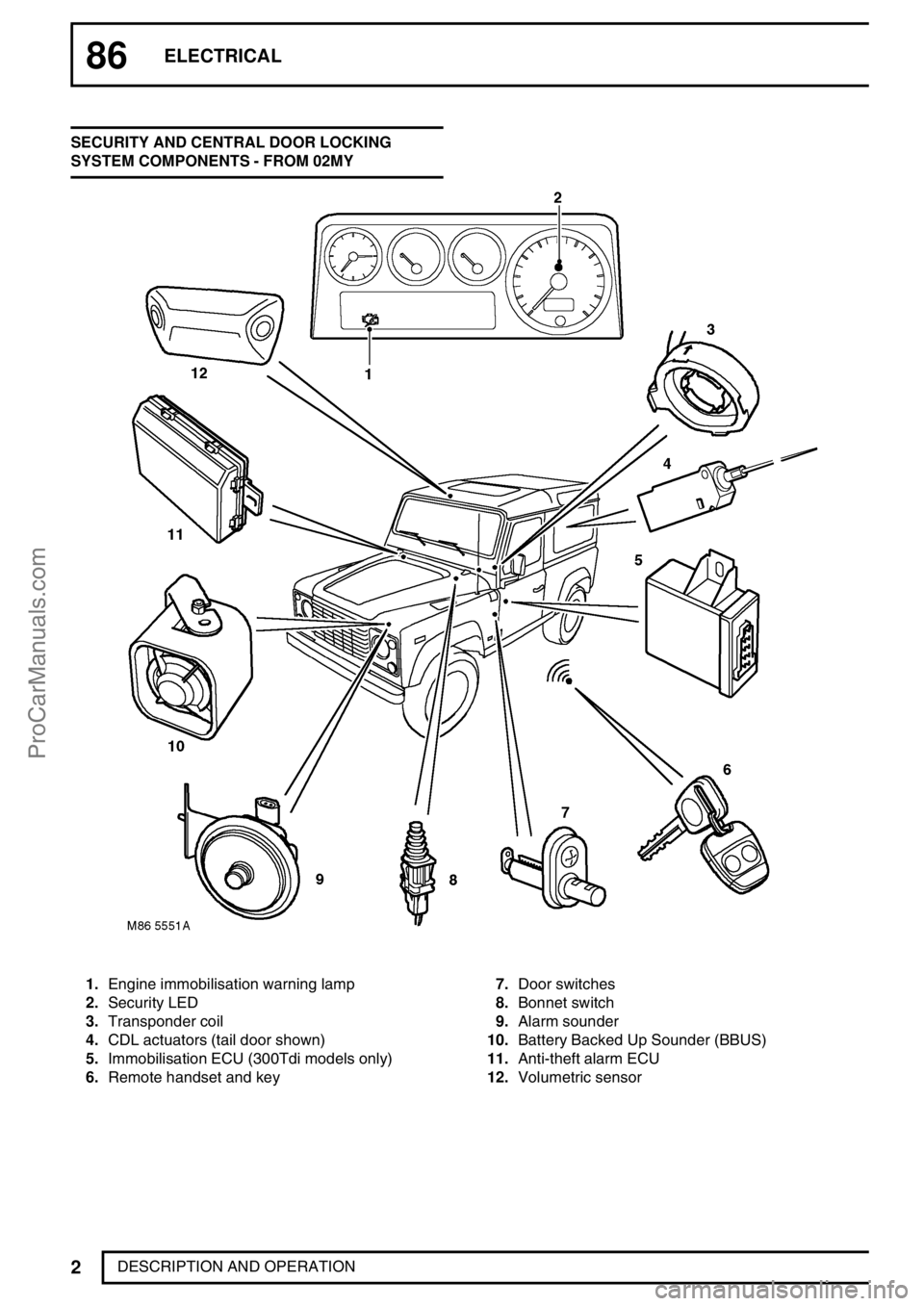

DESCRIPTION AND OPERATION SECURITY AND CENTRAL DOOR LOCKING

SYSTEM COMPONENTS - FROM 02MY

1.Engine immobilisation warning lamp

2.Security LED

3.Transponder coil

4.CDL actuators (tail door shown)

5.Immobilisation ECU (300Tdi models only)

6.Remote handset and key7.Door switches

8.Bonnet switch

9.Alarm sounder

10.Battery Backed Up Sounder (BBUS)

11.Anti-theft alarm ECU

12.Volumetric sensor

ProCarManuals.com

Page 612 of 667

ELECTRICAL

3

DESCRIPTION AND OPERATION ANTI-THEFT ALARM - FROM 02MY

The alarm and immobilisation system on 2002MY Defender is similar to that used on Discovery Series I (LJ)

models from 1996MY. The alarm system comprises the anti-theft alarm ECU, bonnet and door switches and a

volumetric sensor.

Anti-Theft Alarm ECU

The anti-theft alarm ECU is located behind the instrument pack and receives a permanent battery supply via fuses

6 and 7 in the under seat fuse box. The ECU also receives a battery supply via the ignition switch position II and

fuse 1 in the passenger compartment fuse box. The ECU is connected to the various supporting components by

two harness connectors.

The ECU controls the alarm system (perimetric and volumetric security), CDL system, engine immobilisation

system (Td5 only) and various other vehicle functions including direction indicators and interior lamps.

The anti-theft alarm ECU incorporates an RF receiver and antenna for reception of RF signals from the remote

handset for locking and alarm arming. The antenna is unterminated at one end, and for optimum performance the

antenna must not be wound around adjoining harnesses.

The anti-theft alarm ECU operates at one of two frequencies which are identified by a label on the unit. The

frequencies are:

433 MHz - Europe, Gulf States, South Africa

315 MHz - North America, South East Asia, Japan, Australia.

The anti-theft alarm ECU also incorporates an integral inertia switch. In the event of an impact of sufficient severity

to trigger the inertia switch when the ignition is on, the ECU will unlock all doors and operate the hazard warning

lamps. The ECU will remain in this condition for a pre-programmed period of 2 minutes. To reinstate CDL

functionality and to deactivate the hazard warning lamps, the ignition should be turned off and then on after the 2

minute timer has expired.

NOTE: There is a separate inertia switch for fuel cut off.

ProCarManuals.com

Page 614 of 667

ELECTRICAL

5

DESCRIPTION AND OPERATION Perimetric Protection

Perimetric protection is the monitoring of each opening door or bonnet to unauthorised intrusion. The anti-theft

alarm ECU uses the door and bonnet switches described previously to determine when illegal intrusion has

occurred.

If a door/bonnet is left open when the alarm system is armed, the ECU will determine a mislock situation which is

indicated by non operation of the hazard warning lamps. If the drivers door is left open, the security LED in the

instrument pack will be illuminated for the 10 second confirmation period. If any other door or the bonnet is left

open the security LED will remain off for the 10 second confirmation period. After the confirmation period, the LED

will revert to the 1Hz deterrent flash.

If the door/bonnetis subsequently closed, the hazard warning lamps will flash to show that full perimetric protection

is now invoked. The security LED will also resume the 10 second confirmation flash.

If only the bonnet is left open, all doors will have perimetric protection and volumetric protection will also be set. If

a door is left open, the volumetric protection is suspended until that door is subsequently closed.

Volumetric Protection

The vehicle alarm system can be armed with or without volumetric protection activated. If volumetric protection is

required, the vehicle must be locked using the lock button on the remote handset. If volumetric protection is not

required, because a pet is to be left in the vehicle for instance, the vehicle must be locked using the vehicle key in

the drivers door lock.

When the vehicle is locked using the remote handset, the volumetric sensor will wait for a period of 15 seconds

before arming. This allows time for the air in the vehicle to settle and prevent incorrect activation of the alarm.

If volumetric protection is set and there is a disturbance in the vehicle, i.e., a window left open or a moving object

in the vehicle, within the 15 second period, the volumetric sensor will not activate. The sensor must detect no

disturbance for the full 15 second period before arming.

ProCarManuals.com