warning LAND ROVER DEFENDER 1999 Repair Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 448 of 667

BRAKES

1

ADJUSTMENT BRAKE SYSTEM BLEED

Service repair no - 70.25.02

Preparation

WARNING: Before bleeding the brake

system refer to general brake service

practice.See this Section. general brake

service practice

During bleed procedure, brake fluid level must

not be allowed to fall below the MIN mark. Keep

reservoir topped up to the MAX mark.

To bleed the hydraulic circuits, four bleed

nipples are provided, one at each caliper.

There are two methods by which air can be removed

from the braking system:-

1.MANUAL BLEED PROCEDURE

2.PRESSURE BLEED PROCEDURE

Pressure bleed procedure

Purpose designed equipment for pressure filling and

bleeding of hydraulic systems may be used on Land

Rover vehicles. The equipment manufacturers

instructions must be followed and the pressure must

not exceed 4.5 bar, 65 lb/in.

Manual bleed procedure

Equipment required

Clean glass receptacle

Bleed hose

Wrench

Approx. 2 litres (3 pts) brake fluid

Master cylinder bleed

1.Disconnect battery negative lead.

2.Depress brake pedal fully and slowly 5 times.

3.Release pedal and wait 10 seconds.

4.Repeat until firm resistance is felt at the pedal.Complete circuit bleed

1.Disconnect battery negative lead.

2.Fit bleed hose to caliper bleed screw.

3.Dip free end of bleed hose into brake fluid in

bleed bottle.

4.Open bleed nipple.

5.Depress brake pedal fully several times until fluid

is clear of air bubbles.

6.Keeping pedal fully depresses, tighten bleed

nipple then release pedal.

7.Repeat procedure for remaining calipers.

8.Fit bleed screw protection caps.

9.Check/top-up fluid level when bleeding is

complete.

ProCarManuals.com

Page 456 of 667

BRAKES

7

REPAIR Refit

11.Position modulator to mounting bracket and

connect multiplug.

12.Fit modulator to mounting bracket and tighten

nuts to9 Nm (7 lbf.ft).

13.Connect 2 multiplugs to rear of modulator.

14.Remove plugs from brake pipes and modulator.

15.Clean brake pipe unions.

16.Connect brake pipe unions to modulator

ensuring pipes are connected to their correct

ports.

17.Tighten all unions to14 Nm (10 lbf.ft).

18.Bleed brake system.See Adjustment.

NOTE: To ensure correct operation, the

ABS system MUST be tested using

TestBook.BRAKE CALIPER - FRONT

Service repair no - 70.55.02

Remove

1.Loosen front road wheel nuts.

2.Raise front of vehicle.

WARNING: Support on safety stands.

3.Remove road wheel.

4.Remove split pins from pad retaining pins.

5.Remove brake pad retainers and springs.

6.Remove brake pads and shim if fitted.

7.Pull back brake hose shield.

8.Clamp brake hose using a suitable clamp.

9.Position container beneath brake caliper to

collect spillage.

10.Loosen brake pipe union and disconnect from

caliper.

11.Plug brake pipe and caliper connections.

12.Remove 2 bolts securing caliper.

13.Remove brake caliper.

ProCarManuals.com

Page 457 of 667

70BRAKES

8

REPAIR Refit

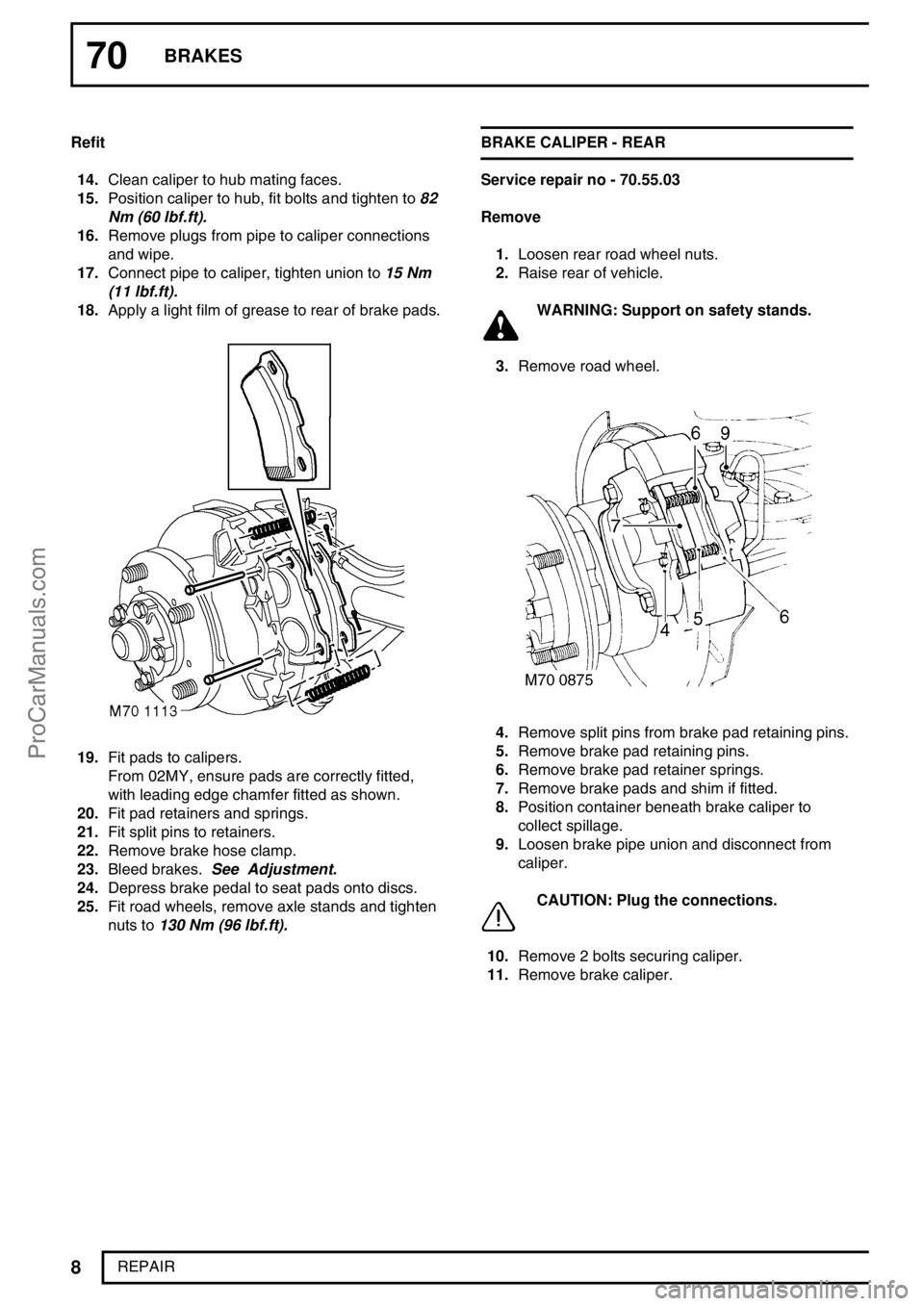

14.Clean caliper to hub mating faces.

15.Position caliper to hub, fit bolts and tighten to82

Nm (60 lbf.ft).

16.Remove plugs from pipe to caliper connections

and wipe.

17.Connect pipe to caliper, tighten union to15 Nm

(11 lbf.ft).

18.Apply a light film of grease to rear of brake pads.

19.Fit pads to calipers.

From 02MY, ensure pads are correctly fitted,

with leading edge chamfer fitted as shown.

20.Fit pad retainers and springs.

21.Fit split pins to retainers.

22.Remove brake hose clamp.

23.Bleed brakes.See Adjustment.

24.Depress brake pedal to seat pads onto discs.

25.Fit road wheels, remove axle stands and tighten

nuts to130 Nm (96 lbf.ft).BRAKE CALIPER - REAR

Service repair no - 70.55.03

Remove

1.Loosen rear road wheel nuts.

2.Raise rear of vehicle.

WARNING: Support on safety stands.

3.Remove road wheel.

4.Remove split pins from brake pad retaining pins.

5.Remove brake pad retaining pins.

6.Remove brake pad retainer springs.

7.Remove brake pads and shim if fitted.

8.Position container beneath brake caliper to

collect spillage.

9.Loosen brake pipe union and disconnect from

caliper.

CAUTION: Plug the connections.

10.Remove 2 bolts securing caliper.

11.Remove brake caliper.

ProCarManuals.com

Page 477 of 667

76CHASSIS AND BODY

8

REPAIR LINER - FRONT WHEEL ARCH

Service repair no - 76.10.48

Remove

1.Raise front of vehicle.

WARNING: Support on safety stands.

2.Remove front wheel.

3.Support axle weight with jack.

4.Remove 6 screws securing damper top cover to

inner wing, remove cover.

5.Remove nut securing damper to top mounting

bracket and collect rubber bush and 2 washers.

6.Remove 4 nuts securing damper to mounting

bracket and collect washers.

7.Remove damper top cover.

8.Remove 4 screws and 3 studs securing liner to

inner wing. Remove liner.

Refit

9.Position liner, secure with screws and studs.

10.Fit damper mounting bracket and tighten nuts.

11.Position damper to mounting bracket, fit rubber

bush and washers and tighten nut.

12.Fit damper cover to inner wing and secure with

screws.

13.Fit road wheel.

14.Remove stands and lower vehicle.

ProCarManuals.com

Page 488 of 667

CHASSIS AND BODY

19

REPAIR LOWER FASCIA PANEL - UP TO 02MY

Service repair no - 76.46.05

Remove

1.Disconnect battery negative lead.

2.Remove steering wheel.See STEERING,

Repair.

3.Remove 7 screws securing nacelle to steering

column.

4.Remove 2 halves of nacelle from steering

column.

5.Remove instrument pack.See ELECTRICAL,

Repair.

6.Remove 3 screws securing heater control cable

assembly to end of fascia.

7.Release heater control cable assembly from

fascia and move aside.

8.Release HRW, Rear Fog Guard Lamp, and

Hazard Warning switches from fascia.

9.Disconnect multiplugs and Lucars from switches.

10.Collect switches.

11.Remove locking rings from both front speakers.

12.Remove 4 screws securing each speaker to

fascia.

13.Disconnect multiplugs from speakers and

remove both front speakers.

ProCarManuals.com

Page 492 of 667

CHASSIS AND BODY

23

REPAIR 59.Fit radio housing to fascia and secure with trim

studs.

60.Position radio to fascia and connect multiplugs

and aerial.

61.Fit radio to fascia.

62.Fit crash pad to fascia and secure with screws.

63.Fit both demister vents to crash pad and secure

with screws.

64.Fit grab handle to fascia and secure with screws.

65.Fit Land Rover decal to grab handle.

66.Position both front speakers to fascia and

connect multiplugs.

67.Fit speakers to fascia and secure with screws.

68.Fit locking rings to speakers.

69.Connect multiplugs and Lucars to HRW, Rear

Fog Guard Lamp, and Hazard Warning

Switches.

70.Fit switches to fascia.

71.Position heater controls to fascia and secure

with screws.

72.Fit instrument pack.See ELECTRICAL,

Repair.

73.Fit 2 halves of nacelle to steering column and

secure with screws.

74.Fit steering wheel.See STEERING, Repair.

75.Reconnect battery negative lead.PANEL - MOUNTING - FRONT DOOR - FROM 02MY

Service repair no - 76.11.28

Remove

1.Remove plastic sheet.See this Section.

2.Lower glass and remove 2 bolts securing door

glass to regulator.

3.Release glass from regulator, raise and wedge

in raised position.

ProCarManuals.com

Page 496 of 667

CHASSIS AND BODY

27

REPAIR FACIA CONSOLE - FROM 02MY

Service repair no - 76.25.03

Remove

1.Disconnect battery earth lead.See

ELECTRICAL, Repair.

2.Remove radio.See ELECTRICAL, Repair.

3.Remove 4 screws securing instrument pack and

release pack from fascia.

4.Disconnect 2 multiplugs from warning lamp

panel.

5.Disconnect instrument pack multiplug from main

harness.

6.Remove instrument pack.

7.Remove 3 screws securing heater control and

release control from fascia.

8.Carefully prise Land Rover decal from grab

handle.

9.Remove 2 screws securing grab handle and

remove handle.

10.Remove 4 screws and remove demister vents.

ProCarManuals.com

Page 499 of 667

76CHASSIS AND BODY

30

REPAIR Refit

7.Insert glass into channels and carefully push to

top of frame.

8.Secure glass channels with screws. Ensure

screw heads are down below bottom of channels

to prevent damage to glass.

9.Fit inner and outer waist seal to door.

10.Fit check strap.

11.Fit check strap torsion bar and tighten nuts to10

Nm (7 lbf.ft).

12.Fit rear door mounting panel.See this Section.GLASS/SEALING RUBBER - TAIL DOOR - FROM

02MY

Service repair no - 76.31.22

Remove

1.Remove spare wheel from tail door.

2.Raise nut cover, remove nut and release wiper

arm.

3.Open rear door.

4.Remove CHMSL assembly.See

ELECTRICAL, Repair.

5.Disconnect 4 Lucar connections.

6.With assistance, from inside of vehicle apply

pressure to glass, relieve seal lip and carefully

remove glass.

WARNING: Wear suitable eye protection

when removing and refitting glass.

ProCarManuals.com

Page 535 of 667

77PANEL REPAIRS

10

SEALING AND CORROSION PROTECTION Underbody Protection Repairs

When body repairs are carried out, always ensure that

full sealing and corrosion protection treatments are

restored. This applies both to the damaged area, and

also to areas where protection has been indirectly

impaired as a result of accident damage or repair

operations.

Prior to straightening out or panel beating, remove all

corrosion protection material in the damaged area.

This applies in particular to panels coated with wax,

PVC underbody sealer, sound deadening pads etc.

WARNING: DO NOT use oxy-acetylene gas

equipment to remove corrosion prevention

materials. Large amounts of fumes and

gases are liberated by these materials when they

burn.

Equipment for the removal of tough anti-corrosion

sealers offers varying degrees of speed and

effectiveness. The compressed air-operated scraper

(NOT an air chisel) offers a relatively quiet mechanical

method of removal using an extremely rapid

reciprocating action. During use, direct the operating

end of the tool along the work surface.

The most common method is by the use of a hot air

blower with integral scraper.

CAUTION: High temperatures can be

generated with this equipment which may

cause fumes. Always exercise care in its

use.

Another tool, and one of the most efficient methods, is

the rapid-cutting’hot knife’. This tool uses a wide

blade and is quick and versatile, able to be used

easily in profiled sections where access is otherwise

awkward.

Use the following procedure when repairing

underbody coatings:

1.Remove existing underbody coatings.2.After panel repair, clean the affected area with a

solvent wipe, and treat bare metal with an etch

phosphate material.

3.Re-prime the affected area.DO NOT under any

circumstances apply underbody sealer

directly to bare metal surfaces.

4.Replace all heat-fusible plugs which have been

disturbed. Use rubber grommets of equivalent

size if plugs are not available, but ensure that

they are embedded in sealer.

5.Mask off all mounting faces from which

mechanical components, hoses and pipe clips,

have been removed. Underbody sealer must be

appliedbeforesuch components are refitted.

6.Brush sealer into all exposed seams.

7.Spray the affected area with an approved

service underbody sealer.

8.Remove masking from component mating faces,

and touch-in where necessary. Allow adequate

drying time before applying underbody wax.

Underbody Wax

After refitting mechanical components, including

hoses, pipes and small fixtures, mask off the brake

discs and apply a coat of approved underbody wax.

NOTE: Where repairs include the

application of finish paint coats in the

areas requiring underbody wax, paint

operations must be carried out BEFORE wax

application.

Underbonnet Wax

Where repairs have involved replacement of engine

bay panels, treat the entire engine compartment

including all components, clips and small fixtures with

an approved underbonnet lacquer or wax.

Proprietary Anti-Corrosion Treatments

The application of proprietary anti-corrosion

treatments in addition to the factory-applied treatment

could invalidate the Corrosion Warranty and should be

discouraged. This does not apply to approved,

compatible, preservative waxes which may be applied

on top of existing coatings.

ProCarManuals.com

Page 560 of 667

PANEL REPAIRS

1

PROCEDURES GENERAL WELDING PRECAUTIONS

The following pages show the procedures to follow

when using welding for repairs. No resistance spot

welds have been used in any of the repairs.

The Aluminium alloy used on all Defender models is a

combination of Aluminium and Magnesium.

When converting a MIG welder for use on Aluminium

it is essential the following components are changed.

The materials shown in brackets are the correct

materials to use:

Torch liner (Teflon or Carbon Fibre)

Contact tip

Feed rollers/wheels

Correct Filler wire (combination of

Aluminium and Magnesium)

Shielding gas (Argon)

When carrying out welding operations the following

criteria must be observed:

Where resistance spot welds have been

used in production, these must be replaced

with either MIG plug welds or rivets.

To replace each production spot weld an 8

mm (0.31 in) hole must be drilled and/or

punched, and a MIG weld then made in its

place. The number of plug welds must

match exactly the number of spot welds

which have been removed.

Where holes are left in an existing panel

after removal of the spot welds, a single

MIG plug weld will be made in each hole as

appropriate.

When MIG welding ensure the correct wire

is used.

The replacement welds in the welding

diagrams are denoted by the following

symbols:

A. MIG Plug welds

B. MIG seam weld

Seat Belt Anchorages

Seat belt anchorages are safety critical. When making

repairs in these areas it is essential to follow design

specifications.

Where possible, the original production assembly

should be used, complete with its seat belt

anchorages, or the cut line should be so arranged that

the original seatbelt anchorage is not disturbed.

All welds within 250mm (9.9in.) of seat belt

anchorages must be carefully checked for weld

quality, including spacing of spot welds. A crack

detection process must be carried out in these areas.

WARNING: Body parts incorporating seat

belt anchorages MUST be renewed

completely if damaged beyond repair, as

the welds in these areas are safety critical and

cannot be disturbed.

ProCarManuals.com