warning LAND ROVER DEFENDER 1999 Owner's Manual

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 145 of 667

12ENGINE

20

REPAIR Refit

9.Fit shield to mounting ensuring cut-away portion

is correctly aligned.

10.Fit mounting and mounting bracket.

11.Fit mounting bracket to cylinder block bolts and

tighten to48 Nm (35 lbf.ft).

12.Fit nuts securing mounting to chassis and tighten

to85 Nm (63 lbf.ft).

13.Fit mounting to mounting bracket nut and tighten

to85 Nm (63 lbf.ft).

14.Remove engine support chains.

15.Clean oil filter adaptor housing and mating face.

16.Fit oil filter adaptor housing using a new gasket

and tighten bolts to25 Nm (18 lbf.ft).

17.Fit centrifuge assembly.See this Section.MOUNTING - FRONT - RH

Service repair no - 12.45.03

Remove

1.Remove engine acoustic cover.See this

Section.

2.Remove fixings, remove battery cover.

3.Disconnect battery negative lead.

4.Raise front of vehicle.

WARNING: Support on safety stands.

5.Remove 4 bolts, move fuel cooler to one side.

6.Fit suitable lifting chains to support engine.

7.Remove 2 nuts securing engine mounting to

chassis.

8.Remove 4 bolts securing engine mounting

bracket to cylinder block.

9.Remove nut securing mounting to mounting

bracket.

10.Remove mounting and mounting bracket.

ProCarManuals.com

Page 181 of 667

12ENGINE

22

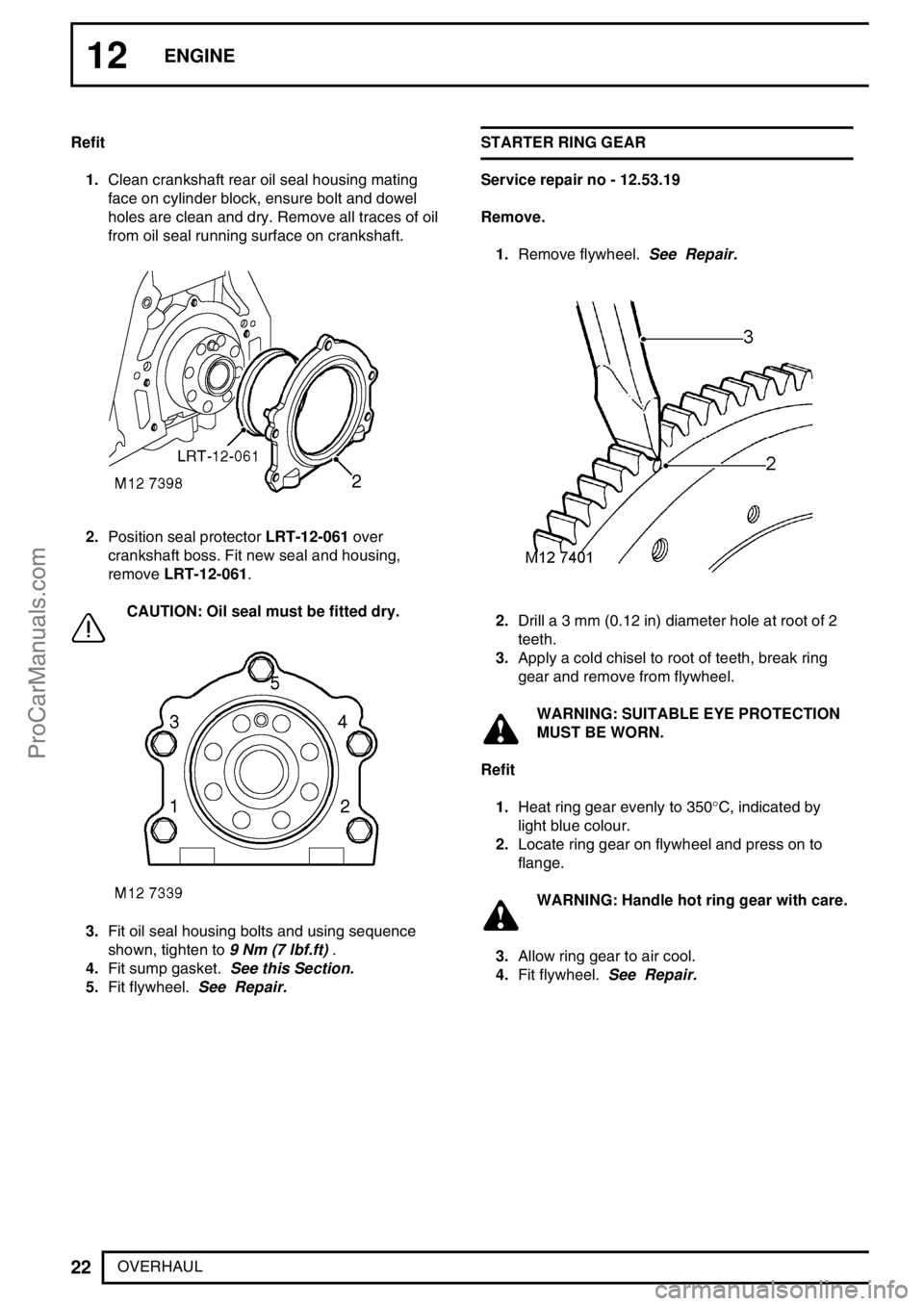

OVERHAUL Refit

1.Clean crankshaft rear oil seal housing mating

face on cylinder block, ensure bolt and dowel

holes are clean and dry. Remove all traces of oil

from oil seal running surface on crankshaft.

2.Position seal protectorLRT-12-061over

crankshaft boss. Fit new seal and housing,

removeLRT-12-061.

CAUTION: Oil seal must be fitted dry.

3.Fit oil seal housing bolts and using sequence

shown, tighten to9 Nm (7 lbf.ft).

4.Fit sump gasket.See this Section.

5.Fit flywheel.See Repair.STARTER RING GEAR

Service repair no - 12.53.19

Remove.

1.Remove flywheel.See Repair.

2.Drill a 3 mm (0.12 in) diameter hole at root of 2

teeth.

3.Apply a cold chisel to root of teeth, break ring

gear and remove from flywheel.

WARNING: SUITABLE EYE PROTECTION

MUST BE WORN.

Refit

1.Heat ring gear evenly to 350°C, indicated by

light blue colour.

2.Locate ring gear on flywheel and press on to

flange.

WARNING: Handle hot ring gear with care.

3.Allow ring gear to air cool.

4.Fit flywheel.See Repair.

ProCarManuals.com

Page 185 of 667

12ENGINE

26

OVERHAUL Refit

1.Clean mating faces of oil pump, stiffener plate

assembly and cylinder block; ensure bolt and

dowel holes are clean and dry.

2.Lubricate a new’O’ring with engine oil and fit to

oil pump housing outlet.

3.Position oil pump and stiffener plate assembly

on to cylinder block ensuring 2 dowels are

correctly located.

4.Fit new bolts and using sequence shown, tighten

to13 Nm (10 lbf.ft).

5.Lubricate a new’O’ring with engine oil and fit to

oil pick-up strainer.

6.Clean threads of oil pick-up strainer Torx screws

and apply Loctite 242 to threads.

7.Fit oil pick-up strainer, fit Torx screws and

tighten to10 Nm (8 lbf.ft).

8.Position oil pump drive sprocket to chain and oil

pump ensuring that the’D’shape on the drive

sprocket is located on the flat on the oil pump

drive shaft.

9.Clean threads of oil pump drive sprocket

retaining bolt and apply Loctite 242 to threads.

10.Fit oil pump drive sprocket bolt and tighten to25

Nm (18 lbf.ft).

11.Fit sump gasket.See this Section.TIMING CHAIN AND SPROCKETS

Service repair no - 12.65.13.01

Remove

1.Remove cylinder head gasket.See this

Section.

CAUTION: If timing chain tensioner is to

be replaced, ensure tensioner is correct

for engine. Tensioner bodies are colour

coded as follows:- Engine Serial No. Prefixes 10P

to 14P - BLACK with, additionally, on later

engines, YELLOW on tensioner hex. head. Engine

Serial No. Prefixes 15P to 19P:- Body is coloured

YELLOW. Later tensioners may be fitted to early

engines provided that the modified adjustable

guide is also fitted.

2.Remove 3 bolts securing crankshaft damper to

pulley, remove damper.

3.PositionLRT-51-003to crankshaft pulley and

secure with 2 bolts.

4.Using assistance, restrain engine and remove

crankshaft pulley bolt; discard bolt.

WARNING: CRANKSHAFT BOLT IS

TIGHTENED TO 460 Nm (340 lbf.ft),

ENSURE THAT ENGINE IS ADEQUATELY

RESTRAINED.

5.Remove crankshaft pulley, remove bolts and

tool.

6.Remove sump gasket.See this Section.

ProCarManuals.com

Page 189 of 667

12ENGINE

30

OVERHAUL

22.Fit oil seal guide, from seal kit, over end of

crankshaft.

23.Fit new oil seal into timing cover using

LRT-12-156.

CAUTION: Oil seal must be fitted dry.

24.RemoveLRT-12-156and oil seal guide.

25.Fit crankshaft pulley, fit crankshaft pulley bolt.

26.FitLRT-51-003to crankshaft pulley and secure

with 2 bolts.

27.Using assistance, restrain engine and using a

torque multiplier, tighten crankshaft bolt to460

Nm (340 lbf.ft).

WARNING: DUE TO THE HIGH TORQUE

LOADING REQUIRED, IT IS ESSENTIAL

THAT ENGINE IS ADEQUATELY

RESTRAINED.

28.RemoveLRT-51-003.

29.Position damper to crankshaft pulley, fit 3 bolts

and tighten to80 Nm (60 lbf.ft).

30.Fit sump gasket.See this Section.

31.Fit cylinder head gasket.See this Section.BEARINGS - CONNECTING RODS

Service repair no - 12.17.16.01

Remove

1.Remove oil pump.See this Section.

2.Mark cylinder reference number on each

connecting rod big-end bearing cap.

3.Make suitable alignment marks between each

big-end bearing cap and connecting rod.

CAUTION: Due to the’fracture split’

method of manufacturing connecting rods

and bearing caps, incorrect fitting of cap

to connecting rod will damage mating faces and

necessitate replacement of connecting rod

assembly.

4.Rotate crankshaft clockwise until No. 1 big-end

is at BDC.

5.Remove and discard 2 bolts securing No. 1

big-end bearing cap.

6.Remove bearing cap, remove and discard

big-end bearing shell.

7.Push connecting rod up cylinder bore until rod is

clear of crankshaft journal.

CAUTION: Ensure that connecting rod

does not contact cylinder bore or oil squirt

jet and piston does not contact the valves

or EUI’s if the cylinder head is fitted.

ProCarManuals.com

Page 222 of 667

18 - ENGINE MANAGEMENT SYSTEM

CONTENTS

Page

DESCRIPTION AND OPERATION

COMPONENT LOCATION 2...................................................................................

DESCRIPTION 5.....................................................................................................

ENGINE CONTROL MODULE (ECM) 6.................................................................

SENSOR - MASS AIR FLOW (MAF) 7....................................................................

SENSOR - AMBIENT AIR PRESSURE AND 8.......................................................

SENSOR - MANIFOLD ABSOLUTE PRESSURE 9................................................

SENSOR - ENGINE COOLANT TEMPERATURE 11.............................................

SENSOR - CRANKSHAFT SPEED AND 12...........................................................

SENSOR - THROTTLE POSITION (TP) 14............................................................

SENSOR - THROTTLE POSITION (TP) 15............................................................

ELECTRONIC UNIT INJECTOR (EUI) 18...............................................................

SENSOR - FUEL TEMPERATURE (FT) 20............................................................

RELAY - FUEL PUMP 21........................................................................................

RELAY - MAIN 21...................................................................................................

SWITCH - BRAKE PEDAL 22.................................................................................

SWITCH - CLUTCH PEDAL 22...............................................................................

MODULATOR - EXHAUST GAS REGULATOR (EGR) 23.....................................

WARNING LAMP - GLOW PLUG 23......................................................................

GLOW PLUGS 24...................................................................................................

TURBOCHARGER 26.............................................................................................

INTERCOOLER 27.................................................................................................

OPERATION 28......................................................................................................

REPAIR

ENGINE CONTROL MODULE (ECM) 1.................................................................

SENSOR - ENGINE COOLANT TEMPERATURE (ECT) 1....................................

SENSOR - CRANKSHAFT SPEED AND POSITION (CKP) 2................................

ProCarManuals.com

Page 228 of 667

ENGINE MANAGEMENT SYSTEM

5

DESCRIPTION AND OPERATION DESCRIPTION

General

An engine control module (ECM) controls the five cylinder direct injection diesel engine, and works on the drive by

wire principal. This means there is no throttle cable, the ECM controls the drivers needs via a signal from the

Throttle Position (TP) sensor on the throttle pedal.

The ECM is a full authoritative diesel specific microprocessor that also incorporates features for air conditioning. In

addition, the ECM supplies output control for the Exhaust Gas Recirculation (EGR) and turbocharger boost

pressure. The ECM has a self diagnostic function, which is able to provide backup strategies for most sensor

failures.

The ECM processes information from the following input sources:

Mass Air Flow (MAF) sensor.

Ambient Air Pressure (AAP) sensor.

Manifold Absolute Pressure (MAP) / Inlet Air Temperature (IAT) sensor.

Engine Coolant Temperature (ECT) sensor.

Crankshaft Speed and Position (CKP) sensor.

Throttle Position (TP) sensor.

Fuel Temperature (FT) sensor.

Air conditioning request.

Air conditioning fan request.

Brake pedal switch.

Clutch pedal switch.

The input from the sensors constantly updates the ECM with the current operating condition of the engine. Once

the ECM has compared current information with stored information within its memory, it can make any adjustment

it requires to the operation of the engine via the following:

Air conditioning clutch relay.

Air conditioning cooling fan relay.

Electronic vacuum regulator solenoid.

Fuel pump relay.

Glow plug warning lamp.

Glow plugs.

Fuel injectors.

Main relay.

Turbocharger wastegate modulator.

Temperature gauge.

The ECM interfaces with the following:

Serial communication link.

Instrument pack.

ProCarManuals.com

Page 234 of 667

ENGINE MANAGEMENT SYSTEM

11

DESCRIPTION AND OPERATION SENSOR - ENGINE COOLANT TEMPERATURE

(ECT)

The ECT sensor is located in the coolant outlet elbow on top of the engine. It provides the ECM with engine

coolant temperature information. The ECM uses this information for the following functions:

Fuelling calculations.

Temperature gauge.

To limit engine operation if coolant temperature is to high.

Cooling fan operation.

Glow plug operating time.

The ECT works as an NTC sensor. As temperature rises, the resistance in the sensor decreases, as temperature

decreases, the resistance in the sensor increases. The ECM compares the voltage signal to stored values and

compensates fuel delivery to ensure optimum driveability at all times.

Inputs / Outputs

The ECT sensor (C0169-2) is provided a feed by the ECM (C0158-7) on a pink/green wire. The sensor is provided

an earth path (C0169-1) via the ECM (C0158-18) on a pink/black wire.

The ECT can fail or supply an incorrect signal if one or more of the following occurs:

Sensor open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Incorrect mechanical fitting.

Signal fixed above 40°C (104°F) not detected.

Signal fixed below 40°C (104°F) not detected.

In the event of an ECT sensor failure, any of the following symptoms may be observed:

Difficult cold start.

Difficult hot start.

Driveability concerns.

Instrument pack warning lamp illuminated.

Temperature gauge reads excessively hot.

Temperature gauge reads excessively cold.

In the event of a component failure the ECM calculates coolant temperature from the fuel temperature signal. If

this occurs, the limit of engine operation if coolant temperature becomes too high becomes inoperative.

ProCarManuals.com

Page 246 of 667

ENGINE MANAGEMENT SYSTEM

23

DESCRIPTION AND OPERATION MODULATOR - EXHAUST GAS REGULATOR (EGR)

The EGR modulator is located on the RH side inner front wing. It regulates the vacuum source to the EGR valve

allowing it to open or close. The ECM utilises the EGR modulator to control the amount of exhaust gas being

recirculated in order to reduce exhaust emissions and combustion noise. Optimum EGR is usually obtained when

the vehicle is operating at light throttle openings, and the vehicle is cruising at approximately 2000 to 3000

rev/min.

Input / Output

The EGR modulator (C0191-1) receives a feed from the main relay (C0063-87) on a brown/orange wire via header

294. The earth path for the modulator (C0191-2) is controlled by the ECM (C0158-3) on a blue wire. The length of

time the ECM supplies an earth is how long the exhaust gases are allowed to recirculate. The ECM decides how

long to supply the earth by looking at engine temperature and engine load.

The EGR modulator can fail in one or more of the following ways:

Solenoid open circuit.

Short circuit to vehicle supply.

Short circuit to earth.

In the event of an EGR modulator failure, the EGR system will become inoperative.

WARNING LAMP - GLOW PLUG

The glow plug warning lamp is located in the instrument pack. It illuminates to alert the driver that the glow plugs

are being heated prior to the engine being started. The length of time that the lamp illuminates and the glow plugs

are operating prior to cranking is the pre-heat period. The length of time of this period is determined by the ECT

sensor signal, controlled by the ECM.

ProCarManuals.com

Page 257 of 667

19FUEL SYSTEM

2

DESCRIPTION AND OPERATION DESCRIPTION

General

The fuel delivery system comprises a fuel tank, fuel pump, fuel pressure regulator, five injectors and a fuel filter.

The system is controlled by the ECM, which energises the fuel pump relay and controls the operation and timing

of each injector solenoid.

Unlike other Diesel engines, the Td5 has no injection pump. The diesel direct injection system receives fuel at

pressure from a two stage fuel pump located in the fuel tank. The system incorporates a fuel return to the fuel

pump, via a fuel cooler attached to the inlet manifold, and a fuel filter. A fuel pressure regulator is located in a

housing on the rear of the cylinder head. The regulator maintains the fuel delivered to the injectors at a constant

pressure and returns excess fuel back to the fuel filter and pump via the fuel cooler.

A fuel filter is positioned on the chassis longitudinal, below the RH rear wheel arch. The fuel feed and return to and

from the engine passes through the filter. The filter also incorporates a water sensor, which illuminates a warning

lamp in the instrument pack.

A moulded fuel tank is located at the rear underside of the vehicle between the chassis longitudinals. The tank

provides the attachment for the fuel pump and the fuel gauge sender unit, which is located inside the tank.

Fuel Tank and Breather

The fuel tank and breather system is a major part of the fuel delivery system. The fuel tank and breathers are

located at the rear of the vehicle between the chassis longitudinals.

Fuel Tank

The moulded fuel tank is made from High Molecular Weight (HMW) High Density Polyethylene (HDPE), and is

manufactured using a proportion of recycled plastic.

The tank is held in position by a metal cradle which is secured to the chassis cross members by four bolts, two

holding the front of the cradle in position, two holding the rear. The fuel tank has a useable capacity of 75 litres

(16.5 gallons).

An aperture in the top surface of the tank allows for the fitment of the fuel pump and fuel gauge sender unit, which

is retained with a locking ring. A reflective metallic covering is attached to the tank with three scrivets to shield the

tank from heat generated by the exhaust system.

Fuel Tank Breather System

The fuel tank filler tube incorporates a tank vent which allows air and fuel vapour displaced from the tank when

filling to vent to atmosphere via the filler neck.

A breather spout within the tank controls the tank’Full’height. When fuel covers the spout it prevents fuel vapour

and air from escaping from the tank. This causes the fuel to’back-up’in the filler tube and shuts off the filler gun.

The position of the spout ensures that when the filler gun shuts off, a vapour space of approximately 10% of the

tanks total capacity remains. The vapour space ensures that the Roll Over Value (ROV) is always above the fuel

level and vapour can escape and allow the tank to breathe.

The ROV is welded to the top surface of the tank. It is connected by a tube to the filler tube, which in turn is

connected to the atmospheric vent pipe. The ROV allows fuel vapour to pass through it during normal vehicle

operation. In the event of the vehicle being overturned the valve shuts off, sealing the tank and preventing fuel

from spilling from the atmospheric vent pipe.

ProCarManuals.com

Page 265 of 667

19FUEL SYSTEM

10

DESCRIPTION AND OPERATION WATER SENSOR

The water sensor has a three pin electrical connector. When the sensor detects water in the fuel filter it illuminates

a warning lamp in the instrument pack.

The water sensor attachment thread has a slot machined down one side. The filter can be purged of water by

partially unscrewing the sensor which aligns the slot in the threads with a corresponding hole in the sensor. When

aligned, water and fuel can flow down the slot and flows from a small cast tube on the side of the sensor.

Re-tightening the sensor mis-aligns the slot and stops the flow of fuel.

The sensor operates by measuring the resistance between its two electrodes, which are submerged in fuel, and

activated by the presence of water. When the ignition switch is moved to position’II’, the warning lamp will

illuminate for approximately 2 seconds to check warning lamp functionality.

When the filter is full with fuel and no water is present, the resistance of the Diesel fuel will show a reading of 15

mA maximum on the feed wire to the instrument pack. When sufficient water surrounds both electrodes, the

resistance of the water will show a reading of 130 mA maximum. This will supply sufficient voltage to the

instrument pack to illuminate the warning lamp, and alert the driver to the presence of water in the fuel system.

ProCarManuals.com