lock LAND ROVER DEFENDER 1999 Manual Online

[x] Cancel search | Manufacturer: LAND ROVER, Model Year: 1999, Model line: DEFENDER, Model: LAND ROVER DEFENDER 1999Pages: 667, PDF Size: 8.76 MB

Page 192 of 667

ENGINE

33

OVERHAUL Cylinder bores - Inspection

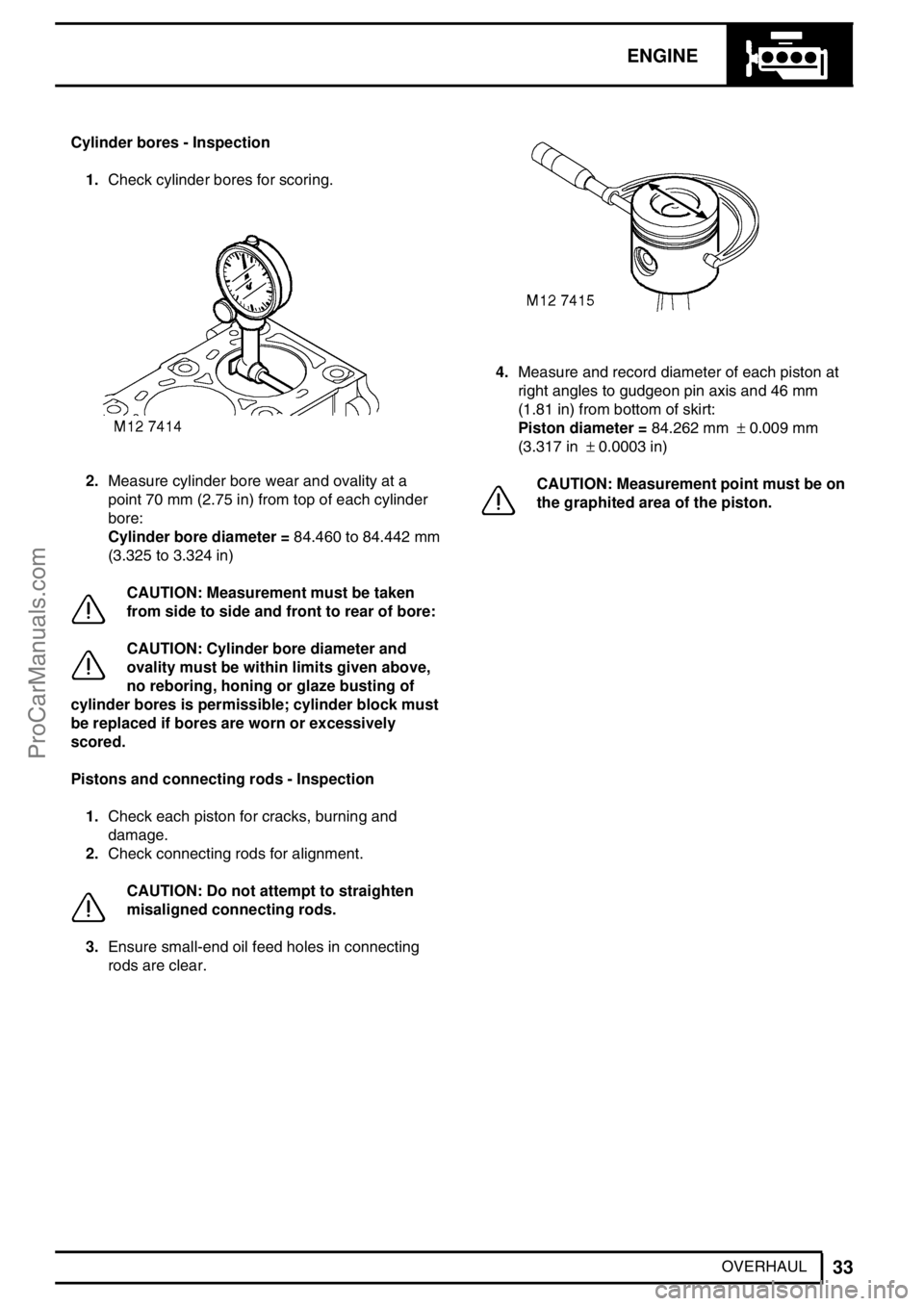

1.Check cylinder bores for scoring.

2.Measure cylinder bore wear and ovality at a

point 70 mm (2.75 in) from top of each cylinder

bore:

Cylinder bore diameter =84.460 to 84.442 mm

(3.325 to 3.324 in)

CAUTION: Measurement must be taken

from side to side and front to rear of bore:

CAUTION: Cylinder bore diameter and

ovality must be within limits given above,

no reboring, honing or glaze busting of

cylinder bores is permissible; cylinder block must

be replaced if bores are worn or excessively

scored.

Pistons and connecting rods - Inspection

1.Check each piston for cracks, burning and

damage.

2.Check connecting rods for alignment.

CAUTION: Do not attempt to straighten

misaligned connecting rods.

3.Ensure small-end oil feed holes in connecting

rods are clear.

4.Measure and record diameter of each piston at

right angles to gudgeon pin axis and 46 mm

(1.81 in) from bottom of skirt:

Piston diameter =84.262 mm±0.009 mm

(3.317 in±0.0003 in)

CAUTION: Measurement point must be on

the graphited area of the piston.

ProCarManuals.com

Page 193 of 667

12ENGINE

34

OVERHAUL

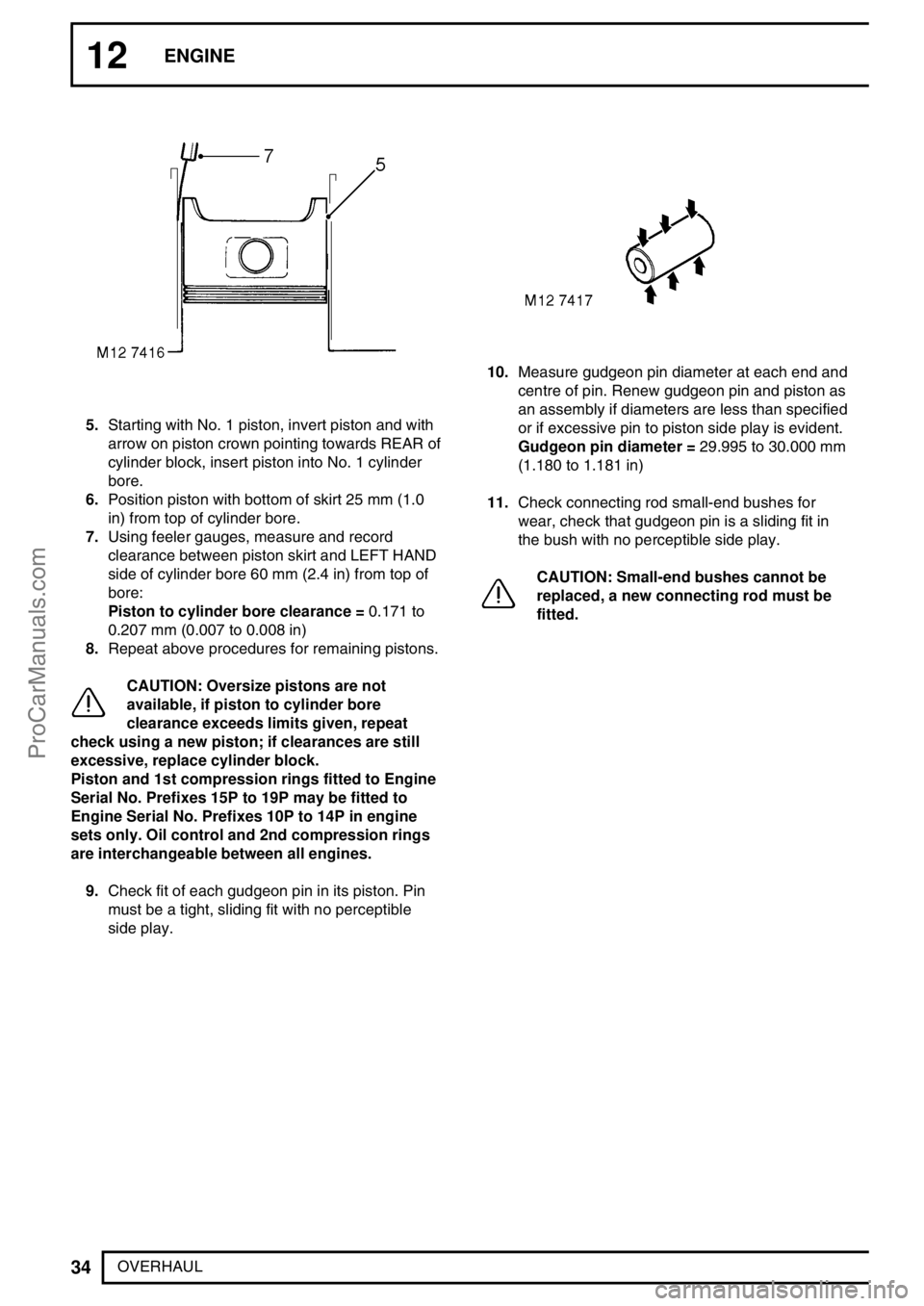

5.Starting with No. 1 piston, invert piston and with

arrow on piston crown pointing towards REAR of

cylinder block, insert piston into No. 1 cylinder

bore.

6.Position piston with bottom of skirt 25 mm (1.0

in) from top of cylinder bore.

7.Using feeler gauges, measure and record

clearance between piston skirt and LEFT HAND

side of cylinder bore 60 mm (2.4 in) from top of

bore:

Piston to cylinder bore clearance =0.171 to

0.207 mm (0.007 to 0.008 in)

8.Repeat above procedures for remaining pistons.

CAUTION: Oversize pistons are not

available, if piston to cylinder bore

clearance exceeds limits given, repeat

check using a new piston; if clearances are still

excessive, replace cylinder block.

Piston and 1st compression rings fitted to Engine

Serial No. Prefixes 15P to 19P may be fitted to

Engine Serial No. Prefixes 10P to 14P in engine

sets only. Oil control and 2nd compression rings

are interchangeable between all engines.

9.Check fit of each gudgeon pin in its piston. Pin

must be a tight, sliding fit with no perceptible

side play.

10.Measure gudgeon pin diameter at each end and

centre of pin. Renew gudgeon pin and piston as

an assembly if diameters are less than specified

or if excessive pin to piston side play is evident.

Gudgeon pin diameter =29.995 to 30.000 mm

(1.180 to 1.181 in)

11.Check connecting rod small-end bushes for

wear, check that gudgeon pin is a sliding fit in

the bush with no perceptible side play.

CAUTION: Small-end bushes cannot be

replaced, a new connecting rod must be

fitted.

ProCarManuals.com

Page 194 of 667

ENGINE

35

OVERHAUL Piston ring gaps - Checking

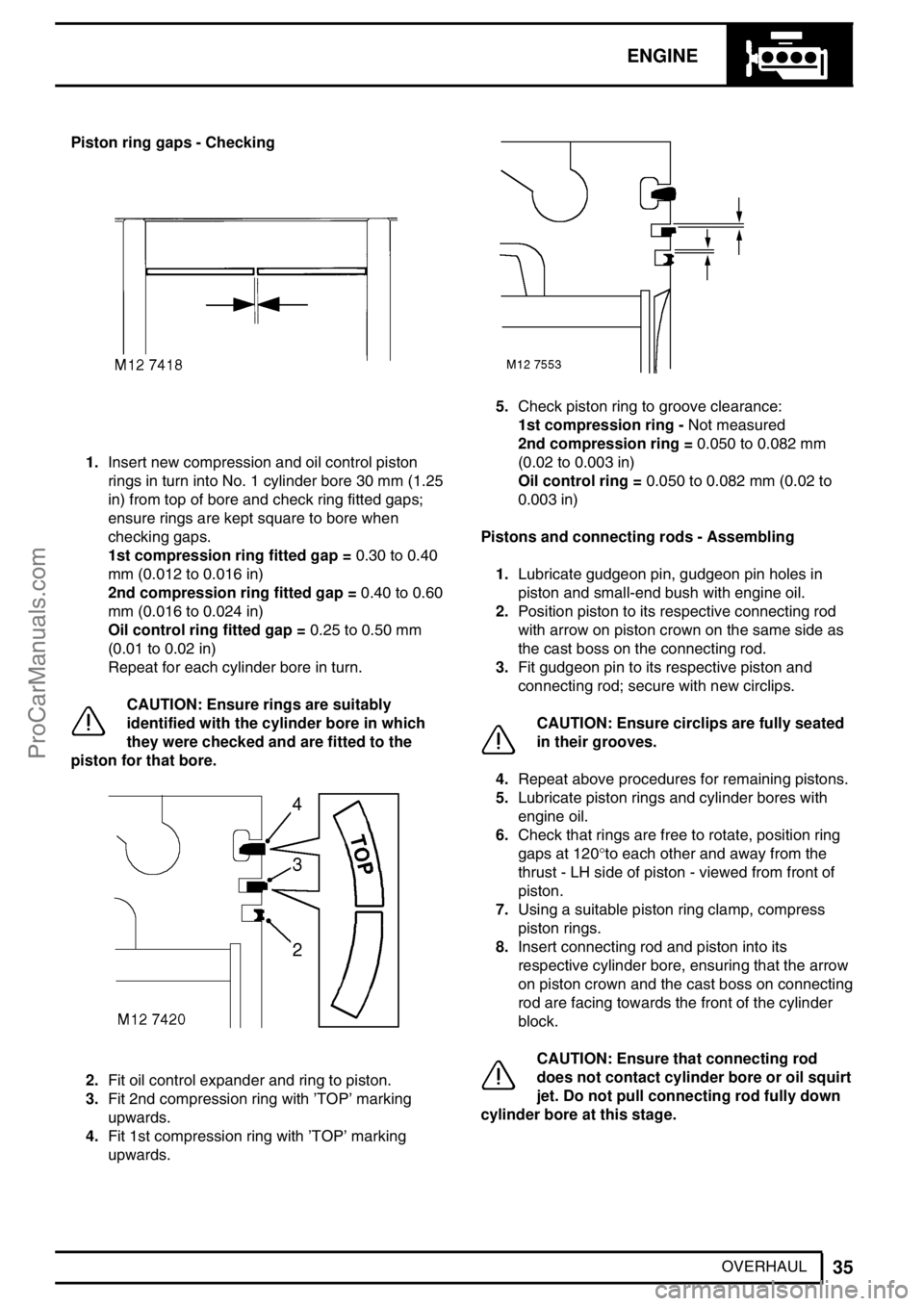

1.Insert new compression and oil control piston

rings in turn into No. 1 cylinder bore 30 mm (1.25

in) from top of bore and check ring fitted gaps;

ensure rings are kept square to bore when

checking gaps.

1st compression ring fitted gap =0.30 to 0.40

mm (0.012 to 0.016 in)

2nd compression ring fitted gap =0.40 to 0.60

mm (0.016 to 0.024 in)

Oil control ring fitted gap =0.25 to 0.50 mm

(0.01 to 0.02 in)

Repeat for each cylinder bore in turn.

CAUTION: Ensure rings are suitably

identified with the cylinder bore in which

they were checked and are fitted to the

piston for that bore.

2.Fit oil control expander and ring to piston.

3.Fit 2nd compression ring with’TOP’marking

upwards.

4.Fit 1st compression ring with’TOP’marking

upwards.

5.Check piston ring to groove clearance:

1st compression ring -Not measured

2nd compression ring =0.050 to 0.082 mm

(0.02 to 0.003 in)

Oil control ring =0.050 to 0.082 mm (0.02 to

0.003 in)

Pistons and connecting rods - Assembling

1.Lubricate gudgeon pin, gudgeon pin holes in

piston and small-end bush with engine oil.

2.Position piston to its respective connecting rod

with arrow on piston crown on the same side as

the cast boss on the connecting rod.

3.Fit gudgeon pin to its respective piston and

connecting rod; secure with new circlips.

CAUTION: Ensure circlips are fully seated

in their grooves.

4.Repeat above procedures for remaining pistons.

5.Lubricate piston rings and cylinder bores with

engine oil.

6.Check that rings are free to rotate, position ring

gaps at 120°to each other and away from the

thrust - LH side of piston - viewed from front of

piston.

7.Using a suitable piston ring clamp, compress

piston rings.

8.Insert connecting rod and piston into its

respective cylinder bore, ensuring that the arrow

on piston crown and the cast boss on connecting

rod are facing towards the front of the cylinder

block.

CAUTION: Ensure that connecting rod

does not contact cylinder bore or oil squirt

jet. Do not pull connecting rod fully down

cylinder bore at this stage.

ProCarManuals.com

Page 195 of 667

12ENGINE

36

OVERHAUL 9.Check that the cut-out in piston skirt is

positioned above the oil squirt jet.

10.Repeat for other pistons in turn ensuring that

pistons and connecting rods are fitted in cylinder

bores from which they were removed.

11.Fit connecting rod bearings.See this Section.

CAUTION: If new pistons, connecting rods

or crankshaft have been fitted, it will be

necessary to select correct thickness of

cylinder head gasket.See this Section.CRANKSHAFT

Service repair no - 12.21.33.01

Remove

1.Remove timing chain and sprockets.See this

Section.

2.Remove crankshaft rear oil seal.See this

Section.

3.Remove connecting rod bearings.See this

Section.

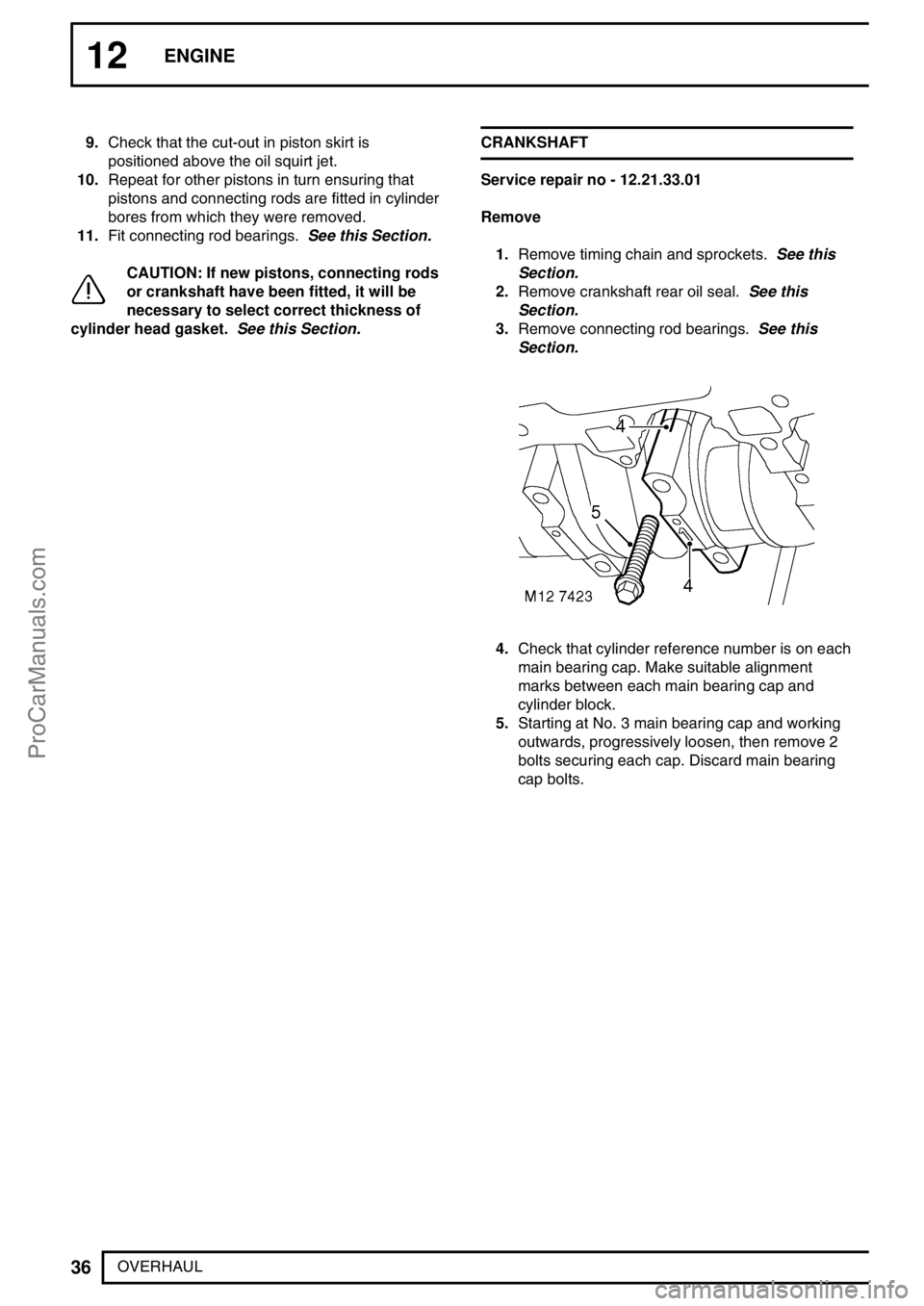

4.Check that cylinder reference number is on each

main bearing cap. Make suitable alignment

marks between each main bearing cap and

cylinder block.

5.Starting at No. 3 main bearing cap and working

outwards, progressively loosen, then remove 2

bolts securing each cap. Discard main bearing

cap bolts.

ProCarManuals.com

Page 196 of 667

ENGINE

37

OVERHAUL

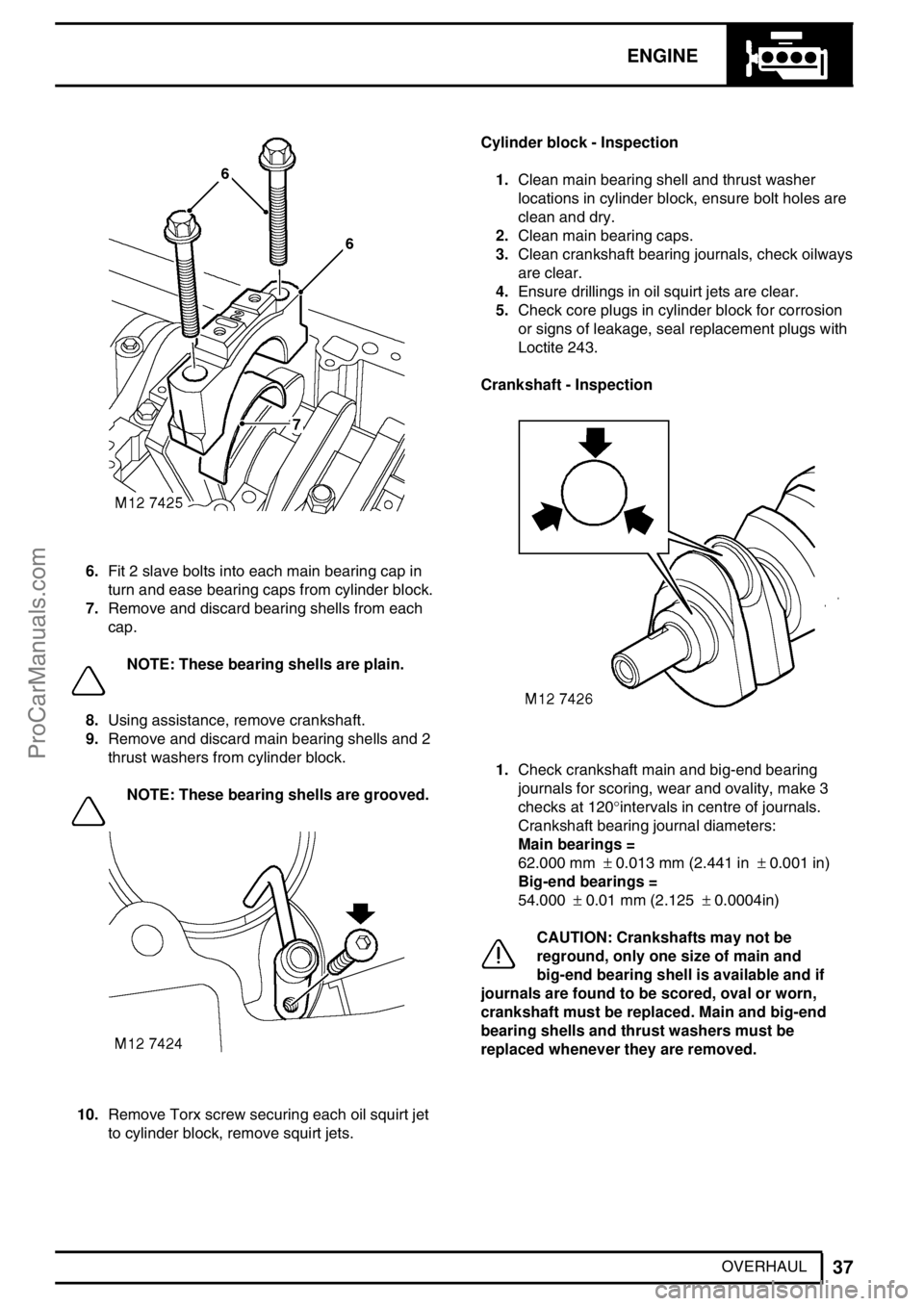

6.Fit 2 slave bolts into each main bearing cap in

turn and ease bearing caps from cylinder block.

7.Remove and discard bearing shells from each

cap.

NOTE: These bearing shells are plain.

8.Using assistance, remove crankshaft.

9.Remove and discard main bearing shells and 2

thrust washers from cylinder block.

NOTE: These bearing shells are grooved.

10.Remove Torx screw securing each oil squirt jet

to cylinder block, remove squirt jets.Cylinder block - Inspection

1.Clean main bearing shell and thrust washer

locations in cylinder block, ensure bolt holes are

clean and dry.

2.Clean main bearing caps.

3.Clean crankshaft bearing journals, check oilways

are clear.

4.Ensure drillings in oil squirt jets are clear.

5.Check core plugs in cylinder block for corrosion

or signs of leakage, seal replacement plugs with

Loctite 243.

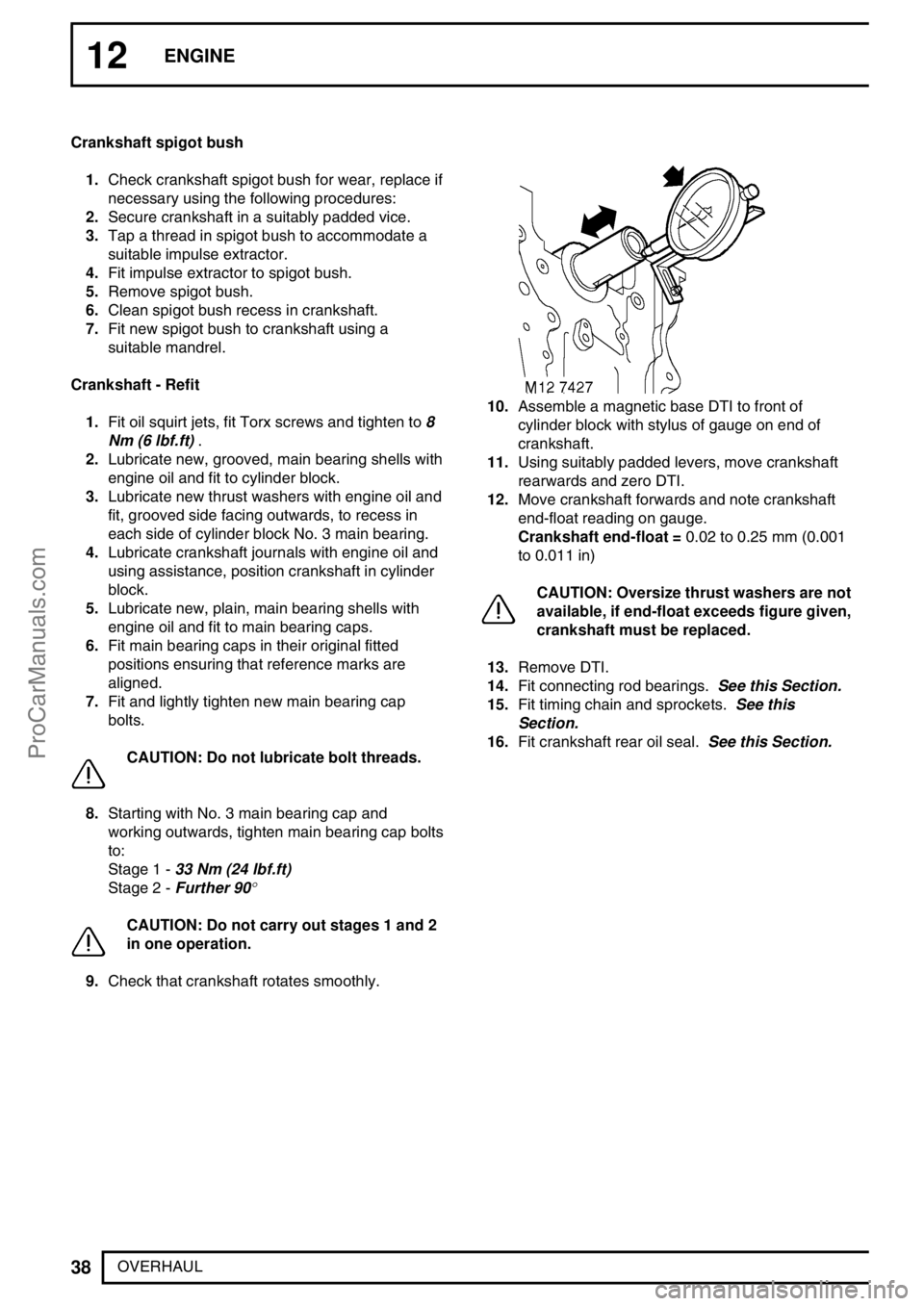

Crankshaft - Inspection

1.Check crankshaft main and big-end bearing

journals for scoring, wear and ovality, make 3

checks at 120°intervals in centre of journals.

Crankshaft bearing journal diameters:

Main bearings =

62.000 mm±0.013 mm (2.441 in±0.001 in)

Big-end bearings =

54.000±0.01 mm (2.125±0.0004in)

CAUTION: Crankshafts may not be

reground, only one size of main and

big-end bearing shell is available and if

journals are found to be scored, oval or worn,

crankshaft must be replaced. Main and big-end

bearing shells and thrust washers must be

replaced whenever they are removed.

ProCarManuals.com

Page 197 of 667

12ENGINE

38

OVERHAUL Crankshaft spigot bush

1.Check crankshaft spigot bush for wear, replace if

necessary using the following procedures:

2.Secure crankshaft in a suitably padded vice.

3.Tap a thread in spigot bush to accommodate a

suitable impulse extractor.

4.Fit impulse extractor to spigot bush.

5.Remove spigot bush.

6.Clean spigot bush recess in crankshaft.

7.Fit new spigot bush to crankshaft using a

suitable mandrel.

Crankshaft - Refit

1.Fit oil squirt jets, fit Torx screws and tighten to8

Nm (6 lbf.ft).

2.Lubricate new, grooved, main bearing shells with

engine oil and fit to cylinder block.

3.Lubricate new thrust washers with engine oil and

fit, grooved side facing outwards, to recess in

each side of cylinder block No. 3 main bearing.

4.Lubricate crankshaft journals with engine oil and

using assistance, position crankshaft in cylinder

block.

5.Lubricate new, plain, main bearing shells with

engine oil and fit to main bearing caps.

6.Fit main bearing caps in their original fitted

positions ensuring that reference marks are

aligned.

7.Fit and lightly tighten new main bearing cap

bolts.

CAUTION: Do not lubricate bolt threads.

8.Starting with No. 3 main bearing cap and

working outwards, tighten main bearing cap bolts

to:

Stage 1 -33 Nm (24 lbf.ft)

Stage 2 -Further 90

°

CAUTION: Do not carry out stages 1 and 2

in one operation.

9.Check that crankshaft rotates smoothly.

10.Assemble a magnetic base DTI to front of

cylinder block with stylus of gauge on end of

crankshaft.

11.Using suitably padded levers, move crankshaft

rearwards and zero DTI.

12.Move crankshaft forwards and note crankshaft

end-float reading on gauge.

Crankshaft end-float =0.02 to 0.25 mm (0.001

to 0.011 in)

CAUTION: Oversize thrust washers are not

available, if end-float exceeds figure given,

crankshaft must be replaced.

13.Remove DTI.

14.Fit connecting rod bearings.See this Section.

15.Fit timing chain and sprockets.See this

Section.

16.Fit crankshaft rear oil seal.See this Section.

ProCarManuals.com

Page 243 of 667

18ENGINE MANAGEMENT SYSTEM

20

DESCRIPTION AND OPERATION SENSOR - FUEL TEMPERATURE (FT)

The FT sensor is located at the RH rear of the engine in the connector block, with the tip of the sensor inserted at

least 10mm into the fuel flow. This allows the sensor to respond correctly to changes in fuel density in relation to

fuel temperature.

The FT sensor works as an NTC sensor. As fuel temperature rises the resistance in the sensor decreases. As

temperature decreases the resistance in the sensor increases. The ECM is able to compare the voltage signal to

stored values and compensates fuel delivery as necessary for hot engine start.

The operating range of the sensor is -40 to 130°C (-40 to 266°F).

Input / Output

The ECM (C0158-19) provides the FT sensor (C0184-2) with a 5 volt supply signal on a yellow/white wire. The

sensor is earthed (C0184-1) via the ECM (C0158-5) on a pink/black wire.

The FT sensor can fail or supply an incorrect signal if one or more of the following occurs:

Sensor open circuit.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Sensor fitted incorrectly.

In the event of an FT sensor signal failure any of the following symptoms may be observed:

Difficult cold start.

Difficult hot start.

Driveability concern.

In the event of a component failure, the ECM reverts to a fixed value of 60°C stored in its memory.

ProCarManuals.com

Page 247 of 667

18ENGINE MANAGEMENT SYSTEM

24

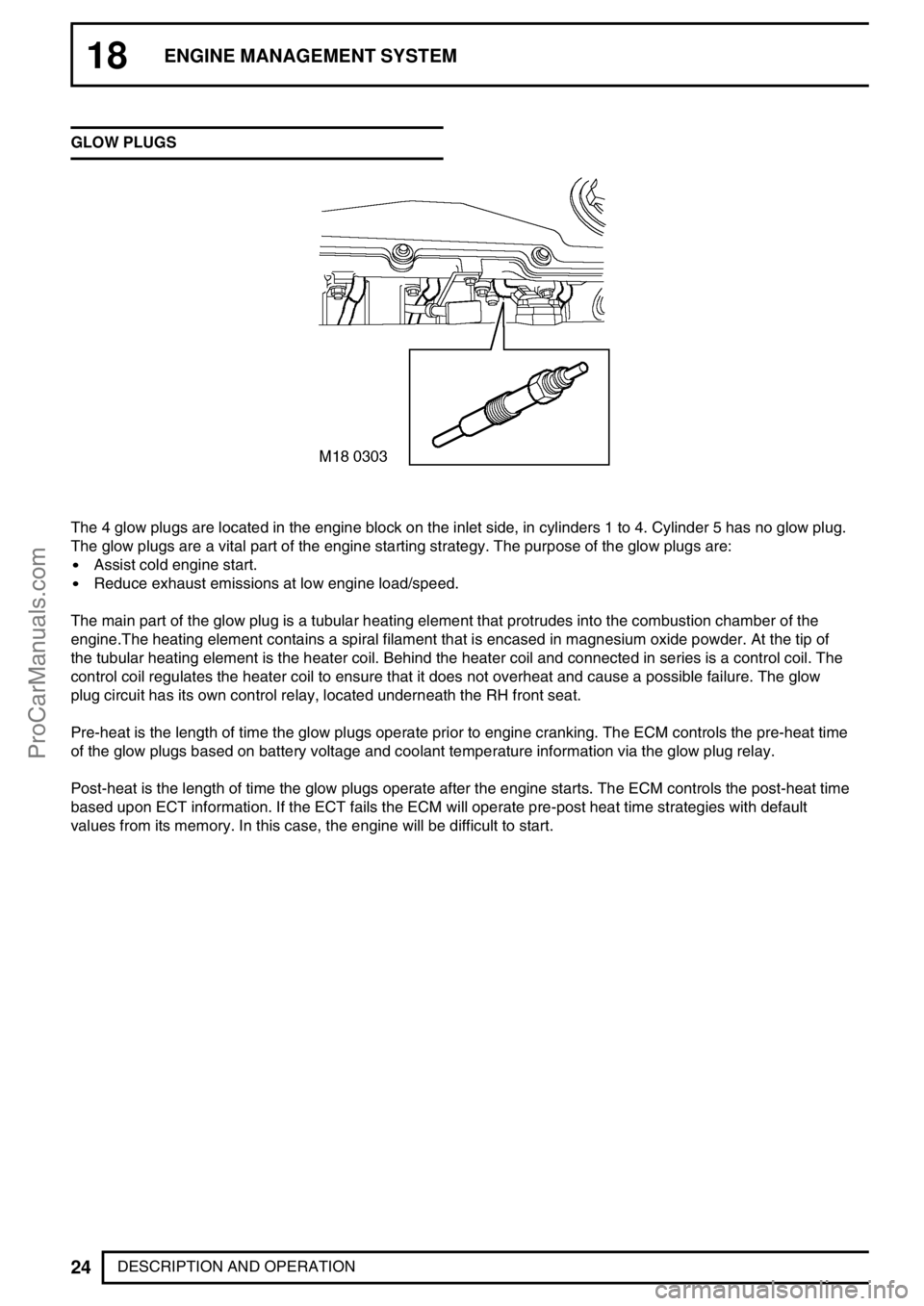

DESCRIPTION AND OPERATION GLOW PLUGS

The 4 glow plugs are located in the engine block on the inlet side, in cylinders 1 to 4. Cylinder 5 has no glow plug.

The glow plugs are a vital part of the engine starting strategy. The purpose of the glow plugs are:

Assist cold engine start.

Reduce exhaust emissions at low engine load/speed.

The main part of the glow plug is a tubular heating element that protrudes into the combustion chamber of the

engine.The heating element contains a spiral filament that is encased in magnesium oxide powder. At the tip of

the tubular heating element is the heater coil. Behind the heater coil and connected in series is a control coil. The

control coil regulates the heater coil to ensure that it does not overheat and cause a possible failure. The glow

plug circuit has its own control relay, located underneath the RH front seat.

Pre-heat is the length of time the glow plugs operate prior to engine cranking. The ECM controls the pre-heat time

of the glow plugs based on battery voltage and coolant temperature information via the glow plug relay.

Post-heat is the length of time the glow plugs operate after the engine starts. The ECM controls the post-heat time

based upon ECT information. If the ECT fails the ECM will operate pre-post heat time strategies with default

values from its memory. In this case, the engine will be difficult to start.

ProCarManuals.com

Page 248 of 667

ENGINE MANAGEMENT SYSTEM

25

DESCRIPTION AND OPERATION Input / Output

The glow plugs receive a feed from the glow plug relay (C0215-3) on a yellow/black then individual black wires.

The ECM provides the earth path for the glow plug relay (C0151-6), working in tandem with the Alarm ECU. The

supply voltage heats the coils to approximately 1000°C (1832°F). The glow plug circuit is wired in parallel, the

body of each glow plug is screwed directly into the engine block which provides each glow plug with an earth path.

The glow plugs can fail in one or more of the following ways:

Heater coil open circuit.

Control coil open circuit.

Poor earth quality.

Short circuit to vehicle supply.

Short circuit to vehicle earth.

Harness fault.

Relay windings open circuit.

Incorrect relay fitted.

In the event of a glow plug failure, any of the following symptoms may be observed:

Difficult starting.

Excessive smoke emissions after engine start.

ProCarManuals.com

Page 250 of 667

ENGINE MANAGEMENT SYSTEM

27

DESCRIPTION AND OPERATION The turbocharger is exposed to extremely high operating temperatures (up to 1000°C, 1832°F) because of the

hot exhaust gases and the high speed revolution of the turbine (up to 15,000 rev/min). In order to resist wear of

the turbine bearings a flow of lubrication oil is supplied from the engine lubrication system to keep the bearings

cool. Oil is supplied from a tapping at the front of the full-flow filter adaptor housing via a metal pipe with banjo

connections. Oil is returned to the sump via a metal pipe which connects to the cylinder block at a port below the

turbocharger assembly.

A heatshield is attached to the LH side of the engine to protect adjacent components from the heat generated at

the turbocharger. The heatshield is attached to the engine by 2 bolts. An additional bolt attaches the heatshield to

the turbocharger casting.

The ECM controls the amount of boost pressure the engine receives by way of the turbocharger. When full boost

is reached a control signal is sent to the wastegate modulator, and a vacuum is applied to the wastegate valve.

The wastegate valve opens, bypassing some of the exhaust gases away from the turbine to be output to the

exhaust system.

The engine should be allowed to idle for 15 seconds following engine start up and before the engine is switched

off to protect the turbocharger by maintaining oil supply to the turbine bearings.

INTERCOOLER

The intercooler is an air-to-air heat exchanger which lowers the intake air temperature to obtain a higher air

density for better combustion efficiency. The intercooler receives compressed air from the turbocharger via a

metal pipe. It cools the intake air via the intercooler matrix and delivers it to the intake manifold by means of a

rubber hose which connects between the intercooler outlet and the intake manifold. The rubber hose is connected

to ports at each end by metal clips.

The intercooler is located at the front of the engine bay, forward of the radiator.

ProCarManuals.com